Академический Документы

Профессиональный Документы

Культура Документы

Essential tools and safety procedures

Загружено:

Jhonny ManjarrezОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Essential tools and safety procedures

Загружено:

Jhonny ManjarrezАвторское право:

Доступные форматы

3.

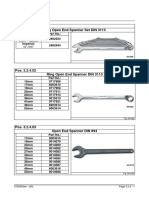

1 TOOLS

3.1 Introduction

3.1.1 Foreword

This Service Manual is designed to familiarize the The Operation and Maintenance Manual must be

user with the machine and its designated use. supplemented by the respective national rules and

regulations for accident prevention and environ-

The documentation relating to the machine is listed mental protection.

according to scope, quantity and language in the

shipping note of the machine or in the covering The Operation and Maintenance Manual must

letter if supplied separately. The Operation and always be available in the operator's cab of the

Maintenance Manual and spare-parts list are machine.

marked with the serial number of the machine.

The Operation and Maintenance Manual must be

On taking receipt of the consignment, please read and put into practice by any person in charge

check that the documentation is complete and in of carrying out work with or on the machine, such

the correct language. as

- operation, including setting-up, troubleshooting

The Operation and Maintenance Manual contains in the course of work, care, evacuation of produc-

important information on how to operate the ma- tion waste and disposal of fuels and consuma-

chine safely, properly and with maximum efficien- bles.

cy. Observing these instructions helps to prevent

hazardous situations, to reduce repair costs and - maintenance (inspection, servicing, repair)

downtimes and to increase the reliability and ser-

vice life of the machine. - transport.

In addition to the Operation and Maintenance

Manual and the mandatory rules and regulations

for accident prevention and environmental protec-

tion in the user's country and at the place where

the machine is to be used, the generally recog-

nized technical rules for safe and proper working

must be observed.

2471309en - (02) Page 3.1 - 1

3.1 TOOLS

3.1.2 Safety

Warnings and symbols Fitted with other attachments, the excavator can

also be used as a special-purpose machine, e.g.

The following signs are used in the manual to des- with a grab. Further detailed information can be

ignate instructions of particular importance: found in the Technical Specifications.

Operating the machine within the limits of the des-

ignated use also involves observing the instruc-

Precautionary rules and measures

tions set out in the Operation and Maintenance

designed to protect the machine

Manual and complying with the inspection and

operator and other persons from

maintenance directives.

life-threatening danger or injuries

and to prevent extensive damage.

Using the excavator or its attach-

ments for purposes other than or

extending beyond those stated

Information and precautionary above, e.g.:

measures designed to prevent

damage to the machine or other for lifting or transporting persons

property. as a working platform

for lifting crane loads without the

equipment being approved for

this purpose

DESIGNATED USE or driving in posts, supports,

sheet-piles etc. without the

The machine has been built in accordance with equipment being approved for

state-of-art standards and the recognized safety this purpose

rules. Nevertheless, its use may constitute a risk to

is considered contrary to the des-

life and limb for the user or third parties or cause

damage to the machine and to other Material ignated use.

property. Improper use may involve a life-

threatening risk for operators or

The machine must be used only in technically per- other personnel or may cause inju-

fect condition in accordance with its designated ry or extensive damage.

use and the instructions set out in the Operation

and Maintenance Manual, and only by safety-

conscious persons who are fully aware of the risks

involved in operating the machine. Any functional The manufacturer/supplier cannot be held liable for

disorders, especially those affecting the safety of any damage resulting from other than the desig-

the machine, should therefore be rectified immedi- nated use. The risk involved in such misuse lies

ately. with the user.

The excavator with backhoe or loading bucket Noise emission specifications are outlined in the

attachment is designed solely for excavating and Operation and Maintenance Manual.

loading:

- excavated soils,

- sand,

- gravel,

- blasted rock,

- ore,

- coal,

and other raw materials.

