Академический Документы

Профессиональный Документы

Культура Документы

Electric Chain Saw: Owner'S Manual

Загружено:

KevinОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Electric Chain Saw: Owner'S Manual

Загружено:

KevinАвторское право:

Доступные форматы

®

ELECTRIC CHAIN SAW

OWNER’S MANUAL

MODELS

LNT-2: 076728K, 099178H, 100089-06, 100089-08, & 107709-01

EL-7: 075762J, 098031J, 099039J, 100089-04, 100089-05,

100089-07, & 107714-02

Pole Saw: 104316-04 (8"), 106890-01(10")

Pole Saw Assembly: 104317 (8"), 106821 (10")

IMPORTANT: Read and understand this manual before assembling or

operating this chain saw. Improper use of saw can cause severe

injury. Keep this manual for future reference.

For parts contact: www.PartsFor.com

®

ELECTRIC CHAIN SAW

SAFETY • eye protection such as safety glasses, body contact with grounded objects

goggles, or face screen such as pipes, fences, and metal posts.

WARNINGS • safety hard hat 12. Keep all parts of body away from chain

• ear mufflers or ear plugs when saw is running.

Make certain you read and un- • hair covering to contain long hair 13. Do not force chain saw while cutting.

derstand all Safety Warnings on • face or dust mask (if working in dusty Apply light pressure. It will do the job

pages 2 and 3. Improper use of areas) better and safer at the rate for which it

this chain saw can cause severe 10. Before cutting, always provide the fol- was intended.

injury or death from fire, electri- lowing: 14. Cut small brush and saplings with ex-

cal shock, body contact with • clear work area treme care. Slender material may catch

moving chain, or falling wood. • secure footing in chain and be whipped toward you.

• planned retreat path from falling tree This could also pull you off balance.

BEFORE OPERATING SAW 11. Inspect tree before cutting down. Make 15. When cutting limb or tree trunk that is

1. Read and understand this owner’s sure there are no dead limbs or branches under tension, use extreme caution. Be

manual before operating chain saw. that may fall on you. alert for wood springing back. When

12. To reduce the risk of electric shock, this wood tension is released, limb could

2. Watch what you are doing. Use com-

saw has a polarized plug (one blade is spring back and strike operator caus-

mon sense. Do not operate saw when

wider than the other). This plug will fit ing severe injury or death.

you are tired.

in a polarized outlet only one way. If 16. Carry chain saw from one place to an-

3. Use chain saw for cutting wood only. other

the plug does not fit fully in the outlet

Do not use chain saw for purpose not • with saw stopped and unplugged

of your extension cord, reverse the plug.

intended. Do not use for cutting plas- • by holding front handle (never use

If it still does not fit, a polarized exten-

tic, masonry, etc. hand guard as handle)

sion cord will be necessary. Do not

4. Only well-instructed adults should op- change the plug in any way. • with finger off trigger

erate chain saw. Never allow children • with guide bar and chain to rear

to operate chain saw. WHILE OPERATING SAW

5. Use only electrical voltage noted on 1. Stay alert. Use common sense while WARNING: This product con-

model plate of chain saw. operating chain saw. tains chemicals known to the

6. Use only extension cords marked for 2. Keep work area clean. Cluttered areas State of California to cause can-

outdoor use. See page 8 for extension invite injuries. cer or birth defects, or other re-

cord requirements. 3. Be aware of extension cord while op- productive harm.

7. Do not operate chain saw erating chain saw. Be careful not to trip

• while under the influence of alcohol, over cord. Keep cord away from chain

medication, or drugs and operator at all times. WARNING: Some dust created

• in rain or in damp or wet areas 4. Keep children, animals, and bystand- by power sanding, sawing, grind-

• where highly flammable liquids or ers away from chain saw and extension ing, drilling, and other construc-

gases are present cord. Only chain saw user should be in tion activities contains chemicals

• if saw is damaged, adjusted wrong, work area. known (to the state of California) to

or not fully and securely assembled 5. Do not cut down a tree unless you are cause cancer, birth defects, or

• if trigger does not turn saw on and off. trained or have expert help. other reproductive harm. Some

Chain must stop moving when you 6. If two or more persons perform buck- examples of these chemicals are:

release trigger. Have faulty switch ing and felling operations at the same • lead from lead-based paints

replaced by authorized service center. time, provide plenty of distance between • crystalline silica from bricks

• while in a hurry operations. Provide distance of at least and cement and other masonry

• while in tree or on a ladder unless twice the height of tree being felled. products

trained to do so 7. Secure wood you are cutting by using • arsenic and chromium from

8. Wear snug-fitting clothes when oper- clamps or chocks. chemically-treated lumber

ating chain saw. Do not wear loose 8. Grip chain saw firmly with both hands. Your risk from these exposures

clothing or jewelry. They can get caught Never operate chain saw with one hand. varies, depending on how often

in moving saw chain. Never use hand guard as handle. you do this type of work. To reduce

9. Wear the following safety gear when 9. Keep finger off trigger until ready to your exposure to these chemicals:

operating chain saw. make cut. work in a well ventilated area, and

• heavy-duty gloves (wear rubber 10. Before starting chain saw, make sure work with approved safety equip-

gloves when working outdoors) chain is not touching anything. ment, such as those dust masks

• steel-toed safety footwear with non- 11. To guard against electrical shock, avoid that are specially designed to filter

skid soles out microscopic particles.

For more information, visit www.desatech.com 2 107990

For parts contact: www.PartsFor.com

OWNER’S MANUAL

SAFETY MAINTENANCE AND

STORAGE OF CHAIN SAW

WARNINGS 1. Unplug chain saw from power source

KICKBACK • when not in use

• before moving from one place to an-

WARNING: Kickback may oc- other

cur when the nose or tip of the • before servicing

guide bar touches an object, or • before changing accessories or at-

when the wood closes in and tachments, such as saw chain and

pinches the saw chain in the cut. Direction guard

Tip contact in some cases may Do Not Let 2. Inspect chain saw before and after each

Guide Bar use. Check saw closely if guard or other

cause a lightning fast reverse re-

Touch Here part has been damaged. Check for any

action, kicking the guide bar up

and back towards the operator. damage that may affect operator safety

Pinching the saw chain along the or operation of saw. Check for align-

top of the guide bar may push the 90° ment or binding of moving parts. Check

guide bar rapidly back towards Quadrant for broken or damaged parts. Do not

the operator. Either of these re- use chain saw if damage affects safety

actions may cause you to lose or operation. Have damage repaired by

control of the saw which could authorized service center.

result in serious injury to user. 3. Maintain chain saw with care.

• Never expose saw to rain.

Kickback Safety Devices On Figure 1 - Kickback Hazard Example: Do • Keep chain sharp, clean, and lubri-

Not Let Nose of Guide Bar Touch Object

This Saw While Chain is Moving cated for better and safer performance.

