Академический Документы

Профессиональный Документы

Культура Документы

Improving The Efficiency of Polycrystall PDF

Загружено:

Sheila Mae CulpableОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Improving The Efficiency of Polycrystall PDF

Загружено:

Sheila Mae CulpableАвторское право:

Доступные форматы

ISSN: 2319-8753

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 3, Issue 1, January 2014

Improving The Efficiency Of Polycrystalline

Solar Panel Via Water Immersion Method

Sayran A. Abdulgafar 1*, Omar S. Omar 2 ,Kamil M. Yousif 3 .

Assistant lecturer, Department of Physics, Faculty of Science, Dohuk University,Dohuk, Kurdistan Region, Iraq*1,2

Assistant Professor,Department of Environment, Faculty of Science, Zakho University, Zakho , Kurdistan Region, Iraq3

*1Corresponding Author

Abstract: Cooling of the solar cells is a critical issue, especially when designing concentrating photovoltaic (PV)

systems. In the present work, the cooling of a photovoltaic panel via Water immersion technique is investigated. The

aim of this project is to optimize the efficiency of a solar panel by submerged it in distillated water at different depths.

Experiment is done for polycrystalline silicon panel. An evident increase of efficiency is found with increasing the

water depth. Results are discussed; thermal drift has been reduced and the solar panel efficiency has increased by about

11% at water depth 6 cm.

Keywords: Solar Cell, Polycrystalline Silicon, Efficiency, Water Immersion technique.

I. INTRODUCTION

Photovoltaic solar energy (PV) is one of the renewable sources of energy. As it is known, the photovoltaic solar cell is

a semiconductor device that generates electricity when light falls on it. A photovoltaic cell converts only a small

fraction (~less than 20 %) of the irradiance into electrical energy [1]. The balance is converted into heating of the cell.

One of the important parameters that affect the energy output of the PV module or system is the operating

temperature .The electrical efficiency of PV cells decreases with temperature increase cooling can improve the

electrical production of standard flat panel PV modules, since cooling keeps the PV cells from reaching temperatures at

which irreversible damage occurs. It has been found that the efficiency and output power of PV module is inversely

proportional to its temperature [2], [3]. A typical value for PV efficiency loss with temperature is 0.5% / oC [4] though

this varies with the type of cell. There are two main effects increase the efficiency of a commercial panel placed in

water [5]:

1-reduction of light reflection (due to lower refraction index)

2- absence of thermal drift

Both water and air are suitable to be used as the cooling fluid to cool the PV module in order to avoid the drop of

electrical efficiency [6].

II.LITERATURE SURVEY

Many studies have been carried out on the cooling PV systems. Submerging the photovoltaic module has been one of

the significant methods to overcome the heat generated by the PV module [7]. Krauter (2004) [8] Suggested a method

of reducing reflection which also provided cooling replacing the front glass surface with a thin (1mm) film of water

running over the face of the panel. It was found that reflective losses in glass can lead to losses in yield of 8-15%. The

water decreased cell temperatures up to 22 o C. The improved optics and cell temperatures increased electrical yield

10.3% over the day. Meneses-Rodriguez et al. (2005) [9] investigated a novel method to improve the electrical

efficiency with cooling. The authors explored the benefits of running PV cells at near their maximum theoretical

temperatures (100-170 oC). Theoretically, the electrical efficiency can be in the range 10-16%. With a sink temperature

Copyright to IJIRSET www.ijirset.com 8127

ISSN: 2319-8753

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 3, Issue 1, January 2014

of 30 o C, the authors estimate a theoretical total efficiency greater than 30%. Royne et al. (2005) [10] have studied a

PV cooling methodologies, for use under concentrated illumination, provide a set of requirements for cooling

techniques, e.g. during the cooling, it is desirable for the temperature to be uniform across the cells. Also, the cooling

method needs to ensure that the operating temperature does not exceed the point at which irreversible degradation

occurs in the cell. Zhu et al (2011) [11], used water cooling system in a high concentration PV system to avoid the cell

degradation. Gardas and Tendolkar (2012) [1] used seven gasses for cooling in PV/thermal system; they found that

hydrogen to be the best gas to maximize the output power of the system. Toe et al (2012) [12] studied air cooling

system to increase the PV efficiency from (7-8%) to (12-14%). Chinamhora et al (2013) [13] used a water cooling

system on the front and back of the PV module and the found that the cooling system could improve the efficiency of

