Академический Документы

Профессиональный Документы

Культура Документы

Isis Drive

Загружено:

Tms ArnОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Isis Drive

Загружено:

Tms ArnАвторское право:

Доступные форматы

Standard Document Revision / Date

D / 26-Mar-01

REVISIONS

REV DATE BY COMMENTS

A 17-Aug-00 G. Smith Release.

B 19-Oct-00 G. Smith Skipped a revision to catch up with drawings.

C 30-Oct-00 G. Smith Added frame centerline clarification in Sec 1.2.1.

Added suggested press-fit numbers for aluminum alloy cranks in Sec

3.1.2.

Added note to grease the interface between the crank and spindle in Sec

3.1.2.

Added diameter symbols for male shoulder diameter and spline major

diameter on drawing sheet one.

Added diameter symbols for female shoulder ID on drawing sheet two.

Changed minimum spline length in crank to 18.5mm from 19.0mm on

drawing sheet two.

Added thread depth, chamfer dimensions, and flag note three for crank

on drawing sheet three.

D 23-Mar-01 G. Smith Increased flute minor diameter by 0.02mm.

Changed spline tolerance scheme on drawing sheets one and two.

Added crank thread depth and washer thickness tolerances on drawing

sheet three.

Added bolt length requirements on drawing sheet three.

Added drawing sheets six and seven showing use of master gages.

Modified text in Sec 3.1.3, Attachment Bolt discussion.

Changed all references from Master Gages to Reference Tooling.

Copyright 2001, ISIS Drive Standard Committee Page 1 of 10

Standard Document Revision / Date

D / 26-Mar-01

1. Overview

1.1. Background

The International Spline Interface Standard (ISIS Drive) was conceived and

executed for the following two reasons:

1. To create a common bottom bracket/crankset interface that can be freely

shared within the industry. Currently the industry is fragmented and non-

standardized with regard to the bottom bracket/crankset interface. This

standard seeks to eliminate this problem and thus allow the easy and fully

compatible exchange of parts among manufacturers.

2. To eliminate or greatly reduce the current problems associated with bottom

bracket and crankset interfaces. These problems include incompatibility,

lack of crankset position control, insufficient interface strength, and

difficulty in determining interface compatibility/conformance.

This standard consists of two parts: one governing the interface between the crank

and bottom bracket spindle, the other describing a set of standard spindle lengths.

The interface portion defines the ISIS Drive interface geometry, insertion depth and

control, and attachment bolt specifications. The spindle length section defines the

relationship between the bottom bracket and the frame centerline for different

standard spindle lengths, thus ensuring the correct position of the crankset relative

to the frame centerline.

1.2. Definitions

1.2.1. Frame Centerline

The frame centerline is defined as the plane running through the middle of

the bottom bracket shell and perpendicular to the bottom bracket spindle

axis. For the purposes of this document it is assumed this plane coincides

with the plane defined by the bicycle frame and dropouts.

1.2.2. Chainline

Chainline measures the relationship of the front chainrings to the frame

centerline. The chainline of a crankset has a major effect on the shifting

performance of the front derailleur, and thus must be controlled and

measured accurately and consistently. Following are the methods of

measuring chainline for the different types of cranksets in the context of this

standard. Sheet five of the standard drawings graphically define the

following chainline measurements.

Copyright 2001, ISIS Drive Standard Committee Page 2 of 10

Standard Document Revision / Date

D / 26-Mar-01

1.2.2.1. Single Chainring Cranksets:

Chainline is measured as the distance from the frame centerline to the

center of the tooth of the single chainring.

1.2.2.2. Double Chainring Cranksets:

Chainline is measured as follows: A = the distance from the frame

centerline to the crank stop shoulder, Cavg = the average of the distances

from the crank stop shoulder to the center of the tooth of the inner and

outer chainrings. The chainline is then the sum of these two

measurements, A + Cavg (see drawing sheet five).

