Академический Документы

Профессиональный Документы

Культура Документы

1319 011

Загружено:

KekeОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1319 011

Загружено:

KekeАвторское право:

Доступные форматы

94 TRANSPORTATION RESEARCH RECORD 1319

•

Jacking Steel Bridge Superstructures In

Washington State

JOHN A. VAN LUND

Lifting steel bridge superstructures in Washington State are de- steel box girders with two side spans of 656 ft (200 m) and a

scribed. The use of jacks is an effective means for raising existing center span of 984 ft (300 m) ..

plate girder bridges to increase vertical clearance, to remove and The side spans were divided along the bridge centerline

replace defective bridge bearings, and to transfer the superstruc- into two equal sections that were barged to the site and lifted

ture dead load from one existing bridge substructure to another.

Case studies are presented for two successful jacking operations 172 ft (52.5 m). Each side span section was 958 ft (292 m)

that involved connecting permanent steel jacking beams to the long and weighed 2,480 tons (2,250 tonnes). The two sections

girders and jacking upward from the substructure. Generally, were lifted concurrently by ring girders, jacking columns, and

data on jacking operations do not appear in the technical liter- twelve 500-ton (450-tonne) jacks. The total load lifted for

ature. In one case study presented, data were recorded from jack each side span was 5,815 tons (5,275 tonnes) and was repeated

gauges, and a comparison between calculated and recorded lifting for the other side span. The time for lifting the side span

loads is presented that indicates the transverse distribution of

loads to the jacks. The total lifting loads recorded exceeded the sections was 84 hr. Finally, the 577-ft (176-m) center span,

calculated loads by 22 to 32 percent. Possible reasons for these weighing 3,770 tons (3,420 tonnes) was lifted 220 ft (67 m)

discrepancies and recommendations for lifting bridge superstruc- from the water level by eight 500-ton jacks and was accom-

tures are given. It is recommended that jacks be sized for at least plished in 6 days. This lifting operation was reported to be

1Yi times the calculated lifting loads. the second-heaviest bridge jacking operation (2).

During new bridge construction, the lifting of heavy steel

Quebec Railway Bridge, St. Lawrence River, Quebec,

superstructure and concrete segments has been accomplished

Canada

by floating the structural elements to the job site on barges

and lifting them from above with long cables or rods and

In September 1917, the 640-ft (195-m) suspended span of the

center-pull jacks. Some notable examples of heavy super-

Quebec Railway Bridge, weighing 5,400 tons (4,900 tonnes),

structure lifts follow.

was successfully lifted into place 150 ft (46 m) above the St.

Lawrence River. An earlier attempt failed on September 11,

1916, when the span was dropped after it had been lifted 12

EXAMPLES OF HEAVY SUPERSTRUCTURE

ft (3.7 m) and 11 workers perished. The raising of the span,

LIFTS

which took 4 days to complete, was the heaviest bridge jacking

operation in the world until the center span of the Fremont

Fremont Bridge, Willamette River, Portland, Oregon

Bridge was lifted in 1973 (3,4).

In March 1973, the steel tied-arch center span, 900-ft (274-

m) long, weighing 6,000 tons (5,443 tonnes), was lifted into

LIFTING EXISTING BRIDGE SUPERSTRUCTURES

place 160 ft (49 m) above the Willamette River in Portland,

Oregon. Thirty-two 200-ton (181-tonne) center-hole jacks and

Existing bridge superstructures are lifted for a variety of rea-

threaded rods of 4-in. (102-mm) diameter were used. The

sons. Road resurfacing on Interstate highways has reduced

total time for the lifting operation was 40 hr. It was reported

the vertical clearances on many of the overhead bridges. Two

to be the longest and heaviest span lifted in the world (J).

solutions are possible: cut and lower the roadway below, or

raise the bridges. According to Ramey (5), raising the bridges

to obtain adequate vertical clearance may be more economical.

Ponte Presidente Costa e Silva, Guanabara Bay,

Bridge superstructures are also raised to rehabilitate and

Brazil

replace bearings on older bridges, or in the case of newer

bridges, to replace defective pot bearings (6). In Washington

The Ponte Presidente Costa e Silva or the Rio Niteroi Bridge

State, existing bridge superstructures have been lifted to im-

over Guanabara Bay connects the cities of Rio de Janeiro

prove steep approach grades, and to remove and replace bear-

and Niteroi, Brazil. The navigation spans consist of parallel

ings. As noted in the Brazilian case study, the dead load of

an existing bridge superstructure was lifted from its existing

Washington State Department of Transportation, Transportation piers and transferred to a new steel-arch supporting system

Building, Olympia, Wash. 98504. by jacking.