PV module during clear days, while it had disadvantages during cloudy days . Asachi (2013) [14] presents a combined

photovoltaic and thermal Solar Panels in order to reduce the heat produced by PV system and enhance the output

energy of PV and thermal collector. In the present work, distillated water immersion technique was used to improve the

performance and the electrical efficiency of polycrystalline silicon panel. The I-V characteristics of a PV module under

different depths of water have been tested.

III.METHODOLOGY

A commercial polycrystalline solar cell with area of 15 cm 2 was tested. Characteristics were determined with the use

of the electrical circuit presented in figure 1. The experimental set up consisted of the following elements: Rheostat

(R) in the range from 0 to 1000 Ω, Ammeter (A), type DT9205A, Voltmeter (V), type MS8205F.

The measurements were carried out in Dohuk, Iraq, at the latitude of 36° 51' during October and November 2012.

Measurements were carried out for direct normal irradiance (DNI) using solar radiation intensity meter (Voltcraft).

The average value I = 700 W/m2. The air temperature was 36 o C, and the water temperature range was between 28 oC

and 30o C. wind speed = 1 m/s. Efficiency of the tested solar cell was calculated by applying the following relation:

η = (Vm·Im/ I·S) ·100% …….(1)

Where:

Vm – maximum voltage [V], Im – maximum current [A],

I – intensity of radiation [W/m2],S – area of the cell [m2].

Fill factor of current – voltage characteristic of solar cells can be calculated by using the following relation:

FF = Vm·Im/Voc·Isc …….(2)

Where:

Voc– open circuit voltage [V],Isc – short circuit current [A].

V

R

Solar cell

Figure1: The experimental set up.

Copyright to IJIRSET www.ijirset.com 8128

ISSN: 2319-8753

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 3, Issue 1, January 2014

IV.RESULTS AND DISCUSSION

Atypical full current – voltage characteristic curve for polycrystalline silicon panel before submerging it in distillated

water (i.e. depth-d=0) and for maximum power are displayed in Figure 2a and figure 2b respectively.

140 d = 0 Cm

I = 700 W/m2

120

100

80

P(W)

60

40

20

0

0 2 4 6 8

V(V) (b)

Figure 2 : (a)I -V characteristics, (b)P-V characteristics and the maximum power of studied polycrystalline

photovoltaic cell.

The maximum voltage Vm = 5.2 V for I = 0.023 A, maximum power P max = 0.119 W and fill factor = 0.65 are

obtained. The current – voltage characteristic, and the power characteristic for the PV panel submerged under

different water depths (d) were presented in Figure 3 and figure4 respectively.

Table (1) illustrate a comparison of the values of maximum voltage V m, maximum current I m, maximum power P max ,

solar irradiance I and fill factor FF for the solar panel submerged under different water depths.

Copyright to IJIRSET www.ijirset.com 8129

ISSN: 2319-8753

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 3, Issue 1, January 2014

0.025 d= 1 Cm

d= 2 Cm

d = 3 Cm

0.02 d = 4 Cm

d = 5 Cm

d = 6 Cm

d = 7 Cm

0.015

I(A)

0.01

0.005

0

0 1 2 3 4 5 6 7

V(V)

Figure 3: I -V characteristics of studied polycrystalline photovoltaic cell submerged under different water

depths (d).

0.12 d = 1cm

d =2cm

d =3cm

0.1 d =4cm

d =5cm

d =6cm

0.08 d =7cm

0.06

P(W)

0.04

0.02

0

0 1 2 3 4 5 6 7

V(V)

Figure 4: P -V characteristics of studied polycrystalline photovoltaic cell submerged under different water

depths (d).