• Follow steps outlined in this manual

This saw has a low-kickback chain and

to sharpen chain.

reduced kickback guide bar. Both items • Never try cutting through two logs at • Keep handles dry, clean, and free of

reduce the chance of kickback. Kickback same time. Only cut one log at a time. oil and grease.

can still occur with this saw. • Do not bury guide bar nose or try plunge • Keep all screws and nuts tight.

Properly install front hand guard. This item cut (boring into wood using guide bar • Inspect power cord often. If dam-

can reduce injuries from kickback. Follow nose). aged, have repaired by authorized

assembly instructions on page 6. Do not • Watch for shifting of wood or other service center.

remove front hand guard. Do not replace forces that may pinch chain. • Never carry chain saw by power cord.

front hand guard with substitute. • Use extreme caution when reentering a • Never yank power cord to unplug it.

The following steps will reduce the risk of previous cut. • Keep power cord from heat, oil, and

kickback. sharp edges.

• Use low-kickback chain and guide bar • Inspect extension cords often and

• Use both hands to grip saw while saw is supplied with this chain saw. Only re- replace if damaged.

running. Use firm grip. Thumbs and place these parts with chains and guide

fingers must wrap around saw handles. bars listed in this manual. 4. When servicing, use only identical re-

placement parts.

• Keep all safety items in place on saw. • Never use dull or loose chain. Keep chain

Make sure they work properly. sharp with proper tension. 5. When not in use, always store chain saw

• in a high or locked place, out of

• Do not overreach or cut above shoulder • Do not hand sharpen chain on automatic children’s reach

height. chain sharpening (Fast Sharp) models. • in a dry place

• Keep solid footing and balance at all Saw Maintenance and Kickback • in a carrying case or with scabbard

times over guide bar

Safety

• Stand slightly to left side of saw. This Keep this manual for reference. It is your

keeps your body from being in direct line Follow maintenance instructions in this

guide to safe and proper operation of this

with chain. manual. Proper cleaning of saw and chain

chain saw.

and guide bar maintenance can reduce

• Do not let guide bar nose touch anything

chances of kickback. Inspect and maintain

when chain is moving (see Figure 1).

saw after each use. This will increase the

service life of your saw. Note: Even with

proper sharpening, risk of kickback can

increase with each sharpening.

107990 3 For more information, visit www.desatech.com

For parts contact: www.PartsFor.com

®

ELECTRIC CHAIN SAW

Low-Kickback Chain Chain that reduces Spiked Bumper (Spike) Pointed teeth at

CHAIN SAW NAMES chance of kickback as required by ANS front of saw body beside guide bar. Keep

AND TERMS B175.1. spiked bumper in contact with wood when

felling or bucking. It helps maintain posi-

Bucking Process of cutting a felled tree or Normal Cutting Position Stance used while

tion of saw while cutting.

log into lengths. making bucking and felling cuts.

Sprocket Toothed wheel that drives chain.

Felling Process of cutting down a tree. Notching Cut Notch cut in tree that directs

fall of tree. Switch Device that completes or interrupts

Felling Cut Final cut when felling a tree. electrical circuit to motor of saw.

Make this cut on opposite side of tree from Oiler Control System for oiling guide bar

notching cut. and chain. Switch Linkage This device connects switch

to trigger. It moves switch when you squeeze

Front Handle Located at front of saw body. Power Head Chain saw without chain and

trigger.

guide bar. Also known as saw body.

Front Hand Guard Shield between front Switch Lockout Device that reduces acci-

handle and guide bar. Protects left hand Pushback (Kickback, Pinch) Rapid

dental starting of saw.

while using saw. pushback of chain saw. Pushback may oc-

cur if chain along top of guide bar is pinched, Trigger Device that turns saw on and off.

Guide Bar Metal bar that extends from saw caught, or contacts a foreign object. Squeezing trigger turns saw on.

body. The guide bar supports and guides chain.

Rear Handle Handle located at rear of saw Releasing trigger turns saw off.

Guide Bar Nose Tip or end of guide bar. body.

Trimming (Pruning) Process of cutting

Kickback Quick backward and upward Reduced Kickback Guide Bar Guide bar limb(s) from a living tree.

motion of guide bar. Kickback may occur that reduces chance of kickback.

when tip of guide bar touches an object Undercut An upward cut from underside of

while chain is moving. The guide bar will Replacement Chain Chain that complies log or limb. This is done while in normal

kick up and back towards operator. with ANS B175.1 when used with a specific cutting position and cutting with top of

saw. It may not meet ANS requirements guide bar.

Limbing Process of cutting limb(s) from a when used with other saws.

felled tree.

Saw Chain (Chain) Loop of chain having

cutting teeth for cutting wood. The motor

drives chain. The guide bar supports chain.

For more information, visit www.desatech.com 4 107990

For parts contact: www.PartsFor.com

OWNER’S MANUAL

PRODUCT UNPACKING

Front Hand

IDENTIFICATION Guard 1. Remove all items from carton.

Guide Bar

Nose 2. Check all items for any shipping dam-

age. If you find any damage or if any

Saw parts are missing, promptly inform

Chain dealer where you bought chain saw.

Rear

Handle

Guide Bar

Sprocket

Cover

Rear Hand

Guard

Power Cord Scabbard

Oil Level Sight Hole

(located on saw body,

hidden by front handle)

Oil Cap With

Squeeze Bulb

Front Handle

Spike

Switch Trigger

Motor Lockout

Housing

Figure 2 - Electric Chain Saw

107990 5 For more information, visit www.desatech.com

For parts contact: www.PartsFor.com

®

ELECTRIC CHAIN SAW

ASSEMBLY 8. Place chain around drive sprocket, then

along top groove of guide bar and CAUTION: Do not place chain

Note: Some models are pre assembled. As- around guide bar nose. Note: Make on saw backwards. If chain is

sembly is not needed on these models. sure cutting edges of chain are facing backwards, saw will vibrate badly

the right direction. Position chain so and will not cut.

See Saw Chain Tension Adjustment, page 7.

cutting edges on top of guide bar face

guide bar nose (see Figure 3). 9. Adjust saw chain tension. Follow steps

WARNING: Cutting edges on under Saw Chain Tension Adjustment,

chain are sharp. Use protective Tapping page 7.

gloves when handling chain. Screw Front Hand

Guard

Cutting

Towards

IMPORTANT: Do not clamp chain Edge

Guide

saw in vise during assembly. Bar Nose

The plastic hardware bag should include:

Cutting Saw

• two guide bar bolts Chain

Edge

• two guide bar nuts Guide Bar

• one Phillips-head tapping screw Bolts

• automatic chain sharpener (Fast Sharp

models only) Mounting Drive

1. Lay chain out flat. Stand-Outs Sprocket

2. Install front hand guard onto saw body.

Do this by pressing two mounting stand-

outs on hand guard into hex-shaped

holes in saw body (see Figure 3).

