Академический Документы

Профессиональный Документы

Культура Документы

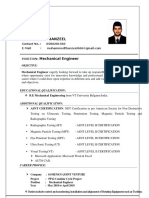

Quality Inspection Engineer

Загружено:

Eswara Rao BodduОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Quality Inspection Engineer

Загружено:

Eswara Rao BodduАвторское право:

Доступные форматы

Quality Inspection Engineer

Implementing the Quality Assurance program and escalate to Client representative

in case of any non-conformity

Carrying out inspections as per the approved QAP, ITP and as directed by Client

representatives.

Carrying out inspections as per the drawings, specifications and other approved

documents

Providing reports to Client about the observations, compliances, non-conformances

Checking & Witnessing field and laboratory tests carried by the vendor / contractors.

Checking and witnessing all QA QC activities related to Asphalt mix production at

HMP + Inspection QA at the Quarry for the Aggregates

Review and provide recommendations/comments on vendor / contractors submittals

related to Quality function

Carrying out audit of contractors QA program as per the MIALs Audit schedule

Carryout inspections at vendors facility if any

Closing of the Snag lists and submission of Closure of Project Documents related to

QA/QC

Good interpersonal skills and working collaboratively with the other teams

Experience with Office applications (Word, Excel, PowerPoint)

Should have in service inspection experience in Pressure equipment like Pressure

Vessels, Piping, Boilers, Furnaces, columns, Heat Exchangers etc

2. Good Engineering judgment to optimize inspection and test intervals

3) Preparation of Reports. 4) Testing the samples as per approved QAP 5) Ensuring

QA/QC as per specifications and standards

• Inspection of Mechanical components.

• The candidate should have experience in following fields.:-Machined components

inspection, Fabrication, Raw material Inspection, NDT Level-2, Welding inspection,

Bought out items Inspection.

• Should be able to Read and interpret Mechanical drawings.

• Knowledge to prepare inspection reports Profile Summary

Day to day supervision and progress monitoring of the implementation work at the

site Ensure implementation adhering to approved design and drawing Ensuring

quality of work at site as per standard practice Ensure adherence to safety standards

at site as per standard practice Registering quantum of daily progress achieved at

site

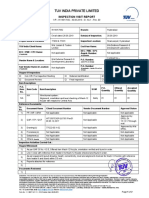

TUV INDIA

Inspection/Quality Surveillance of site construction/ shop fabrication/ testing in crude

oil / gas refinery sector or in the petrochemical/ chemicals industry or Power Sector

of - pressure vessels, Heat Exchangers, Pumps, other equipment, Storage tanks,

line pipes, cross country pipelines, Plant Piping, structures, materials, NDT

Diploma Engineers / Graduate Engineers – Mechanical Engineering.

Level II, NDT qualification (RT, PT, UT and MT) is a must. Membership of

professional bodies such as Indian Institute of Welding (IWE/ IWT), American

Welding Society(AWS), CSWIP, Institute of Chartered Engrs. etc. is preferable.

Вам также может понравиться

- NDT - Phased Array Ultrasonic Testing (PAUT)Документ15 страницNDT - Phased Array Ultrasonic Testing (PAUT)Ashwini SinghОценок пока нет

- Chapter 51Документ611 страницChapter 51phanthanhhungОценок пока нет

- Og&C Standard Work Process Procedure Welding ProgramДокумент15 страницOg&C Standard Work Process Procedure Welding ProgramGordon LongforganОценок пока нет

- CV-Navaneethan-Vendor Inspection CoordinatorДокумент12 страницCV-Navaneethan-Vendor Inspection CoordinatorShanmuga NavaneethanОценок пока нет

- C.V Utekar Assistant Manager ASNT Level IIIДокумент4 страницыC.V Utekar Assistant Manager ASNT Level IIIShrikant UtekarОценок пока нет

- CV (Sr. QA QC Engineer)Документ5 страницCV (Sr. QA QC Engineer)mansih457100% (1)

- Welding Joint SymbolsДокумент32 страницыWelding Joint SymbolsMarcelo CunhaОценок пока нет