Page 3.1 - 2 2471309en - (02)

3.1 TOOLS

Organisational measures operation, stop the machine immediately and re-

port the malfunction to the competent authori-

The Operation and Maintenance Manual must ty/person.

always be at hand at the place of use of the ma-

chine, e.g. by stowing them in the place provided Never make any modifications,

for such purpose. additions or conversions which

might affect safety without the

In addition to the operating instructions, observe supplier's approval. This also ap-

and instruct the user In all other generally applica- plies to the installation and ad-

ble legal and other mandatory regulations relevant justment of safety devices and

to accident prevention and environmental protec- valves as well as to welding work

tion. on load-bearing elements.

These compulsory regulations may also deal with

the handling of hazardous substances, issuing

and/or wearing of personal protective equipment or Spare parts must comply with the technical re-

traffic regulations. quirements specified by the manufacturer. Spare

parts from original equipment manufacturers can

The Operation and Maintenance Manual must be be relied on to do so.

supplemented by instructions covering the duties

involved in supervising and notifying special organ- Replace hydraulic hoses within stipulated and

isational features, such as job organisation, work- appropriate intervals, even if no safety-relevant

ing sequences or the personnel entrusted with the defects have been detected.

work.

Adhere to prescribed intervals or those specified in

Personnel entrusted with work on the machine the Operation and Maintenance Manual for routine

must have read the Operation and Maintenance checks and inspections.

Manual and in particular the chapter on safety

before beginning work. Reading the instructions For the execution of maintenance work, tools and

after work has begun is too late. This applies es- workshop equipment adapted to the task on hand

pecially to persons working only occasionally on are absolutely indispensable.

the machine, e.g. during setting up or mainte-

nance. The personnel must be familiar with the location

and operation of fire extinguishers.

Check - at least from time to time - whether the

personnel is carrying out the work in compliance Observe all fire-warning and fire-fighting proce-

with the Operation and Maintenance Manual and dures.

paying attention to risks and safety factors.

For reasons of security, long hair must be tied

back or otherwise secured, garments must be

close-fitting and no jewellery, such as rings, may

be worn. Injury may result from being caught up in

the machinery or from rings catching on moving

parts.

Use protective equipment wherever required by

the circumstances or by law.

Observe all safety instructions and warnings at-

tached to the machine.

See to it that safety instructions and warnings at-

tached to the machine are always complete and

perfectly legible.

In the event of safety-relevant modifications or

changes in the behaviour of the machine during

2471309en - (02) Page 3.1 - 3

3.1 TOOLS

Selection and qualification of person- Safety instructions governing specific

nel - basic responsibilities operational phases

Any work on and with the machine must be exe- Standard operation

cuted by reliable personnel only. Statutory mini-

mum age limits must be observed. Avoid any operational mode that might be prejudi-

cial to safety.

Employ only trained or instructed staff and set out

clearly the individual responsibilities of the person- Before beginning work, familiarize yourself with the

nel for operation, set-up, maintenance and repair. surroundings and circumstances of the site, such

as obstacles in the working area and the bearing

Make sure that only authorized personnel works capacity of the soil.

on or with the machine.

Take the necessary precautions to ensure that the

Define the machine operator's responsibilities giv- machine is in a safe and reliable state.

ing the operator the authority to refuse instructions

by third parties that are contrary to safety. Operate the machine only if all protective and safe-

ty-oriented devices, such as removable safety

Do not allow persons to be trained or instructed or devices, emergency shut-off equipment, sound-

persons taking part in a general training course to proofing elements and exhausts, are in place and

work on or with the machine without being perma- fully functional.

nently supervised by an experienced person.

Check the machine at least once per working shift

Work on the electrical system and equipment of for obvious damage and defects. Report any

the machine must be carried out only by a skilled changes (incl. changes in the machine's working

electrician or by instructed persons under the su- behaviour) to the competent organisation/person

pervision and guidance of a skilled electrician and immediately. If necessary, stop the machine im-

in accordance with electrical engineering rules and mediately and lock it.

regulations.

In the event of malfunction, stop the machine im-

Work on chassis and brake systems must be per- mediately and lock it. Have any defects rectified

formed by skilled personnel only, which has been immediately.

specially trained for such work.