3 Insert tapping screw through hand

guard and into saw handle. Tighten Guide

screw firmly. Bar

4. Turn adjusting screw counterclockwise

(see Figure 4). Continue to turn adjust- Adjusting

ing screw until adjusting block is to rear Hole

of adjusting plate. Guide Bar

5. Install guide bar onto saw body. Place Nuts

rear of guide bar between adjusting

plate and sprocket support.

IMPORTANT: Make sure to insert ad-

justing block into oval adjusting hole Figure 3 - Assembling Guide Bar, Chain, and Hand Guard

on guide bar.

6. Line up holes on sprocket support with Adjusting Adjusting

center slot on guide bar and holes in Block Plate

saw body.

7. Insert guide bar bolts through front

hand guard, saw body, center slot of

guide bar, and sprocket support. Attach Adjusting

guide bar nuts to guide bar bolts. Screw

IMPORTANT: Tighten guide bar nuts

finger tight only. Make sure adjust-

ing block is in oval adjusting hole on

guide bar.

Sprocket

Support

Figure 4 - Part Locations For Assembling Guide Bar

For more information, visit www.desatech.com 6 107990

For parts contact: www.PartsFor.com

OWNER’S MANUAL

SAW CHAIN 4. After chain tension is correct, tighten FILLING OIL TANK

guide bar nuts firmly. If not, guide bar

TENSION will move and loosen chain tension. 1. Remove oil cap.

This will increase the risk of kickback.

ADJUSTMENT This can also damage saw. Note: A new

2. Fill oil tank with SAE #30 motor oil.

Note: For temperatures below 30°F, use

chain will stretch. Check new chain SAE #10 oil. For temperatures above

WARNING: Unplug chain saw after first few minutes of operation. 75°F, use SAE #40 oil.

from power source before adjust- Allow chain to cool down. Readjust

3. Replace oil cap at once. Tighten oil cap

ing saw chain tension. chain tension.

firmly for good seal. This will avoid oil

seepage from tank.

WARNING: Cutting edges on

4. Wipe off excess oil.

chain are sharp. Use protective

gloves when handling chain. Note: It is normal for oil to seep when saw

is not in use. Empty oil tank after each use to

WARNING: Maintain proper prevent seepage.

chain tension always. A loose

chain will increase the risk of

kickback. A loose chain may jump

out of guide bar groove. This may

injure operator and damage

chain. A loose chain will cause

chain, guide bar, and sprocket to

wear rapidly.

Note: For pre-assembled models, the saw

chain tension is properly set at factory. A

new chain will stretch. Check new chain Figure 5 - Turning Adjusting Screw

after first few minutes of operation. Allow

chain to cool down. Follow steps below to

readjust saw chain tension. Guide Bar Nuts

1. Before adjusting chain, make sure

guide bar nuts are only finger tight (see

Figure 3, page 6). Also make sure adjust-

ing block is in oval adjusting hole on

guide bar (see Figures 3 and 4, page 6). Guide Bar

2. Turn adjusting screw clockwise until

all slack is out of chain (see Figure 5).

Note: There should be no gap between Guide Bar

side links of chain and bottom of guide

bar (see Figure 6). Correct

Gap Tension

3. Wearing protective gloves, move chain

around guide bar. Chain should move

Incorrect

freely. If chain does not move freely, Tension

loosen chain by turning adjusting screw

counterclockwise. Figure 6 - Saw Chain Adjustment

107990 7 For more information, visit www.desatech.com

For parts contact: www.PartsFor.com

®

ELECTRIC CHAIN SAW

OPERATING CHAIN Keep cord away from cutting area. Make CUTTING WITH THE CHAIN

sure cord does not catch on branches or logs SAW

SAW during cutting. Inspect cords often. Replace

1. Connect saw to extension cord. Con-

damaged cords.

nect extension cord to power supply.

WARNING: Read and under- The extension cord may come undone from

stand this owner’s manual be- 2. Make sure section of log to be cut is

the power cord during use. To avoid this,

fore operating this saw. Make not laying on ground. This will keep

make a knot with the two cords as shown in

certain you read and understand chain from touching ground as it cuts

Figure 7 below.

all Safety Warnings, pages 2 and through log. Touching ground with

3. Improper use of this chain saw moving chain will dull chain.

Extension Chain Saw

can cause severe injury or death Cord Power Cord 3. Use both hands to grip saw. Always use

from fire, electrical shock, or body left hand to grip front handle and right

contact with moving chain, or hand to grip rear handle. Use firm grip.

falling wood. Thumbs and fingers must wrap around

saw handles (see Figure 9).

EXTENSION CORDS 4. Make sure your footing is firm. Keep

Use proper extension cords with this saw. feet apart. Divide your weight evenly

Use only extension cords marked for out- on both feet.

door use. The cord must be marked with Figure 7 - Tying Extension Cord and 5. When ready to make a cut, press in

Power Cord in Knot switch lockout with right thumb and

suffix W or W-A following the cord type

designation. Example: SJTW-A or SJTW. OILING CHAIN squeeze trigger (see Figure 9). This will

turn saw on. Releasing trigger will turn

Use proper sized cord with this saw. Cord Always check oil level before using saw. To saw off. Make sure saw is running at

must be heavy enough to carry current oil chain, press squeeze bulb on oil cap. Do full speed before starting a cut.

needed. An undersized cord will cause volt- not attempt to operate the oiler while cutting

age drop at saw. Saw will lose power and 6. When starting a cut, place moving

with the saw. Oil will feed onto guide bar chain against wood. Hold saw firmly

overheat. Follow cord size requirements and chain. Press squeeze bulb on oil cap at

listed below. in place to avoid possible bouncing or

least once before each cut. Check oil level skating (sideways movement) of saw.

often by looking at oil sight level hole. Oil

Cord Length AWG Cord Size sight level hole is on left side of saw, be- 7. Guide saw using light pressure. Do not

tween front handle and front hand guard. force saw. The motor will overload and

25 feet 16 AWG

can burn out. It will do the job better

50 feet 16 AWG and safer at the rate for which it was

100 feet 16 AWG intended.

8. Remove saw from a cut with saw run-

150 feet 14 AWG

ning at full speed. Stop saw by releas-

Models LNT-2: 076728K, 099178H, ing trigger. Make sure chain has

100089-06, & 100089-08; Pole Saw Assy stopped before setting saw down.

104317 &106821; Pole Saw 104316-04 (8")

9. Practice until you can maintain a steady,

& 106890 (10")

even cutting rate.