- JD QAQC Engineer Mech 2016Документ2 страницыJD QAQC Engineer Mech 2016Sebastian Rajesh100% (1)

- GasДокумент18 страницGassojeck0% (1)

- Dhanasekaran CV QCI Welding PaintingДокумент6 страницDhanasekaran CV QCI Welding PaintingulocksystemОценок пока нет

- Resume: Kasar Mayur TulsidasДокумент4 страницыResume: Kasar Mayur TulsidasFAB HUBОценок пока нет

- Curriculum Vitae Of: Correspondence/Permanent Address: EmailДокумент19 страницCurriculum Vitae Of: Correspondence/Permanent Address: EmailsojeckОценок пока нет

- Mechanical Engineer: Mohd. Layeequr RahmanДокумент7 страницMechanical Engineer: Mohd. Layeequr RahmanmdlayeequeОценок пока нет

- Application For The Post of Suitable Position For Mechanical QA/QC INSPECTORДокумент4 страницыApplication For The Post of Suitable Position For Mechanical QA/QC INSPECTORAhmed Imtiaz RaoОценок пока нет

- Usman CV Piping Inspector 11Документ3 страницыUsman CV Piping Inspector 11Digital InfoОценок пока нет

- Curriculum Vitae: Khermache MokhtarДокумент4 страницыCurriculum Vitae: Khermache MokhtarMokhtar KhermacheОценок пока нет

- QC Manager-Johnson CVДокумент7 страницQC Manager-Johnson CVShanmuga NavaneethanОценок пока нет

- Abs Group of Saudi ArabiaДокумент24 страницыAbs Group of Saudi ArabiaMq SharozОценок пока нет

- Faizur Rahman CVДокумент6 страницFaizur Rahman CVmuneeshwaraperumalОценок пока нет

- ASNT Level III, AWS-CWI, CSWIP, PCNДокумент5 страницASNT Level III, AWS-CWI, CSWIP, PCNShrikant UtekarОценок пока нет

- K e y SK I L L S:: Experience HiglightsДокумент5 страницK e y SK I L L S:: Experience Higlightswins zxcОценок пока нет

- Inspection Engineer Grade 1Документ43 страницыInspection Engineer Grade 1ahmad taiyabiОценок пока нет

- Api, Qa, QC, Welding, Painting, NDT InspectorДокумент7 страницApi, Qa, QC, Welding, Painting, NDT InspectorBalaji ViswanathanОценок пока нет

- Bechtel QAQC AdvisorДокумент5 страницBechtel QAQC Advisoryoonchankim0911100% (1)

- Craig Allan CVДокумент5 страницCraig Allan CVCraigОценок пока нет

- E&i QC Inspector Resum and DocumentsДокумент24 страницыE&i QC Inspector Resum and DocumentsIrfan 786pakОценок пока нет

- Mech Welding QA QC CVДокумент13 страницMech Welding QA QC CVMohammed Abdul ParwezОценок пока нет

- Qatar ResumeДокумент5 страницQatar Resumepursuitforhappyness_Оценок пока нет

- 1godwin A. Udoakan CV.Документ7 страниц1godwin A. Udoakan CV.Godwin A.udo-akanОценок пока нет

- Rakesh Rahulan1Документ6 страницRakesh Rahulan1rakeshОценок пока нет

- Leonard Marshal.X: M/s. Br. Cat International Co LTD, Saudi ArabiaДокумент5 страницLeonard Marshal.X: M/s. Br. Cat International Co LTD, Saudi ArabiaibrahimОценок пока нет

- Contact No: - Contact Address: - C/OДокумент5 страницContact No: - Contact Address: - C/Ovishal bailur100% (1)

- Usman CV QC Work SДокумент3 страницыUsman CV QC Work SDigital InfoОценок пока нет

- JD BoilerДокумент2 страницыJD Boilerمحمد أزها نو الدينОценок пока нет

- Mechanical and Piping Inspector HДокумент3 страницыMechanical and Piping Inspector HHafiz Shabbir HussainОценок пока нет

