Академический Документы

Профессиональный Документы

Культура Документы

Eurofluor GD13.2 PPE 160406

Загружено:

Roger BoursИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Eurofluor GD13.2 PPE 160406

Загружено:

Roger BoursАвторское право:

Доступные форматы

Personal Protective Equipment (PPE)

Hydrogen Fluoride – Hydrofluoric Acid Solutions

Eurofluor (European Technical Committee for Fluorine)

www.eurofluor.org

Version: 06.04.2016

CONTENT PPE

• INTRODUCTION

• CLASSIFICATION OF HF

• REGULATIONS

• LEVELS OF PROTECTION

• α – Level

• β – Level

• γ – Level

• δ – Level

• TRAINING

• CHOICE OF SUITABLE PPE

• HOW TO USE PPE

• MORE INFORMATION

PERSONAL PROTECTIVE EQUIPMENT - PPE

INTRODUCTION

• This Recommendation is based on the various measures taken by

member companies of Eurofluor.

• It in no way is intended as a substitute for the various national or

international regulations, which should be respected in an integral

manner.

• It results from the understanding and many years experience of the

AHF/HF producers in their respective countries at the date of issue

of this particular document.

• Established in good faith, this recommendation should not be used

as a standard or a comprehensive specification, but rather as a

guide which should, in each particular case, be adapted and utilised

in consultation with an AHF/HF manufacturer, supplier or user, or

other experts in the field.

INTRODUCTION

• It has been assumed in the preparation of this publication that the

user will ensure that the contents are relevant to the application

selected and are correctly applied by appropriately qualified and

experienced people for whose guidance it has been prepared.

• Eurofluor does not, and indeed cannot, make any representation or

give any warranty of guarantee in connection with material

published in Eurofluor publications and expressly disclaims any legal

liability or responsibility for damage or loss resulting from the use,

or misuse, of information contained in this document.

GENERAL INFORMATION ABOUT ANHYDROUS HF

Concen- CLP CLASSIFICATION ADR / RID CLASSIFICATION

tration

CLP – Classification, Labelling and Packaging ADR - European Agreement on International Carriage of

% Dangerous Goods

RID – Regulations Concerning the International Carriage of

Dangerous Goods

ACUTE TOXICITY (oral, dermal and inhalation) HYDROGEN FLUORIDE, ANHYDROUS

Cat. 1 and 2 CLASS 8 PG I

SKIN CORROSION CT1 : CORROSIVE SUBSTANCE, TOXIC, LIQUID

Cat 1A

AHF 886

HF > 85% 1052

HYDROFLUORIC ACID with more than 85% of hydrogen

Hazard statements (H Statement) fluoride

CLASS 8 PG I

H300: Fatal if swallowed CT1 : CORROSIVE SUBSTANCE, TOXIC, LIQUID

H310: Fatal in contact with skin

H330: Fatal if inhaled 886

H314: Causes severe skin burns and eye 1790

damage

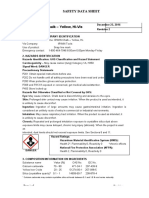

GENERAL INFORMATION ON AQUEOUS HYDROFLUORIC ACID (HF)

Concen- CLP CLASSIFICATION ADR / RID CLASSIFICATION

tration CLP – Classification, Labelling and Packaging ADR - European Agreement on International Carriage

% of Dangerous Goods

RID – Regulations Concerning the International

Carriage of Dangerous Goods

ACUTE TOXICITY (oral, dermal and inhalation) HYDROFLUORIC ACID

Cat 1 and 2 with more than 60% but not more than 85% hydrogen

SKIN CORROSION fluoride

Cat 1A CLASS 8 PG I

HF > 60%

CT1 : CORROSIVE SUBSTANCE, TOXIC, LIQUID

HF < 85%

886

1790

Hazard statements (H Statement) HYDROFLUORIC ACID

with not more than 60% of hydrogen fluoride

H300: Fatal if swallowed CLASS 8 PG II

H310: Fatal in contact with skin

HF ≤ 60% CT1 : CORROSIVE SUBSTANCE, TOXIC, LIQUID

H330: Fatal if inhaled

H314: Causes severe skin burns and eye damage

86

1790

REGULATIONS

Directive 89/686/EEC on personal protective equipment

• HOW TO MANUFACTURE AND COMERCIALIZE PPE

• It lays down the conditions governing its placing on the market

and free movement within the Community and the basic safety

requirements which PPE must satisfy in order to ensure the

health protection and safety of users.