Cord Length AWG Cord Size Switch

Lockout

25 feet 16 AWG

Figure 8 - Pressing Squeeze Bulb on Oil

50 feet 16 AWG Cap to Oil Chain

100 feet 14 AWG

150 feet 12 AWG

Models EL-7: 075762J, 098013J, 099039J,

100089-04, 100089-05, & 100089-07

Trigger

Figure 9 - Switch Lockout and Trigger

Location

For more information, visit www.desatech.com 8 107990

For parts contact: www.PartsFor.com

OWNER’S MANUAL

Direction

OPERATING CHAIN Retreat

of Fall

Path

SAW Hinge

Continued Direction 3rd Cut -

of Fall Felling Cut 2nd Cut -

FELLING A TREE Upper

2 Notch Cut

(Cutting Down a Tree) Inches

45°

2"

WARNING: 1st Cut -

• Avoid kickback. Kickback can Retreat Tree Lower

result in severe injury or death. Path Notch Cut

See Kickback, page 3 to avoid Figure 10 - Retreat Path From Tree

risk of kickback.

• Do not fell a tree without ample Felling Procedure

skill or expert help. A) Felling Notch

• Keep children, animals, and

bystanders away from area A properly placed felling notch will deter-

mine direction tree will fall. Place felling Figure 11 - Felling A Tree

when felling a tree.

• If two or more persons perform notch on side of tree in direction you want 3. As felling cut nears hinge, tree should

bucking and felling operations tree to fall (see Figure 11). Follow direc- begin to fall. Note: If needed, drive

tions below to create a felling notch. wedges into felling cut to control direc-

1. Make lower notch cut as close to tion of fall. If tree settles back and pinches

WARNING: When felling a ground as possible. Hold saw so guide chain, drive wedges into felling cut to

tree, be aware of your surround- bar is horizontal. Cut 1/3 the diameter remove saw. Only use wedges made of

ings. Do not endanger any per- of tree trunk (see Figure 11). Note: Al- wood, plastic, or aluminum. Never use

son, strike utility lines, or cause ways make this horizontal lower notch wedge made of steel. This could cause

property damage. If tree strikes cut first. If you make this cut second, kickback and damage to chain.

utility lines, contact utility com- tree can pinch chain or guide bar. 4. When tree begins to fall, quickly

pany at once. 2. Start upper notch cut the same distance • remove saw from felling cut

above first cut as first cut is deep. • release trigger to turn saw off

Felling is the process of cutting down a tree. • put saw down

Make sure your footing is firm. Keep feet Example: If lower notch cut is eight

inches deep, start upper notch cut eight • exit area using retreat path

apart. Divide your weight evenly on both

feet. Follow directions below to fell a tree. inches above it. Cut downward at 45°

angle. The upper notch cut should meet WARNING: Be alert for falling

Before Felling a Tree end of lower notch cut (see Figure 11). overhead limbs. Watch your foot-

1. Before felling, inspect tree. Make sure 3. Remove tree trunk wedge created by ing while exiting area.

there are no dead limbs or branches that notching cuts.

may fall on you. Study natural lean of

tree, location of larger branches, and B) Felling Cut

wind direction. This will help you judge 1. Make felling cut two inches higher than

which way tree will fall. lower notch cut and on opposite side

2. Clear work area around tree. of tree (see Figure 11). Keep felling cut

parallel to lower notch cut.

3. Plan and clear a retreat path before fell-

ing. Make retreat path opposite to 2. Cut towards notch.

planned direction of fall of tree and at

45° angle (see Figure 10). WARNING: Do not cut all the

4. Remove dirt, stones, loose bark, nails, way through tree. Leave about

staples, and wire from tree where you two inches of tree diameter un-

will make felling cuts. cut directly behind felling notch

(see Figure 11). This uncut por-

5. Stay on uphill side when felling tree.

tion acts as a hinge. The hinge

Tree could roll or slide downhill af-

helps keep tree from twisting and

ter falling.

falling in wrong direction.

Continued

107990 9 For more information, visit www.desatech.com

For parts contact: www.PartsFor.com

®

ELECTRIC CHAIN SAW

OPERATING CHAIN BUCKING A LOG Entire Length Of Log On

Ground

SAW WARNING: Avoid kickback. Cut log from top (see Figure 13).

Continued Kickback can result in severe in-

jury or death. See Kickback, page

LIMBING A TREE 3 to avoid risk of kickback.

WARNING: Avoid kickback.

WARNING:

Kickback can result in severe in-

• If on slope, make sure log will

jury or death. See Kickback, page

not roll down hill. Secure log

3 to avoid risk of kickback.

by using wooden stakes. Drive

wooden stakes into ground on

WARNING: When cutting limb downhill side of log. Stand on

that is under tension, use extreme uphill side of log while cutting.

caution. Be alert for wood spring- Log may roll after cutting.

ing back. When wood tension is • Never try cutting through two

released, limb could spring back logs at same time. This could

and strike operator causing se- increase the risk of kickback. Figure 13 - Bucking Log With Entire

vere injury or death. • While cutting log, never hold Length On Ground

log with your hand, leg, or foot.

Limbing is removing branches from a fallen • While cutting log, never allow Log Supported On One End

tree. Make sure your footing is firm. Keep another person to hold log. 1. Make first cut on underside of log (see

feet apart. Divide your weight evenly on • Turn off and unplug saw be- Figure 14). Use top of guide bar to

both feet. Do not remove larger limbs under fore moving from one place to make this cut. Cut 1/3 through diam-

tree that support log off ground. Remove another. eter of log. This cut will keep section

each limb with one cut (see Figure 12). from splintering when cut.

Clear cut limbs from work area often. This Bucking a log is cutting a log into sections.

will help maintain a safe work area. Make sure your footing is firm. Keep feet 2. Make second cut directly above first

apart. Divide your weight evenly on both feet. cut. Cut down to meet first cut. This

Make sure you start your cut where limb cut will keep log from pinching guide

When possible, raise log or section off ground.

will not pinch saw during cutting. To avoid bar and chain.

Do this by using limbs, logs, chocks, etc.

pinching, start cut on freely hanging limbs

from above limb. Start cut on limbs under When cutting through log, maintain control

tension from under limb. If pinch occurs, by reducing cutting pressure near end of cut.

turn saw off, lift limb, and remove saw. Do not relax your grip on chain saw handles.

Do not let moving chain touch ground. 2nd Cut

Ground will dull moving chain. After cut-

ting through log, release trigger to turn saw

off before moving saw.

Follow directions below to buck a log.

1st Cut

Figure 14 - Bucking Log When Log Is

Figure 12 - Limbing A Tree Supported On One End

For more information, visit www.desatech.com 10 107990

For parts contact: www.PartsFor.com

OWNER’S MANUAL

TRIMMING A TREE (Pruning) 2nd Cut -

OPERATING CHAIN Pruning Cut

4th Cut -

SAW WARNING: Avoid kickback.

Final Stub

(to avoid pinching)

Continued Cut

Kickback can result in severe in-

jury or death. See Kickback, page

Log Supported On Both Ends

3 to avoid risk of kickback.