Start the machine from the driver's seat only.

Work on hydraulic systems must be carried out

only by personnel with special knowledge and During start-up and shut-down procedures always

experience of hydraulic equipment. watch the indicators in accordance with the Opera-

tion and Maintenance Manual.

Before setting the machine in motion, make sure

that nobody is at risk.

Before starting work or travelling with the machine,

check that braking, signalling and lighting systems

are fully functional.

Before setting the machine in motion always check

that the accessories have been safely stowed

away.

In conditions of poor visibility and after dark always

switch on the lighting system.

When crossing underpasses and bridges or when

passing under overhead fines always make sure

that there is sufficient clearance.

Page 3.1 - 4 2471309en - (02)

3.1 TOOLS

Always keep a distance from the working face and Special work in conjunction with utili-

from slopes. sation of the machine - maintenance

Avoid any operation that might be a risk to ma- and repairs during operation - disposal

chine stability. of parts and consumables

Never travel across slopes; always keep the work- Observe the adjusting, maintenance and inspec-

ing equipment and the load close to the ground, tion activities and intervals set out in the Operation

especially when travelling downhill. and Maintenance Manual, including information on

the replacement of parts and equipment. These

On sloping terrain always adapt your travelling activities may be executed by skilled personnel

speed to the prevailing ground conditions. only.

Before leaving the driver's seat always secure the Brief operating personnel before beginning special

machine against inadvertent movement and unau- Operation and maintenance work, and appoint a

thorized use. Shut off the engine. person to supervise the activities.

In any work concerning the operation, conversion

or adjustment of the machine and its safety-

oriented devices or any work related to mainte-

nance, inspection and repair, always observe the

start-up and shut-down procedures set out in the

Operation and Maintenance Manual and the infor-

mation on maintenance work.

Ensure that the maintenance area is adequately

secured.

If the machine is completely shut down for mainte-

nance and repair work, it must be secured against

inadvertent starting by:

- removing the ignition key and

- attaching a warning sign.

Carry out maintenance and repair work only if the

machine is positioned on stable and level ground

and has been secured against inadvertent move-

ments.

To avoid the risk of accidents, individual parts and

large assemblies being moved for replacement

purposes should be carefully attached to lifting

tackle and secured. Use only suitable and techni-

cally perfect lifting gear and suspension systems

with adequate lifting capacity. Never work or stand

under suspended loads.

The fastening of loads and the instructing of crane

operators should be entrusted to experienced per-

sons only. The marshaller giving the instructions

must be within sight or sound of the operator.

For carrying out overhead assembly work always

use specially designed or otherwise safety-

oriented ladders and working platforms. Never use

machine parts as a climbing aid.

2471309en - (02) Page 3.1 - 5

3.1 TOOLS

Wear a safety harness when carrying out mainte-

nance work at greater heights. Warning of special dangers

Keep all handles, steps, handrails, platforms, land-

ings and ladders free from dirt, snow and ice.

Electric energy

Clean the machine, especially connections and Use only original fuses with the

threaded unions, of any traces of oil, fuel or pre- specified current rating. Switch off

servatives before carrying out maintenance/repair. the machine immediately if trouble

Never use aggressive detergents. Use lint-free occurs in the electrical system.

cleaning rags.

When working with the machine,

Before cleaning the machine with water, steam jet maintain a safe distance from

(high-pressure cleaning) or detergents, cover or overhead electric lines. If work is

tape up all openings which - for safety and func- to be carried out close to overhead

tional reasons - must be protected against water, lines, the working equipment must

steam or detergent penetration. Special care must be kept well away from them.

be taken with electric motors and switch-gear cab-

inets.

Caution, danger!

Ensure during cleaning of the machine that the

temperature sensors of the fire-warning and fire- Check out the prescribed safety

fighting systems do not come into contact with hot distances.

cleaning agents as this might activate the fire-

fighting system.

If your machine comes into contact

After cleaning remove all covers and tapes applied with a live wire

for that purpose.