1.2.2.3. Triple Chainring Cranksets:

Chainline is measured as the distance from the frame centerline to the

center of the tooth of the middle chainring.

2. Design Overview and Advantages

This new interface was designed to eliminate or greatly reduce the problems with

current bottom bracket/crankset interfaces. These problems are identified below with

the new interface’s design features following.

2.1. Current Interface Limitations

2.1.1. No “Standard”

There is currently no “one” standard that defines the geometry and interface

relationship between the crankarm and bottom bracket spindle. This results

in compatibility problems among manufacturers and has severely limited the

ability of bicycle manufacturers and the general public to freely choose

among bottom brackets and cranksets across companies.

2.1.2. Structural Capability

The use of bicycles in extreme conditions has clearly demonstrated the

limited structural capability of the tapered square interface. Common failures

of this interface include spindle strength, crank arm interface deformation,

and low impact strength and fatigue life of both the spindle and crankarm.

2.1.3. Insertion Depth/Chainline

Copyright 2001, ISIS Drive Standard Committee Page 3 of 10

Standard Document Revision / Date

D / 26-Mar-01

Chainrings and front derailleurs have evolved to produce exceptional and

reliable shifting performance under all types of riding conditions.

Unfortunately the degree of shifting performance is greatly influenced by

very small differences in chainline. Only in recent years have some square

bottom brackets utilized a chainline control stop for the drive-side crankarm.

This has certainly been a step in the right direction, but problems still occur

with Q-factor and insertion depth for the non-drive crankarm. Further, only a

few companies currently produce bottom brackets with this drive-side

chainline control stop, thus limiting the compatible bottom bracket choices

available to consumers and manufacturers.

2.1.4. Design/Manufacturing Differences

As mentioned above, no one standard exists for the bottom bracket interface

geometry. Thus, it is impossible for manufacturers to produce bottom

brackets and cranksets that are freely interchangeable, each manufacturer

following a different standard or no standard at all. Further, there is no

reference tooling available for checking the conformance of any bottom

bracket to a known reference, so it becomes difficult to ensure that

manufacturer A’s bottom bracket is interchangeable with manufacturer B’s

bottom bracket. These manufacturing differences produce nothing but

confusion for bottom bracket and crankset manufacturers, customers, and

users.

2.2. ISIS Drive Features

2.2.1. One Open Standard

This standard, by definition, eliminates the compatibility problems among

manufacturers by disclosing a free, common interface for all companies and

individuals to produce parts to.

2.2.2. Structural Capability

When used with appropriately engineered materials, a spline system to

transfer load between the crankset and bottom bracket greatly increases the

strength and durability of the bottom bracket/crankset interface. The ISIS

Drive interface also includes additional support structures to stabilize the

crankarm relative to the spindle. This standard recognizes the different

requirements of spindle materials and riding conditions and therefore

includes two different attachment bolt sizes so engineers can choose the

optimum bolt size for their specific application.

2.2.3. Insertion Depth/Chainline Control

Copyright 2001, ISIS Drive Standard Committee Page 4 of 10

Standard Document Revision / Date

D / 26-Mar-01

A critical component of the interface standard is the use of a crank stop

shoulder on the bottom bracket spindle to ensure consistent axial crankarm

location. These stop shoulders are the datums from which the entire interface

standard is derived.

2.2.4. Standard Reference Tooling

Parts manufactured to this standard may be checked with precision reference

tooling to ensure they meet the standard requirements. Two types of

reference tools are available through the standard home page

(www.isisdrive.com), one a GO/NO-GO gage for checking ISIS Drive

bottom bracket spindles, the other an “Ideal Spindle” reference gage. It is

critically important that all manufacturers producing parts to this standard

use the reference tooling in their quality procedures. The standard committee

will maintain a list of companies who have purchased the reference tools and

proven their products conform to this standard. This Compatibility List will

be available on the standard home page. The Compatibility List’s purpose is

to ease the introduction of the standard by providing a resource of companies

that manufacture parts conforming to the standard and are therefore

compatible with each other.