- Mon Finlqaqce. 3Документ4 страницыMon Finlqaqce. 3ulocksystemОценок пока нет

- Ansar Ahmad Updated CV - Present-WordДокумент6 страницAnsar Ahmad Updated CV - Present-WordansarОценок пока нет

- CV-MICHAEL (QA QC Quality Engineer Const & Procurement)Документ5 страницCV-MICHAEL (QA QC Quality Engineer Const & Procurement)Mike PushОценок пока нет

- NAV Shutdown CVДокумент23 страницыNAV Shutdown CVShanmuga NavaneethanОценок пока нет

- Trimurtulu. Pedasingu: Assurance & Control With An Organisation of High Repute in Oil & Gas IndustryДокумент4 страницыTrimurtulu. Pedasingu: Assurance & Control With An Organisation of High Repute in Oil & Gas IndustrySài TejaОценок пока нет

- QAQC Objective & Key Career AchievementsДокумент3 страницыQAQC Objective & Key Career Achievementssaffririzal4237100% (2)

- #The Career Objective & SummaryДокумент1 страница#The Career Objective & SummaryIzzatul FarhanaОценок пока нет

- Project QAQC Inspector - Quality MSДокумент4 страницыProject QAQC Inspector - Quality MSAdil HasanovОценок пока нет

- Curriculum Vitae: Name: Upendra KumarДокумент6 страницCurriculum Vitae: Name: Upendra KumarNitin KarboОценок пока нет

- Baraneedharan Raju CV UpdatedДокумент7 страницBaraneedharan Raju CV UpdatedBaraneedharanОценок пока нет

- CV Aravind API InspectorДокумент12 страницCV Aravind API Inspectorநான் மகான் அல்லОценок пока нет

- Roles Ansn Responsibilities of QC Engineer/Manager ResponsibilitiesДокумент4 страницыRoles Ansn Responsibilities of QC Engineer/Manager ResponsibilitiesEngr Primus ChinonyeОценок пока нет

- Ajin BabuДокумент4 страницыAjin BabuJithuJohnОценок пока нет

- OpenfileДокумент3 страницыOpenfileSuhas SopeОценок пока нет

- Usman CV QC Work ShopДокумент3 страницыUsman CV QC Work ShopDigital InfoОценок пока нет

- Resume Rajkiran Updated - GenДокумент4 страницыResume Rajkiran Updated - GenRaj KiranОценок пока нет

- Georgy Abraham - Mech EnggДокумент5 страницGeorgy Abraham - Mech EngggeorgyОценок пока нет

- CV - Linkedin 2Документ5 страницCV - Linkedin 2Samir ChaudharyОценок пока нет

- JD / Design Engineer, Gas Analyzer SystemДокумент3 страницыJD / Design Engineer, Gas Analyzer SystemDuong Hoang Tin tin-dhОценок пока нет

- Project Engineer - Afsal - 30 Mar 2016Документ3 страницыProject Engineer - Afsal - 30 Mar 2016Mohamed AfsalОценок пока нет

- Asnt Level Ii - NDT In: Application For The Post Of: QC PIPING INSPECTORДокумент34 страницыAsnt Level Ii - NDT In: Application For The Post Of: QC PIPING INSPECTORJAMHSED KHANОценок пока нет

- Muhammad Salem: Top Level AssignmentsДокумент5 страницMuhammad Salem: Top Level AssignmentsMОценок пока нет

- Resume of Mohd Illias Uddin (SR Welding-Mech QC)Документ7 страницResume of Mohd Illias Uddin (SR Welding-Mech QC)Mohammed IlliasuddinОценок пока нет

- Key ResponsibilitiesДокумент1 страницаKey ResponsibilitiesSiddhu AraganjiОценок пока нет

- Mechanical Engineer - Static & Rotry - ThanzeelДокумент5 страницMechanical Engineer - Static & Rotry - ThanzeelMuhammed ThanzeelОценок пока нет

- CV - Linkedin 4Документ6 страницCV - Linkedin 4Samir ChaudharyОценок пока нет

- Ahmed Sayef Uddin CV - Piping QCДокумент3 страницыAhmed Sayef Uddin CV - Piping QCMuhammed ThanzeelОценок пока нет

