Академический Документы

Профессиональный Документы

Культура Документы

CM2 GTX000 2002 03

Загружено:

Akmal ZuhriОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CM2 GTX000 2002 03

Загружено:

Akmal ZuhriАвторское право:

Доступные форматы

CM2-GTX000-2002

AT9000 Advanced Transmitter

Supplement Manual for

HART®Communication Option

NOTICE

While the information in this manual is presented in good faith and

believed to be accurate, Azbil Corporation disclaims any implied

warranty of merchantability or fitness for a particular purpose and

makes no express warranty except as may be stated in its written

agreement with and for its customer.

In no event shall Azbil Corporation be liable to anyone for any indirect,

special or consequential damages. This information and specifications

in this document are subject to change without notice.

© 2008-2012 Azbil Corporation All Rights Reserved.

About This Publication

This manual is intended as a detailed “how to” reference for

operating Azbil Corporation's AT9000 Advanced Transmitters

with HART® communication option. It is based on using the

HART® Communicator as the operator interface for the transmit-

ter.

Note that this manual does not include a detailed reference for

installing, piping the transmitter or detail operations of the

HART® Communicator. Refer the user's manuals of AT9000

Advanced Transmitters (CM2-GTX100-2001) and the HART®

Communicator.

Table of Contents

Chapter 1 : Starting Communications

1.1 : Connecting communicator .............................................................................. 1-1

1.2 : HART® communicator keyboard .................................................................... 1-3

1.3 : Symbols on communicator screen ................................................................. 1-4

1.4 : Key Operation ................................................................................................. 1-4

1.5 : Establishing communications.......................................................................... 1-6

1.6 : Checking basic data........................................................................................ 1-7

Chapter 2 : Configuration

2.1 : Top menu ........................................................................................................ 2-1

2.2 : Process Variables menu summary ................................................................. 2-2

2.3 : Device menu summary ................................................................................... 2-3

2.4 : Diagnostic menu summary ............................................................................. 2-7

Chapter 3 : Start-up and Operation

3.1 : Process Variables ........................................................................................... 3-3

3.1.1: Process Variables > Process Variables .............................................. 3-3

3.1.2: Process Variables > Pressure............................................................. 3-4

3.1.3: Process Variables > Output ................................................................ 3-4

3.1.4: Process Variables > Temperature ...................................................... 3-5

3.1.5: Process Variables > All Variables ....................................................... 3-5

3.2 : Device ............................................................................................................. 3-6

3.2.1: Device > Basic Setup.......................................................................... 3-7

3.2.2: Device > Sensors................................................................................ 3-9

3.2.3: Device > Sensors................................................................................ 3-10

3.2.4: Device > Output Condition .................................................................. 3-15

3.2.5: Device > Alarm.................................................................................... 3-19

3.2.6: Device > Display ................................................................................. 3-25

3.2.7: Device > Device information ............................................................... 3-28

3.2.8: Device > Calibration............................................................................ 3-30

3.2.9: Device > Review ................................................................................. 3-43

3.3 : Diagnostic ....................................................................................................... 3-44

3.3.1: Diagnostic > Diagnostic Status ........................................................... 3-44

3.3.2: Diagnostic > Status Records............................................................... 3-47

Supplement Manual for HART Communication Option

Chapter 1 : Starting Communications

Instructions for connecting HART® Communicator to this transmitter.

Basic instructions for Key-pad operation.

1.1 : Connecting communicator

You connect the communicator directly to signal terminals on the transmitter's termi-

nal block or at any location in the 4 to 20 mA loop. (Polarity of the communicator con-

nection does not matter)

Power supply

+

Receiving

instrument

+

250 Ω *

HART Communicator AT9000

Figure 1-1 Wiring for connection with AT9000

Supplement Manual for HART Communication Option 1-1

Starting Communications Azbil Corporation

1482

1345

Load resistance (W)

Operative limit

Supply voltage - 12.5

=

Load resistance (Ω)

0.0219

Operating Range

245

0 12.5 17.9 42 45

Supply voltage (V DC)

Figure 1-2 Supply voltage vs. load resistance

Do not hook up the HART® Communicator to the bilingual AT9000 in “DE Enable”

while the control loop is in the automatic mode.

When the HART® communicator is hooked up to the bilingual AT9000 in “DE

Enable”, the transmitter output might trip due to the rush current generated by the big

capacitance in the HART® communicator.

1-2 Supplement Manual for HART Communication Option

Azbil Corporation Starting Communications

1.2 : HART® communicator keyboard

Figure 1-3 HART® 375 Communicator

Supplement Manual for HART Communication Option 1-3

Starting Communications Azbil Corporation

1.3 : Symbols on communicator screen

Flashing heart icon in the upper right corner indicates that the transmit-

ter and communicator are communicating.

This left arrow symbol indicates that the left arrow on the keypad

brings you back to previous menu.

Kor L These arrows indicate there is more column to scroll though, using the

indicated arrow on the keypad.

This terminate icon in the upper right corner of the touch screen is used

to end the application.

1.4 : Key Operation

Arrow keys

Pressing the arrow keys selects the menu items in the menu structure.

Pressing the right arrow (?) key returns to the previous menu.

Tab key

Pressing the Tab key selects the next menu item from those available.

Enter key

Pressing the Enter key executes the item selected (highlighted) by

pressing the Tab key.

Alphanumeric keys

These keys are used to key in characters such as letters, numbers, and

punctuation. Numeric mode or alphanumeric mode can be selected for

data entry and option selection. For certain applications, the mode will

be automatically selected.

In alphanumeric mode, pressing an alphanumeric key several times

quickly displays the corresponding letter or number. To key in “Z,” for

example, quickly press the “9” key 4 times in a row.

Function key

The select functions for key entry can be used by pressing the Function

key. The select functions are indicated in gray at the upper portion of

each key.

When the Function key is enabled, the Multifunction LED flashes

orange and then an indicator appears on the “Soft Input Panel (SIP).”

Pressing the key again disables this function.

1-4 Supplement Manual for HART Communication Option

Azbil Corporation Starting Communications

The ON/OFF key has been pressed long enough to turn on the power.

Multifunction LED Status

The green LED is on. The power is ON.

The green LED is flashing. Power saving mode is ON, display is OFF.

The green and orange The Function key is enabled.

LEDs are on

The green and orange The ON/OFF key has been pressed long enough to

LEDs are flashing. turn on the power.

Supplement Manual for HART Communication Option 1-5

Starting Communications Azbil Corporation

1.5 : Establishing communications

This procedure starts communications between the transmitter and the communicator:

STEP Action and/or Description

1 Turn on communicator. The communicator runs a self-test check then

determines if it is connected to a transmitter.