Van Lund 95

CASE STUDY 1: FRANKLIN FALLS BRIDGE, { G1rder

SR-90, KING COUNTY, WASHING TON

I

The Franklin Falls Bridge is located approximately 50 mi (80 '" (/.2/n Synm abl. '1

km) east of Seattle, Washington, on westbound Interstate 90. f bridge~

This continuous, steel-plate girder bridge has two spans of

350 ft (107 m) each (Figure 1). The four plate girders are 13

ft (4 m) deep and are spaced at 14 ft (4.3 m) centers. Originally

built in 1971, the bridge was raised in 1978 during the con-

struction of the Denny Creek Bridge.

Sp/ ice II' ·s

The bridge was jacked 20.6 ft (6.3 m) at Pier 1, 17.1 ft (5.2

m) at Pier 2, and 13.6 ft (4.1 m) at Pier 3 to provide additional

vertical clearance for avalanches that pass below the bridge.

The raising resulted in a 4 percent final grade across the

bridge, which was less than the original 5 percent grade.

Jacking

At the end piers or abutments, jacking stiffeners were added FIGURE 2 Jacking diaphragms at the intermediate

pier, Pier 2.

2.25 ft (0. 7 m) from the existing girder bearing stiffeners so

that the four girders could be jacked concurrently. The total

dead load to be lifted at each end pier was 700 tons (636

11 10

tonnes). Four 300-ton (272-tonne) jacks, one jack per girder,

II [Jl 24 '"

24 '"

I---

were used to lift the bridge superstructure at the end piers. ·12 ,n

24 in

The ratio of total jack capacity to total calculated dead load ~ 1Z ,n

was 1.7. I S "12 '"

Pier J

At the intermediate pier, Pier 2, jacking diaphragms con- Pier 1

Pier 2

sisting of plate girders 75 in. (1,905 mm) deep were connected

with high-strength bolts (ASTM A490) of 7/s-in. (22-mm) di- (a) [] Deno/es Jacking sequence

ameter to the existing bearing stiffeners in the exterior bays

(Figure 2). The total dead load to be jacked was 2,500 tons 24 '"

(2,268 tonnes). Sixteen 300-ton jacks, four jacks per lift point,

24 in

with a total capacity of 4,800 tons (4,354 tonnes) were used

to lift the superstructure. The ratio of total jack capacity to Pier J

total calculated dead load was 1. 9.

FIGURE 3 Jacking (a) Stage 1, and

Jacking Sequence and Deflection Limitations (b) subsequent stages.

The jacking was done in four or more stages as shown in

Figures 3a and 3b. When each stage was completed , concrete Vertical deflection limits were established to avoid over-

was placed in 4-ft (1.2-m) lifts and cured before proceeding stressing the concrete deck, steel girders, and crossframes.

to the next jacking stage. These were not to be exceeded during any jacking sequence.

The relative vertical deflection between any girder at a pier

location was ± V4 in. (6.4 mm). During end pier jacking, the

upward deflection between the end piers and intermediate

-1 "'l "'I pier, Pier 2, was not to exceed 24 in. (610 mm). When the

:;;. :.,. :..·

.;:I <>= i <>=I

superstructure was jacked at Pier 2, the deflection was not to

J50fl 35011 I exceed 12 in. (305 mm) relative to the end piers. These vertical

l/OJ/nl

I I 1 deflection limits are shown in Figures 4a and 4b.

Bracing

l Or1g1nal ground 26(/

""

iEj

!1:

No jacking was permitted when the wind velocity exceeded

25 mph (40 km/hr). To prevent the bridge from shifting or

righl of bridge f ·-·

swaying, transverse restrainer struts were connected between

FIGURE 1 Elevation of Franklin Falls Bridge the exterior girders and concrete side walls at each end abut-

before jackin.g. ment. At Pier 2, vertical cantilever wind-bracing pipes were

96 TRANSPORTATION RESEARCH RECORD 1319

____/Jacking sequence

I] Q]

Span 7 S,9'111 2 Span J Span 4

75 /1(1 61.8]// 6J.8Jt r lJ. 11/1

122. 'An! l/9. 4m!

-.

"' Ii

-~~ a:..... ...~ :ii

I;;

ci: ci:

.::.

.:::

(b)

E

1 --- I

- --- .,1

I

Pier J

I Pier 2 [x1st

Pier I I Pier 2

I

FIGURE 4 Vertical deflection limits for (a) f

jacking at Piers 1 and 3, and (b) jacking at

Pier 2.

Lin lnterc;tate 5

.m 78411 156 . Im)

FIGURE 5 Elevation, Capitol Boulevard Bridge.

attached to the pier top and enclosed by a wind-bracing frame

attached to the girders in the center bay.

Eight longitudinal tie rods 2 in. (51 mm) in diameter were

~- ---~5Jl!..1:!f!!!:sdr 14..lSft lt . )lm/

connected to the bottom flange of the jacking diaphragms and

the concrete deck to ensure that the jacking diaphragms would

remain plumb. These were located at each lift point.