1. Make first cut from above log (see Fig- 6"

ure 15). Cut 1/3 through diameter of

WARNING: Do not operate

log. This cut will keep section from

chain saw while

splintering when cut. 2" to 4"

• in a tree

2. Make second cut on underside of log, • on a ladder or any other un- 1st Cut -

directly under first cut. Use top of guide stable surface Pruning Undercut

bar to make this cut. Cut up to meet • in any awkward position (to avoid splintering)

first cut. This will keep log from pinch- You may lose control of saw caus-

ing guide bar and chain. ing severe injury.

WARNING: Do not cut limbs 3rd Cut - Stub Undercut

higher than your shoulders. (to avoid splintering)

1st Cut

Figure 16 - Cutting A Limb

CAUTION: Seek professional

help if facing conditions beyond

your ability.

Trimming a tree is the process of cutting

limbs from a living tree. Make sure your

footing is firm. Keep feet apart. Divide your

weight evenly on both feet. Follow direc-

tions below to trim a tree.

2nd Cut 1. Make first cut six inches from tree trunk

on underside of limb. Use top of guide

Figure 15 - Bucking Log When Log Is

Supported On Both Ends bar to make this cut. Cut 1/3 through

diameter of limb (see Figure 16).

2. Move two to four inches farther out on

limb. Make second cut from above limb.

Continue cut until you cut limb off.

3. Make third cut as close to tree trunk as

possible on underside of limb stub. Use

top of guide bar to make this cut. Cut

1/3 through diameter of stub.

4. Make fourth cut directly above third

cut. Cut down to meet third cut. This

will remove limb stub.

107990 11 For more information, visit www.desatech.com

For parts contact: www.PartsFor.com

®

ELECTRIC CHAIN SAW

CLEANING AND CARE OF GUIDE BAR Normal Guide Bar Maintenance

1. Remove guide bar from chain saw.

MAINTENANCE Uneven bar wear causes most guide bar

problems. Incorrect sharpening of chain 2. Remove sawdust from guide bar

cutter and depth gauge settings often cause groove periodically. Use putty knife or

NOTICE: Below are instructions this. When bar wears unevenly, it widens wire.

for servicing your chain saw. Any guide bar groove (see Figure 17). This causes 3. Clean oil slots after each day of use.

servicing not mentioned below chain clatter and rivet popping. Saw will not 4. Remove burrs from sides of guide bar.

should be done by an authorized cut straight. Replace guide bar if this occurs. Use flat file to make side edges square.

service center.

Inspect guide bar before sharpening chain. Replace guide bar when

A worn or damaged guide bar is unsafe. A

CLEANING SAW BODY worn or damaged guide bar will damage • bar is bent or cracked

chain. It will also make cutting harder. • inside groove of bar is badly worn

WARNING: Unplug chain saw Note: When replacing guide bar, see Re-

from power source before servic- placement Parts and Accessories, page 19,

ing. Severe injury or death could Guide Bar for proper bar.

occur from electrical shock or Groove

body contact with moving chain. Burr

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

Guide Bar

WARNING: When cleaning

saw body,

• do not submerge saw in any Flat File

liquids

• do not use products that con-

tain ammonia, chlorine, or

abrasives Guide Bar

• do not use chlorinated clean- Normal Guide Guide Bar

ing solvents, carbon tetrachlo- Bar With Uneven Cleaning Groove With

ride, kerosene, or gasoline Wear Putty Knife

Figure 17 - Guide Bar Cross Section Show-

Keep saw body clean. Use a soft cloth damp- ing Uneven Bar Wear

ened with a mild soap and water mixture.

Wipe saw body to clean.

Oil Slot

Figure 18 - Guide Bar Maintenance

For more information, visit www.desatech.com 12 107990

For parts contact: www.PartsFor.com

OWNER’S MANUAL

CLEANING AND Sharpening Cutters 4. Hold file guide level. Make sure 30°

mark on file guide is parallel to center

MAINTENANCE Use file guide for 30° filing. of guide bar (see Figure 19). This will

Continued 1. Adjust chain for proper tension (see Saw insure that you file cutters at 30° angle.

Chain Tension Adjustment, page 7). 5. File from inside towards outside of cut-

SHARPENING SAW CHAIN 2. Clamp guide bar in vise to hold saw ter until sharp. Only file in this one direc-

steady. Note: Do not clamp chain. tion (see Figure 19). Note: Two or three

WARNING: Unplug chain saw 3. Press 5/32" round file (attached to file strokes with file should sharpen cutter.

from power source before servic- guide) into groove between top plate 6. After each cutter is sharpened, move

ing. Severe injury or death could and depth gauge on chain. File guide chain forward to sharpen next cutter.

occur from electrical shock or should rest on both top plate and depth File all cutters on one side of chain.

body contact with moving chain. gauge (see Figures 19 and 20). Note: 7. Move to other side of chain and repeat

File at midpoint of guide bar. process.

WARNING: Cutting edges on Filing

chain are sharp. Use protective Direction

gloves when handling chain.

30° Guide

Mark File

Keep chain sharp. Your saw will cut faster

Guide

and more safely. A dull chain will cause

FILE

undue sprocket, guide bar, chain, and motor

wear. If you must force chain into wood and

cutting creates only sawdust with few large 5/32"

chips, chain is dull. Round File

HOLDER

Items Needed to Sharpen Chain

Purchase these items from your local dealer,

hardware store, or chain saw supplies outlet. Note: This illustration

shows file guide

• 5/32" round file placement and filing

• Depth gauge tool direction for sharpen-

• File guide ing cutters on left side

of chain.

• Vise

• Medium sized flat file

Figure 19 - File and File Guide Placement On Chain

Groove

Depth Gauge

(left side of chain) Depth Gauge

Left Side of

(right side

Chain

of chain)

Groove

Top Plate Top Plate

(left side of chain) (right side of chain)

Right Side of

Chain

Figure 20 - Chain Part Locations

Continued

107990 13 For more information, visit www.desatech.com

For parts contact: www.PartsFor.com

®

ELECTRIC CHAIN SAW

CLEANING AND Front Corner

TECHNICAL

MAINTENANCE .025"

SERVICE

Continued

Filing Cutter Depth Gauges

Figure 22 - Round Off Front Corner Of

The cutter depth gauge clearance is reduced Depth Gauge

as cutters are sharpened. After every second

or third sharpening, reset cutter depth gauges.

1. Place depth gauge tool (.025") firmly

REPLACING SAW CHAIN

across top of two cutters. Make sure Replace chain when cutters are too worn to SERVICE

depth gauge enters slot in depth gauge sharpen or when chain breaks. Only use

tool (see Figure 21). replacement chain noted in this manual. PUBLICATIONS

2. Use medium flat file. File depth gauge Always include new drive sprocket when You can receive an illustrated parts list free

level with depth gauge tool. replacing chain. This will maintain proper

of charge. Send a self-addressed stamped

driving of chain. Note: For proper chain and

3. Remove depth gauge tool. With flat file, envelope to address on back page of this

drive sprocket, seeReplacement Parts and

round off front corner of cutter depth manual.