• ALL personal protective equipment is required to carry the 'CE'

marking as a sign that the product complies with the essential

requirements of directive 89/686/EEC.

• Personal protective equipment must be tested using the

standard test protocol against the relevant hazard(s) and

manufactured under an approved Quality Assurance system

(e.g. ISO 9002).

PERSONAL PROTECTIVE EQUIPMENT - PPE

REGULATIONS

Directive 89/686/EEC on personal protective equipment

• HOW TO MANUFACTURE AND COMERCIALIZE PPE

• An EC-type examination certificate is then issued by the notified

body certifying that the personal protective equipment satisfies

the relevant provisions of the Personal Protective Equipment

Directive.

• The manufacturer then issues an EC Declaration of Conformity

for the personal protective equipment and affixes a CE mark.

PERSONAL PROTECTIVE EQUIPMENT - PPE

REGULATIONS

Directive 89/686/EEC on personal protective equipment

PPE is divided into one of three categories:

Simple Design

• This equipment is designed for minimal risks only and where the

effects of any hazard are of minimal risk and the consequences of

any exposure are reversible.

Intermediate Design

• Personal protective equipment which has been tested against at

least one hazard and is approved by a notified body.

PERSONAL PROTECTIVE EQUIPMENT - PPE

REGULATIONS

Directive 89/686/EEC on personal protective equipment

PPE is divided into one of three categories :

Complex Design

• This equipment is designed for hazards which cause irreversible

effects or mortal danger.

• For use in tasks where contact with HF may occur only Complex

Design personal protective equipment is acceptable.

• Where personal protective equipment does not display the relevant

CE mark it cannot be employed at a European facility handling HF.

• Relevant test protocol and standards are referred to where possible.

PERSONAL PROTECTIVE EQUIPMENT - PPE

REGULATIONS

Directive 89/656/EEC use of personal protective equipment

• HOW TO USE THE PPE´S BY WORKERS

• Lays down minimum requirements for personal protective

equipment used by workers at work.

PERSONAL PROTECTIVE EQUIPMENT - PPE

LEVELS OF PROTECTION

• There are four levels of protection:

α – Level (emergency response)

β – Level (operational equipment for increased risks)

PERSONAL PROTECTIVE EQUIPMENT - PPE

LEVELS OF PROTECTION

• There are four levels of protection:

γ – Level (routine operational equipment)

δ – Level (standard on plant equipment)

PERSONAL PROTECTIVE EQUIPMENT - PPE

LEVELS OF PROTECTION

α – Level (emergency response)

• is used for emergency response or where the risk assessment has identified a

high degree of probability that the task could result in a significant exposure

and when an air line is not a practical option, for example, the air line will not

give sufficient mobility.

• α Level should use equipment designed to prevent ingress of HF and should

give full protection from potential HF exposures.

• The health impact of using this level of personal protective equipment should

not be under-estimated. The wearing of fully encapsulated suits and

breathing apparatus (BA) whilst working, particularly in hot climates, can

lead to additional health risks for the employees involved. The additional risks

associated should be identified and assessed in the risk assessment.

• α Level personal protective equipment is used for emergency response and is

designed to be gas tight and to provide full protection against the ingress of

HF.

• Specific training is required to ensure correct fitting and safe undressing.

PERSONAL PROTECTIVE EQUIPMENT - PPE

LEVELS OF PROTECTION

α – Level (emergency response)

• Fully encompassing HF resistant suit

• (EN 943-2)

• Suitable gloves either built in or completely sealed at the wrists

• (EN 488)

• BA (Breathing Aparatus) Set

• (EN 132 : 1990 Annex A) or, if practicable,

• air line providing suitable supply of breathing air

• (EN 132 : 1990 Annex A; EN 270 : 1994; EN 137)

• Standard hard hat or bump cap worn inside the suit

• (EN 397)

• HF resistant Wellington-type boot with steel toe and shank worn inside outer

leg seal

• (EN 943-2: 1995)

PERSONAL PROTECTIVE EQUIPMENT - PPE

LEVELS OF PROTECTION

β – Level (Operational Equipment for Increased Risks)

• β Level personal protective equipment is used for routine

operational tasks involving invasive interactions with process

equipment or for non-routine interactions which have been

identified as requiring a higher level of protection.