Copyright to IJIRSET www.ijirset.com 8130

ISSN: 2319-8753

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 3, Issue 1, January 2014

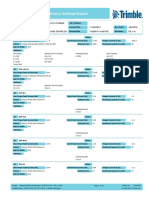

Table (1): characteristic of the solar panel under different water depths

d (Cm) Vm (V) Im(A) Pmax(W) I (W/m2) FF

1 5.3 0.0211 0.111 444 0.7

2 5.3 0.0186 0.0985 360 0.72

3 5.6 0.014 0.078 295 0.69

4 5.5 0.0096 0.0528 180 0.75

5 5.4 0.007 0.0378 130 0.72

6 5.4 0.0061 0.0329 100 0.71

7 5.2 0.0055 0.0286 100 0.61

Figure 5 plots the % efficiency for the PV panel as a function of water depth.

Increments in efficiency can be observed with increasing water depth, there is a maximum value for the efficiency

about 22 % at a depth of 6 cm.This increase in efficiency may be related to change in the band gap of the

corresponding absorber material in the PV cell, since the value of temperature coefficient is correlated to the band gap

[2]. It was found that when the depth of water is more than 6 cm, the efficiency for the PV panel started to decrease.

This may be related to electrolytic reaction at the electrodes or connections of the PV panel. [11]. Our results agree

with many previous studies (such as ref. 1,3, 5, 7, 10, 11).

25.00%

20.00%

15.00%

efficiency %

10.00%

5.00%

0.00%

0 2 4 6 8

d (Cm)

Figure 5 : The Relative Efficiency of PV panel as a function of water depth

V.CONCLUSION

The behaviour of a photovoltaic (PV) panel submerged in water is studied. The PV panel performance improved after

it was cooled by water. A sizeable increase of electric power output is found for shallow distillated water. The

repeal of thermal drift increases the solar panel efficiency by about 11% at water depth 6 cm. Our results are in line

with data presented in the literature.

Copyright to IJIRSET www.ijirset.com 8131

ISSN: 2319-8753

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 3, Issue 1, January 2014

REFERENCES

[1] B. B. Gardas and M V Tendolkar: Design of Cooling System for Photovoltaic Panel for Increasing its Electrical Efficiency, International

Journal of Mechanical and Production Engineering (IJMPE), 1(2012). p. 63-67.

[2] A.Virtuani, D. Pavanello, and G. Friesen: Overview of Temperature Coefficients of Different Thin Film Photovoltaic Technologies.. 5th World

Conference on Photovoltaic Energy Conversion, 6-10 September 2010, Valencia, Spain.

[3] D.L. King , NM, ; Kratochvil, J.A. ; Boyson, W.E.: Temperature Coefficients for PV Modules and Arrays: Measurement Methods, Difficulties,

and Results. Photovoltaic Specialists Conference, 29 Sep -03 Oct 1997, Anaheim, CA. USA.

[4] SEI, (2004). Photovoltaics Design and Installation Manual. New Society Publishers.

[5] M.Rosa-Clot, P.Rosa-Clot, G.M.Tina, P.F.Scandura: Submerged Photovoltaic solar panel: SP2, Renewable Energy 35 (2010) 1862-1865.

[6] F. Hussain, Z.Anuar, S. Khairuddin, M.Y.H. Othman, B. Yatim, H. Ruslan, and K. Sopian. Comparison study of air -based

photovoltaic/thermal (PV/T) collector with different designs of heat exchanger. Proceedings of World Renewable Energy Forum 2012

(WREF2012), Denver, Colorado, USA.

[7] G.M. Tinaa, , M. Rosa-Clotb, P. Rosa-Clotb and P.F. Scandurac: Optical and thermal behavior of submerged photovoltaic solar panel: SP2,

Energy 39 (2012) 17-26.

[8] Krauter, S. (2004). “Increased electrical yield via water flow over the front of photovoltaic panels.” Solar Energy Materials & Solar Cells, 82,

131–137.

[9] Meneses-Rodriguez, D., Horley, P. P., Gonzalez-Hernandez, J., Vorobiev, Y. V., and Gorley, P. N. (2005). “Photovoltaic solar cells

performance at elevated temperatures.” Solar Energy, 78, 243–250.

[10] Royne, A., Dey, C. J., and Mills, D. R. (2005). “Cooling of photovoltaic cells under concentrated illumination: a crit ical review.” Solar

Energy Material & Solar Cells, 86, 451–483.