After a while, the “375 Main Menu” screen will appear. Select “HART

Application” and then press the right arrow (J) key.

2 When communication is correctly established, the communicator will

automatically proceed to step 3.

If a message “(No. Device Found)” appears on the communicator, select

“2 Online” and then press the right arrow (J) key. If “(No. Device

Found)” is still displayed, check the following items.

• Loop resistance: Is there a minimum of 250 Ω resistance between the

communicator and the power supply?

• Power supply: Is power applied? Is there greater than 11 volts at the

transmitter?

Correct any problems, and try communicating again. If the message, or

any other error message, appears again, refer to user’s manual of

AT9000 Advanced Transmitter (CM2-GTX100-2001 “Chapter 7: Main-

tenance and Troubleshooting”).

3 When the “Online” display - shown below - appears, you have estab-

lished communication with the transmitter.

The flashing heart icon in the upper right corner indicates the communi-

cator and the transmitter are communicating.

1-6 Supplement Manual for HART Communication Option

Azbil Corporation Starting Communications

1.6 : Checking basic data

This procedure checks the transmitter's factory-set configuration parameters:

STEP Action and/or Description

1 From the “Online” menu, enter “Device setup” by pressing the right

arrow (J) key on the communicator keypad.

2 Press the down arrow (L) key to scroll down to menu-item “5 Review”.

3 Press PREV and/or NEXT to scroll through the configuration data

including:

• Model

• Measurement Type

• Transfer Function

• Cutoff Mode

• Height

• PROM No.

• Software Rev

• Damping

• Lower Range Value (0%)

• Upper Range Value (100%)

• Upper Range Limit

• Fail Safe Direction

• Display Mode

• Disp. Unit

• User Unit

• EULO (0%)

• EUHI (100%)

• Exponent

• Output Low Limit

• Output High Limit

• Output Alarm

• Lower Output Alarm

• Upper Output Alarm

• Sensor Temp. Alarm

• Lower Sensor Temp. Alarm

• Upper Sensor Temp. Alarm

• Contact Output ON/OFF

• Alarm Status

• Contact Output Mode

• Contact Output Status

• Output

• Pressure

• Sensor Temp.

Supplement Manual for HART Communication Option 1-7

Starting Communications Azbil Corporation

STEP Action and/or Description

4 Press left arrow to go back to the “Device” menu

5 Tap the icon in the upper right corner of the touch screen to finish

the communication.

“HART Application” is finished and back to “375 Main Menu.”

1-8 Supplement Manual for HART Communication Option

Chapter 2 : Configuration

This section introduces you configuration of AT3000 with HART® option using the

HART® Communicator.

This section also provides an overview of the HART® Communicator, including

menus and keyboards.

2.1 : Top menu

The “Top menu” consists of 3 items.

1. Process Variables

2. Device

3. Diagnostic

Supplement Manual for HART Communication Option 2-1

Configuration Azbil Corporation

2.2 : Process Variables menu summary

⇔ ⇔ Pressure

⇔ Output

⇔ Analog Output

Process Variables

⇔ Sensor Temp.

⇔ Lower Range Value (0%)

⇔ Upper Range Value (100%)

⇔ ⇔ Pressure Chart

⇔ Pressure

⇔ Lower Range Value (0%)

Pressure

⇔ Upper Range Value (100%)

⇔ Analog Output

⇔ Output

⇔ ⇔ Output Chart

⇔ Output

Process Variables

⇔ Analog Output

Output

⇔ Pressure

⇔ Lower Range Value (0%)

⇔ Upper Range Value (100%)

⇔ Temperature ⇔ Temperature Chart

⇔ Sensor Temp.

⇔ ⇔ Pressure Gauge

⇔ Pressure

⇔ Analog Output Gauge

⇔ Analog Output

All Variables

⇔ Output Gauge

⇔ Output

⇔ Temperature Gauge

⇔ Sensor Temp.

2-2 Supplement Manual for HART Communication Option

Azbil Corporation Configuration

2.3 : Device menu summary

⇔ ⇔ Tag

⇔ Lower Range Value (0%)

⇔ Upper Range Value (100%)

Basic Setup

⇔ Upper Range Limit

⇔ Damping

⇔ Transfer Function

⇔ ⇔ Pressure

⇔ Pressure Unit

Sensors ⇔ Upper Range Limit

⇔ Sensor Temp.

⇔ Temp. Unit

⇔ ⇔ Lower Range Value (0%)

⇔ Upper Range Value (100%)

⇔ Upper Range Limit

⇔ Damping

⇔ Transfer Function

Device

⇔ Change Cutoff Mode

Signal Condition

⇔ Height

⇔ Output

⇔ Contact Output Status

⇔ Apply zero value

⇔ Apply span value

⇔ Set LRV (Actual)

⇔ ⇔ ⇔ Analog Output

⇔ Output Low Limit

Analog Output

⇔ Output High Limit

⇔ Loop Test

Output Condition

⇔ ⇔ Fail Safe Direction

Fail Safe

⇔ Failure Alarm Simulation Mode

⇔ ⇔ Poll Address

HART Output

⇔ Num Req Preams

(Continued)

Supplement Manual for HART Communication Option 2-3

Configuration Azbil Corporation

(Continued from previous page)

⇔ ⇔ ⇔ Output Alarm

⇔ Lower Output Alarm

⇔ Upper Output Alarm

Alarm Settings ⇔ Sensor Temp. Alarm

⇔ Lower Sensor Temp. Alarm

⇔ Upper Sensor Temp. Alarm

⇔ Contact Output Mode

⇔ ⇔ Output Low

⇔ Output High

Contact Output ON/OFF

Alarm ⇔ Sensor Temp. Low

⇔ Sensor Temp. High

⇔ Contact Output Simulation ⇔ Open

Mode

⇔ Close

Device

⇔ ⇔ ⇔ Output Alarm Low

⇔ Output Alarm High

Alarm Status ⇔ Sensor Temp. Alarm Low

⇔ Sensor Temp. Alarm High

⇔ Contact Output Status

⇔ ⇔ Display Mode

⇔ Display Function

⇔ Transfer Function

⇔ EULO(0%)

Display

⇔ EUHI(100%)

⇔ Disp. Unit

⇔ User Unit

⇔ Exponent

(Continued)

2-4 Supplement Manual for HART Communication Option

Azbil Corporation Configuration

(Continued from previous page)

⇔ ⇔ Manufacturer

⇔ Model

⇔ Measurement Type

⇔ Device ID

⇔ Tag

⇔ Date

⇔ Descriptor

⇔ Message

⇔ Sensor Serial Number

⇔ PROM No.

