Академический Документы

Профессиональный Документы

Культура Документы

Joints (Qw-402) Details

Загружено:

Naqqash SajidИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Joints (Qw-402) Details

Загружено:

Naqqash SajidАвторское право:

Доступные форматы

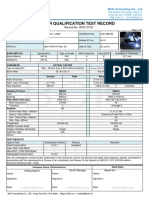

Company Name: Siddique Ice By

Welding Procedure Specification NO. 002 Date: 28/02/2019

Supporting PQR NO.(s) Revision No.

00

Welding Process(es): GTAW+SMAW Types: Manual

JOINTS(QW-402) Details

Joints Design Groove Butt Joint (Shown In Figure)

Backing: Yes No

Backing materials (Type) None

(Refer to both backing and retainers)

□ Metal Non fusing □ Metal

□ Nonmetallic □ Other

Sketches, Production Drawings, Weld Symbols, or Written Description

Should show the general arrangement of the parts to be welded. Where

Applicable, the root Spacing and the details of weld groove may be

specified.

[At the option of the Manufacturer, sketches may be attached to illustrate

Joint design, weld layers, and bead sequence (e.g., for notch toughness

Procedures, for multiple process procedures, etc.)]

*BASE METALS (QW-403)

P-No. 01 Group No. 01 to P-No. 01 Group No. 01

OR

Specification Type and Grade ASTM A53 A106 API 5L GR. B

To Specification Type and Grade ASTM A53 A106 API 5L GR. B

OR

Chem. Analysis and Mech. Prop.

To Chem. Analysis and Mech. Prop.

Thickness Range:

Base Metal: Groove 1.5 mm to 16mm Fillet All

Other

*FILLER METALS (QW-404) GTAW SMAW

Spec. No. (SFA) 5.18 5.1

AWS No. (Class) ER70S-3 E-7018

F-No. 6 4

A-No. 1 1

Size of Filler Metals 2.0 mm & 2.5 mm 2.5mm & 3.2 mm

Weld Metal Thickness Range:

Groove 2-3 mm Remaining Up to Weld reinforcement

Fillet All All

Electrode-Flux (Class) None Low Hydrogen iron powder

Flux Trade Name None None

Consumable Insert None None

Other

Each base metal –filler metal combination should be recorded individually.

WPS No. 001 Rev.

00

POSITIONS (QW -405) Post weld heat treatment (QW-407)

Position(s) of Groove All Temperature Range N/A

Welding Progression: Up Down Time Range N/A

Position(s) of Fillet

GAS (QW-408)

Preheat (QW-406) Percent Composition

Preheat Temperature, Minimum 10°C Gas(es) (Mixture) Flow Rate

Interpass Temperature, Maximum 300°C

Preheat Maintenance (See Notes below) Shielding Argon

Notes: (Continuous or special heating, where applicable, Trailing

should be recorded) Backing

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC DC Polarity Positive & Negative

Amps (Range) 70-160 Amp Volts (Range) 20-35 V

(Amps and volts range should be recorded for each electrode size,

Position, and thickness, etc. This information may be listed in a

Tabular form similar to that shown below.)

Tungsten Electrode Size and Type Size - 2.4 mm, Type - 2% Thorium

Mode of Metal Transfer for GMAW N/A

Electrode Wire Feed Speed Range Manual

Weld Pass(es) Process Consumables Consumables Polarity Current (Amperes)

(AWS No.) (Size)

Root GTAW ER70S-3 2.4 mm DC Negative 70-150

Hot GTAW ER70S-3 2.4mm DC Negative 70-160

Filling SMAW E7018 3.2 mm DC Positive 90-160

Capping SMAW E7018 3.2 mm DC Positive 90-160

TECHNIQUE (QW-410)

String or Weave Bead String and Weave Bead

Orifice or Gas Cup Size 4, 6, 8mm

Initial and interpass Cleaning (Brushing, Grinding, etc.) Power Brushing & Grinding

Method of Back Gouging N/A

Oscillation N/A

Contact Tube to Work Distance Manual

Multiple or Single Pass (Per Side) Multipass

Multiple or Single Electrodes Single

Travel Speed (Range) Manual

Вам также может понравиться

- 03 WPS CS 1Документ3 страницы03 WPS CS 1mohammadОценок пока нет

- P. WpsДокумент14 страницP. WpsIsmiArdyОценок пока нет

- Welding Procedure SpecificationДокумент3 страницыWelding Procedure SpecificationAhmed saber100% (2)