[11] Li Zhu, Robert F. Boehm, Yiping Wang, Christopher Halford and Yong Sun: Water immersion cooling of PVcells in a high concentrati on

system, Solar Energy Materials & Solar Cells 95(2011)538–545.

[12] H.G. Teo, P.S. Lee and M.N.A. Hawlader: An Active Cooling System for Photovoltaic Modules, Applied Energy 90 (2012) 309–315.

[13] T. Chinamhora, G. Cheng, Y. Tham and W. Irshad: PV Panel Cooling System for Malaysian Climate Conditions, International Conference on

Energy and Sustainability, April 27, 2013, Karachi, Pakistan.

[14] Gheorghe Asachi: Combined Photovoltaic and Thermal Solar Panels -Enhanced Energy Conversion and Heat Transfer, Termotehnica

(2013):135-140.

Copyright to IJIRSET www.ijirset.com 8132

Вам также может понравиться

- Improving The Efficiency of Polycrystalline Solar Panel Via Water Immersion MethodДокумент7 страницImproving The Efficiency of Polycrystalline Solar Panel Via Water Immersion Methodaniket bobadeОценок пока нет

- Performance of A Solar Panel With Water Immersion Cooling TechniqueДокумент12 страницPerformance of A Solar Panel With Water Immersion Cooling Techniqueaniket bobadeОценок пока нет

- Performance of A Solar Panel With Water Immersion Cooling TechniqueДокумент13 страницPerformance of A Solar Panel With Water Immersion Cooling TechniqueDIPESH JAJALОценок пока нет

- 32Документ5 страниц32Jawad HamritiОценок пока нет

- Clarke 1996Документ6 страницClarke 1996neamaОценок пока нет

- Water Stagnant of Solar ModulesДокумент6 страницWater Stagnant of Solar ModulesNITIN MISHRAОценок пока нет

- International Journal of Engineering and Advanced Technology August 2019Документ4 страницыInternational Journal of Engineering and Advanced Technology August 2019deemahhwОценок пока нет

- A Combined Experimental and Simulation Study On The Effects of - 2015 - Energy PДокумент8 страницA Combined Experimental and Simulation Study On The Effects of - 2015 - Energy PSana SyedОценок пока нет

- Design and Simulation of Intelligent Control MPPT Technique For PV Module Using MATLAB/ SIMSCAPEДокумент13 страницDesign and Simulation of Intelligent Control MPPT Technique For PV Module Using MATLAB/ SIMSCAPEMuhammad Nur SururiОценок пока нет

- Variation of Temperature Coefficient of Different Technology Photovoltaic Modules With Respect To IrradianceДокумент6 страницVariation of Temperature Coefficient of Different Technology Photovoltaic Modules With Respect To IrradiancebirinchiОценок пока нет

- The Factors Affecting The Performance of Solar Cell: Bhalchandra V. Chikate Y.A. SadawarteДокумент5 страницThe Factors Affecting The Performance of Solar Cell: Bhalchandra V. Chikate Y.A. Sadawartepragya mitaОценок пока нет

- The Effect of Temperature Variations On Solar Cell EfficiencyДокумент6 страницThe Effect of Temperature Variations On Solar Cell EfficiencyVishal FernandesОценок пока нет

- Simulating Using Com SolДокумент5 страницSimulating Using Com SolRavin KumarОценок пока нет

- IJCRT2005548Документ6 страницIJCRT2005548afshooabadaniОценок пока нет

- Thermal Modeling of A Combined System of Photovoltaic Thermal PVT Solar Water HeaterДокумент11 страницThermal Modeling of A Combined System of Photovoltaic Thermal PVT Solar Water HeaterUmer AbbasОценок пока нет

- Monitoring of Grid Tied Photovoltaic System Efficiency in Operating ConditionsДокумент4 страницыMonitoring of Grid Tied Photovoltaic System Efficiency in Operating ConditionskubikОценок пока нет

- Analysis of Mathematical Model of PV Cell Module in Matlab/Simulink EnvironmentДокумент7 страницAnalysis of Mathematical Model of PV Cell Module in Matlab/Simulink EnvironmentskrtamilОценок пока нет