Device Information ⇔ Final Assembly Number

⇔ Revision Numbers ⇔ Universal Rev

⇔ Field Device Rev

Device ⇔ Software Rev

⇔ Write Protect ⇔ Hardware Write Protect

⇔ Software Write Protect

⇔ Change SW Write Protect

⇔ Software Version

⇔ ⇔ ⇔ Zero Trim

⇔ Correct Input LRV

Correct Input ⇔ Correct Input URV

⇔ Reset Corrects

Calibration

⇔ Restore factory setting

⇔ Output Calibration ⇔ D/A Trim

⇔ Scaled D/A Trim

(Continued)

Supplement Manual for HART Communication Option 2-5

Configuration Azbil Corporation

(Continued from previous page)

⇔ ⇔ Model

⇔ Measurement Type

⇔ Transfer Function

⇔ Cutoff Mode

⇔ Height

⇔ PROM No.

⇔ Software Rev

⇔ Damping

⇔ Lower Range Value (0%)

⇔ Upper Range Value (100%)

⇔ Upper Range Limit

⇔ Fail Safe Direction

⇔ Display Mode

⇔ Disp. Unit

⇔ User Unit

⇔ EULO (0%)

⇔ EUHI (100%)

⇔ Exponent

⇔ Output Low Limit

⇔ Output High Limit

⇔ Output Alarm

Device Review

⇔ Lower Output Alarm

⇔ Upper Output Alarm

⇔ Sensor Temp. Alarm

⇔ Lower Sensor Temp. Alarm

⇔ Upper Sensor Temp. Alarm

⇔ ⇔ Output Low

⇔ Output High

Contact Output ON/OFF

⇔ Sensor Temp. Low

⇔ Sensor Temp. High

⇔ ⇔ Output Alarm Low

⇔ Output Alarm High

Alarm Status

⇔ Sensor Temp. Alarm Low

⇔ Sensor Temp. Alarm High

⇔ Contact Output Mode

⇔ Contact Output Status

⇔ Output

⇔ Pressure

⇔ Sensor Temp.

2-6 Supplement Manual for HART Communication Option

Azbil Corporation Configuration

2.4 : Diagnostic menu summary

⇔ ⇔ Status

⇔ Critical Status

Diagnostic Status

⇔ Internal Data Inconsistency

⇔ Non-Critical Status

⇔ ⇔ Clear status records

⇔ Critical Status Records

Status Records Internal Data Inconsistency

Diagnostic ⇔

Records

⇔ Non-Critical Status Records

⇔ ⇔ 1(Latest)

⇔ 2

Zero-Error Int. Data ⇔ 3

⇔ 4

⇔ 5

Supplement Manual for HART Communication Option 2-7

Note

Chapter 3 : Start-up and Operation

This section identifies how to access typical data associated with the start-up and the

operation of AT9000 with HART® communication option. It includes the procedure

for running an analog output check

Supplement Manual for HART Communication Option 3-1

Start-up and Operation Azbil Corporation

Index

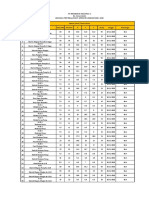

Items HART parameters Sections

Prepara- Checking the list of set Review 1.6 : Checking basic data

tion and values

adjustment Checking and setting the TAG 3.2.7: Device > Device infor-

TAG NO. mation

Checking the current Pressure, Output 3.1.1: Process Variables > Pro-

input and output values cess Variables

Checking and changing Lower Range Value 3.2.1: Device > Basic Setup

the setting range Upper Range Value

Checking and setting the Transfer Function 3.2.1: Device > Basic Setup

linear and square-root

outputs

Checking and setting the Damping 3.2.1: Device > Basic Setup

damping time constants

Checking and setting the Pressure Unit 3.2.2: Device > Sensors

pressure unit

Performing zero adjust- Apply zero value 3.2.3: Device > Sensors

ment

Checking the output Fail Sage Direction 3.2.4: Device > Output Condi-

direction when an error tion

occurs

Performing a loop test Loop Test 3.2.4: Device > Output Condi-

tion

Checking and changing Alarm Settings 3.2.5: Device > Alarm

the alarm settings

Checking the alarm sta- Alarm Status 3.2.5: Device > Alarm

tus

Checking and changing Contact Output ON/ 3.2.5: Device > Alarm

the settings of the contact OFF

outputs

Setting the indicator Display 3.2.6: Device > Display

Mainte- Performing calibration Correct Input 3.2.8: Device > Calibration

nance Resetting the calibrated Restore factory set- 3.2.8: Device > Calibration

values to factory settings ting

Checking the self-diag- Diagnostic Status 3.3.1: Diagnostic > Diagnostic

nostic messages Status

Checking the error Status Records 3.3.2: Diagnostic > Status

records Records

Please use this index to find the information you need.

3-2 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

3.1 : Process Variables

To check PV values, etc., enter the “Process Variables” menu.

Select “Process Variables” from the top menu.

On the “Process Variables” menu, the settings for 5 items can be checked.

3.1.1: Process Variables > Process Variables

If “Process Variables” is selected from the “Process Variables” menu, the settings for 6

items can be checked.

Supplement Manual for HART Communication Option 3-3

Start-up and Operation Azbil Corporation

3.1.2: Process Variables > Pressure

If “Pressure” is selected from the “Pressure Variables” menu, the settings for 6 items

can be checked.

Selecting “Pressure Chart” will display the chart.

~Note This chart can be displayed in case 375 communicator is licensed for

“Graphics”.

3.1.3: Process Variables > Output

If “Output” is selected from the “Process Variables” menu, the settings for 6 items can

be checked.

3-4 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

3.1.4: Process Variables > Temperature

If “Temperature” is selected from the “Process Variables” menu, the settings for 2

items can be checked.

3.1.5: Process Variables > All Variables

If “All Variables” is selected from the “Process Variables” menu, the settings for 8

items can be checked. The eighth item is “Sensor Temperature”.

Selecting “Pressure Gauge”, “Analog Output Gauge”, “Output Gauge”, or “Tempera-

ture Gauge” will display the corresponding value (analog display).

~Note This graph can be displayed in case 375 communicator is licensed for

“Graphics”.

Supplement Manual for HART Communication Option 3-5

Start-up and Operation Azbil Corporation

3.2 : Device

To set the device, enter the “Device” menu.

Select “Device” from the top menu.

The “Device” menu consists of 9 menu items.

3-6 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

3.2.1: Device > Basic Setup

On the “Basic Setup” screen, the settings for 6 items can be checked and changed.