After cleaning, examine all fuel, lubricant, brake do not leave the machine

and hydraulic fluid lines for leaks, loose connec- drive the machine out of the hazard

tions, chafe marks and damage. Any defect found zone.

must be rectified without delay.

warn others against approaching

Always tighten any screwed connections that have and touching the machine

been loosened during maintenance and repair.

have the live wire de-energized

Any safety devices removed for set-up, mainte- do not leave the machine until the

nance or repair purposes must be refitted and damaged or contacted line has

checked immediately upon completion of mainte- been safely de-energized.

nance and repair work.

Ensure that all consumables and replaced parts The electrical equipment of ma-

are disposed of safely and with minimum environ- chines is to be inspected and

mental impact. checked at regular intervals. De-

fects such as loose connections or

scorched cables must be rectified

immediately.

Page 3.1 - 6 2471309en - (02)

3.1 TOOLS

Gas, dust, steam and smoke Noise

Operate internal combustion en- During operation, all sounds baf-

gines and fuel-operated heating fles of the machine must be

systems only on adequately venti- closed.

lated premises. Before starting the

Always wear the prescribed ear

machine on enclosed premises,

protectors.

make sure that there is sufficient

ventilation.

Observe the regulations in force at

the respective site.

Carry out welding, flame-cutting

Oil, grease and other chemi-

and grinding work on the machine cal substances

only if this has been expressly When handling oil, grease or other

authorized, as there may be a risk chemical substances, observe the

of explosion and fire. product-related safety regulations.

Before carrying out welding, flame- Be careful when handling hot con-

cutting and grinding Operation, sumables (risk of burning or scald-

clean the machine and its sur- ing).

roundings from dust and other

inflammable substances and make

sure that the premises are ade-

quately ventilated (risk of explo-

sion). Transporting and recommis-

sioning

The machine must be loaded and

transported only in accordance

Hydraulic equipment with the Operation and Mainte-

nance Manual.

Check all lines, hoses and screwed

connections regularly for leaks and Use only appropriate means of

obvious damage. Repair damage transport and lifting gear of ade-

immediately. Splashed oil may quate capacity.

cause injury and fire.

The recommissioning procedure

Depressurize all system sections must be strictly in accordance with

and pressure pipes (hydraulic sys- the Operation and Maintenance

tem) to be removed in accordance Manual.

with the specific instructions for

the unit concerned before carrying

out any repair work.

Hydraulic lines must be laid and

fitted properly. Ensure that no

connections are interchanged. The

fittings, length and quality of the

hoses must comply with the tech-

nical requirements.

2471309en - (02) Page 3.1 - 7

3.1 TOOLS

3.1.3 General

This Service Manual contains information in addi- The Service Manual is not subject to technical

tion to the Operation and Maintenance Manual updates after delivery.

and the Spare Parts List, to familiarize the per- Technical modifications, which are introduced after

sonnel with the designated use, maintenance and delivery of the machine may possibly also be in-

repair of the CAT excavator. corporated in machines which are already in oper-

ation.

The information in the SERVICE MANUAL corre- In this case there will normally be no automatic

sponds to the standard technical specification of update of already supplied Service Manuals.

the machine when it was delivered.

All Caterpillar Global Mining HMS manuals are

All sketches and drawings show principles. They issued in German and then translated. Even a

do not necessarily represent the actual design of good translation may give rise to questions which

the machine and are not to be used for manufac- Caterpillar Global Mining HMS GmbH will be

turing. pleased to answer. Please contact Your local CAT

dealer or Your Caterpillar subsidiary.

Special equipment is normally not considered.

The production of the SERVICE MANUAL was

done in great thoroughness.

If still clarification is required or errors are found

please contact Your local CAT dealer or Your

Caterpillar subsidiary.

Page 3.1 - 8 2471309en - (02)

3.1 TOOLS

Application of Gleitmo 815

3.1.4 Corrosion protection for pins

and bearings Clean off grease, oil, dirt and corrosion protection

agents from pins and bearings using white spirit or

diesel fuel.

Corrosion protection for pins and bearings (bush-

ing and hubs)

Rust patches must be thoroughly removed, if any.