CASE STUDY 2: CAPITOL BOULEVARD BRIDGE,

SR-5, OLYMPIA, WASHINGTON

The Capitol Boulevard Bridge over Interstate 5 was originally

built in 1957 and was reconstructed in 1987-1988 (7). The

existing steel-plate girder superstructure was retained, and a

new steel-arch supporting system was constructed to replace FIGURE 6 Section at end piers.

the existing concrete piers that were removed so that the

Interstate below could be widened from four to eight lanes.

One of the most interesting and challenging engineering

problems involved the transfer of the existing superstructure

dead load to the new arches by jacking.

Bearing Replacement at End Piers 1 and 4

Jacking Sequences 1 and 2

Jacking was done at one location at a time beginning at Pier

1 followed by Pier 4 (Figure 5). Eight 100-ton (91-tonne)

hydraulic jacks were used to raise the superstructure at the

end piers so that the existing steel slide bearings could be

removed and replaced with new ones. As shown in Figure 6,

permanent steel jacking beams, W16 x 57 (ASTM A588), were

connected to the existing girders with 7/s-in.-diameter high-

strength bolts (ASTM A490). Lift points for jacks were lo-

cated 2.25 ft (0.7 m) from the girders. The hydraulic system

used is shown in Figure 7.

The maximum vertical deflection permitted at the end piers

was 2.5 in. (64 mm) to prevent overstressing the girders during

jacking. In the transverse direction, the relative vertical dis-

placement between adjacent girders was not to exceed ±'Is

in. ( ± 3.2 mm), and the relative vertical_deflection of the jacks FIGURE 7 Hydraulic jacking system.

Van Lund 97

on each side of a girder was not to exceed ± V6 in. ( ± 1.6 as a percentage, the transverse distribution of the total lifting

mm). These limits on vertical displacement were established load exhibited good correlation with calculated values for the

so that the original 30-year-old concrete deck, which was to exterior jacks. However, the actual transverse distribution of

be retained, would not be overstressed. the lifting load to the interior jacks was not consistent between

Piers 1 and 4 and did not correlate well with the calculated

values.

Calculated Lifting Loads at End Piers

The total lifting load at the end pier was calculated for the Load Transfer at End Crossframes and Crown

original three-span continuous structure shown in Figure 8 by Crossbeam

the computer program STRUDL. The noncomposite stiffness

of the five steel girders was used because there were no shear The existing superstructure dead load was transferred to the

connectors and the concrete deck had a joint 1-in. (25-mm) new steel-arch supporting system by sequential jacking of the

wide over each pier. superstructure at each end crossframe and crown crossbeam.

The end pier reaction was 300 kips (1,334 kN) for the span The existing pier bearings were removed, and the superstruc-

dead loads, 20 kips (89 kN) for the concentrated dead load ture was lowered on the new bearings at the end crossframes

at the centerline of bearings, and 20 kips to lift the system and crown crossbeam. Jacking was done at one location at a

2.5 in. (63.5 mm). The total calculated lifting load was 340 time following the sequence shown in Figure 5.

kips (1,512 kN). Before jacking, new bearing stiffeners were connected to

The transverse distribution of the total calculated lifting the existing plate girders, and permanent steel jacking beams

load to the jacks was determined by applying five equal loads (W33 x 118 at the end crossframes and W27 x 84 at the crown

of 68 kips (302 kN) at each girder. crossbeam) were connected to the stiffeners. All field con-

nections were made with 7/s-in.-diameter high-strength bolts

(ASTM A325), and all steel was 50-ksi (344-MPa) high-strength

Results of End Pier Jacking steel. A typical connection detail between an exterior girder

and a jacking beam is shown in Figure 9.

The calculated and recorded lifting loads at each jack are

presented in Table 1 and are also expressed as a percent of

the total. The total loads recorded were 417.6 kips (1,857 kN)

at Pier 1 and 447.8 kips (1,992 kN) at Pier 4, which were 23 Jacks, Deflection Limitations, and Blocking

and 32 percent greater than those calculated. When expressed

Sixteen 100-ton jacks, two jacks per lift point, were used to

raise the superstructure at the end crossframes (Figure 10)

(oncenlraled dead load and the hydraulic system shown in Figure 7 was doubled.

20k1ps 189kN! s - Un1lorm drad load The vertical deflection criteria for lifting at the end cross-

+ frames were the same as those specified for the end pier

jacking. However, the total vertical deflection permitted at

ll1Jir1f1$

1302. SkN!

Pier 1

8111

fl'>.('"/

t

Pier l

FIGURE 8 Original spans, end pier jacking.

.,, -1

the crown crossbeam was reduced to 2.0 in. (51 mm). Because

of their close proximity to the end crossframes, the existing

intermediate piers served as convenient reference points to

check both the total and relative deflections of the girders

during jacking.