To change the settings, select an item you want to change. The changed item will be

indicated by an asterisk (*). The “SEND” button will appear in the lower part of the

screen. To transmit the setting information to the device and determine the change, tap

this button.

When you tap the “SEND” button, the following confirmation screen will appear. Tap

“OK” if it is correct.

Supplement Manual for HART Communication Option 3-7

Start-up and Operation Azbil Corporation

After the transmission is completed, the following WARNING screen will appear.

Follow the instruction and then tap “OK”.

When the transmission is successfully completed, the asterisk will disappear.

For “Transfer Function”, you may select “Linear” or “Square Root”.

3-8 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

3.2.2: Device > Sensors

On the “Sensors” screen, the settings for 5 items can be checked, and the settings for

“Pressure Unit” and “Temp. Unit” can be changed.

On the “Pressure Unit” screen, you may select the unit from 16 units [mmH2O,

mH2O, inH2O, kPa, MPa, hPa, Pa, bar, mbar, mmHg, inHg, g/cm2, kg/cm2, atm, Torr,

and psi].

On the “Temp. Unit” screen, you may select the unit from 4 units [degC, degF, degR,

and Kelvin].

Supplement Manual for HART Communication Option 3-9

Start-up and Operation Azbil Corporation

3.2.3: Device > Sensors

On the “Signal Condition” screen, the settings for 11 items can be checked or changed.

The sixth item “Height” will appear only when a remote-sealed type transmitter is

used.

On the “Basic Setup” screen, the settings for 6 items can be checked and changed.

3-10 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

Device > Signal Condition > Apply zero value

The “Apply zero value” function is used to set the current input value to LRV. When

you tap “Apply zero value”, the following WARNING message will appear. Tap “OK”

if you want to continue.

Key in the pressure value equivalent to 4 mA and then tap “OK”.

When the pressure becomes stable, tap “OK”.

The current input value will be displayed. If it is correct, select “Set as 4 mA value”

and then tap “ENTER”.

If you want to change the input value, change the value. Then, select “Read new

value” and tap “ENTER” to check the new input value.

Supplement Manual for HART Communication Option 3-11

Start-up and Operation Azbil Corporation

To exit, select “Leave as found” and then tap “ENTER”.

Select “Set as 4 mA value” and then tap “ENTER”. The following message will be

displayed for a few seconds.

After that, the following NOTE will appear. After confirmation, tap “OK”.

“Lower Range Value (0%)” will be the current input value, and “Output” will be 0%.

3-12 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

Device > Signal Condition > Apply span value

The “Apply span value” function is used to set the current input value to URV. The

same procedure as the “Apply zero value” function applies, except that the input pres-

sure is set to a value equivalent to 20 mA.

Device > Signal Condition > Set LRV (Actual)

The “Set LRV (Actual)” function is used to set LRV so that the current output value

will be the desired value without changing the “span”. Tapping “Set LRV (Actual)”

will display the following WARNING message. After confirmation, tap “OK”.

The following confirmation message will appear. After confirmation, tap “OK”.

Key in the desired Output value and then tap “ENTER”.

The confirmation screen will appear. Tap “ENTER” if it is correct.

Supplement Manual for HART Communication Option 3-13

Start-up and Operation Azbil Corporation

If you want to change the input value and recalculate “New LRV”, select “Read new

value” and then tap “Enter”.

To exit, select “Leave as found” and then tap “ENTER”.

The following NOTE will appear. After confirmation, tap “OK”.

It can be confirmed that the settings for “Lower Range Value (0%)” and “Upper Range

Value (100%)” have changed and that “Output” is the designated value.

3-14 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

3.2.4: Device > Output Condition

On the “Output Condition” screen, the setting for “Analog Output” can be checked

and changed, the setting for “Fail Safe” can be checked, and the setting for “HART

Output” can be checked and changed..

Device > Output Condition > Analog Output

The “Analog Output” menu consists of 4 menu items.

The “Analog Output” value can be checked, the output limit can be set, and the con-

stant current output can be set.

Supplement Manual for HART Communication Option 3-15

Start-up and Operation Azbil Corporation

Device > Output Condition > Analog Output > Loop Test

Tapping “Loop Test” will display the following WARNING screen. After confirma-

tion, tap “OK”.

Select the desired output value and then tap “ENTER”.

To manually key in a value, select “Other”.

If “4 -> 8-> 12 -> 20 mA” is selected, the value will change in this order.

To exit this screen, select “END” and tap “ENTER”. At this time, constant-current

source mode will be disabled.

If “4 mA” is selected and “ENTER” is tapped, 4 mA constant-current source mode is

entered. The following screen will appear.

To return to the previous screen, tap “OK”.

3-16 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

If “Other” is selected and “ENTER” is tapped, the following entry screen will appear.

Key in the desired output value and tap “ENTER”.

Device > Output Condition > Fail Safe

The setting for “Fail Safe Direction” can be checked and “Failure Alarm Simulation”

can be executed.

The “Fail Safe Simulation” function is used to simulate “Fail Safe” operation.

Tapping “Fail Safe Simulation” will display the following WARNING screen. After

confirmation, tap “OK”.

Supplement Manual for HART Communication Option 3-17

Start-up and Operation Azbil Corporation

The following screen will appear. Tapping “OK” will execute simulated “Fail Safe”

operation.

During “Fail Safe Simulation”, the following screen is shown.

Wait about 10 minutes, and “Fail Safe Simulation Mode” will be automatically dis-

abled. To enter “Fail Safe Simulation Mode” again, select “Continue Simulation

Mode”, and then tap “ENTER”.

To exit, select “End Simulation Mode”, and then tap “ENTER”.

Device > Output Condition > HART Output

On the “HART Output” screen, “Polling Address” can be set and the setting for “Num-

ber of Request Preambles” can be checked.

3-18 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

3.2.5: Device > Alarm

The “Alarm” menu consists of 4 menu items.

Device > Alarm > Alarm Settings

On the “Alarm Settings” menu, “Output Alarm”, “Sensor Temperature Alarm”, and

“Contact Output Mode” can be set.

To enable “Output Alarm”, tap “Output Alarm”.

Tapping “Output Alarm” will display the following screen. Select an item you want to

set. If you want to set “Lower Limit” only, select “Lower Limit” and tap “ENTER”. If

you want to set “Upper Limit” only, select “Upper Limit” and tap “ENTER”. If you

want to set both “Lower Limit” and “Upper Limit”, select “Lower/Upper Limit” and

tap “ENTER”.

Supplement Manual for HART Communication Option 3-19

Start-up and Operation Azbil Corporation

After changing the setting, tap “SEND” to transmit the setting information. After that,

the limit value can be set.