- Simulation of Mono Layer Solar Cell Using COMSOL and Fabrication in Particle Controlled BAEC Clean RoomДокумент5 страницSimulation of Mono Layer Solar Cell Using COMSOL and Fabrication in Particle Controlled BAEC Clean RoomSardar Masud Rana100% (1)

- Evaluation The Influences of Temperature Dust andДокумент13 страницEvaluation The Influences of Temperature Dust andElias Kondorura BawanОценок пока нет

- Power Generation Efficiency and Prospects of Floating Photovoltaic SystemsДокумент7 страницPower Generation Efficiency and Prospects of Floating Photovoltaic SystemsリズキーОценок пока нет

- 1 s2.0 S1877705812013525 MainДокумент9 страниц1 s2.0 S1877705812013525 Mainravi_2008Оценок пока нет

- Design of A Photovoltaic System For A Rural House: M.Aminy, N.Barhemmati, A.Hadadian, F.ValiДокумент5 страницDesign of A Photovoltaic System For A Rural House: M.Aminy, N.Barhemmati, A.Hadadian, F.ValiHypnotic KnightОценок пока нет

- The Rating of Photovoltaic PerformanceДокумент4 страницыThe Rating of Photovoltaic PerformanceJaymin RayОценок пока нет

- ThSci 3OHGZYAR6JbenchmarkingpaperДокумент7 страницThSci 3OHGZYAR6Jbenchmarkingpaperbharanitharan kОценок пока нет

- Experimental Investigation of PV PanelДокумент8 страницExperimental Investigation of PV PanelGanapathi RОценок пока нет

- TP Sur Les Défauts Des Systèmes PVДокумент9 страницTP Sur Les Défauts Des Systèmes PVSamah Ali BenamaraОценок пока нет

- Exergetic Analysis of A New Design PhotovoltaicДокумент5 страницExergetic Analysis of A New Design PhotovoltaicİSMAİL ÇİYLEZОценок пока нет

- The Experiment of Double Solar Energy by Reflection Light MethodДокумент9 страницThe Experiment of Double Solar Energy by Reflection Light MethodkyleОценок пока нет

- Automatic Cleaning System For Solar PanelДокумент8 страницAutomatic Cleaning System For Solar PanelSHIELDОценок пока нет

- Exergetic Analysis of A New Design Photovoltaic and Thermal (PV/T) SystemДокумент5 страницExergetic Analysis of A New Design Photovoltaic and Thermal (PV/T) SystemBranislavPetrovicОценок пока нет

- 75 Tist V5N2.Документ4 страницы75 Tist V5N2.ROOSSVELT PRABHU TEACHINGОценок пока нет

- Water PVT Collectors Performance ComparisonДокумент6 страницWater PVT Collectors Performance ComparisonAlexandruIonutОценок пока нет

- Droplet Based Electricity GenerationДокумент4 страницыDroplet Based Electricity GenerationVIVA-TECH IJRIОценок пока нет

- Dark and Illuminated Characteristics of Photovoltaic Solar Modules. Part I: Influence of Dark Electrical StressДокумент11 страницDark and Illuminated Characteristics of Photovoltaic Solar Modules. Part I: Influence of Dark Electrical StressSarkarОценок пока нет

- Experimental Study of Solar Hydrogen Production PeДокумент9 страницExperimental Study of Solar Hydrogen Production PeManu MonaОценок пока нет

- 154 Icrera2013 SpainДокумент10 страниц154 Icrera2013 SpainMarian EnachescuОценок пока нет

- Experiment Study of Water Based Photovoltaic-Thermal (PV/T) CollectorДокумент8 страницExperiment Study of Water Based Photovoltaic-Thermal (PV/T) CollectorYulia FithryОценок пока нет

- An Investigation Into The Failure Mechanisms of Schottky Barrier Diodes, As Commonly Implemented As Bypass Diodes in Photovoltaic ModulesДокумент9 страницAn Investigation Into The Failure Mechanisms of Schottky Barrier Diodes, As Commonly Implemented As Bypass Diodes in Photovoltaic ModulesbitudayОценок пока нет