Accessories, page 19.

gauge (see Figure 22). When writing, include model number and

After several hand filings, have authorized serial number of saw. You will find these

service center or sharpening service machine STORAGE numbers on saw motor housing decal.

sharpen chain. This will insure even filing. If storing saw for more than 30 days, follow

Flat File steps below.

1. Drain oil tank.

Depth Gauge 2. Remove and clean guide bar and chain.

Clean guide bar and chain by soaking

in petroleum based solvent or mild soap

and water mixture.

3. Dry guide bar and chain.

Depth

Gauge

4. Place chain in container filled with oil.

Tool This will prevent rust.

5. Wipe a thin coating of oil over surface

of guide bar.

6. Wipe off outside of saw body. Do this

Depth

Gauge with soft cloth dampened with a mild

Slot soap and water mixture.

7. Store chain saw

• in a high or locked place, out of

children’s reach

Figure 21 - Depth Gauge Tool On Chain • in a dry place

• in a carrying case or with scabbard

over guide bar

For more information, visit www.desatech.com 14 107990

For parts contact: www.PartsFor.com

OWNER’S MANUAL

TROUBLESHOOTING WARNING: Unplug chain saw from power source before servicing.

Note: For additional help, visit our Severe injury or death could occur from electrical shock or body contact

technical service web site at with moving chain.

www.desatech.com.

OBSERVED FAULT POSSIBLE CAUSE REMEDY

Saw runs, but does not cut Chain assembled backwards on guide bar See Assembly, page 6

Saw does not cut unless heavily forced. Chain is dull See Sharpening Saw Chain, page 13

Cutting produces only sawdust with few

large chips

Saw runs slow. Saw stalls easily Low power supply voltage Extension cord wire size too small. See

Extension Cords, page 8

Motor of saw does not run when you squeeze 1. Switch lockout not pressed in to release 1. Press in switch lockout before squeez-

trigger trigger ing trigger

2. Extension cord connections loose 2. Check cord connections

3. Open line fuse or circuit breaker 3. Check line fuse or circuit breaker

4. Bad motor brushes 4. See authorized service center

5. Open wiring circuit on saw 5. See authorized service center

Motor of saw runs, but chain does not move Gear train failure See authorized service center

Chain does not get oil 1. Clogged oil slot in guide bar 1. Remove guide bar and clean oil slot

2. Oil is too thick 2. Use correct weight of oil. See Filling Oil

Tank, page 7

Chain comes off guide bar 1. Chain is loose 1. Tighten chain. See Saw Chain Tension

Adjustment, page 7

2. Guide bar and chain not assembled right 2. See Assembly, page 6

Saw smokes Saw damaged. Do not use saw See authorized service center

Saw leaks oil Oil cap is not secure Tighten oil cap. Note: Empty oil tank when

not in use

107990 15 For more information, visit www.desatech.com

For parts contact: www.PartsFor.com

OWNER’S MANUAL

REPLACEMENT WARNING: Use only replacement parts and accessories described in

PAR TS AND this manual. Use of other parts or accessories could damage saw or

injure operator.

ACCESSORIES

Purchase these accessories and parts from You can also visit our technical service web

your nearest dealer or service center. If they site at www.desatech.com .

can not supply these accessories or parts,

either contact your nearest Parts Dealer or

DESA Specialty Products™ for referral infor-

mation. Parts dealers are listed in this manual.

LNT-2 EL-7, 098031J, 099039J, 100089-04, POLE SAW, 106890-01 (10")

Part Number Description 100089-05 POLE SAW ASSEMBLY, 106821

104302-01S# Guide bar, 8" Part Number Description Part Number Description

104301S# Chain, 8" 097572-03S Guide bar, 16" 097567-01S Guidebar, 10"

097567-01S Guide bar, 10" 091375-02S Chain, 16" 091371S Chain, 10"

091371S Chain, 10" 107713-01 Drive sprocket 107713-01 Drive Sprocket

097568-02S Guide bar, 12"

091373-02S Chain, 12" POLE SAW, 104316-04 (8") General

107713-01 Drive sprocket POLE SAW ASSEMBLY, 104317 Part Number Description

Part Number Description 079963-02 Plastic scabbard, 8" & 10"

099178H, 100089-06, 100089-07, 104302-01S Guidebar, 8" 079963-04 Plastic scabbard,

100089-08, & EL-1 104301S Chain, 8" 12", 14", & 16"

Part Number Description 107713-01 Drive Sprocket 106809-01 Hand Guard

097570-01S Guide bar, 14" 077155 Adjusting Plate Assy.

091374-02S Chain, 14"

107713-01 Drive sprocket

#

Must order both pieces.

107990 23 For more information, visit www.desatech.com

For parts contact: www.PartsFor.com

Click on the picture above for part numbers or to purchase parts

Key # Model Number Description

1 107709-01 Trigger Switch

2 107709-01 Oil Bottle and Cap

3 107709-01 Cap and Bulb

4 107709-01 Screw Tap Flat-HD PR #25

5 107709-01 Chain Adjuster Assy

6 107709-01 Saw Chain

7 107709-01 Guide Bar

8 107709-01 Sprocket Gear Kit

9 107709-01 Drive gear ( ½” H )

10 107709-01 Roller Bearing

11 107709-01 Sprocket ( 3.5” )

12 107709-01 Sprocket Support

13 107709-01 Retainer, E-Ring

14 107709-01 Kit, Sprocket Cover

For parts contact: www.PartsFor.com 616-791-0505

Вам также может понравиться

- Remington Electric ChainsawДокумент40 страницRemington Electric ChainsawNMB5150Оценок пока нет

- Poulan 2900 Type 2 Owner's ManualДокумент17 страницPoulan 2900 Type 2 Owner's ManualKipper KreminОценок пока нет

- Poulan PRO /: Manual de Instrucciones Manuel D'lnstructionsДокумент59 страницPoulan PRO /: Manual de Instrucciones Manuel D'lnstructionsMike BraceОценок пока нет

- PDF CropДокумент57 страницPDF CropRichard RoperОценок пока нет

- Remington Chainsaw Model 100015 - ManualДокумент16 страницRemington Chainsaw Model 100015 - ManualOnceUponAThingОценок пока нет

- Mj404e 360manual - Eng04072017 M PDFДокумент20 страницMj404e 360manual - Eng04072017 M PDFjОценок пока нет

- Ii:Rrftsmfin I: Double InsulatedДокумент16 страницIi:Rrftsmfin I: Double InsulatedJL AlexanderОценок пока нет