TABLE 1 END PIER JACKING: CALCULATED AND RECORDED

LIFTING LOADS

Lift Points

Description 1 4 5 6 7 Total

Calculated 81.4 15. 7 40.8 32.1 32.1 40.8 15. 7 81.4 340.0

Piers 1 &4 (362) (70) (181) (143) (143) (181) (70) (362) ( 1512)

Percent 24.0 4.6 12 .0 9.4 9.4 12.0 4.6 24.0 100 . 0

Recorded 110.0 25 .4 17 .0 60. 6 55.2 19 .0 24.4 106. 0 417. 6

Pier 1 (489) (113) (76) (270) (245) (85) (108) (471) (1857)

Percent 26.3 6.1 4.1 14. 5 13 . 2 4.5 5.9 25.4 100.0

Recorded 98.4 37 . 5 39.0 42.0 47.4 40.0 4 1. 0 102.5 447.8

Pier 4 (438) (167) (173) (187) (211) (178) (182) (456) (1992)

Percent 22 .0 8.4 8.7 9.4 10. 6 8.9 9.1 22 . 9 100 . 0

Loads are in kips (k.N)

98 TRANSPORTATION RESEARCH RECORD 1319

-----------.. \_,_ _,_1_11..J!.rll.JJ

~ ~-l 1/I point flections during all jacking sequences. Once the calculated

lifting loads were determined, a second analysis was per-

f - - - - - - - l/P-:sk l• - ;- -

19 s, J5&Tm!

1

ro. ~~ ;,11 Js

I }

formed to obtain the transverse load distribution to each jack

by assuming the total lifting load to be applied as five equal

loads at each girder.

..

lt'vel

;. ·· ~

·~ i -f WJJx 718 Jacking Sequence 3

..::::. ::

• • J.: •

~= ~

Jacking

beam

.... ..t. ... K' - · Figure 11 shows jacking at the first end crossframe. The su-

W.P~

,' -~ ~ Jacking

•• i;• • . ~ s I 1 f feners

perstructure was still attached to the opposite existing pier,

If'~ in

2re ·s 7~ x5t which prevented the superstructure from moving both lon-

,. (n,m x 7JJnmJ

17Jnm! -

~ 1=~===1

gitudinally and transversely. The spaces between the girders

and unjacked end crossframe were tightly blocked; this block-

ing induced a compressive force in the unjacked end cross-

Remove ex1sl ing

paint. qr ind and c ltn 15 7nm!

frame as the arch deflected upwards.

shim lo bear c Jin I l&Tm! The total calculated load which would lift the superstructure

I fyp . bol 1- -

- Bearinq st 1/fener

off existing Pier 2 and maintain the original grade was 1,164

!Pl!·

In IJ&m! kips (5,177 kN). The calculated deflection, which is the sum

of the end crossframe deflection, arch deflection, and the

l x/{'r!Or girder

upward deflection of the superstructure, varied from 1.3 in.

FIGURE 9 Jacking beam to girder connection. (33 mm) at the exterior girders to 1.6 in. (41 mm) at the

middle girder.

The total lifting load, recorded from the jack gauges, was

f------ _____ I li1rd_ef'S_d!_ li]5jl f_( Ji!ll)_ ________ _ -1 1,422 kips (6,325 kN), and the measured deflection at liftoff

' varied from 1.375 in. (35 mm) to 1.625 in. (41 mm). The total

- Jacking bedms I

WJJx118 i recorded lifting load was 22 percent greater than that calcu-

I

A [ lated. The measured deflections were 0.075 in. (2 mm) greater

_J I than that calculated at the exterior girders and 0.025 in. (0.6

mm) greater at the middle girder. This provided a good check

on the computer analyses.

Jacking Sequence 4

Figure 12 shows jacking at the opposite end crossframe, where

the total calculated load that would lift the superstructure off

existing Pier 3 was 1,190 kips (5,293 kN). The actual lifting

'i4fl !In 'iml

f Arch

.-Jacking sequence

Arch

d1 f

i

FIGURE 10 End crossframe, jacking beams, and 7n 1164 kips

jacks. 15711 kNJ

During the end crossframe jacking, steel shims were in-

stalled as blocking at the existing pier bearings. If a jack

should fail, the girders would not be displaced relative to one FIGURE 11 Jacking Sequence 3-end

another by more than the shim thickness of Vs in. (5 mm). crossframe jacking.

Jacking s~QIJPl>C"\

Calculated and Recorded Lifting Loads f ffi

i I

7

The existing superstructure had a total dead load of 2,840 7790 kips 1190 kips

kips (12,630 kN). Under final conditions, 2,120 kips (9,430 15293 kNJ

kN) or 75 percent is transmitted to the arches by the two end

crossframes. During jacking, loads greater than these oc-

curred because of the sequence followed.

Computer analyses using STRUDL were performed to de- FIGURE 12 Jacking Sequence 4-end

termine the magnitude and distribution of the loads and de- crossframe jacking.

Van Lund 99

load was 1,494.6 kips (6,648 kN) or 26 percent greater than f

¥Jack 1ng sequence

that calculated. The recorded and calculated loads at each

jack are presented in Table 2 for Jacking Sequences 3 and 4.