- Design and Analysis of Power Generating TilesДокумент4 страницыDesign and Analysis of Power Generating TilesVenkat TamminaОценок пока нет

- NPSC RVI InsulatorsДокумент4 страницыNPSC RVI InsulatorsJordan RileyОценок пока нет

- Impact of Two Types Flat Reflector Materials On Solar Panel CharacteristicsДокумент12 страницImpact of Two Types Flat Reflector Materials On Solar Panel CharacteristicsedumacerenОценок пока нет

- Is 12834 1989Документ12 страницIs 12834 1989Siddharth SinghОценок пока нет

- J Solener 2010 12 022Документ10 страницJ Solener 2010 12 022Adrian StelistuОценок пока нет

- Transparent Photovoltaic CellsДокумент8 страницTransparent Photovoltaic CellsjoseОценок пока нет

- Energies 05 03450Документ15 страницEnergies 05 03450Johnny TestОценок пока нет

- Project Report On Solar Module Manufacturing UnitДокумент9 страницProject Report On Solar Module Manufacturing UnitEIRI Board of Consultants and PublishersОценок пока нет

- MATLAB Simulation of Photovoltaic and Photovoltaic/Thermal Systems PerformanceДокумент9 страницMATLAB Simulation of Photovoltaic and Photovoltaic/Thermal Systems PerformanceReda AlHamwiОценок пока нет

- Electricalthermal Performance of Hybrid PVT SystemДокумент6 страницElectricalthermal Performance of Hybrid PVT SystemUmair IqbalОценок пока нет

- Solar RefrigeratorДокумент5 страницSolar RefrigeratorJournalNX - a Multidisciplinary Peer Reviewed JournalОценок пока нет

- Paper123151 3156 PDFДокумент6 страницPaper123151 3156 PDFDrSachin GuptaОценок пока нет

- Full Length Article: SciencedirectДокумент9 страницFull Length Article: SciencedirectSanne VandevoordeОценок пока нет

- Modeling and Simulation of Wind Solar Hybrid System Using Matlab/SimulinkДокумент7 страницModeling and Simulation of Wind Solar Hybrid System Using Matlab/SimulinkAngelo Aco MendozaОценок пока нет

- Polymer MEMS ActuatorsДокумент9 страницPolymer MEMS ActuatorsAmir ReuvenyОценок пока нет

- 228 Sakshi Pahade EE 6Документ8 страниц228 Sakshi Pahade EE 6Sakshi PahadeОценок пока нет

- The Pulsed Electron Accelerator For Radiation Technologies: Korenev, Corporation, LibertyvilleДокумент3 страницыThe Pulsed Electron Accelerator For Radiation Technologies: Korenev, Corporation, LibertyvilledyahputriaОценок пока нет

- Effect of Room Air Exposure On The Field Emission Performance ofДокумент6 страницEffect of Room Air Exposure On The Field Emission Performance ofbrokОценок пока нет

- 35 Simulation PDFДокумент7 страниц35 Simulation PDFDias Nur SaputroОценок пока нет

- Yuan 2015Документ8 страницYuan 2015AdiKurdiОценок пока нет

- Analysis of Output DC Current Injection in 100kW Grid Connected VACON 8000 Solar InverterДокумент4 страницыAnalysis of Output DC Current Injection in 100kW Grid Connected VACON 8000 Solar InverteriaetsdiaetsdОценок пока нет

- Ept For TeachersДокумент5 страницEpt For TeachersSheila Mae CulpableОценок пока нет

- Beautiful Trauma Album (P!NK) LyricsДокумент17 страницBeautiful Trauma Album (P!NK) LyricsSheila Mae CulpableОценок пока нет

- National Vocational Training Institute: Trade Testing Regulations and SyllabusДокумент35 страницNational Vocational Training Institute: Trade Testing Regulations and SyllabusSheila Mae CulpableОценок пока нет

- HARDWAREДокумент112 страницHARDWARESheila Mae CulpableОценок пока нет

- Waste To Energy: Course Code Category Hours / Week Credits Maximum Marks L T P C CIA SEE TotalДокумент2 страницыWaste To Energy: Course Code Category Hours / Week Credits Maximum Marks L T P C CIA SEE Totals sОценок пока нет