• β Level equipment is designed to prevent the ingress of HF

and should give full protection from potential HF exposures.

• β Level personal protective equipment is to be used for

operations where the risk of contact with process fluid may

be reasonably significant.

PERSONAL PROTECTIVE EQUIPMENT - PPE

LEVELS OF PROTECTION

β – Level (operational equipment for increased risks)

• Airfed HF resistant jacket with high waisted trousers

• (EN 467 : 1995)

• sealed at Wellington-type boots and gloves with integral, air fed hood

• (Visor to EN 146; air fed hood to EN 270) or

• fully encompassing HF resistant one piece suit

• (Visor to EN 146; prEN 943-2)

• Standard hard hat or bump cap worn inside the jacket

• (EN 397)

• HF resistant gloves

• (EN 374-3)

• Air line (resistant to HF attack) providing suitable supply of breathing air

• (EN 132 : 1990 Annex A; EN 270 : 1994; EN 137)

• HF resistant Wellington-type boots or overboots with steel toe and shank

• (EN 345 with additional testing to EN 369 [specifically for HF])

• Boots permanently attached to a one-piece, gas tight suit may also be worn

• (EN 943)

PERSONAL PROTECTIVE EQUIPMENT - PPE

LEVELS OF PROTECTION

γ – Level (routine operational equipment)

• γ Level personal protective equipment is used for routine

operational tasks involving non-invasive interactions with

process equipment.

• It is designed to give a greater degree of protection against

incidental contact with process fluids for individuals working

in the HF handling area.

• γ Level personal protective equipment should be used for

operations which involve interaction with the process but

which are not expected to cause a release of process fluids.

PERSONAL PROTECTIVE EQUIPMENT - PPE

LEVELS OF PROTECTION

γ – Level (routine operational equipment)

• Standard hard hat

• (EN 397)

• with HF resistant nape

• (EN 467 : 1995)

• and face visor (Visor MUST be in the down position when in the HF handling area)

• (EN 166-B)

• Chemical goggles (Goggles MUST be worn under visor when within the plant

boundaries)

• (EN 166-345-B)

• HF resistant gloves

• (EN 374-3)

• HF resistant jacket with sleeves sealed at gloves

• (EN 467 : 1995)

• HF resistant high waisted trousers sealed at Wellington-type boots

• (EN 467 : 1995)

• HF resistant Wellington-type boots or overboots with steel toe and shank

• (EN 345 with additional testing to EN 369 [specifically for HF])

PERSONAL PROTECTIVE EQUIPMENT - PPE

LEVELS OF PROTECTION

δ – Level (standard on-plant equipment)

• δ Level personal protective equipment is the minimum

level of personal protective equipment required to enter

an HF handling facility and is not designed for use when

there is a risk of potential exposure to HF.

• δ Level personal protective equipment is specified when

the risk assessment has indicated that no physical contact

with acid containing equipment is likely and, therefore,

only minimal protection is needed.

Acid resistant clothes • It is intended to give protection against potentially small,

Type 6 unforeseen exposures e.g. drips, surface

PERSONAL PROTECTIVE EQUIPMENT - PPE

LEVELS OF PROTECTION

δ – Level (standard on-plant equipment)

• Standard hard hat

• (EN 397)

• Safety spectacles with side shields or chemical goggles

• (EN 166-345-B)

• HF resistant boots, overboots or safety shoes with steel toe

• (EN 345)

• HF resistant gloves (may also be required)

• (EN 374-3)

• Acid resistant jacket and trousers

• (EN 340 pREN13034 (type 6))

Acid resistant clothes

• Escape air packs or suitable filtration systems should also be readily

Type 6 available to enable an escape in the unlikely event of a leak.