Also presented are the percentages of the total at each jack,

which exhibit good correlation in predicting the transverse

distribution of the total load to the jacks.

Jacking Sequence 5

FIGURE 13 Jacking Sequence 5-crown

After completion of the end crossframe jacking, the super- crossbeam jacking.

structure at the crown crossbeam was jacked and the bearings

installed (Figures 13 and 14). The intent was to induce pre-

compression in each bearing to offset any live load uplift. The

total desired precompression was 200 kips (890 kN). The total

load recorded was 233 .6 kips (1,039 kN) or 17 percent over I

[

that desired. A comparison between the recorded and cal- I

culated loads at the jacks and the percent of the total at each

jack are presented in Table 3.

Final Dead Load Distribution I

I )Jcks

After completion of the superstructure jacking, the existing f-

I

Jm tM ..,,_, _ _ _ _ __,

deck was resurfaced with a latex concrete wearing course f A1·c/i Arch

1Y2-in. (38-mm) thick . The additional dead load, applied to I

the superstructure uniformly, was 1.12 kips/ft (16.3 kN/m).

FIGURE 14 Crown crossbeam, jacking beams, and

The final superstructure dead load distribution to the arches jacks.

is shown in Figure 15.

of the calculated dead load on the basis of the calculated and

Reasons for Higher Lifting Loads measured deflections.

2. The jacks may not be plumb or loaded concentrically,

The total loads recorded during the jacking operations were which may cause the piston to bind or seize up. These internal

higher than those calculated by 23 percent at Pier 1, 32 percent forces must be overcome to lift the superstructure. They may

at Pier 4, and 22 to 26 percent at the end crossframes. There have caused the jack gauges to record higher lifting loads than

are several possible reasons for these discrepancies: those calculated.

3. Frozen bearings and possible composite action of the

1. The concrete deck may be thicker than that shown in concrete deck may have contributed to higher lifting loads.

the original contract plans, which would increase the dead 4. The jacks may not have been placed at the same locations

load . The actual dead load is probably within 5 to 6 percent that were used for calculating the jack loads. This difference

TABLE 2 END CROSSFRAME JACKING: CALCULATED AND

RECORDED LIFTING LOADS

L1ft Points

Description 3 4 Total

Calculated 273.5 89. 6 103. 6 115 .2 115. 2 103. 6 89. 6 273. 5 1164.0

X-Frame 2 (1216) (399) (461) (512) (512) (461) (399) (1216) (5176)

Percent 23.5 7.7 8.9 9.9 9. 9 8.9 7.7 23. 5 100.0

Recorded 348.6 95.6 103 , 6 165.4 155. 6 104 .11 101 . 6 31, 7 . 2 1"22 . 0

X-Frame 2 (1551) (425) (461) (73 6) (692) (464) (452) (1544) (632 5 )

Percent 24. 5 6. 7 7.3 11.6 11.0 7.4 7.1 24 . 4 100. 0

Calculated 279.7 91. 6 105 . 9 117. 8 117. 8 105 .9 91. 6 279 . 7 1190. 0

X-Frame 3 (1244) (407) (471) (524) (524) (471) ( 407) ( 1244) (5292)

Percent 23. 5 7.7 8. 9 9. 9 9.9 8. 9 7.7 23.5 100.0

Recorded 352.6 120.6 124.4 142.8 138 . 2 114.4 119.4 382.2 1494 . 6

X-Frame 3 (1568) (536) (553) (635) (615) (509) (531) (1700) (6647)

Percent 23.6 8 .1 8. 3 9.5 9 .2 7. 7 8.0 25.6 100.0

Loads are in kips (kN)

100 TRA NSPOR TA TION RESEAR CH R ECORD 1319

TABLE 3 CROWN CROSSBEAM JACKING : CALCULATED AND

RECORDED LIFfING LOADS

Lift Points

Description 4 6 7 Total

Calculated 46.0 18 . l 16 . l 19 . 8 19 . 8 16. l 18 . l 46.0 200 . 0

(205) (80) (72) (88) ( 88) (72) (80) (205) (8 90 )

Percent 23. 0 9.0 8 .0 10.0 10. 0 8.0 9.0 23 .0 100. 0

Recorded 37 . 8 29 . 0 38 .4 29.4 30. 6 14 . 6 10 .0 43 . 8 233 . 6

(168) (129) (171) ( 131) ( 1 36) ( 65 ) (44) ( 1 95 ) ( 1039)

Percent 16 . 2 12 . 4 16 . 4 12. 6 13 . l 6.3 4. 3 18 .7 100.0

Loads are in kips (kN)

6. Do not permit traffic on the bridge or the presence of

T,O kif!'

any unnecessary construction personnel near the bridge dur-

I' 7150 4.i ps r. n

JOO kips (5775 kN! 11111 kNI JOO kips ing lifting. Shim and block as the superstructure is being lifted.