- Operator'S Manual: Electric Lawn MowerДокумент22 страницыOperator'S Manual: Electric Lawn Mowersoutherly001Оценок пока нет

- SierraДокумент24 страницыSierraAngelica PerezОценок пока нет

- Motorsåggk1630 UkДокумент20 страницMotorsåggk1630 UkJack NinwayОценок пока нет

- Milwaukee 6390 InfoДокумент19 страницMilwaukee 6390 InfoREVECAОценок пока нет

- Operators ManualДокумент24 страницыOperators ManualaОценок пока нет

- 5008mga ImДокумент32 страницы5008mga ImInstructores InsternosОценок пока нет

- Manual de Esmerilador de Disco (Ingles) PDFДокумент32 страницыManual de Esmerilador de Disco (Ingles) PDFfrancescoОценок пока нет

- Craftsman 3.7 Cu - in 24 Inch Guide Bar Chain SawДокумент30 страницCraftsman 3.7 Cu - in 24 Inch Guide Bar Chain Sawsnowman1579100% (1)

- Amoladora Makita 9557PBДокумент28 страницAmoladora Makita 9557PBjoyli22Оценок пока нет

- Circular Saw: 185 MM (7-1/4") MODEL 5007NLДокумент16 страницCircular Saw: 185 MM (7-1/4") MODEL 5007NLdan-gabiОценок пока нет

- 328494-01, DW678 DW677 ManualДокумент27 страниц328494-01, DW678 DW677 ManualBladi GpОценок пока нет

- Makita 3 25 Power PlanerДокумент32 страницыMakita 3 25 Power PlanerP BurinskasОценок пока нет

- 58-14-6477d7 Circular Saw Manual Usuario MilwaukeeДокумент40 страниц58-14-6477d7 Circular Saw Manual Usuario MilwaukeeRicardo MedranoОценок пока нет

- Circular Saw Manual MakitaДокумент16 страницCircular Saw Manual MakitaFei RuiОценок пока нет

- Manejo de Camara NikonДокумент36 страницManejo de Camara NikonalianzaperuОценок пока нет

- Husquvarna Brush TrimmerДокумент16 страницHusquvarna Brush TrimmerJon LewisОценок пока нет

- makita4200NH Saw PDFДокумент20 страницmakita4200NH Saw PDFtkmrmrОценок пока нет

- Llave de Impacto cbb001 - TW1000 - IM PDFДокумент20 страницLlave de Impacto cbb001 - TW1000 - IM PDFpercy f.fОценок пока нет

- Power ToolsДокумент9 страницPower ToolsNatalia Lopez RobredoОценок пока нет

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorДокумент36 страницOperator'S Manual Manuel de L'Utilisateur Manual Del OperadorDaniel RuizОценок пока нет

- MT190 ManualДокумент12 страницMT190 ManualDamien ButlerОценок пока нет

- Mower ManualДокумент48 страницMower ManualrodjohnseyОценок пока нет

- 34' Hex Demolition Hammer 5337-20Документ28 страниц34' Hex Demolition Hammer 5337-201092 hanna (primary soul)Оценок пока нет

- L0902184 ManualДокумент19 страницL0902184 ManualBianca WilliamsОценок пока нет

- Llave de Impacto 6906Документ12 страницLlave de Impacto 6906percy f.fОценок пока нет

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorДокумент11 страницOperator'S Manual Manuel de L'Utilisateur Manual Del Operadorapek1Оценок пока нет

- Sierra CirculaДокумент32 страницыSierra CirculaMaritza HernandezОценок пока нет

- Makita 9557nb Manual de UsuarioДокумент32 страницыMakita 9557nb Manual de UsuarioZacek TorresОценок пока нет

- CRAFTSMAN 358.794960 Instruction ManualДокумент28 страницCRAFTSMAN 358.794960 Instruction ManualJosé Luis MorenoОценок пока нет

- Sierra Electrica Total 1400WДокумент10 страницSierra Electrica Total 1400Wmaria fernanda oliverosОценок пока нет

- Manual M8700Документ24 страницыManual M8700Carlos BosquesОценок пока нет

- Minitrim ST Minitrim Auto ST Minitrim Auto XT: Original InstructionsДокумент8 страницMinitrim ST Minitrim Auto ST Minitrim Auto XT: Original InstructionsRichardt LootsОценок пока нет

- CD121KДокумент7 страницCD121KmkapkrОценок пока нет

- Angle Grinder Meuleuse D'angle Esmeriladora Angular: Instruction Manual Manuel D'Instruction Manual de InstruccionesДокумент28 страницAngle Grinder Meuleuse D'angle Esmeriladora Angular: Instruction Manual Manuel D'Instruction Manual de InstruccionescapureiОценок пока нет

- General Circular Saw SafetyДокумент5 страницGeneral Circular Saw SafetyTyler BassОценок пока нет

- 4719 Robot Mower Manual Aw3Документ32 страницы4719 Robot Mower Manual Aw3silviuОценок пока нет

- Serra Circular Makita 5007 ManualДокумент32 страницыSerra Circular Makita 5007 ManualEduardo PennaОценок пока нет

- Manual M9510GДокумент28 страницManual M9510GArmando RiveraОценок пока нет

- UVA Prep 3Документ12 страницUVA Prep 3Serkan AkşanlıОценок пока нет

- Portable Cut-Off: MODEL 2414NBДокумент16 страницPortable Cut-Off: MODEL 2414NBwisnuОценок пока нет

- Ii:Rrftsmrn'I: Operator'S ManualДокумент26 страницIi:Rrftsmrn'I: Operator'S Manualzoryan1Оценок пока нет

- Manual 5007NДокумент32 страницыManual 5007NKevin WalshОценок пока нет

- Portable Cut-Off Tronçonneuse Portative Tranzadora de MetalДокумент28 страницPortable Cut-Off Tronçonneuse Portative Tranzadora de MetalPakito XtradaОценок пока нет

- MANUAL Rotomartillo HR2470Документ28 страницMANUAL Rotomartillo HR2470Melissa P. DiazОценок пока нет

- Electric Snow Thrower: Important!Документ16 страницElectric Snow Thrower: Important!Vake AuuОценок пока нет

- Toro 51587 Super Blower Vac Manual, 1998-1999Документ16 страницToro 51587 Super Blower Vac Manual, 1998-1999fogdartОценок пока нет

- Craftsman-917.773762 - Wheel WeedtrimmerДокумент44 страницыCraftsman-917.773762 - Wheel WeedtrimmerJesus RodriguezОценок пока нет

- M18CCS66 Product ManualДокумент12 страницM18CCS66 Product Manualcbturtle10Оценок пока нет

- Makita 3709 Manual de UsuarioДокумент28 страницMakita 3709 Manual de UsuarioHernando PuglieseОценок пока нет

- 6 - Esmeril Makita 7 Ga7040s Ga9040sДокумент32 страницы6 - Esmeril Makita 7 Ga7040s Ga9040sJose Raschio CarpioОценок пока нет