PERSONAL PROTECTIVE EQUIPMENT - PPE

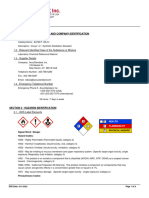

COMPARISON

Eurofluor / OSHA /

ACTION CIA UK HFIPI USA API

CTEF EPA

Emergency

EMERGENCY RESPONSE α A D A

Response

SIGNIFICANT EXPOSURE IS EXPECTED (E.G. SMALL

β High Risk B C B

LEAKAGES)

MAINTENANCE AFTER GROSS HF REMOVAL β-γ High Risk B C B

ROUTINE OPERATIONAL WORK IN ACID HANDLING Medium

β-γ C B C

AREAS (E.G. LOADING / UNLOADING STATION) Risk

HF (> 40%) SAMPLING γ High Risk C B C

STANDARD ON-PLANT EQUIPMENT (OPERATIONS) δ Low Risk D A D

CIA UK Chemical Industry Association United Kingdom

HFIPI North American Hydrogen Fluoride Industry Practices Institute

API American Petroleum Institute Safe Operation of Hydrofluoric Acid Alkylation Units

OSHA US Occupational Safety and Health Administration

EPA US Environmental Protection Agency

PERSONAL PROTECTIVE EQUIPMENT - PPE

TRAINING

• In all cases personal protective equipment should only be worn

by those trained in its use, application and decontamination.

• Training must include to dress and undress with the specific PPE.

• The training requirements for operators, maintenance,

contractors, management and visitors should be clearly

identified and must be strictly followed.

• Periodic re-training should also be provided.

• In all cases training and re-training should be recorded and

these records maintained for a suitable period.

PERSONAL PROTECTIVE EQUIPMENT - PPE

CHOICE OF PPE FOR WORKING WITH AHF/HF

• It should be noted that all materials have some permeability

to HF, particularly liquid HF, and direct contact should be

avoided.

• Procedures should therefore ensure that, where contact with

liquid HF may have taken place, the wearer should endeavour

to decontaminate and inspect the equipment at the earliest

possible opportunity.

• Also, once HF has penetrated the outer protective layer, it

cannot be removed by the decontamination process,

therefore a suitable operational lifespan should be

determined.

PERSONAL PROTECTIVE EQUIPMENT - PPE

CHOICE OF PPE FOR WORKING WITH AHF/HF

PERSONAL PROTECTIVE EQUIPMENT - PPE

CHOICE OF PPE FOR WORKING WITH AHF/HF

Protection against permeation

Protection index Breakthrough time

1 >10 minutes

2 >30 minutes

3 > 60 minutes

4 >120 minutes

5 >240 minutes

6 > 480 minutes

PERSONAL PROTECTIVE EQUIPMENT - PPE

CHOICE OF PPE FOR WORKING WITH AHF/HF

• In order to select the most appropriate material the user should contact

the various companies supplying personal protective equipment and

should

• request the up to date data on breakthrough times for the various products,

• the test procedure followed and

• the recommended maximum working time.

• Alternatively, contact your supplier of HF and request information on suitable

personal protective equipment.

• It is recommended to check the fabric in the facilities to verify if the

material is suitable for AHF and diluted HF.

PERSONAL PROTECTIVE EQUIPMENT - PPE

HOW TO USE PPE

STORAGE

VERIFICATION VERIFICATION

(make sure the (make sure the

PPE is safe) PPE is safe)

WASH

DISINFECTION USE

DRYING

DECONTA-

MINATION

PERSONAL PROTECTIVE EQUIPMENT - PPE

MORE INFORMATION PPE

For more information, please download:

STS Group 7:

Recommendation on safety management for handling

of Anhydrous Hydrogen Fluoride and Hydrofluoric Acid

solutions

www.eurofluor.org

If you need any other information do not hesitate to

contact to info@eurofluor.org

PERSONAL PROTECTIVE EQUIPMENT - PPE

Вам также может понравиться

- Safety Data Sheet: November 1, 2014Документ8 страницSafety Data Sheet: November 1, 2014DANY SUJIОценок пока нет

- MSDS-rev12 - LF ProductsДокумент9 страницMSDS-rev12 - LF ProductsOfer ShochetОценок пока нет

- MSDS Oex Ob 8162 MMT 62Документ7 страницMSDS Oex Ob 8162 MMT 62Justine JoseОценок пока нет

- MSDSДокумент4 страницыMSDSmolobe mkhondoОценок пока нет

- 20041-62743-15651-013302 800 2T Road Racing MSDSДокумент8 страниц20041-62743-15651-013302 800 2T Road Racing MSDSwswoonОценок пока нет

- Fds Alkacide en 2016 10Документ11 страницFds Alkacide en 2016 10Agunk IstriОценок пока нет