( IJJ4 kNJ

In the event of a jack failure, there will be no significant

differential settlement and a back-up jack can be quickly in-

stalled . Permit traffic on the bridge only after the superstruc-

ture has been blocked or shimmed and the load is released

FIGURE 15 Final superstructure dead load from the jacks .

distribution. 7. Ensure that the superstructure does not move or sway

in any direction by establishing maximum permissible deflec-

tions and by providing positive restraining systems. This is

would cause discrepancies in the transverse distribution of the particularly important for bridges on a steep grade or those

total lifting loads. located in wind-prone locations.

8. Disconnect any utilities, railings, and traffic barrier cover

plates to facilitate lifting.

9. The working drawings, jacking procedures , and calcu-

RECOMMENDATIONS FOR LIFTING BRIDGE

lations should be prepared , stamped, and signed by a profes-

SUPERSTRUCTURES

sional engineer licensed in the state where the lifting is to

take place. This engineer or his designated representative

Recommendations based on experience at the Washington

should inspect all aspects of the lifting operation and be pres-

State Department of Transportation, on guidelines from Orr

ent during the lifting.

(8), and on the New York State Department of Transportation

Standard on Structural Lifting Operations (9) are as follows:

SUMMARY

1. Calculate the dead load to be lifted. Include the weight

of any construction equipment. 1. Two case studies are presented that demonstrate the use

2. Locate the lift points and indicate the calculated lifting of jacks to lift steel bridge superstructures in Washington

loads in the contract plans. These should also be shown in State.

the working drawings prepared by the contractor. 2. The first case study involves raising the bridge super-

3. If jacks are to be used, the cylinder capacity should be structure by as much as 20.6 ft (6 .3 m) so that avalanches

from 1Y2 (9) to 2 (8) times the calculated lifting load. The could pass below without hitting the superstructure.

manufacturers' name plate and rated capacity should be at- 3. In the second case study, jacking is used as a means to

tached to each jack. The schematic hydraulic layout, including transfer the superstructure dead load from one existing sub-

gauges, valves, manifolds, and other equipment, should be structure to another. Data were recorded, and a comparison

shown in the working drawings . between cakulaletl anti measured lifting loads and deflections

4. If special lift or supporting equipment such as jacking was presented.

beams or frames are required, they should be properly de- 4. Computer analyses are essential in determining the an-

tailed with particular attention to connection details. Include ticipated lifting loads and deflections during jacking. The sec-

the type and grade of all materials in the contract and working ond case study indicated that the total recorded lifting loads

drawings. exceeded the calculated loads by 22 to 32 percent.

S. So as not to overstress the existing structural members S. Possible reasons for discrepancies between recorded and

during lifting, indicate the maximum distance to be jacked at calculated lifting loads were given.

each lift point and the maximum relative displacements per- 6. Recommendations for lifting bridge superstructures were

mitted between adjacent lift points and between adjacent gird- presented.

ers . Include any special lift instructions or stage jacking re- 7. Jacks should be sized for a minimum of 1Y2 times the

quirements for high lifts. calculated lifting loads.

Van Lund 101

ACKNOWLEDGMENTS 2. T. J. Upstone and D. Reily. Construction of the Navigation Spans

ofthe Rio Niteroi Bridge, Brazil. Proc., Institution of Civil Engineers,

The author wishes to thank the Washington State Department Part I, Vol. 66, May 1979, pp. 227-246.

3. H. Barker. Quebec Suspended Span Successfully Hung from Can-

of Transportation (WSDOT) for support in preparing this tilevers. Engineering News-Record, Vol. 79, No. 13, September

paper. 27, 1917, pp. 580-589.

The Franklin Falls superstructure lift project was designed 4. D. B. Steinman. Famous Bridges of the World . Random House,

byRaymondT. Shaefer, checked byH. HansonandH. Knoper, New York, 1953, pp. 79-80.

5. G. E. Ramey. Lift System for Raising Continuous Concrete Bridges.

and supervised by G . T. Markich, W. B. Horn, and C. S. Journal of Transportation Engineering , ASCE, Vol. 109, No. 5,

Gloyd, Office of Bridge and Structures, WSDOT. The field Sept. 1983, pp. 733- 746.

engineer was John L. Vatshell, WSDOT. 6. C. Redfield and C. Seim. Pot Bearing Replacements-Two Case

The superstructure lift for the Capitol Boulevard Bridge Studies: Cline Avenue Interchange and I-285/I-85 Interchange.

was designed by the author, checked by Y. A. Mhatre and Joint Sealing and Bearing Systems for Concrete Structures, Vol. 2,

SP-94. American Concrete Institute, Detroit, Mich., 1986, pp.