Use Gleitmo 815 anti-corrosive All parts must present a dry, bright metal surface.

agent only.

Apply a thin layer of Gleitmo 815 on pins and all

Other agents are not approved by

bearings using a brush or a spray can. Pin shafts

Caterpillar Global Mining HMS

and bearings must be completely covered by the

GmbH. protective layer.

If the protective layer of a pin already treated with

All pins and bearings (bushings and hubs) of the Gleitmo 815 is damaged, these areas must be

working equipment or in equipment components touched up before fitting the part.

must be treated with Gleitmo 815 anticorrosive

agent before fitting. Fitting and securing of pins

If the pin is too heavy to be fitted manually, apply

Gleitmo 815: Gleitmo 815 at first only at. a quarter of the pin’s

length

permits easy fitting and dismantling

Then position pin by means of a lifting gear ready

for fitting.

protects against rust, oxidation and similar

wear Apply Gleitmo 815 on the remaining length of pin

shaft, fit pin and secure.

prevents seizing and fretting corrosion in

non-moving parts of bearings.

This is achieved by aluminium and copper particles

forming a protective layer on the metal. This layer

removes surface irregularities and does not sweat,

seize or harden.

Part Nos. for Gleitmo 815:

2 764 305

Available from the Caterpillar Global Mining HMS

Spare-Parts Service

2471309en - (02) Page 3.1 - 9

3.1 TOOLS

Page 3.1 - 10 2471309en - (02)

Вам также может понравиться

- Fiat Kobelco Wheel Loader w50-w60-w70 Service ManualДокумент594 страницыFiat Kobelco Wheel Loader w50-w60-w70 Service Manualjony100% (4)

- Risk Assessment - Installation of Ventilation FanДокумент6 страницRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Screws, Fittings, Seals BucyrusДокумент16 страницScrews, Fittings, Seals BucyrusJhonny ManjarrezОценок пока нет

- Essential Skills Manual: Automotive Service TechnicianДокумент255 страницEssential Skills Manual: Automotive Service TechnicianJosé MonteiroОценок пока нет

- Komatsu PC27R-8 Service ManualДокумент196 страницKomatsu PC27R-8 Service Manualirnan Nazri100% (2)

- IG2.GTSC EgyptДокумент18 страницIG2.GTSC EgyptAbdellatef Hossam100% (3)

- Ups Operation ManualДокумент67 страницUps Operation Manualmohamed100% (1)

- New Holland Ec130 Excavator Repair Service Workshop Manual PDFДокумент718 страницNew Holland Ec130 Excavator Repair Service Workshop Manual PDFjose alberto cortez campos100% (6)

- Manual de Diagnostico D3E PDFДокумент72 страницыManual de Diagnostico D3E PDFJosé Luis Contreras Calderón100% (3)

- TW7 TW9 TW10 Service-Manual en PDFДокумент258 страницTW7 TW9 TW10 Service-Manual en PDFbrunosamaeianОценок пока нет

- 3008 1 1-2017 PDFДокумент8 страниц3008 1 1-2017 PDFdavid ricardo barrera pinto0% (12)

- Air Compressor CompairДокумент64 страницыAir Compressor CompairRajesh0% (1)

- Workshop Manual MH6.6 PDFДокумент638 страницWorkshop Manual MH6.6 PDFАлександр ПанкратовОценок пока нет

- Screw Compressor L132 - L250 Speed-Controlled Screw Compressor L160 - L250 RSДокумент56 страницScrew Compressor L132 - L250 Speed-Controlled Screw Compressor L160 - L250 RSfauzy syaeful100% (2)

- ITC 120 Service Manual - 2011-05-18-NeuДокумент210 страницITC 120 Service Manual - 2011-05-18-NeuDisd100% (1)

- 5elevator Installation Manual For Elevator With Machine Room V1.4 - 1Документ113 страниц5elevator Installation Manual For Elevator With Machine Room V1.4 - 1aneesh tОценок пока нет

- Electrical Technician CVДокумент1 страницаElectrical Technician CVAnees Painkal33% (6)