- Fds Alkacide en 2016 10Документ11 страницFds Alkacide en 2016 10Kadek Ayang Cendana PrahayuОценок пока нет

- MSDS Alkacide PDFДокумент11 страницMSDS Alkacide PDFSandy HidayatОценок пока нет

- MSDS ISTHMUS CRUDE OIL Load PajaritosДокумент4 страницыMSDS ISTHMUS CRUDE OIL Load PajaritosEsteban Enrique Posan BalcazarОценок пока нет

- Turco 5351 MsdsДокумент5 страницTurco 5351 MsdsElías VillegasОценок пока нет

- Guidelines For Open Plant StructuresДокумент6 страницGuidelines For Open Plant StructuresIndrawОценок пока нет

- SDS Overwax RF PDFДокумент4 страницыSDS Overwax RF PDFArif UzОценок пока нет

- ZChek CL Aerosol MSDSДокумент7 страницZChek CL Aerosol MSDSharshileng3992Оценок пока нет

- 510 MSDSДокумент7 страниц510 MSDSAhmed Emad AhmedОценок пока нет

- Material Safety Data Sheet: Hydrochloric AcidДокумент4 страницыMaterial Safety Data Sheet: Hydrochloric AcidSIDIBEОценок пока нет

- PRF7024II: Material Safety Data SheetДокумент6 страницPRF7024II: Material Safety Data SheetOnnuri WonОценок пока нет

- Cerablanket - Cerachem BlanketДокумент8 страницCerablanket - Cerachem BlanketTrandafira IonescuОценок пока нет

- Material Safety Data Sheet: BJ Services CompanyДокумент6 страницMaterial Safety Data Sheet: BJ Services CompanyizzybjОценок пока нет

- Acetalde MSDSДокумент5 страницAcetalde MSDSJaymit PatelОценок пока нет

- CERAMIX-R (DGR)Документ5 страницCERAMIX-R (DGR)Atazha AguilarОценок пока нет

- MSDS Potassium ChlorideДокумент6 страницMSDS Potassium ChlorideokiОценок пока нет

- Electroclean A Quick Dry PDFДокумент8 страницElectroclean A Quick Dry PDFCatalin SevastianОценок пока нет

- SDS MSDS 000029 Refractory Ceramic Fiber 1996 08-15 LuciferДокумент13 страницSDS MSDS 000029 Refractory Ceramic Fiber 1996 08-15 LucifereadriesОценок пока нет

- 6087 MSDS PDFДокумент11 страниц6087 MSDS PDFNduong NguyenОценок пока нет

- MSDS 150NДокумент7 страницMSDS 150NevyОценок пока нет

- SDS - Astm P 135 01Документ7 страницSDS - Astm P 135 01Omar SaaedОценок пока нет

- MSDS Castrol Transaqua HT-Hydraulic FluidДокумент4 страницыMSDS Castrol Transaqua HT-Hydraulic FluidTeguh S0% (1)

- 1 LW Stain ThetrachloroethaneДокумент7 страниц1 LW Stain ThetrachloroethaneSebastian ZuMarОценок пока нет

- DMDS MSDSДокумент11 страницDMDS MSDSamirhosseine00Оценок пока нет

- Air Cooler CleanerДокумент19 страницAir Cooler CleanerArdyas Wisnu BaskoroОценок пока нет

- Safety Data Sheet Nitoprime Zincrich Plus: Revision Date: 05/08/2015 Revision: 6bДокумент13 страницSafety Data Sheet Nitoprime Zincrich Plus: Revision Date: 05/08/2015 Revision: 6bmohamed ayadОценок пока нет

- Safety Data Sheet Nitoprime Zincrich Plus: Revision Date: 05/08/2015 Revision: 6bДокумент13 страницSafety Data Sheet Nitoprime Zincrich Plus: Revision Date: 05/08/2015 Revision: 6bIzzul Asyraf ZulkifliОценок пока нет

- SDS - Astm P 133 01Документ6 страницSDS - Astm P 133 01Omar SaaedОценок пока нет

- KellersДокумент13 страницKellersGT-LUCAS BARCIОценок пока нет

- SDS - Astm P 127 02Документ7 страницSDS - Astm P 127 02Omar SaaedОценок пока нет

- MSDS Ponceau SXДокумент4 страницыMSDS Ponceau SXArthur Reynaldo DevicoОценок пока нет