- TopCoreBelco 101 FCДокумент9 страницTopCoreBelco 101 FCCesar ArellanoОценок пока нет

- Welder Qualification Register 01Документ3 страницыWelder Qualification Register 01Andrei UrsacheОценок пока нет

- WPQ Template (Asme Ix) No LogoДокумент4 страницыWPQ Template (Asme Ix) No LogorcpretoriusОценок пока нет

- WPS 19Документ15 страницWPS 19Avishek Gupta100% (1)

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsДокумент11 страницCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONОценок пока нет

- Format WPQДокумент2 страницыFormat WPQAkash Singh TomarОценок пока нет

- Weld Test Checklist: Welder (S) DetailsДокумент2 страницыWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Manual Joints (QW - 402) : Page 1 of 12Документ12 страницManual Joints (QW - 402) : Page 1 of 12miteshpatel191Оценок пока нет

- Saudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 ElectДокумент1 страницаSaudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 Electkarthi51289Оценок пока нет

- Welding Procedure Qualification Record: Shipyard LogoДокумент4 страницыWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Guidance To Prepare Wps PQR For WeldingДокумент1 страницаGuidance To Prepare Wps PQR For WeldingHamid MansouriОценок пока нет

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationДокумент2 страницыASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaОценок пока нет

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Документ2 страницыWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangОценок пока нет

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Документ2 страницыLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidОценок пока нет

- PT Kuwera Karya Me: PanduДокумент2 страницыPT Kuwera Karya Me: PanduGalang Pratama PutraОценок пока нет

- BPV IX-16-3 QW-283 - ButteringДокумент1 страницаBPV IX-16-3 QW-283 - ButteringyutweldingОценок пока нет

- WPS FGPДокумент1 страницаWPS FGPShabbir HussainОценок пока нет

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Документ1 913 страницPipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- Pipeline Weld Joint & Ragiograph Film Numbering SystemДокумент9 страницPipeline Weld Joint & Ragiograph Film Numbering Systemgst ajah100% (2)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Документ3 страницыWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielОценок пока нет

- 10.LPI. Report FormatДокумент1 страница10.LPI. Report FormatEr Sumant Kumar SinghОценок пока нет

- B H e L Limited RTДокумент13 страницB H e L Limited RTbhavin17850% (2)

- WQT Aws D1.1Документ1 страницаWQT Aws D1.1Ali HammoudaОценок пока нет

- Wps Mma PipeДокумент2 страницыWps Mma PipeDimitris NikouОценок пока нет

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalДокумент1 страницаWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavОценок пока нет

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionДокумент31 страницаALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahОценок пока нет

- WPQ-1083 3G PDFДокумент2 страницыWPQ-1083 3G PDFduendex360100% (1)

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldДокумент2 страницыWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisОценок пока нет

- Aws 001Документ1 страницаAws 001akshay sarfareОценок пока нет

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Документ4 страницыAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Proposed WPSДокумент2 страницыProposed WPSChisom Ikengwu100% (2)

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryДокумент1 страницаMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalОценок пока нет

- PQR WPQ Witness Report LatestДокумент1 страницаPQR WPQ Witness Report LatestSatish KeskarОценок пока нет

- WPS ListДокумент2 страницыWPS ListAdeel OmerОценок пока нет

- Welding Proposed Pwps For Our Jubail WorkДокумент2 страницыWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Wps Mig PDF FreeДокумент3 страницыWps Mig PDF Freehanz bermejoОценок пока нет

- Offshore Marinetech PVT - LTD: Electrode Baking RegisterДокумент3 страницыOffshore Marinetech PVT - LTD: Electrode Baking RegisterPrathamesh OmtechОценок пока нет

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelДокумент3 страницыWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanОценок пока нет

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreДокумент3 страницыWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniОценок пока нет

- PWPS WPS CAP 039 PQR 035Документ15 страницPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRОценок пока нет

- Hardness Test Report: Test Details Machine DetailsДокумент1 страницаHardness Test Report: Test Details Machine DetailsESHWAR CHARYОценок пока нет