- SM - MH6.6 - MH8.6 - ENДокумент646 страницSM - MH6.6 - MH8.6 - ENGuillermo Guardia GuzmanОценок пока нет

- Fiat Kobelco w80 Wheel Loader Technical HandbookДокумент20 страницFiat Kobelco w80 Wheel Loader Technical Handbookmarion100% (42)

- Roller Sakai R2H-2 Shop ManualДокумент151 страницаRoller Sakai R2H-2 Shop ManualQuang Tuan100% (4)

- New Holland MH 5 6 EN City Plus PDF (001 312)Документ312 страницNew Holland MH 5 6 EN City Plus PDF (001 312)John Ronald Huacho100% (1)

- Operating and Maintenance InstructionsДокумент241 страницаOperating and Maintenance InstructionsTaras KutsykОценок пока нет

- 1 984-EkskavatoraДокумент225 страниц1 984-EkskavatoraericОценок пока нет

- Name: - Grade Level and Section: - Date: - RatingДокумент4 страницыName: - Grade Level and Section: - Date: - RatingJoseph GuintoОценок пока нет

- For Information For Review For Approval For Construction As-BuiltДокумент21 страницаFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçОценок пока нет

- Netzsch 2Документ44 страницыNetzsch 2edI_restrepo_1100% (1)

- N - 20AM, 25AM, 30AM, 36AM, 41AM (ANSI) - JLG - Service - EnglishДокумент84 страницыN - 20AM, 25AM, 30AM, 36AM, 41AM (ANSI) - JLG - Service - Englishandy habibiОценок пока нет

- Screw Air Compressor manual60A-100AДокумент13 страницScrew Air Compressor manual60A-100AInge NecoОценок пока нет

- Parts Catalogue L75-L132Документ72 страницыParts Catalogue L75-L132Ahmad Sarip60% (5)

- Mini Metering ManualДокумент31 страницаMini Metering ManualMansoor AliОценок пока нет

- Manual Bomba NetzschДокумент40 страницManual Bomba Netzschjotapin843352Оценок пока нет

- BA Maxicat-GB Juni 2015 PDFДокумент14 страницBA Maxicat-GB Juni 2015 PDFKheiro BelhadiaОценок пока нет

- 02 Safety GuidlinesДокумент14 страниц02 Safety GuidlinesRIAN NOFENDRIОценок пока нет

- Manual DPG PDFДокумент8 страницManual DPG PDFMangesh MohiteОценок пока нет

- Fischer Ds21 Instruction ManualДокумент16 страницFischer Ds21 Instruction ManualВасилий ЗайцевОценок пока нет

- Fundamental Safety InstructionsДокумент22 страницыFundamental Safety InstructionsMuneeb QayyumОценок пока нет

- 一级反渗透高压泵安装维修保养手册(英文)Документ63 страницы一级反渗透高压泵安装维修保养手册(英文)kamal arabОценок пока нет

- Sideshifter T 151 P2: Operating ManualДокумент13 страницSideshifter T 151 P2: Operating ManualLakiОценок пока нет

- Download-Guide To Install PDFДокумент40 страницDownload-Guide To Install PDFTran Cong HauОценок пока нет

- Fischer Da09 Instruction ManualДокумент8 страницFischer Da09 Instruction Manualwillen munemoОценок пока нет

- User Manual Automatic PFCs PCRJ8 14Документ72 страницыUser Manual Automatic PFCs PCRJ8 14Carlos PrietoОценок пока нет

- Operating and Maintenance InstructionsДокумент238 страницOperating and Maintenance InstructionsTaras KutsykОценок пока нет

- Deu - + - Engl - CD 250 BKДокумент381 страницаDeu - + - Engl - CD 250 BKMohammed El rajyОценок пока нет

- Book13 - Roller Screen RR1439 - P0EBD72 (TR 1-59)Документ59 страницBook13 - Roller Screen RR1439 - P0EBD72 (TR 1-59)Cuộc Sống MàОценок пока нет