The alarm values that can be changed, “Lower Output Alarm” or/and “Upper Output

Alarm”, will be displayed. If you want to change any of these values, tap the item you

want to change, change the setting, and then transmit the setting information.

The settings for “Sensor Temperature Alarm” can be changed in the same manner.

3-20 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

After the setting information is transmitted, values that can be set will be indicated...

After the setting information is transmitted, the following screen will appear.

Tapping “Contact Output Mode” selects “Normally Open” or “Normally Close”.

Supplement Manual for HART Communication Option 3-21

Start-up and Operation Azbil Corporation

Device > Alarm > Contact Output ON/OFF

On the “Contact Output ON/OFF” screen, the alarm for “Contact Output” can be

selected...

Tapping the item you want to change will display the following screen. To change the

setting to ON, tap the “ON” button located at the lower part of the screen, and then tap

“ENTER”.

To return to the previous screen without changing the setting, tap the “ESC” button.

To transmit the setting information, tap “SEND” on this screen.

3-22 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

Device > Alarm > Contact Output Simulation Mode

On the “Contact Output Simulation Mode” screen, “Contact Output” can be set to

“Open” or “Close” in a simulated (forcible) manner.

Tapping “Open” or “Close” will display the following WARNING screen. After con-

firmation, tap “OK”.

The following confirmation screen will appear. Tap “OK” if you want to execute the

simulation.

During simulation mode, the following screen will appear. If the screen is left

unchanged, simulation mode will be automatically disabled after about 10 minutes. To

enter simulation mode again, select “Continue Simulation Mode”, and then tap

“ENTER”.

Supplement Manual for HART Communication Option 3-23

Start-up and Operation Azbil Corporation

To exit simulation mode, select “End Simulation Mode”, and then tap “ENTER”.

Device > Alarm > Alarm Status

On the “Alarm Status” screen, the status of the Alarm settings and “Contact Output”

can be checked.

3-24 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

3.2.6: Device > Display

The settings for “Display” can be checked and changed.

The menu items displayed differ depending on the setting of “Display Mode”.

When “Display Mode” is “%”.

If “Display Function” is set to “Square Root”, the square root of the output linear is

extracted. The “Disp ” segment will be displayed on the LCD.

Tapping “Display Mode” will display the following setting screen.

Select the item you want to set and tap “ENTER”.

The changed item will be indicated by an asterisk (*). Tap “SEND” to transmit the set-

ting information.

Supplement Manual for HART Communication Option 3-25

Start-up and Operation Azbil Corporation

When “Display Mode” is set in “Pressure”, only “Transfer Function” can be set.

When “Display Mode” is set in “Scale”, more items can be set.

To use a unit not registered in “Disp. Unit” and optionally set in “User Unit”, set

“Disp. Unit” to “user define unit”.

3-26 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

“X10”, “X100”, or “X1000” can be displayed by setting “Exponent”. “X1”, if

selected, is not displayed.

Supplement Manual for HART Communication Option 3-27

Start-up and Operation Azbil Corporation

3.2.7: Device > Device information

On the “Device Information” screen, the following items can be checked and changed.

On the “Revision Number” screen, the following items can be checked.

3-28 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

On the “Write Protect” screen, the status of “Hardware Write Protect” and “Software

Write Protect” can be checked, and the setting for “Software Write Protect” can be

changed.

On the “Change SW Write Protect” screen, “Yes” or “No” can be selected.

On the “Software Version” screen, the Software Version can be checked.

Tapping “Software Version” will display the following screen. Tap “OK” to execute it.

The Software Version will appear. To return the previous screen, tap “OK”.

Supplement Manual for HART Communication Option 3-29

Start-up and Operation Azbil Corporation

3.2.8: Device > Calibration

The “Calibration” menu consists of 2 menu items, “Correct Input” and “Output Cali-

bration”.

Device > Calibration > Correct Input

The “Correct Input” menu consists of 5 menu items.

3-30 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

Device > Calibration > Correct Input > Zero Trim

The “Zero Trim” function is used to calibrate zero point.

Tapping “Zero Trim” will display the following WARNING screen. After confirming

the setting, tap “OK”.

The following WARNING screen will appear. Tap “OK” if there is no problem.

Key in “0” for the sensor, and then tap “OK”.

Supplement Manual for HART Communication Option 3-31

Start-up and Operation Azbil Corporation

After the following screen is displayed for a while, the next screen will appear.

After the following screen is displayed for a while, the next screen will appear.

The “NOTE” screen will appear. After confirmation, tap “OK”. The procedure for

“Zero Trim” is completed.

Device > Calibration > Correct Input > Correct Input LRV

The “Correct Input LRV” function is used to perform calibration by entering the same

value as LRV. The basic procedure is the same as that for “Zero Trim”.

Device > Calibration > Correct Input > Correct Input URV

The “Correct Input URV” function is used to perform calibration by entering the same

value as URV. The basic procedure is the same as that for “Zero Trim”.

3-32 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

Device > Calibration > Correct Input > Correct Resets

The “Reset Corrects” function is used to reset the calibrated values to the default val-

ues.

Tapping “Reset Corrects” will display the following WARNING screen. After confir-

mation, tap “OK”.

Tap “OK” to execute “Reset Corrects”.

After the following screen is displayed for a while, the next screen will appear.

Supplement Manual for HART Communication Option 3-33

Start-up and Operation Azbil Corporation

“Reset Corrects” is completed. Tap “OK”.

The following NOTE screen will appear. After confirmation, tap “OK”. The procedure

for “Reset Corrects” is completed.

3-34 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

Device > Calibration > Correct Input > Reset factory setting

The “Restore factory setting” function is used to reset the calibrated values to the fac-

tory settings.

Tapping “Restore factory setting” will display the following WARNING screen. After

confirmation, tap “OK”.

Tap “OK” to execute “Restore factory setting”.

Device > Calibration > Output Calibration

The “Output Calibration” menu consists of 2 menu items.

Supplement Manual for HART Communication Option 3-35

Start-up and Operation Azbil Corporation

Device > Calibration > Output Calibration > D/A trim

The “D/A trim” function is used to calibrate 4 mA and 20 mA outputs. Tapping “D/A

trim” will display the following WARNING screen. After confirmation, tap “OK”.

Connect the reference meter and then tap “OK”.

The device is set to 4 mA output. Tap “OK” if there is no problem.

3-36 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

Key in the value indicated by the reference meter and then tap “ENTER”.

When the value indicated by the reference meter becomes 4 mA, select “Yes” and then

tap “ENTER” to complete the procedure.

If the value does not become 4 mA, select “No” and then tap “ENTER” to repeat the

procedure.