- Welding Procedure Specification (WPS) : N.A N.AДокумент1 страницаWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiОценок пока нет

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQДокумент4 страницы163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Welding Procecure SpecificationДокумент9 страницWelding Procecure SpecificationNwoha PeterОценок пока нет

- WPS Asme IxДокумент4 страницыWPS Asme Ixjcarlosherrerac7100% (1)

- Weldment Visual Inspection RequirementsДокумент10 страницWeldment Visual Inspection RequirementsKarthik P MuraliОценок пока нет

- WOPQ Form English1Документ2 страницыWOPQ Form English1oaperuchenaОценок пока нет

- WPS-PQR ListДокумент1 страницаWPS-PQR ListSandra SandersОценок пока нет

- Ins-P-021, Long Seam Set UpДокумент4 страницыIns-P-021, Long Seam Set UpDeepak100% (1)

- Welding Report For Tank 1Документ1 страницаWelding Report For Tank 1Rifki HasyaОценок пока нет

- Registro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Документ2 страницыRegistro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Anonymous Xa5rkMZm9ZОценок пока нет

- PQRДокумент3 страницыPQRnazirulhakimОценок пока нет

- Revised Wps For Gtaw - Xls Dated 25.01.2017Документ2 страницыRevised Wps For Gtaw - Xls Dated 25.01.2017GopinathОценок пока нет

- Wps Pip Gtaw - ArabianДокумент1 страницаWps Pip Gtaw - ArabianIshack MohammedОценок пока нет

- Joints (Qw-402) DetailsДокумент3 страницыJoints (Qw-402) DetailsNaqqash SajidОценок пока нет

- WPS & WPQR (Asme Section IX)Документ7 страницWPS & WPQR (Asme Section IX)Rizaldy PhoenksОценок пока нет

- Final - WPS PQR 86Документ4 страницыFinal - WPS PQR 86Parag WadekarОценок пока нет

- Election Results Circular NOV 07, 2023Документ4 страницыElection Results Circular NOV 07, 2023Naqqash SajidОценок пока нет

- Slant Fin Engineering DataДокумент2 страницыSlant Fin Engineering DataNaqqash SajidОценок пока нет

- Pacheco Home Residence Drawings-EssentialsДокумент4 страницыPacheco Home Residence Drawings-EssentialsNaqqash SajidОценок пока нет

- HVAC Duct & Fittings Area Calculation Formulas ??Документ12 страницHVAC Duct & Fittings Area Calculation Formulas ??Naqqash Sajid100% (2)

- ,,,,,,,,,,,,, Heat Transfer Coefficient Input ParametersДокумент2 страницы,,,,,,,,,,,,, Heat Transfer Coefficient Input ParametersNaqqash SajidОценок пока нет

- International Journal of Heat and Mass Transfer: B.K. Hardik, P.K. Baburajan, S.V. PrabhuДокумент17 страницInternational Journal of Heat and Mass Transfer: B.K. Hardik, P.K. Baburajan, S.V. PrabhuNaqqash SajidОценок пока нет

- Enhancement of Heat Transfer Coefficient Through Helical CoilДокумент5 страницEnhancement of Heat Transfer Coefficient Through Helical CoilNaqqash SajidОценок пока нет

- Project SummaryДокумент10 страницProject SummaryNaqqash SajidОценок пока нет

- Energy Audit ReportДокумент22 страницыEnergy Audit ReportNaqqash SajidОценок пока нет

- Commodity ClassificationsДокумент24 страницыCommodity ClassificationsNaqqash SajidОценок пока нет

- Eco-Smart HEPA ERV: Best Indoor Air For YouДокумент1 страницаEco-Smart HEPA ERV: Best Indoor Air For YouNaqqash SajidОценок пока нет

- General Demolition Notes: Mercy Hall RenovationДокумент17 страницGeneral Demolition Notes: Mercy Hall RenovationNaqqash SajidОценок пока нет

- Huayi Compressor CMLT90LD N R404A 115 60Документ2 страницыHuayi Compressor CMLT90LD N R404A 115 60Naqqash SajidОценок пока нет

- Helical Coil Length - UpdДокумент2 страницыHelical Coil Length - UpdNaqqash SajidОценок пока нет