- AG193 Skid Resistance Tester User GuideДокумент22 страницыAG193 Skid Resistance Tester User GuideEduardo PradosОценок пока нет

- Service Instruction Provent enДокумент29 страницService Instruction Provent enAndriano LeeОценок пока нет

- ProVent - MANN + HUMMEL ProVent - Oil Separator For Open and Closed Crankcase Ventilation SystemsДокумент29 страницProVent - MANN + HUMMEL ProVent - Oil Separator For Open and Closed Crankcase Ventilation SystemsJosephОценок пока нет

- Wheel Balancer User ManualДокумент29 страницWheel Balancer User ManualBIEXIM AutoОценок пока нет

- CN842 HBДокумент15 страницCN842 HBElif SarıoğluОценок пока нет

- DE38#######KS###: Data Sheet and Instruction Manual DE38 Digital Differential Pressure Transmitter / SwitchДокумент12 страницDE38#######KS###: Data Sheet and Instruction Manual DE38 Digital Differential Pressure Transmitter / SwitchAmirouche BenlakehalОценок пока нет

- Transmisor de Posicion Tp290meДокумент44 страницыTransmisor de Posicion Tp290meTntОценок пока нет

- WB 350Документ27 страницWB 350dionisio emilio reyes jimenezОценок пока нет

- Wheel Balancer User Manual: Pls Read This Manual Before OperationДокумент27 страницWheel Balancer User Manual: Pls Read This Manual Before OperationbabitzinОценок пока нет

- Pneumatic Cylinder Actuator: Operation, Maintenance and Instruction ManualДокумент76 страницPneumatic Cylinder Actuator: Operation, Maintenance and Instruction Manualsuhai miОценок пока нет

- DE38#######KR###: Data Sheet and Instruction Manual DE38 Digital Differential Pressure Transmitter / SwitchДокумент12 страницDE38#######KR###: Data Sheet and Instruction Manual DE38 Digital Differential Pressure Transmitter / SwitchOchoa Para La BandaОценок пока нет

- BR CB956Документ29 страницBR CB956David Eduardo Drew PerezОценок пока нет

- Golz FS400 Operators and Parts ManualДокумент48 страницGolz FS400 Operators and Parts ManualdrmassterОценок пока нет

- Manual 916R-EN-0127 270418 TRAD-1Документ20 страницManual 916R-EN-0127 270418 TRAD-1Alberto Sanchez PamplonaОценок пока нет

- Someks Manual GL1000 CompleteOperatorsManual enДокумент135 страницSomeks Manual GL1000 CompleteOperatorsManual endmitriy.astakhovОценок пока нет

- Installation and Operating Instructions for Suction Units V 250-V 1200Документ20 страницInstallation and Operating Instructions for Suction Units V 250-V 1200edy susalistioОценок пока нет

- Tolva Sand BlastingДокумент34 страницыTolva Sand Blastingalvaro yepes oviedoОценок пока нет

- Peiner Motor Dual Scoop Grabs - MZG - S3 - NG30 - Part03 - ServiceДокумент68 страницPeiner Motor Dual Scoop Grabs - MZG - S3 - NG30 - Part03 - ServiceJan Ernst DepactoОценок пока нет

- Warning: MC FILE NUMBER: 161-0278 Date of Issue: 06/30/78 Revision: J, 12/2007Документ12 страницWarning: MC FILE NUMBER: 161-0278 Date of Issue: 06/30/78 Revision: J, 12/2007Luis Fernando Flores CarrilloОценок пока нет

- Safety StandardsДокумент1 страницаSafety StandardsKumar AОценок пока нет

- TP 301 MeДокумент50 страницTP 301 Mevahid.baha2000Оценок пока нет

- PC110R-1 M Weam000402 PC110R-1 PDFДокумент212 страницPC110R-1 M Weam000402 PC110R-1 PDFap919976Оценок пока нет

- Portable Press 50 KN Capacity: Instruction ManualДокумент12 страницPortable Press 50 KN Capacity: Instruction ManualJorge Armando Ysuiza RomeroОценок пока нет