Next, perform adjustment for 20 mA. Tap “OK” if there is no problem.

Supplement Manual for HART Communication Option 3-37

Start-up and Operation Azbil Corporation

Key in the value indicated by the reference meter and then tap “ENTER”.

When the value indicated by the reference meter becomes 20 mA, select “Yes” and

then tap “ENTER” to complete the procedure.

If the value does not become 20 mA, select “No” and then tap “ENTER” to repeat the

procedure.

When all the procedures are completed, the following NOTE screen will appear. After

confirmation, tap “OK”.

3-38 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

Device > Calibration > Output Calibration > Scaled D/A Trim

The “Scaled D/A Trim” function is used to calibrate 4 mA and 20 mA outputs using

other units such as 1 V and 5 V.

Tapping “Scaled D/A Trim” will display the following WARNING screen. After con-

firmation, tap “OK”.

To perform adjustment with 1_5 V, select “Change scale” and then tap “ENTER” to

change the scale.

Key in “Lo output value” and then tap “ENTER”.

Supplement Manual for HART Communication Option 3-39

Start-up and Operation Azbil Corporation

Next, key in “Hi output value” and then tap “ENTER”.

Check that the scale has changed. Then, select “Proceed” and tap “ENTER”.

Connect the reference meter and then tap “OK”.

Set the reference meter to 4 mA output. Tap “OK” if there is no problem.

3-40 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

Key in the value indicated by the reference meter and then tap “ENTER”.

When the value indicated by the reference meter becomes the set value, select “Yes”

and then tap “ENTER” to complete the procedure.

If the value does not become the set value, select “No” and then tap “ENTER” to

repeat the procedure.

Next, perform adjustment for 20 mA. Tap “OK” if there is no problem.

Supplement Manual for HART Communication Option 3-41

Start-up and Operation Azbil Corporation

Key in the value indicated by the reference meter and then tap “ENTER”.

When the value indicated by the reference meter becomes the set value, select “Yes”

and then tap “ENTER” to complete the procedure.

If the value does not become the set value, select “No” and then tap “ENTER” to

repeat the procedure.

After constant-current source mode is disabled, the following NOTE screen will

appear. After confirmation, tap “OK”. All the procedures are completed.

3-42 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

3.2.9: Device > Review

On the “Review” screen, the major settings can be displayed. These settings cannot be

changed on this screen.

Supplement Manual for HART Communication Option 3-43

Start-up and Operation Azbil Corporation

3.3 : Diagnostic

On the “Diagnostic” screen, the self-diagnostic results are displayed.

“Diagnostic” consists of 3 menu items.

3.3.1: Diagnostic > Diagnostic Status

On the “Diagnostic Status” screen, the current diagnostic results of the device can be

checked.

Diagnostic > Diagnostic Status > Status

On the “Status” screen, the diagnostic results currently generated are displayed.

3-44 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

Diagnostic > Diagnostic Status > Critical Status

On the “Critical Status” screen, all the “Critical Status” items are displayed. If such

status occurs, “ON” is displayed. If not, “OFF” is displayed.

Diagnostic > Diagnostic Status > Internal Data Inconsistency

On the “Internal Data Inconsistency” screen, “Invalid Database” is displayed. If there

is any “Invalid Database”, “ON” is displayed. If not, “OFF” is displayed.

Supplement Manual for HART Communication Option 3-45

Start-up and Operation Azbil Corporation

Diagnostic > Diagnostic Status > Non-Critical Status

On the “Non-Critical Status” screen, all the “Non-Critical Status” items are displayed.

If such status occurs, “ON” is displayed. If not, “OFF” is displayed.

3-46 Supplement Manual for HART Communication Option

Azbil Corporation Start-up and Operation

3.3.2: Diagnostic > Status Records

The “Status Records” function is used to store generated self-diagnostic results. This

function allows you to check temporary phenomena even after they have been

removed.

Diagnostic > Status Records > Clear status records

This function is used to clear the stored self-diagnostic results.

Diagnostic > Status Records > Critical Status Records

On the “Critical Status Records” screen, all “Critical Status” items are displayed. If

there is any occurrence record, “ON” is displayed. If not, “OFF” is displayed.

Supplement Manual for HART Communication Option 3-47

Start-up and Operation Azbil Corporation

Diagnostic > Status Records > Internal Data Inconsistency

Records

On the “Internal Data Inconsistency Records” screen, all “Invalid Database” items are

displayed. If there is any occurrence record, “ON” is displayed. If not, “OFF” is dis-

played.

Diagnostic > Status Records > Non-Critical Status Records

On the “Non-Critical Status Records” screen, all “Non-Critical Status” items are dis-

played. If there is any occurrence record, “ON” is displayed. If not, “OFF” is dis-

played.

3-48 Supplement Manual for HART Communication Option

Document Number: CM2-GTX000-2002

Document Name: AT9000 Advanced Transmitter

Supplement Manual for

HART® Communication Option

Date: 1st edition: May 2008

3rd edition: Oct. 2012

Issued/Edited by: Azbil Corporation

Вам также может понравиться

- Table of Contents - Category Logger App L003-507: Operator Manual Rev 2.01Документ26 страницTable of Contents - Category Logger App L003-507: Operator Manual Rev 2.01gustavoОценок пока нет

- Tapcon: Digital On-Load Tap-Changer Controller For Voltage Regulating TransformersДокумент6 страницTapcon: Digital On-Load Tap-Changer Controller For Voltage Regulating TransformersAlejandro MoreiraОценок пока нет

- Installation Manual NEW-BRMДокумент17 страницInstallation Manual NEW-BRMAndriZiОценок пока нет

- Marine MCS PDFДокумент7 страницMarine MCS PDFCrespo JorgeОценок пока нет

- WI-130 WDAC - Service ManualДокумент54 страницыWI-130 WDAC - Service ManualCleeeeestonОценок пока нет

- C4.4 EsquemaДокумент7 страницC4.4 EsquemavicenteОценок пока нет

- SENR11930001Документ5 страницSENR11930001Muhammad RamadhanОценок пока нет

- XK3100 Series IbnДокумент9 страницXK3100 Series IbnLuis HuertaОценок пока нет

- PM135 Quick Start Manual: Win A Tablet!Документ4 страницыPM135 Quick Start Manual: Win A Tablet!Vũ MinhОценок пока нет

- Schematic System Electrycal Trasmision TH55-E70 AND TH55-E90Документ9 страницSchematic System Electrycal Trasmision TH55-E70 AND TH55-E90Gerald GutierrezОценок пока нет