3. Part A – Bottom Bracket Spindle/Crankarm Interface

The ISIS Drive interface may be easily produced using a variety of manufacturing

methods. The spindle may be machined or formed; the crankarm may be broached

or broached and coined. Major and minor diameters of the interface were chosen to

conform to as much existing tooling as possible, including current crank forging

dies, fixing bolts, and removal tools. The interface was purposely designed not to

be compatible with any other known interface. This was done to ensure that non-

ISIS Drive parts could not be forced onto the ISIS Drive interface.

3.1. Geometry Description

3.1.1. Bottom Bracket Spindle

Sheet one of the standard drawings graphically describes the spindle

interface geometry.

The spindle is a constant outer diameter shaft with 10 evenly spaced flutes

machined or forged into each end. The flute cuts themselves are 6mm in

diameter and inclined at a 1° angle to the spindle axis. In addition to the

tapered flutes, a hard stop is positioned 16mm from the end of the spindle on

Copyright 2001, ISIS Drive Standard Committee Page 5 of 10

Standard Document Revision / Date

D / 26-Mar-01

both sides of the bottom bracket. The spindle is symmetric relative to the

bottom bracket shell centerline.

It is noted on the drawing that the 3.000mm sweep-out distance of the flute

cuts use a 3.0mm minimum radius. These dimensions are requirements if the

male crank-stop shoulder is integrally formed with the spindle. An

alternative to this design is the use of a separate pressed-on crank-stop. If the

pressed-on shoulder configuration is used for the male crank-stop then the

3.000mm sweep-out dimension refers to the pressed-on crank stop rather

than the stop shoulder integrally formed with the spindle. This allows the

flute terminating sweep-out to extend along a greater distance, thus

decreasing the stress concentration present at the flute termination and

possibly improving workability. Figure 1 illustrates an example of this

alternative configuration.

Figure 1. Alternative spindle flute sweep-out configuration.

Spindle bearing assemblies are not part of this standard.

3.1.2. Crankarm

Sheet two of the standard drawings graphically describes the crankarm

interface geometry.

The crank interface maintains a constant minor diameter bore of 17.90-

18.10mm and a constant major diameter of 22.0-22.4mm. The tapered

profile of the crank interface exactly matches that of the spindle (1° inclined

angle relative to the spindle axis) with 2 exceptions: the constant major and

Copyright 2001, ISIS Drive Standard Committee Page 6 of 10

Standard Document Revision / Date

D / 26-Mar-01

minor diameters found in the crank interface as just described, and the offset

of the gage lines to produce the required amount of press-fit between the

parts. The crankarm spline may be created using several manufacturing

methods but the simplest and quickest is through a broaching or broaching

and coining operation.

As mentioned above, the interface requires a certain amount of press-fit

between the crankarm and spindle. The magnitude of press-fit is defined as

the distance between the female shoulder on the crankarm and the male

shoulder on the spindle when the crankarm is pressed onto the spindle by

hand. The shown 4.000 gage-line dimension for section B-B produces a

nominal press-fit of 5.0mm. Note that the distance between the gage-lines

remains constant for both the spindle and crankarm.

Each manufacturer must determine the allowable magnitude of the press-fit

for their specific crankarm. However, to avoid problems with the crankarm

loosening and ensure accurate crankset location, it is recommended that the

crankarm “bottom out” against the male shoulder of the spindle prior to

reaching the full installation torque specified by the manufacturer. When

aluminum alloys are used for the crankarm, a press-fit between 3.0 – 6.0mm

has been found to produce the best results.

The interface was designed to be thoroughly greased between the crankarm

and spindle.

3.1.3. Attachment Bolt

This standard recognizes the different requirements of spindle materials and

riding conditions and therefore includes two different attachment bolt sizes

so engineers can choose the optimum bolt size for their specific application.

The larger of the two bolt sizes uses an M15x1 bolt while the smaller size

uses an M12x1 bolt. With all else being equal, the M12 bolt will create a

stronger spindle due to the increased wall thickness through the spline area.