- Owner's Manual: Variable Speed / Reversible Double InsulatedДокумент12 страницOwner's Manual: Variable Speed / Reversible Double InsulatedLuciano RenteriaОценок пока нет

- Hypoid Saw Scie Hypoïde Sierra Circular: Instruction Manual Manuel D'Instruction Manual de InstruccionesДокумент32 страницыHypoid Saw Scie Hypoïde Sierra Circular: Instruction Manual Manuel D'Instruction Manual de InstruccionesEdward CambroneroОценок пока нет

- Noise Suppression Guide: 000NOISEIGДокумент5 страницNoise Suppression Guide: 000NOISEIGKevinОценок пока нет

- TechData T4512-04Документ4 страницыTechData T4512-04Anonymous D1zTrHОценок пока нет

- Electric Chain Saw: Owner'S ManualДокумент17 страницElectric Chain Saw: Owner'S ManualKevinОценок пока нет

- Red Max G2500TS PDFДокумент36 страницRed Max G2500TS PDFKevinОценок пока нет

- Preparations Canceling The Display Demonstrations: CD Receiver: Instructions/InstallationДокумент4 страницыPreparations Canceling The Display Demonstrations: CD Receiver: Instructions/InstallationKevinОценок пока нет

- Kac - 629SДокумент2 страницыKac - 629SRoberto Andrés Cares LiraОценок пока нет

- Ford Intake ManifoldДокумент2 страницыFord Intake ManifoldKevinОценок пока нет

- JBL GTQ 240 AmplifierДокумент12 страницJBL GTQ 240 AmplifierKevinОценок пока нет

- Deh p2000 Installation ManualДокумент2 страницыDeh p2000 Installation ManualKevin100% (1)

- Ford Intake ManifoldДокумент2 страницыFord Intake ManifoldKevinОценок пока нет

- Drawing A Crankcase, Cylinder: BG 45, BG 46, BG 55, BG 65, BG 85 1 SCS 01-2011 3.33Документ78 страницDrawing A Crankcase, Cylinder: BG 45, BG 46, BG 55, BG 65, BG 85 1 SCS 01-2011 3.33KevinОценок пока нет

- Electric Chain Saw: Owner'S ManualДокумент24 страницыElectric Chain Saw: Owner'S ManualKevin100% (1)

- Instruction Manual Manual de Instrucciones Manuel D'instructionsДокумент22 страницыInstruction Manual Manual de Instrucciones Manuel D'instructionsKevinОценок пока нет

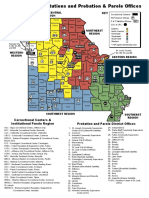

- State Prisons MapДокумент1 страницаState Prisons MapKevinОценок пока нет

- Toril Moi - I Am Not A Feminist, But SummaryДокумент2 страницыToril Moi - I Am Not A Feminist, But SummaryAucklandUniWIPОценок пока нет

- Lite Central VisayasДокумент4 страницыLite Central VisayasBianca Gaitan100% (4)

- Vocabulary O Level - TEST 46-60Документ15 страницVocabulary O Level - TEST 46-60Giok ZaimaОценок пока нет

- Section A-A Detail of Rubble Paving at Wing Wall: 60Mm Thk. Wearing CourseДокумент1 страницаSection A-A Detail of Rubble Paving at Wing Wall: 60Mm Thk. Wearing CoursesathiyanОценок пока нет

- Contoh Format Final Paper (Technique)Документ7 страницContoh Format Final Paper (Technique)Nini Nurani RakhmatullahОценок пока нет

- MODULE 1 Art - HumanitiesДокумент96 страницMODULE 1 Art - HumanitiesRejaelSenoro67% (9)

- Ted Harrison Art Work DecДокумент4 страницыTed Harrison Art Work Decapi-384125792Оценок пока нет

- DUNGEONS ExtendidoДокумент112 страницDUNGEONS ExtendidoEdgardo De La CruzОценок пока нет

- Criminal Law 1 Assign 7 1-20 LIST2Документ2 страницыCriminal Law 1 Assign 7 1-20 LIST2monchievaleraОценок пока нет

- Non Vital BleachingДокумент19 страницNon Vital BleachingPriyabrat Pattanaik100% (1)

- General Turning Insert Nomenclature For CNC DummiesДокумент4 страницыGeneral Turning Insert Nomenclature For CNC DummiesSumitОценок пока нет

- Perfume Attars and Their HistoryДокумент6 страницPerfume Attars and Their Historykiez3b79ju100% (1)

- Script For Literary NightДокумент4 страницыScript For Literary NightJoezer Gumangan VeranoОценок пока нет

- 17 Paket Grammar PDFДокумент72 страницы17 Paket Grammar PDFSyekhmundu jambukarangОценок пока нет

- Editable Test Unit 2 Challenge LevelДокумент4 страницыEditable Test Unit 2 Challenge LevelAlba Lucía Corrales ReinaОценок пока нет

- YsyasyaДокумент26 страницYsyasyaPravalika KanthetiОценок пока нет

- RawPedia BookДокумент187 страницRawPedia BookMike Ignatius Nelson100% (1)

- Chức năng giao tiếp-okДокумент8 страницChức năng giao tiếp-okHaMeiОценок пока нет

- Graphic Design Basic PrinciplesДокумент273 страницыGraphic Design Basic PrinciplesPedro Bento d'Almeida100% (23)

- Exclamation Points and PeriodsДокумент2 страницыExclamation Points and PeriodsXie AlbertОценок пока нет

- Bruce Lee - Jeet Kune Do - OverviewДокумент2 страницыBruce Lee - Jeet Kune Do - OverviewstОценок пока нет

- Companion Quartet Book 1 - The Secret of The SirensДокумент168 страницCompanion Quartet Book 1 - The Secret of The Sirensadelene60% (5)

- Spiritual Authority and Spiritual Power by RevДокумент12 страницSpiritual Authority and Spiritual Power by RevAndy EbhotaОценок пока нет

- P Et B FinalДокумент207 страницP Et B FinalzallpallОценок пока нет

- Footing Tie Beam Details: Left MID RightДокумент1 страницаFooting Tie Beam Details: Left MID RightLong Live TauОценок пока нет

- English Majorship 1Документ40 страницEnglish Majorship 1Arjie DiamosОценок пока нет

- Ma EnglishДокумент19 страницMa EnglishKAMALSUTHAR6061AОценок пока нет

- Unit 4 TestДокумент4 страницыUnit 4 TestJuanJesusOcañaAponteОценок пока нет

- Red Queen by Victoria Aveyard ExtractДокумент53 страницыRed Queen by Victoria Aveyard ExtractOrion Publishing Group85% (20)

- Gerunds and InfinitivesДокумент2 страницыGerunds and InfinitivesMartabm29100% (1)