- Diagrama de La Powershit 420 EДокумент24 страницыDiagrama de La Powershit 420 EEdison Pfoccori BarrionuevoОценок пока нет

- P/N 974128 08/05 Rev. D ECO # 30337Документ52 страницыP/N 974128 08/05 Rev. D ECO # 30337bakri fattalОценок пока нет

- D2002E (A) Electric Weighing IndicatorДокумент19 страницD2002E (A) Electric Weighing Indicatorjonathan sanchezОценок пока нет

- ED 340 1eng Manuale Rapido 1 - 0Документ2 страницыED 340 1eng Manuale Rapido 1 - 0Abdullah100% (2)

- TLE2141 and TLE2141-Q1 EMI Immunity Performance: Application ReportДокумент5 страницTLE2141 and TLE2141-Q1 EMI Immunity Performance: Application ReportDandy PrasetyoОценок пока нет

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Документ10 страницInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768IkeoОценок пока нет

- Digital Panel Meter: Model A2100 Series Operation ManualДокумент2 страницыDigital Panel Meter: Model A2100 Series Operation ManualAung MhОценок пока нет

- A12 Ss User ManualДокумент12 страницA12 Ss User Manualanon_758951955Оценок пока нет

- Wiring and Programming: Table ofДокумент9 страницWiring and Programming: Table ofJairo FlechasОценок пока нет

- EN - Allen Bradley PV300 For SMOKjet-RHДокумент16 страницEN - Allen Bradley PV300 For SMOKjet-RHCristiano Rodrigues AlvesОценок пока нет

- LG Mu-60pz95v (ET)Документ43 страницыLG Mu-60pz95v (ET)Julio A. Hernandez100% (1)

- Viper3000 InstallationДокумент39 страницViper3000 InstallationEdgar P. Putong Jr.Оценок пока нет

- T1201 Operation ManualДокумент4 страницыT1201 Operation ManualTestor Nestor BОценок пока нет

- Kapcsolási Rajz C9.3 Tier IVi. UENR1201Документ9 страницKapcsolási Rajz C9.3 Tier IVi. UENR1201András FehérОценок пока нет

- Weighing Indicator A19 User ManualДокумент16 страницWeighing Indicator A19 User Manualmtrserv gmail.comОценок пока нет

- VSWR & Power Measurement Process On Anritsu Site MasterДокумент4 страницыVSWR & Power Measurement Process On Anritsu Site MasterArvindОценок пока нет

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Документ8 страницInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768dinny blanco rojasОценок пока нет

- LG Pa51d Chassis 42pc3dv SMДокумент117 страницLG Pa51d Chassis 42pc3dv SMdann222Оценок пока нет

- Kenr9501kenr9501-01 - Sis C32 Emcp4.3Документ12 страницKenr9501kenr9501-01 - Sis C32 Emcp4.3Halit YalçınkayaОценок пока нет

- User Manual Achook-1080, G726A, UM0084 - LatestДокумент24 страницыUser Manual Achook-1080, G726A, UM0084 - Latestprajith555Оценок пока нет

- Range R™ Count 3000 Series: Instruction ManualДокумент37 страницRange R™ Count 3000 Series: Instruction Manualmr pentakillОценок пока нет

- Plasma TV: Service ManualДокумент38 страницPlasma TV: Service ManualrolobingoОценок пока нет

- Ds3 User ManualДокумент23 страницыDs3 User ManualPT. Cahaya Surya Abadi SejahteraОценок пока нет

- EL Meaure MeterДокумент40 страницEL Meaure MeterRangasamyОценок пока нет

- VI 101 Weighing Indicator: U U Ss Ee RR M M Aa NN Uu Aa LLДокумент11 страницVI 101 Weighing Indicator: U U Ss Ee RR M M Aa NN Uu Aa LLRicardo CorredorОценок пока нет

- Electrical 336el 03Документ48 страницElectrical 336el 03rjan7pe100% (1)

- Operations and Maintenance Manual Ams4A048 Touch Screen Winch Operators PanelДокумент60 страницOperations and Maintenance Manual Ams4A048 Touch Screen Winch Operators PanelAyman MaezaОценок пока нет

- Hracmv9 Ib140010enДокумент15 страницHracmv9 Ib140010enTodea Mihai IulianОценок пока нет

- PM135 QuickstartДокумент4 страницыPM135 QuickstartNguyen Danh HuyОценок пока нет

- XK 3190-A 1Документ21 страницаXK 3190-A 1aldo100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Документ12 страницInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Mahmoud ElbakryОценок пока нет

- Tps Can Ban Can San TPSSERI DHДокумент18 страницTps Can Ban Can San TPSSERI DHdaocongdablОценок пока нет

- FST3253 D-2314273Документ8 страницFST3253 D-2314273C LiviuОценок пока нет

- Tettex TRR 2795Документ4 страницыTettex TRR 2795Ilic NebojsaОценок пока нет

- Quick StartДокумент22 страницыQuick Startshawn allenОценок пока нет

- TV Plasma LG 42px3dbv Uc 42px3dlv Uc Chassis Af 044cДокумент28 страницTV Plasma LG 42px3dbv Uc 42px3dlv Uc Chassis Af 044cvideosonОценок пока нет

- Cat - Dcs.sis - Controller LRJ d6nДокумент20 страницCat - Dcs.sis - Controller LRJ d6nRuanWheelingОценок пока нет

- YHT7E WeighingДокумент11 страницYHT7E Weighingmohsin bilalОценок пока нет

- Computer Systems Technology Ug1 201: Peakvalue RmsДокумент7 страницComputer Systems Technology Ug1 201: Peakvalue RmsRonald MutendaОценок пока нет

- Multiaxes Numerical Control CNC - Siax150: Installation GuideДокумент80 страницMultiaxes Numerical Control CNC - Siax150: Installation GuideGOST TECH GOST-технология67% (3)

- Switchview 1000 Switch: Installer/User GuideДокумент20 страницSwitchview 1000 Switch: Installer/User GuideDiОценок пока нет

- Multisim Tutorial: Component ToolbarДокумент9 страницMultisim Tutorial: Component ToolbarDeepikaОценок пока нет

- Instruction Manual: Digital Weighing IndicatorДокумент44 страницыInstruction Manual: Digital Weighing IndicatorHernando luis Fang pedrozaОценок пока нет

- DH Eng Manual FinalДокумент19 страницDH Eng Manual Finalluis garciaОценок пока нет

- SDG1000X QuickStart enДокумент20 страницSDG1000X QuickStart enriberadОценок пока нет

- Kobastar K1 User ManualДокумент10 страницKobastar K1 User Manualgustian141Оценок пока нет