H. L. Coffman, and supervised by U. C. Vasishth, G. T. 817-823.

Markich, and C. S. Gloyd, Office of Bridge and Structures, 7. J. A. Van Lund et al. Steel Arches Used in Bridge Reconstruction

WSDOT. The field data were provided by Kevin Dayton, over Interstate 5. In Transportation Research Record 1223, TRB,

District 3, WSDOT. National Research Council, Washington , D .C., 1989, pp. 46-53.

8. J. Orr. Planning, Knowledge Keys to Safe Bridge Lifting. Roads

& Bridges, Vol. 26, No. 4, April 1988, pp. 85-87.

9. Structural Lifting Operations. Standard Specifications Construc-

REFERENCES tion and Materials, Section 585. New York State Department of

Transportation, Jan . 1985, pp. 5-108-5-110.

1. A. J. Takala and E. J. Wortman. Erecting the Center Span of the

Fremont Bridge. Civil Engineering, ASCE, Vol. 43, No. 7, July Publication of this paper sponsored by Committee on Construction of

1973, pp. 62-65 . Bridges and Structures.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Highway Structures: Approval Procedures and General Design Section 3 General DesignДокумент32 страницыHighway Structures: Approval Procedures and General Design Section 3 General DesignKekeОценок пока нет

- BD5701Документ11 страницBD5701songkkОценок пока нет

- Highway Structures: Approval Procedures and General Design Section 3 General DesignДокумент32 страницыHighway Structures: Approval Procedures and General Design Section 3 General DesignKekeОценок пока нет

- BD 33-94 Expansion Joints For Use in Highway Bridge DecksДокумент18 страницBD 33-94 Expansion Joints For Use in Highway Bridge DecksBeacher QОценок пока нет

- Fdot bd545 36 RPT PDFДокумент96 страницFdot bd545 36 RPT PDFsamОценок пока нет

- Fdot bd545 36 RPT PDFДокумент96 страницFdot bd545 36 RPT PDFsamОценок пока нет

- BD5701Документ11 страницBD5701songkkОценок пока нет

- Stability of Long Precast GirdersДокумент10 страницStability of Long Precast GirdersAriel D Urieta HОценок пока нет

- Live Load Deflection Limits For Australian Road Bridges: Vic Nechvoglod Mieaust Cpeng and FrankДокумент16 страницLive Load Deflection Limits For Australian Road Bridges: Vic Nechvoglod Mieaust Cpeng and FrankKekeОценок пока нет

- Construction Loads PDFДокумент7 страницConstruction Loads PDFKekeОценок пока нет

- BD 33-94 Expansion Joints For Use in Highway Bridge DecksДокумент18 страницBD 33-94 Expansion Joints For Use in Highway Bridge DecksBeacher QОценок пока нет

- Lateral Instability of Long-Span Prestressed Concrete Beams On Flexible BearingsДокумент4 страницыLateral Instability of Long-Span Prestressed Concrete Beams On Flexible BearingsKekeОценок пока нет

- CAESAS-1 2nd Edition July 2012Документ14 страницCAESAS-1 2nd Edition July 2012annccknarimeОценок пока нет

- Resonance Characteristics of Two-Span Continuous Beam Under Moving High Speed TrainsДокумент16 страницResonance Characteristics of Two-Span Continuous Beam Under Moving High Speed TrainsKekeОценок пока нет

- Introduction To: Autodesk Structural Bridge Design: Andrew Manze, Product Specialist Sales ExecutiveДокумент32 страницыIntroduction To: Autodesk Structural Bridge Design: Andrew Manze, Product Specialist Sales ExecutiveKekeОценок пока нет

- 14 - 04 01 0030Документ7 страниц14 - 04 01 0030KekeОценок пока нет

- 5 5253 01 1 PDFДокумент276 страниц5 5253 01 1 PDFMarekОценок пока нет

- Eurocode 4Документ70 страницEurocode 4leodegarioporral100% (2)

- Cable Supported Bridges Concept and Design 1st EdДокумент412 страницCable Supported Bridges Concept and Design 1st EdKekeОценок пока нет

- Irjet V2i552 PDFДокумент6 страницIrjet V2i552 PDFKekeОценок пока нет

- Welding ConnectionДокумент60 страницWelding ConnectionKekeОценок пока нет

- HA IAN 124-11 Use of Eurocodes For The Design of Highway Structures (July 2011)Документ70 страницHA IAN 124-11 Use of Eurocodes For The Design of Highway Structures (July 2011)sandycastleОценок пока нет

- Is 4651 4 1989Документ13 страницIs 4651 4 1989CiddarthnОценок пока нет

- Is 1161-1998Документ2 страницыIs 1161-1998Nishant GuptaОценок пока нет

- Asshto LRFDДокумент108 страницAsshto LRFDJose Belito Belito ManchaОценок пока нет

- 5624-1993-Specification of Foundation Bolts PDFДокумент9 страниц5624-1993-Specification of Foundation Bolts PDFKekeОценок пока нет

- Aci 2014Документ66 страницAci 2014Shafiullah KhanОценок пока нет

- Sheet Pile Design HandbookДокумент368 страницSheet Pile Design HandbookLandon Mitchell92% (12)