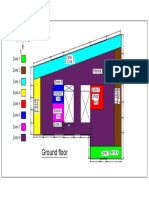

- Ground Floor: N E W S Zone 3 4.1x54.7 Internal Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8Документ1 страницаGround Floor: N E W S Zone 3 4.1x54.7 Internal Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8Naqqash SajidОценок пока нет

- Project 2: The Capital Asset Pricing Model and Portfolio TheoryДокумент11 страницProject 2: The Capital Asset Pricing Model and Portfolio TheoryNaqqash SajidОценок пока нет

- AD10B AD10B: E4 Intake at West Areaway E4 Intake at West AreawayДокумент24 страницыAD10B AD10B: E4 Intake at West Areaway E4 Intake at West AreawayNaqqash SajidОценок пока нет

- Evaporator DesignДокумент1 страницаEvaporator DesignNaqqash SajidОценок пока нет

- Comparsion of Existing System and New SystemДокумент4 страницыComparsion of Existing System and New SystemNaqqash SajidОценок пока нет

- Design DataДокумент283 страницыDesign DataNaqqash SajidОценок пока нет

- Report FinalДокумент99 страницReport FinalNaqqash SajidОценок пока нет

- Condenser DesignДокумент1 страницаCondenser DesignNaqqash SajidОценок пока нет

- Load CalculationДокумент13 страницLoad CalculationNaqqash SajidОценок пока нет

- Load Calculation NewДокумент13 страницLoad Calculation NewNaqqash SajidОценок пока нет

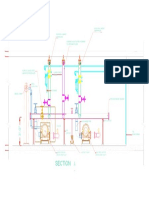

- Fire Fighting LayoutДокумент1 страницаFire Fighting LayoutNaqqash SajidОценок пока нет

- Tank 4 Ice Filling New DesignДокумент14 страницTank 4 Ice Filling New DesignNaqqash SajidОценок пока нет

- SLC Motor Oil Series 1Документ8 страницSLC Motor Oil Series 1Anonymous QE8o0gjОценок пока нет

- D 2069 - 91 (1998) PDFДокумент4 страницыD 2069 - 91 (1998) PDFAl7amdlellahОценок пока нет

- WWW Grupoag Es Siderurgicabalboa en Proceso Productivo ProceДокумент5 страницWWW Grupoag Es Siderurgicabalboa en Proceso Productivo ProceAnonymous dIK4xERPОценок пока нет

- Derivatización Por Dansyl o DabsylДокумент13 страницDerivatización Por Dansyl o DabsylmagicianchemistОценок пока нет

- Brief Summary of The ProjectДокумент6 страницBrief Summary of The ProjectNikunjОценок пока нет

- Atomic StructureДокумент162 страницыAtomic StructurevaughanОценок пока нет

- TA Lab ManualДокумент27 страницTA Lab ManualSharon K ThomasОценок пока нет

- Creep of Outlet Pigtail Tubes of Steam Reformer and Grain Size Effect On Creep of An Incoloy 800H MaterialДокумент12 страницCreep of Outlet Pigtail Tubes of Steam Reformer and Grain Size Effect On Creep of An Incoloy 800H MaterialOwais Malik100% (1)

- D and F Block ElementsДокумент104 страницыD and F Block ElementsPanksteinОценок пока нет

- CHM1207 Lab 7Документ3 страницыCHM1207 Lab 7Nikoli Major100% (1)

- PYQ of Organic Nomenclature NEET 2022Документ25 страницPYQ of Organic Nomenclature NEET 2022Saloni tyagi100% (2)

- Isasmelt - WikipediaДокумент114 страницIsasmelt - WikipediaCECILIAОценок пока нет

- 14 - Nuclear Plant Materials and CorrosionДокумент54 страницы14 - Nuclear Plant Materials and Corrosionmihaela_filip_8Оценок пока нет

- Low Alloy Steels For Cryogenic ApplicationsДокумент0 страницLow Alloy Steels For Cryogenic ApplicationsidienОценок пока нет

- Effects of Elements On SteelДокумент4 страницыEffects of Elements On SteelmichaelОценок пока нет

- Chemistry Notes For Neet Chapter 31Документ16 страницChemistry Notes For Neet Chapter 31harshadmaharajthiruvenkadamОценок пока нет