- Dimethylformamide - Nugentec Ghs MsdsДокумент8 страницDimethylformamide - Nugentec Ghs MsdsstabinmathewОценок пока нет

- Safety Data Sheet: Telephone (704) 987-4555 8935 Northpointe Executive Huntersville, NC 28078 DRДокумент6 страницSafety Data Sheet: Telephone (704) 987-4555 8935 Northpointe Executive Huntersville, NC 28078 DRRinaldi SatriaОценок пока нет

- Resin MSDS 2Документ82 страницыResin MSDS 2kponnu31Оценок пока нет

- SDS10Документ5 страницSDS10Octavian Sever CoifanОценок пока нет

- Baker Hughes: Material Safety Data SheetДокумент5 страницBaker Hughes: Material Safety Data SheetbayuОценок пока нет

- Cedar FiberДокумент6 страницCedar Fibersajad gohariОценок пока нет

- SDS - Astm P 132 04Документ6 страницSDS - Astm P 132 04Omar SaaedОценок пока нет

- Material Safety Data Sheet: BJ Services CompanyДокумент5 страницMaterial Safety Data Sheet: BJ Services CompanyizzybjОценок пока нет

- SDS - Astm P 132 02Документ6 страницSDS - Astm P 132 02Omar SaaedОценок пока нет

- MSDS - Text Spin H (E)Документ4 страницыMSDS - Text Spin H (E)Athiphap SrisupareerathОценок пока нет

- PBF MSDS AsphaltДокумент11 страницPBF MSDS AsphaltAgustn LopzОценок пока нет

- Safety Data Sheet: According To EC Directive 91/155/EECДокумент5 страницSafety Data Sheet: According To EC Directive 91/155/EECSiti HannaОценок пока нет

- MSDS-Acumer 1110Документ6 страницMSDS-Acumer 1110daniОценок пока нет

- Spray Paint MsdsДокумент4 страницыSpray Paint MsdsHillary RyanОценок пока нет

- CDT Cutting Oil (Aerosol) - CRC IndДокумент4 страницыCDT Cutting Oil (Aerosol) - CRC IndBiju_PottayilОценок пока нет

- Barite SDS March 2016 (Qmax)Документ4 страницыBarite SDS March 2016 (Qmax)Baher SaidОценок пока нет

- SDS - Astm P 126 01Документ6 страницSDS - Astm P 126 01Omar SaaedОценок пока нет

- Material Safety Data SheetДокумент7 страницMaterial Safety Data SheetCatalin SevastianОценок пока нет

- Fuel 380 Chem ResistanceДокумент11 страницFuel 380 Chem ResistancecraponzelОценок пока нет

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationДокумент6 страницMaterial Safety Data Sheet: 1. Chemical Product and Company IdentificationThusith WijayawardenaОценок пока нет

- 4139 Jo0mc5kubДокумент6 страниц4139 Jo0mc5kubNandar Min HtetОценок пока нет

- 55586-Terojet MSDSДокумент8 страниц55586-Terojet MSDScandraОценок пока нет

- Sulfato de Niquel - MSDS (En 7.08.2020) - Anders Peru S.A.C.Документ91 страницаSulfato de Niquel - MSDS (En 7.08.2020) - Anders Peru S.A.C.Mel Janice Fran ChangОценок пока нет

- Occupational Radiation Protection in the Uranium Mining and Processing IndustryОт EverandOccupational Radiation Protection in the Uranium Mining and Processing IndustryОценок пока нет

- 8.9024.00.0 Desalination - PR Application GuideДокумент2 страницы8.9024.00.0 Desalination - PR Application GuideRoger BoursОценок пока нет

- rr1113 HSE Vapour Cloude Explosion PDFДокумент326 страницrr1113 HSE Vapour Cloude Explosion PDFRoger BoursОценок пока нет

- OrgalimeДокумент18 страницOrgalimeRoger BoursОценок пока нет

- rr1113 HSE Vapour Cloude Explosion PDFДокумент326 страницrr1113 HSE Vapour Cloude Explosion PDFRoger BoursОценок пока нет

- HTTP WWW - Schneider-Kessel - Com Products InookДокумент2 страницыHTTP WWW - Schneider-Kessel - Com Products InookRoger BoursОценок пока нет

- Tantaline Surface Alloy For Bursting Disc HoldersДокумент2 страницыTantaline Surface Alloy For Bursting Disc HoldersRoger BoursОценок пока нет