- Handramohan Akshmipathy: ENIOR Quality Professional - Nearly 26 Years of ExperienceДокумент5 страницHandramohan Akshmipathy: ENIOR Quality Professional - Nearly 26 Years of ExperienceANIL PLAMOOTTILОценок пока нет

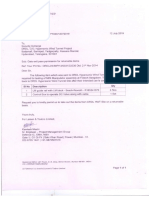

- Permission LetterДокумент1 страницаPermission LetterEswara Rao BodduОценок пока нет

- Asme Introduction & Inspection of Pressure Vessel: (ASME Section VIII Div. 1, Ed. 2015)Документ47 страницAsme Introduction & Inspection of Pressure Vessel: (ASME Section VIII Div. 1, Ed. 2015)TayfunwОценок пока нет

- New - Reinforcement of NozzleДокумент31 страницаNew - Reinforcement of NozzleChagar HarshpalОценок пока нет

- Notification AP Postal Circle GDS Posts PDFДокумент105 страницNotification AP Postal Circle GDS Posts PDFsssОценок пока нет

- (OTPR) On The Website Viz.Документ28 страниц(OTPR) On The Website Viz.Nallanki Raja KumarОценок пока нет

- Cswipwi 692 Sup 01Документ4 страницыCswipwi 692 Sup 01Madley Rock100% (1)

- PT-MT Kurs NotuДокумент300 страницPT-MT Kurs NotuBahadir TekinОценок пока нет

- Electrode BookletДокумент184 страницыElectrode BookletNavanitheeshwaran SivasubramaniyamОценок пока нет

- Bi-699 Skid Piping Leakage Test Report 22 05 18Документ1 страницаBi-699 Skid Piping Leakage Test Report 22 05 18Eswara Rao BodduОценок пока нет

- NDT For Fabrication IndustriesДокумент2 страницыNDT For Fabrication IndustriesvivekdhavanОценок пока нет

- Electrode BookletДокумент184 страницыElectrode BookletNavanitheeshwaran SivasubramaniyamОценок пока нет

- LT Press Release SOU Completion FinalДокумент2 страницыLT Press Release SOU Completion FinalPraveen Kumar JeyaprakashОценок пока нет

- Tuv India Private Limited: Inspection Visit ReportДокумент2 страницыTuv India Private Limited: Inspection Visit ReportEswara Rao BodduОценок пока нет

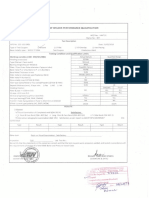

- WPQ SS 1 Inch PipeДокумент1 страницаWPQ SS 1 Inch PipeEswara Rao BodduОценок пока нет

- Welder Testing Procedure 2014 2Документ3 страницыWelder Testing Procedure 2014 2Sandip JawalkarОценок пока нет

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Документ2 страницыBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduОценок пока нет

- Cswipwi 692 Sup 01Документ4 страницыCswipwi 692 Sup 01Madley Rock100% (1)

- English Grammar BookДокумент8 страницEnglish Grammar BookGaurav KumarОценок пока нет

- Cswip Welding Inspection PDFДокумент27 страницCswip Welding Inspection PDFEswara Rao BodduОценок пока нет

- Welder Testing Procedure 2014 2Документ3 страницыWelder Testing Procedure 2014 2Sandip JawalkarОценок пока нет

- NDT & QCДокумент20 страницNDT & QCEswara Rao Boddu100% (1)

- Forged Flanges Pressure RatingsДокумент1 страницаForged Flanges Pressure RatingsEswara Rao BodduОценок пока нет

- ASTM Specifications For Bolt FastenersДокумент4 страницыASTM Specifications For Bolt FastenersEswara Rao BodduОценок пока нет

- List of HospitalsДокумент5 страницList of HospitalsEswara Rao BodduОценок пока нет

- Ps in TeluguДокумент16 страницPs in TeluguEswara Rao BodduОценок пока нет

- (OTPR) On The Website Viz.Документ28 страниц(OTPR) On The Website Viz.Nallanki Raja KumarОценок пока нет

- Radio Graphic ExaminationДокумент33 страницыRadio Graphic ExaminationEswara Rao BodduОценок пока нет