Both sizes require a minimum thread depth of 12mm in the spindle.

To maintain compatibility among parts with different threads, the attachment

bolt should be supplied with the bottom bracket. Drawing sheet three depicts

standard dimensions for the crank bolt interface to ensure compatibility

between bolts and cranks. The use of a washer between the bolt head and

crankarm is required to prevent excessive deformation of the crankarm. The

outside diameter of the bolt head itself may fall within a fairly wide range,

but the length should fall the dimensions specified. Further, when a washer

is used, the smooth side of the washer is best placed against the crankarm to

prevent the washer from shearing through softer crank materials. A note of

Copyright 2001, ISIS Drive Standard Committee Page 7 of 10

Standard Document Revision / Date

D / 26-Mar-01

caution: it is highly recommended that the length of threads in the spindle

combined with the bolt length itself make it impossible for the bolt to

“bottom-out” in the spindle if a washer is not used. This is to prevent

possible damage to the spindle in the event of mis-installation.

3.2. Standard Reference Tools

Standard reference tooling is available through the ISIS Drive web page

(www.isisdrive.com). This reference tooling allows for the quick and easy

determination of whether a crankarm and bottom bracket spindle meet the ISIS

Drive geometry requirements. The tools can therefore be used to ensure that parts

are manufactured correctly and are interchangeable with each other. All

manufacturers of ISIS Drive parts are strongly urged to use these reference tools in

their quality procedures.

The ISIS Drive web page contains a list of companies that have purchased

reference tooling and proven they can produce products that are compatible with

the standard geometry. These companies are then given the right to use the ISIS

Drive mark on their products, thus providing assurance that their products conform

to the ISIS Drive geometry. Use of the ISIS Drive mark in no way guarantees

structural integrity of components, only geometric compatibility with the ISIS

Drive standard. Companies who wish to be included in the Compatibility List can

find information about reference tool purchasing, part geometry validation, and

ISIS Drive trademark licensing on the ISIS Drive web page (www.isisdrive.com).

Trademark licensing and legal issues are also discussed in Section 5 of this

document.

4. Part B – Positional Relationships

In order for the insertion depth/chainline control feature of this standard to be

effective, dimensions for spindle lengths and distance from spindle crank-stop to

frame centerline must be defined. This section defines these dimensions for a set of

standard spindle lengths and therefore ensures the consistent location of the

crankarm from the frame centerline for a given spindle length. Sheet four of the

standard drawings defines these dimensions.

4.1. Spindle Lengths

Four standard spindle lengths are currently defined in this standard. The lengths

and their recommended purposes are shown in Table 1 below. All spindles are

symmetric relative to the bottom bracket shell centerline. The spindle designation

refers to the nominal distance between the crank-stops; add 32mm to the spindle

designation for the nominal overall spindle length.

Copyright 2001, ISIS Drive Standard Committee Page 8 of 10

Standard Document Revision / Date

D / 26-Mar-01

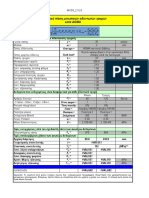

Table 1. Standard spindle designations, lengths, and recommended purposes.

Spindle Designation Spindle Length Recommended Purpose

76 108mm Narrow Mountain, Double Road

81 113mm Standard Mountain

86 118mm Wide Mountain, Triple Road

96 128mm Downhill Specific

These spindle lengths were chosen for the following reasons:

• With the exception of the downhill bottom bracket, each spindle length

difference is a multiple of 5mm, or 2.5mm on each side. This allows a

single crankset to produce two different chainlines, differing by 2.5mm,

simply through the use of a different bottom bracket.

• The 10mm difference between a 76 and 86 spindle is sufficient to allow one

crankset to perform the function of either a road double or road triple

simply by adding a chainring and switching spindles.