- Durr VS-Series Dental Suction Unit - Installation and User ManualДокумент22 страницыDurr VS-Series Dental Suction Unit - Installation and User ManualaseelОценок пока нет

- Warning: Sentinel Electric Remote Control SystemДокумент16 страницWarning: Sentinel Electric Remote Control SystemphieroОценок пока нет

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsОт EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsОценок пока нет

- (Dust Suppression SystemДокумент4 страницы(Dust Suppression SystemJhonny ManjarrezОценок пока нет

- 4.2 Travel System: 4.2.1 GeneralДокумент6 страниц4.2 Travel System: 4.2.1 GeneralJhonny ManjarrezОценок пока нет

- 03 02 04-3720693enДокумент6 страниц03 02 04-3720693enJhonny ManjarrezОценок пока нет

- 4.5 Bottom RollersДокумент2 страницы4.5 Bottom RollersJhonny ManjarrezОценок пока нет

- Pos. 3.2.3.01 Electric Connector AssortmentДокумент4 страницыPos. 3.2.3.01 Electric Connector AssortmentJhonny ManjarrezОценок пока нет

- Torque Specification - CAT ENGLISH (SAE)Документ3 страницыTorque Specification - CAT ENGLISH (SAE)Jhonny Manjarrez100% (1)

- Project Engineer Mohamed Moumin HassanДокумент9 страницProject Engineer Mohamed Moumin HassanHussein MohamedОценок пока нет

- Valu TrolДокумент13 страницValu TrolIsrael SalasОценок пока нет

- Christopher ChampagneДокумент4 страницыChristopher ChampagneChristopher ChampagneОценок пока нет

- Electrician Career Research PaperДокумент8 страницElectrician Career Research Paperc9sqf3ke100% (1)

- Electrician of Tomorrow 2023Документ18 страницElectrician of Tomorrow 2023Steven HamiltonОценок пока нет

- Powers and Duties of the Board of Electrical EngineeringДокумент4 страницыPowers and Duties of the Board of Electrical Engineeringangelo macatangayОценок пока нет

- Instructions ReportДокумент2 страницыInstructions Reportapi-593787552Оценок пока нет

- Owner's Manual for Honda EX350 GeneratorДокумент40 страницOwner's Manual for Honda EX350 GeneratorGaby ŠerićОценок пока нет

- MMD-AP0726HP-E MMD-AP0966HP-E: Installation ManualДокумент30 страницMMD-AP0726HP-E MMD-AP0966HP-E: Installation ManualHong HuyОценок пока нет

- English Test FinalДокумент3 страницыEnglish Test FinalIrene TeachОценок пока нет

- Muhammad Usman CVДокумент1 страницаMuhammad Usman CVUsman khiyaleОценок пока нет

- Philips 2Документ2 страницыPhilips 2mcrajpuraОценок пока нет

- Shut Down ProceduresДокумент3 страницыShut Down ProceduresAnand AgrawalОценок пока нет

- Introduction To Basic Electrical Drawings and Test Equipment - RevisedДокумент7 страницIntroduction To Basic Electrical Drawings and Test Equipment - RevisedShiela Mae Pacampara GonzalesОценок пока нет

- Ps Courses-2019 Lowres PDFДокумент216 страницPs Courses-2019 Lowres PDFعبدالغني القباطيОценок пока нет

- Electrician CV Seeks New RoleДокумент17 страницElectrician CV Seeks New RoleKamrul Islam0% (1)

- The Electrical Worker July 2011Документ20 страницThe Electrical Worker July 2011Kathryn R. ThompsonОценок пока нет

- MGE Galaxy 3500 Bypass PanelДокумент20 страницMGE Galaxy 3500 Bypass Panel11111Оценок пока нет

- Hydro One/PWU Joint Electrical Training Committee - Hydro One ApprenticeДокумент3 страницыHydro One/PWU Joint Electrical Training Committee - Hydro One ApprenticeKagitaMikamОценок пока нет

- 9-Engineering Data AnalysisДокумент4 страницы9-Engineering Data AnalysisJevan CalaqueОценок пока нет