- Keli D30-2 ManualДокумент7 страницKeli D30-2 ManualTakaSensei100% (1)

- Fluke 87 V Secret MenuДокумент8 страницFluke 87 V Secret MenuMehmet Serdar TekeОценок пока нет

- Concise Operating Instructions: Frequency Converter For HOISTING - TRAVEL (Siemens)Документ9 страницConcise Operating Instructions: Frequency Converter For HOISTING - TRAVEL (Siemens)Pablo Hidalgo ValenzuelaОценок пока нет

- Neraca BahanДокумент14 страницNeraca BahanAkmal ZuhriОценок пока нет

- Laporan Study Banding: Kwala Madu, 21 - 28 Agustus 2020Документ2 страницыLaporan Study Banding: Kwala Madu, 21 - 28 Agustus 2020Akmal ZuhriОценок пока нет

- Chapter 1: Instrumentation Equipment Module 1: Introduction To InstrumentationДокумент9 страницChapter 1: Instrumentation Equipment Module 1: Introduction To InstrumentationAkmal ZuhriОценок пока нет

- Square Profile Cylinders DNC - Inch SeriesДокумент26 страницSquare Profile Cylinders DNC - Inch SeriesAkmal ZuhriОценок пока нет

- CalibratioN Instrument PG Kwala MaduДокумент11 страницCalibratioN Instrument PG Kwala MaduAkmal ZuhriОценок пока нет

- Control Valve Specification PDFДокумент5 страницControl Valve Specification PDFAkmal ZuhriОценок пока нет

- Form Individual Test 2018 IsianДокумент9 страницForm Individual Test 2018 IsianAkmal ZuhriОценок пока нет

- General Test Stasiun Listrik / Power House: TA1 TA2 Standard No. Keterangan UraianДокумент1 страницаGeneral Test Stasiun Listrik / Power House: TA1 TA2 Standard No. Keterangan UraianAkmal ZuhriОценок пока нет

- CM2 CFS100 2002 04Документ32 страницыCM2 CFS100 2002 04Akmal ZuhriОценок пока нет

- Individual TestДокумент6 страницIndividual TestAkmal ZuhriОценок пока нет

- Ar ExportsДокумент1 страницаAr ExportsRais AlamОценок пока нет

- Rolling Bearings VRMДокумент2 страницыRolling Bearings VRMRollerJonnyОценок пока нет

- RadarДокумент65 страницRadarAsifa LiaqatОценок пока нет

- The DSG DQ200 LifespanДокумент1 страницаThe DSG DQ200 Lifespanqt99qzyhrbОценок пока нет

- Bams 1st Rachna Sharir Joints and Their Classification 16-05-2020Документ15 страницBams 1st Rachna Sharir Joints and Their Classification 16-05-2020Sanjana SajjanarОценок пока нет

- L23 - Axial Flow CompressorДокумент17 страницL23 - Axial Flow CompressorRohan GuptaОценок пока нет

- DattadasДокумент4 страницыDattadasJéssica NatáliaОценок пока нет

- Carbon Emissions Don't Cause Global Warming: BackgroundДокумент5 страницCarbon Emissions Don't Cause Global Warming: BackgroundLibertyAustraliaОценок пока нет

- Action, Desire and Subjectivity in Prabhakara MimamsaДокумент28 страницAction, Desire and Subjectivity in Prabhakara Mimamsasiddy_777Оценок пока нет

- Nav Bharat Nirman: Indispensable Ideas For Green, Clean and Healthy IndiaДокумент4 страницыNav Bharat Nirman: Indispensable Ideas For Green, Clean and Healthy IndiaRishabh KatiyarОценок пока нет

- 2011 33 MaintenanceДокумент16 страниц2011 33 MaintenanceKrishna Khandige100% (1)

- Microscopio Olympus CX31 Serv PDFДокумент36 страницMicroscopio Olympus CX31 Serv PDFalejandra0% (1)

- BSN Curriculum 2012Документ1 страницаBSN Curriculum 2012Joana Bless PereyОценок пока нет

- List of Irc Publications Referred To in The Specifications: AppendicesДокумент17 страницList of Irc Publications Referred To in The Specifications: AppendicesPrasad BoniОценок пока нет

- BSO 04cДокумент267 страницBSO 04cSamikshya BОценок пока нет

- BiosintezaДокумент8 страницBiosintezaLovin BiancaОценок пока нет

- Planetary Characteristics: © Sarajit Poddar, SJC AsiaДокумент11 страницPlanetary Characteristics: © Sarajit Poddar, SJC AsiaVaraha Mihira100% (11)

- Blood Glucose Units Conversion Table: Endocrinology & Diabetes UnitДокумент1 страницаBlood Glucose Units Conversion Table: Endocrinology & Diabetes UnitDrFarah Emad AliОценок пока нет

- Medgroup Packet Tracer Skills Integration Challenge: - Design and Prototype The New Medgroup TopologyДокумент4 страницыMedgroup Packet Tracer Skills Integration Challenge: - Design and Prototype The New Medgroup TopologyvilanchОценок пока нет

- Here Is Why Skincare Is ImportantДокумент3 страницыHere Is Why Skincare Is ImportantKevin OkunguОценок пока нет

- IJETR022563Документ5 страницIJETR022563erpublicationОценок пока нет

- LTE 3GPP Band13 Test Entrance CriteriaДокумент130 страницLTE 3GPP Band13 Test Entrance CriteriaBuchi Reddy0% (1)

- Ficha-Tecnica-Tuberia MechДокумент2 страницыFicha-Tecnica-Tuberia MechCarlos salazarОценок пока нет

- Astrophysics & CosmologyДокумент2 страницыAstrophysics & CosmologyMarkus von BergenОценок пока нет

- R OR K C S V: EG Epair Its For Ylinder and Ervice AlvesДокумент5 страницR OR K C S V: EG Epair Its For Ylinder and Ervice AlvesLeonardoFabioCorredorОценок пока нет

- 2019 BMS1021 Practice Questions Answers PDFДокумент12 страниц2019 BMS1021 Practice Questions Answers PDFaskldhfdasjkОценок пока нет

- MicrosoftDynamicsNAVAdd OnsДокумент620 страницMicrosoftDynamicsNAVAdd OnsSadiq QudduseОценок пока нет

- DuctBank For Electrical SystemДокумент4 страницыDuctBank For Electrical SystemAnonymous XYAPaxjbYОценок пока нет

- The Six Types of Simple MachinesДокумент4 страницыThe Six Types of Simple MachinesmarroОценок пока нет

- Contactor - SchniderДокумент28 страницContactor - SchniderPramod DixitОценок пока нет