- SL NM - Dia Sch. THK Rem Arks Weld Material The. WT.: Description Seam NoДокумент2 страницыSL NM - Dia Sch. THK Rem Arks Weld Material The. WT.: Description Seam NoEswara Rao BodduОценок пока нет

- QAQC Weekly Report (14072017)Документ15 страницQAQC Weekly Report (14072017)Namta GeorgeОценок пока нет

- Condition Monitoring of Naval ShipДокумент25 страницCondition Monitoring of Naval ShipKen NgОценок пока нет

- API 570 Study Guide 2010 Chevron Angola May 2010 PDFДокумент316 страницAPI 570 Study Guide 2010 Chevron Angola May 2010 PDFkbpatel123100% (1)

- A4-P - 8 0 - enДокумент6 страницA4-P - 8 0 - enmkpqОценок пока нет

- 2016 Catalogue English CompleteДокумент288 страниц2016 Catalogue English CompleteLexa BelicОценок пока нет

- UT Testing-Section 0Документ16 страницUT Testing-Section 0Charlie Chong100% (2)

- 01 Warm GearДокумент21 страница01 Warm GearAndri SaputraОценок пока нет

- Non-Destructive Testing of Concrete and Civil Engineering StructuresДокумент2 страницыNon-Destructive Testing of Concrete and Civil Engineering StructuresMuhammad Rifky RiansyahОценок пока нет

- Procedure For Magnetic Particle Testing: Ramachal NDT ServicesДокумент3 страницыProcedure For Magnetic Particle Testing: Ramachal NDT ServicesAman SarfarazОценок пока нет

- Non Destrucutive TestingДокумент18 страницNon Destrucutive TestingDevangMarvaniaОценок пока нет

- Astm E2375-08Документ24 страницыAstm E2375-08Zamri IcutОценок пока нет

- ATTAR Course Schedule 1Документ9 страницATTAR Course Schedule 1Arash ShamsОценок пока нет

- Met 312 NDTДокумент8 страницMet 312 NDTJanit JijiОценок пока нет

- Shear Wave PDFДокумент6 страницShear Wave PDFcutefrenzyОценок пока нет

- Pakistan Council of Scientific and Industrial Research (PCSIR)Документ29 страницPakistan Council of Scientific and Industrial Research (PCSIR)Zubair KambohОценок пока нет

- Questions & Answers - Ultrasonic Instrument Characterizations Level 2Документ6 страницQuestions & Answers - Ultrasonic Instrument Characterizations Level 2Sathishkumar Srinivasan100% (1)

- Application of Higher-Strength Hull Structural Thick Steel Plates in Container CarriersДокумент65 страницApplication of Higher-Strength Hull Structural Thick Steel Plates in Container CarriersMahdiОценок пока нет

- Bauteilspezifische Angaben Für Rohrleitungen: Ausgabe/Edition 1999-06Документ19 страницBauteilspezifische Angaben Für Rohrleitungen: Ausgabe/Edition 1999-06EdAlm100% (1)

- New Resume Mohd Shukri Yusuf 2019Документ14 страницNew Resume Mohd Shukri Yusuf 2019Yogi Dwi AndiОценок пока нет

- Ultra Conic Thickness Gauge Tt110Документ3 страницыUltra Conic Thickness Gauge Tt110kmats7770Оценок пока нет

- Schedule Training SLV 2023Документ3 страницыSchedule Training SLV 2023Moch ridhwan ariefОценок пока нет

- Hardness Test ProcedureДокумент5 страницHardness Test Proceduremanojballa100% (1)

- API 6D Valves Bonney Forge PDFДокумент12 страницAPI 6D Valves Bonney Forge PDFSQUALO_122Оценок пока нет

- Prds & Piping QapДокумент2 страницыPrds & Piping QapPavul RajОценок пока нет

- E 142Документ3 страницыE 142Durgarao Vasa100% (1)

- TP114HEP Reexaminations FewerLocations HigherConfidenceДокумент14 страницTP114HEP Reexaminations FewerLocations HigherConfidenceKurt CobainОценок пока нет