- Unit I Fuel Tech Final AДокумент25 страницUnit I Fuel Tech Final AAldrin BennyОценок пока нет

- Molecular Volumes and The Stokes-Einstein EquationДокумент10 страницMolecular Volumes and The Stokes-Einstein EquationchitreauОценок пока нет

- Chemsheets GCSE 1106 (Titrations 2) ANS Lkep9Документ2 страницыChemsheets GCSE 1106 (Titrations 2) ANS Lkep9J 63420% (1)

- Types of FatДокумент3 страницыTypes of FatDennis Mark PalimaОценок пока нет

- Biosorption of Heavy Metals From Aqueous Solutions by Chemically ModifiedДокумент6 страницBiosorption of Heavy Metals From Aqueous Solutions by Chemically ModifiedEswin Hernandez ObregonОценок пока нет

- Cambridge International Advanced Subsidiary and Advanced LevelДокумент12 страницCambridge International Advanced Subsidiary and Advanced LevelRina DasОценок пока нет

- On The Prediction of Strength From Hardness For Copper AlloysДокумент7 страницOn The Prediction of Strength From Hardness For Copper AlloysHammadОценок пока нет

- Unit 5.2. POLYMERДокумент12 страницUnit 5.2. POLYMERAnusha PanchumarthiОценок пока нет

- OverviewДокумент21 страницаOverviewgreenhen15Оценок пока нет

- Latin America WireДокумент3 страницыLatin America WirepacocardenasОценок пока нет

- Alcohol, Phenol Ether Complete Notes 022 023Документ17 страницAlcohol, Phenol Ether Complete Notes 022 023adityasinghnegi426Оценок пока нет

- 2017 OrganicAcids CharacteristicsPropertiesandSynthesis 978-1-63485-952-3 EBookAUTHORSCOMPLEMENTARYДокумент157 страниц2017 OrganicAcids CharacteristicsPropertiesandSynthesis 978-1-63485-952-3 EBookAUTHORSCOMPLEMENTARYAfrad HossainОценок пока нет

- Haloalkanes HaloareneДокумент23 страницыHaloalkanes HaloarenegtfhrfvhwcvfrwdpitОценок пока нет

- Fat-Soxhlet, by Acid HydrolysisДокумент2 страницыFat-Soxhlet, by Acid HydrolysisAnju DoraisamyОценок пока нет

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincОт EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincРейтинг: 3.5 из 5 звезд3.5/5 (137)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeОт EverandChemistry for Breakfast: The Amazing Science of Everyday LifeРейтинг: 4.5 из 5 звезд4.5/5 (14)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactОт EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactРейтинг: 5 из 5 звезд5/5 (1)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactОт EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactРейтинг: 5 из 5 звезд5/5 (5)

- ICH Quality Guidelines: An Implementation GuideОт EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleОценок пока нет

- Essential Chemistry for Formulators of Semisolid and Liquid DosagesОт EverandEssential Chemistry for Formulators of Semisolid and Liquid DosagesРейтинг: 5 из 5 звезд5/5 (2)

- Chemistry: a QuickStudy Laminated Reference GuideОт EverandChemistry: a QuickStudy Laminated Reference GuideРейтинг: 5 из 5 звезд5/5 (1)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsОт EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsРейтинг: 5 из 5 звезд5/5 (3)

- Lime and Limestone: Chemistry and Technology, Production and UsesОт EverandLime and Limestone: Chemistry and Technology, Production and UsesРейтинг: 4 из 5 звезд4/5 (1)

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesОт EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesОценок пока нет

- The Periodic Table: A Very Short IntroductionОт EverandThe Periodic Table: A Very Short IntroductionРейтинг: 4.5 из 5 звезд4.5/5 (4)

- The Production of Volatile Oils and Perfumery Plants in the United StatesОт EverandThe Production of Volatile Oils and Perfumery Plants in the United StatesОценок пока нет

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeОт EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeРейтинг: 4 из 5 звезд4/5 (1)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeОт EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeОценок пока нет

- The Nature of Drugs Vol. 2: History, Pharmacology, and Social ImpactОт EverandThe Nature of Drugs Vol. 2: History, Pharmacology, and Social ImpactОценок пока нет

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolОт EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolОценок пока нет