- Ce704 PrestressДокумент91 страницаCe704 PrestressNatarajan Saravanan50% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Cone Crusher CH Series: Rock Processing Chapter DДокумент1 страницаCone Crusher CH Series: Rock Processing Chapter DMortal KombatОценок пока нет

- RCC SLAB 11-12 Rate AnalysisДокумент2 страницыRCC SLAB 11-12 Rate AnalysisRiazahemad B Jagadal0% (1)

- KS - Series - QuadCore - Masterformat - CSI Specification - NAДокумент14 страницKS - Series - QuadCore - Masterformat - CSI Specification - NAHector Danilo Guerrero GОценок пока нет

- Zhejiang A&F University: Undergraduate Graduation Project (Thesis)Документ11 страницZhejiang A&F University: Undergraduate Graduation Project (Thesis)Kadijah ThiamОценок пока нет

- Bill No 4 - External Works ContractДокумент4 страницыBill No 4 - External Works ContractBernard AsamoahОценок пока нет

- Seshadri Memorial LibraryДокумент11 страницSeshadri Memorial LibraryLikitha GirishОценок пока нет

- DESIGN OF MULTISTOREY BUILDING-1.pptx NEWДокумент7 страницDESIGN OF MULTISTOREY BUILDING-1.pptx NEWPavan BurraОценок пока нет

- 42.0 - Pre-Cast Construction v3.0 EnglishДокумент20 страниц42.0 - Pre-Cast Construction v3.0 EnglishchumairabbasОценок пока нет

- Concrete Work Material Prices in Addis AbabaДокумент2 страницыConcrete Work Material Prices in Addis AbabaAbreham Berhan100% (1)

- Shincoil Compression PDFДокумент98 страницShincoil Compression PDFThe Soker YTОценок пока нет

- GB 50010-2010-EnДокумент243 страницыGB 50010-2010-Enrahman fatah60% (5)

- 06 Social Science Civics Key Notes Ch08 Rural LivelihoodsДокумент3 страницы06 Social Science Civics Key Notes Ch08 Rural LivelihoodsNitin PatsariyaОценок пока нет

- Catalog Shear ConnectorДокумент16 страницCatalog Shear ConnectordedeОценок пока нет

- Capslon ProjectДокумент8 страницCapslon ProjectAnkush LilhareОценок пока нет

- Umer Associates Builders, Engineers & Contructors: Abstract of Quantities SR - No Description Unit Earthwork/ExcavationДокумент4 страницыUmer Associates Builders, Engineers & Contructors: Abstract of Quantities SR - No Description Unit Earthwork/ExcavationSaqib Ali100% (1)

- Road Work - Estimation & CostingДокумент22 страницыRoad Work - Estimation & CostingHiren ThakkarОценок пока нет

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Документ5 страницEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingОценок пока нет

- A4 Report Sample Pages 2020Документ5 страницA4 Report Sample Pages 2020121715502003 BOLLEMPALLI BINDU SREE SATYAОценок пока нет

- NOCДокумент11 страницNOCVedam Shanmukha HrushikeshОценок пока нет

- Unit III Set Up Time Reduction, TQM, 5s, VSMДокумент54 страницыUnit III Set Up Time Reduction, TQM, 5s, VSMsaravanan SaranОценок пока нет

- Nptel: Ground Improvement Techniques - Video CourseДокумент2 страницыNptel: Ground Improvement Techniques - Video CourseHarish R BommidiОценок пока нет

- LIT-SUZ-B-EN Channels and Accessories PDFДокумент81 страницаLIT-SUZ-B-EN Channels and Accessories PDFAristo OnanОценок пока нет

- BV STR Steel Warehouse r1Документ10 страницBV STR Steel Warehouse r1Dhika PutraОценок пока нет

- Chemtrend Thermoplastics Purging Compound ProductsДокумент2 страницыChemtrend Thermoplastics Purging Compound Productsbap06Оценок пока нет

- Supply Chain and Materials ManagementДокумент23 страницыSupply Chain and Materials Managementgeorge calОценок пока нет

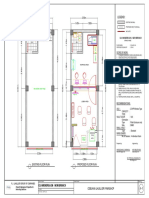

- CLH Mondragon Existing & Proposed LayoutДокумент1 страницаCLH Mondragon Existing & Proposed LayoutLimar SetatraОценок пока нет

- Narayangharh-Mugling HighwayДокумент85 страницNarayangharh-Mugling HighwayRm1262Оценок пока нет

- BOQ UttungaДокумент3 страницыBOQ UttungaSmart ShivaОценок пока нет

- Ireps Tender 3Документ22 страницыIreps Tender 3Project DS EnterpriseОценок пока нет

- 2key Personnel Affidavit PayladoДокумент11 страниц2key Personnel Affidavit PayladoRichard DamiagoОценок пока нет