- Civil Solar TreeДокумент17 страницCivil Solar TreeSreejith Reddy Sree50% (2)

- Hybrid Power Generation by Using Solar and Wind Energy: Case StudyДокумент13 страницHybrid Power Generation by Using Solar and Wind Energy: Case Studynahom samuelОценок пока нет

- Advantages and Disadvantages of GasДокумент1 страницаAdvantages and Disadvantages of GasIzzam MuzammirОценок пока нет

- PPTДокумент41 страницаPPTOkta KurniawanОценок пока нет

- Factor Capacity CalculationДокумент7 страницFactor Capacity CalculationImran AnamiОценок пока нет

- (P&id1) PDFДокумент1 страница(P&id1) PDFHatem FaroukОценок пока нет

- Harga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) OCTOBER 2019Документ8 страницHarga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) OCTOBER 2019Adnan NstОценок пока нет

- Nuclear Energy: Prepared By: Mary Grace BacoyДокумент14 страницNuclear Energy: Prepared By: Mary Grace BacoyMary Grace CarallasОценок пока нет

- Siempelkamp Biomass Power Plant EngДокумент8 страницSiempelkamp Biomass Power Plant EngWasim AshfaqОценок пока нет

- AppendixДокумент28 страницAppendixDilla WahabОценок пока нет

- An Overview of Binary ORC Technology With Focus On Turboden's Revamp of Lightning Dock Plant in New MexicoДокумент6 страницAn Overview of Binary ORC Technology With Focus On Turboden's Revamp of Lightning Dock Plant in New MexicoRinnoОценок пока нет

- Flash Steam Geothermal TechnologyДокумент7 страницFlash Steam Geothermal TechnologyMearegОценок пока нет

- MEE1011 Renewable-Energy-Sources ETH 1 AC40Документ2 страницыMEE1011 Renewable-Energy-Sources ETH 1 AC40Kishan GajjarОценок пока нет

- Solar Wind Hybrid SystemДокумент13 страницSolar Wind Hybrid Systemanon_485825334100% (3)

- ATD RAnkin Assignment-2011Документ3 страницыATD RAnkin Assignment-2011Mradul Yadav0% (2)

- A Report On Thermoelectric GeneratorДокумент27 страницA Report On Thermoelectric GeneratorBhaskar Singh75% (4)

- Sources of Energy ScriptДокумент15 страницSources of Energy ScriptShah ChenzenОценок пока нет

- How Does A Gas Turbine Power Plant WorkДокумент6 страницHow Does A Gas Turbine Power Plant WorkokemmaОценок пока нет

- Improving The Efficiency of Afbc Boiler by Recycling Carbon Rich Fly-Ash by Group-10Документ26 страницImproving The Efficiency of Afbc Boiler by Recycling Carbon Rich Fly-Ash by Group-10Rupesh Anand100% (1)

- Coal and Coal ChemicalsДокумент54 страницыCoal and Coal ChemicalsVishal DhapaОценок пока нет

- HRSG Vertical PresentationДокумент77 страницHRSG Vertical PresentationAnonymous BzGb2fnfEОценок пока нет

- Solar Water Heating (Presentation) .Документ22 страницыSolar Water Heating (Presentation) .Malak Atizaz HasanОценок пока нет

- Protective Device SettingsДокумент36 страницProtective Device Settingswaseem kausarОценок пока нет

- 1447123719Документ528 страниц1447123719Bela Lutfika HapsariОценок пока нет

- Boiler CombustionДокумент20 страницBoiler CombustionAnand SwamiОценок пока нет

- Introduction To Hydro EnergyДокумент2 страницыIntroduction To Hydro EnergyShubham SarafОценок пока нет

- HFLD Literature ReviewДокумент5 страницHFLD Literature ReviewMuhammad AamirОценок пока нет

- Ch6 Hydro Power PlantДокумент23 страницыCh6 Hydro Power PlantAzraqul IlmiОценок пока нет

- Coal and Petroleum: E E E E E P P P P PДокумент6 страницCoal and Petroleum: E E E E E P P P P PMaharghya BiswasОценок пока нет