- Sec D CH 12 Regression Part 2Документ66 страницSec D CH 12 Regression Part 2Ranga SriОценок пока нет

- Multiphase FlowДокумент80 страницMultiphase FlowAnjo VasquezОценок пока нет

- 7.proceeding Snib-Eng Dept, Pnp-IndonesiaДокумент11 страниц7.proceeding Snib-Eng Dept, Pnp-IndonesiamissfifitОценок пока нет

- Data 6005AДокумент1 страницаData 6005AErick De La RoSaОценок пока нет

- Medical Development PowerPoint TemplateДокумент16 страницMedical Development PowerPoint TemplatesugamОценок пока нет

- 1977 The Reactive Agility TestДокумент6 страниц1977 The Reactive Agility TestJessica Sepúlveda SalasОценок пока нет

- Lorma Scope of WorkДокумент2 страницыLorma Scope of WorkJb TiscubОценок пока нет

- Project Risk ManagementДокумент104 страницыProject Risk Managementtsrinivasan5083Оценок пока нет

- Parts Catalog: Imagerunner Advance 6075/6065/6055 SeriesДокумент201 страницаParts Catalog: Imagerunner Advance 6075/6065/6055 SeriesTally LeonОценок пока нет

- 01 - Basic Radio TheoryДокумент34 страницы01 - Basic Radio TheoryClaudio SantoroОценок пока нет

- 1 - KSU Research Methodology Overview (A Mandil, Oct 2009)Документ25 страниц1 - KSU Research Methodology Overview (A Mandil, Oct 2009)Fatamii IiiОценок пока нет

- Adc 0808Документ14 страницAdc 0808Vikas PatelОценок пока нет

- Asus X550JF x550jxДокумент7 страницAsus X550JF x550jxCiprian BalalauОценок пока нет

- Practices Venn DiagramДокумент2 страницыPractices Venn DiagramNathanОценок пока нет

- Ambience LightingДокумент340 страницAmbience Lightingdambe22Оценок пока нет

- B e EceДокумент85 страницB e Ecedeepika raviОценок пока нет

- 5 Symbolic Frame Worksheet 1Документ3 страницы5 Symbolic Frame Worksheet 1api-529132129Оценок пока нет

- 20.29 147192 (CM9383)Документ10 страниц20.29 147192 (CM9383)marcelo sampaioОценок пока нет

- Tests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water LevelДокумент6 страницTests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water Levelahmed121Оценок пока нет

- CH 15Документ42 страницыCH 15mah b0% (1)

- DYNAMIC MODELLING AND CONTROL OF A 3-DOF PLANAR PARALLEL ROBOTIC (XYthetaZ MOTION) PLATFORMДокумент10 страницDYNAMIC MODELLING AND CONTROL OF A 3-DOF PLANAR PARALLEL ROBOTIC (XYthetaZ MOTION) PLATFORMVinoth VenkatesanОценок пока нет

- Iready at Home Activity Packets Student Math Grade 5 2020Документ32 страницыIready at Home Activity Packets Student Math Grade 5 2020Jennifer HongОценок пока нет

- Heater & Air ConditionerДокумент104 страницыHeater & Air ConditionerMusat Catalin-Marian100% (1)

- Fundamental Neuroscience For Basic and Clinical Applications 5Th Edition Duane E Haines Full ChapterДокумент67 страницFundamental Neuroscience For Basic and Clinical Applications 5Th Edition Duane E Haines Full Chaptermaxine.ferrell318100% (8)

- Rec1967 124Документ70 страницRec1967 124anaghaОценок пока нет

- Department of Education: Performance Monitoring and Coaching Form SY 2021-2022Документ3 страницыDepartment of Education: Performance Monitoring and Coaching Form SY 2021-2022Sheena Movilla96% (24)

- Attitude Summary MFДокумент8 страницAttitude Summary MFAraz YagubluОценок пока нет

- Social Construction of DisasterДокумент385 страницSocial Construction of DisasterPratik Kumar BandyopadhyayОценок пока нет

- Be11 enДокумент12 страницBe11 enSaqlain Mir100% (1)

- Sample Ravens SPM Online ReportДокумент5 страницSample Ravens SPM Online ReportAyaw Jud Ko LabdaОценок пока нет