• The 15mm difference (7.5mm on each side) between the 81 and 96 spindles

is roughly the same distance as typically exists between a middle and large

chainring on a mountain bike crankset. When using some chain-guides,

downhill bicycles require a large chainring be placed in the middle

chainring position. To allow clearance between the bicycle frame and large

chainring, this wider spindle places a crankset further from the frame

centerline such that the middle chainring position ends up where the large

chainring would normally be. Note that even with the many possibilities of

downhill chain-guide set-ups, this spindle is still symmetric about the

bottom bracket shell centerline.

4.2. Information Disclosure Recommendations

Disclosure of the following specifications is recommended to allow users to make

informed decisions when choosing among cranksets and bottom brackets:

• Recommended bottom bracket spindle designation for a given chainline.

• Distance from the frame centerline to the inside of each chainring.

• ‘I’ Factor.

• ‘Q’ Factor.

5. Trademark Licensing and Legal Issues

ISIS Drive and the ISIS Drive logo are pending trademarks in the United States of

America. Manufacturers wishing make ISIS Drive compatible products and use the ISIS

Drive mark may do so after completing the following:

Copyright 2001, ISIS Drive Standard Committee Page 9 of 10

Standard Document Revision / Date

D / 26-Mar-01

• Purchasing reference tools for their product and agreeing to actively use these

tools as part of their quality procedures.

• Providing at least one sample of their product to the ISIS Drive standard

committee that conforms to the geometry requirements set forth in this

standard.

• Agreeing to and signing the license agreement that then gives them the legal

right to use the ISIS Drive mark on the certified product.

A copy of the license agreement may be obtained by contacting the ISIS Drive

committee through the ISIS Drive web site (www.isisdrive.com). Please note that this

license entails no fees or royalties, but simply requires that the ISIS Drive mark be used

only on products conforming to the ISIS Drive geometry and indemnifies the ISIS

Drive standard committee, its members and companies, from any liability arising from

the ISIS Drive geometry as used in the product.

The ISIS Drive standard discloses geometry only. Each company manufacturing parts to

this standard is responsible for their own engineering to ensure their products are safe

for use in their intended application. This standard makes no claims as to strength or

safety of products manufactured to conform to the ISIS Drive geometry. Geometry

alone has no strength until associated with a material and manufacturing process. The

ISIS Drive standard discloses no information regarding appropriate materials for use

with the geometry; this is left to the engineers associated with manufacturers producing

ISIS Drive products.

6. Contact Information

Further information regarding this standard as well as updates to the standard and

ISIS Drive artwork may be obtained from the ISIS Drive web page:

www.isisdrive.com

Copyright 2001, ISIS Drive Standard Committee Page 10 of 10

THE INFORMATION CONTAINED HEREIN IS INTENDED TO BE

PUBLIC DOMAIN. HOWEVER, CHANGES TO THE

THE DRAWINGS HERE ARE NOT PRODUCT DRAWINGS. THEY ARE TO REVISIONS

SPECIFICATIONS CONTAINED HEREIN MAY BE PERFORMED BE USED AS REFERENCE DOCUMENTS FOR THE DETERMINATION OF REV. DATE CHANGES

ONLY BY THE ISSUER OF THIS PRINT. PRODUCT NOT IN FINAL PRODUCTION SPECIFICATIONS. THESE FINAL SPECIFICATIONS

COMPLIANCE TO THE SPECIFICATIONS CONTAINED HEREIN A 9/5/00 CHANGES IS ITALICS, PRE LOAD

WILL BE CONSIDERED INCOMPATABLE WITH THIS ARE THE RESPONSIBILITY OF THE MANUFACTURER WHO INTENDS WORDING, GAUGE LINES ALL RELATIVE

STANDARDIZED DESIGN. TO COMPLY WITH THIS GEOMETRY. TOSTOP

B 9/12/00 NOCHANGE

C 10/16/00 NOCHANGE

D 2/3/01 INCREASE FLUTE MINOR Ø 0.02MM, BOX

DIMSTO LOCATEGAGE PLANES

UNLESS OTHERWISE

SPECIFIED:

DIMENSIONS IN MILLIMETERS

ISIS DRIVE

EDGE BREAK R 0.10/0.30MM DRAWN DATE NAME

ALL DIAMETERS CONCENTRIC

TO SPINDLEBEARING RACES

±0.30 MM

MOROURKE 10-16-00

CHECKED DATE

SPINDLE

REMOVE ALL BURRS PN REV

ALL DIMENSIONS AFTER

FINISHING

APPROVED DATE

D

RELEASED DATE SIZE SCALE SHEET OF

A 1.6:1 1 7

THE INFORMATION CONTAINED HEREIN IS INTENDED TO BE

PUBLIC DOMAIN. HOWEVER, CHANGES TO THE

THE DRAWINGS HERE ARE NOT PRODUCT DRAWINGS. THEY ARE TO REVISIONS

SPECIFICATIONS CONTAINED HEREIN MAY BE PERFORMED BE USED AS REFERENCE DOCUMENTS FOR THE DETERMINATION OF REV. DATE CHANGES

ONLY BY THE ISSUER OF THIS PRINT. PRODUCT NOT IN FINAL PRODUCTION SPECIFICATIONS. THESE FINAL SPECIFICATIONS

COMPLIANCE TO THE SPECIFICATIONS CONTAINED HEREIN A 9/5/00 CHANGE FLUTE CUT DIAMETER. FIX NOTE

WILL BE CONSIDERED INCOMPATABLE WITH THIS ARE THE RESPONSIBILITY OF THE MANUFACTURER WHO INTENDS 2. ADD "EQUALLY SPACED"

STANDARDIZED DESIGN. TO COMPLY WITH THIS GEOMETRY. B 9/12/00 REGENERATE PROFILESTO REFLECT 5.90

NOMINAL CRANK FLUTES

C 10/10/00 18.5MM MIN FLUTE DEPTH FROM19MM

D 3/15/01 BOXDIM CHANGES TO GAUGEPLANE

LOCATIONS, INCREASE FLUTE MINOR Ø

.02MM, CHANGES IN ITALICS

UNLESS OTHERWISE

SPECIFIED:

DIMENSIONS IN MILLIMETERS

ISIS DRIVE

EDGE BREAK R 0.10/0.30MM DRAWN DATE NAME

ALL DIAMETERS CONCENTRIC

TO SPINDLEBEARING RACES

±0.30 MM

MOROURKE 10-16-00

CHECKED DATE

CRANK

REMOVE ALL BURRS PN REV

ALL DIMENSIONS AFTER

FINISHING

APPROVED DATE

D

RELEASED DATE SIZE SCALE SHEET OF

A 1.6:1 2 7

THE INFORMATION CONTAINED HEREIN IS INTENDED TO BE

PUBLIC DOMAIN. HOWEVER, CHANGES TO THE

THE DRAWINGS HERE ARE NOT PRODUCT DRAWINGS. THEY ARE TO REVISIONS

SPECIFICATIONS CONTAINED HEREIN MAY BE PERFORMED BE USED AS REFERENCE DOCUMENTS FOR THE DETERMINATION OF REV. DATE CHANGES

ONLY BY THE ISSUER OF THIS PRINT. PRODUCT NOT IN FINAL PRODUCTION SPECIFICATIONS. THESE FINAL SPECIFICATIONS

COMPLIANCE TO THE SPECIFICATIONS CONTAINED HEREIN A 9/5/00 CHANGES IN ITALICS

WILL BE CONSIDERED INCOMPATABLE WITH THIS ARE THE RESPONSIBILITY OF THE MANUFACTURER WHO INTENDS B 9/12/00 NO CHANGES

STANDARDIZED DESIGN. TO COMPLY WITH THIS GEOMETRY. C 10/16/00 ADDED MIN CHAMFER, WASHER

THICKNESS, FIXED PROFILE, ADDED

8.5MM THREAD DEPTH

D 3/15/01 REMOVE NOTE 1, ADD DIMSTO BOLT

LENGTH, TOLERANCE CRANK THREAD

DEPTH AND WASHER THICKNESS

UNLESS OTHERWISE

SPECIFIED:

DIMENSIONS IN MILLIMETERS

ISIS DRIVE

EDGE BREAK R 0.10/0.30MM DRAWN DATE NAME

ALL DIAMETERS CONCENTRIC MOROURKE 10-16-00

TO SPINDLEBEARING RACES

±0.30 MM CHECKED DATE CRANK AND BOLT

REMOVE ALL BURRS PN REV

ALL DIMENSIONS AFTER

FINISHING

APPROVED DATE

D

RELEASED DATE SIZE SCALE SHEET OF

A 1:1 3 7

THE INFORMATION CONTAINED HEREIN IS INTENDED TO BE

PUBLIC DOMAIN. HOWEVER, CHANGES TO THE

THE DRAWINGS HERE ARE NOT PRODUCT DRAWINGS. THEY ARE TO REVISIONS

SPECIFICATIONS CONTAINED HEREIN MAY BE PERFORMED BE USED AS REFERENCE DOCUMENTS FOR THE DETERMINATION OF REV. DATE CHANGES

ONLY BY THE ISSUER OF THIS PRINT. PRODUCT NOT IN FINAL PRODUCTION SPECIFICATIONS. THESE FINAL SPECIFICATIONS 9/5/00

COMPLIANCE TO THE SPECIFICATIONS CONTAINED HEREIN

A NO CHANGES

WILL BE CONSIDERED INCOMPATABLE WITH THIS ARE THE RESPONSIBILITY OF THE MANUFACTURER WHO INTENDS B 9/12/00 NO CHANGES

STANDARDIZED DESIGN. 10/16/00 NO CHANGES

TO COMPLY WITH THIS GEOMETRY. C

D 3/15/01 NO CHANGES

UNLESS OTHERWISE

SPECIFIED:

DIMENSIONS IN MILLIMETERS

ISIS DRIVE

EDGE BREAK R 0.10/0.30MM DRAWN DATE NAME

ALL DIAMETERS CONCENTRIC

TO SPINDLEBEARING RACES

±0.30 MM

MOROURKE 10/16-00

CHECKED DATE

BB DESIGNATION

REMOVE ALL BURRS PN REV

ALL DIMENSIONS AFTER

FINISHING

APPROVED DATE

D

RELEASED DATE SIZE SCALE SHEET OF

A 1:1 4 7

THE INFORMATION CONTAINED HEREIN IS INTENDED TO BE

PUBLIC DOMAIN. HOWEVER, CHANGES TO THE

THE DRAWINGS HERE ARE NOT PRODUCT DRAWINGS. THEY ARE TO REVISIONS

SPECIFICATIONS CONTAINED HEREIN MAY BE PERFORMED BE USED AS REFERENCE DOCUMENTS FOR THE DETERMINATION OF REV. DATE CHANGES

ONLY BY THE ISSUER OF THIS PRINT. PRODUCT NOT IN FINAL PRODUCTION SPECIFICATIONS. THESE FINAL SPECIFICATIONS

COMPLIANCE TO THE SPECIFICATIONS CONTAINED HEREIN A 9/5/00 CHANGES IN ITALICS

WILL BE CONSIDERED INCOMPATABLE WITH THIS ARE THE RESPONSIBILITY OF THE MANUFACTURER WHO INTENDS B 9/12/00 NO CHANGE

STANDARDIZED DESIGN. TO COMPLY WITH THIS GEOMETRY. C 10/16/00 NO CHANGE

D 3/15/01 NO CHANGE

UNLESS OTHERWISE

SPECIFIED:

DIMENSIONS IN MILLIMETERS

ISIS DRIVE

EDGE BREAK R 0.10/0.30MM DRAWN DATE NAME

ALL DIAMETERS CONCENTRIC

TO SPINDLEBEARING RACES

±0.30 MM

MOROURKE 10-16-00

CHECKED DATE CHAINLINE

REMOVE ALL BURRS PN REV

ALL DIMENSIONS AFTER

FINISHING

APPROVED DATE

D

RELEASED DATE SIZE SCALE SHEET OF

A 1:4 5 7

THE INFORMATION CONTAINED HEREIN IS INTENDED TO BE

PUBLIC DOMAIN. HOWEVER, CHANGES TO THE

THE DRAWINGS HERE ARE NOT PRODUCT DRAWINGS. THEY ARE TO REVISIONS

SPECIFICATIONS CONTAINED HEREIN MAY BE PERFORMED BE USED AS REFERENCE DOCUMENTS FOR THE DETERMINATION OF REV. DATE CHANGES

ONLY BY THE ISSUER OF THIS PRINT. PRODUCT NOT IN FINAL PRODUCTION SPECIFICATIONS. THESE FINAL SPECIFICATIONS

COMPLIANCE TO THE SPECIFICATIONS CONTAINED HEREIN D 3/20/01 RELEASE

WILL BE CONSIDERED INCOMPATABLE WITH THIS ARE THE RESPONSIBILITY OF THE MANUFACTURER WHO INTENDS

STANDARDIZED DESIGN.

TO COMPLY WITH THIS GEOMETRY.

UNLESS OTHERWISE

SPECIFIED:

DIMENSIONS IN MILLIMETERS

ISIS DRIVE

EDGE BREAK R 0.10/0.30MM DRAWN DATE NAME

ALL DIAMETERS CONCENTRIC

TO SPINDLE BEARING RACES

±0.30 MM

MOROURKE 10-16-00

CHECKED DATE

PN

IDEAL SPINDLE USE REV

REMOVE ALL BURRS

ALL DIMENSIONS AFTER

FINISHING

APPROVED DATE

D

RELEASED DATE SIZE SCALE SHEET OF

A 1:1 6 7

THE INFORMATION CONTAINED HEREIN IS INTENDED TO BE

PUBLIC DOMAIN. HOWEVER, CHANGES TO THE

THE DRAWINGS HERE ARE NOT PRODUCT DRAWINGS. THEY ARE TO REVISIONS

SPECIFICATIONS CONTAINED HEREIN MAY BE PERFORMED BE USED AS REFERENCE DOCUMENTS FOR THE DETERMINATION OF REV. DATE CHANGES

ONLY BY THE ISSUER OF THIS PRINT. PRODUCT NOT IN FINAL PRODUCTION SPECIFICATIONS. THESE FINAL SPECIFICATIONS

COMPLIANCE TO THE SPECIFICATIONS CONTAINED HEREIN D 3/20/01 RELEASE

WILL BE CONSIDERED INCOMPATABLE WITH THIS ARE THE RESPONSIBILITY OF THE MANUFACTURER WHO INTENDS

STANDARDIZED DESIGN. TO COMPLY WITH THIS GEOMETRY.

UNLESS OTHERWISE

SPECIFIED:

DIMENSIONS IN MILLIMETERS

ISIS DRIVE

EDGE BREAK R 0.10/0.30MM DRAWN DATE NAME

ALL DIAMETERS CONCENTRIC

TO SPINDLEBEARING RACES

±0.30 MM

MOROURKE 10-16-00

CHECKED DATE SPINDLE GAUGE USE

REMOVE ALL BURRS PN REV

ALL DIMENSIONS AFTER

FINISHING

APPROVED DATE

D

RELEASED DATE SIZE SCALE SHEET OF

A 1.25:1 7 7

Вам также может понравиться

- A Comparison of The AGMA Gear Design Stresses, The LewisДокумент41 страницаA Comparison of The AGMA Gear Design Stresses, The LewisJulendra AriatedjaОценок пока нет

- Agma 2002 b88Документ48 страницAgma 2002 b88Nursena SEVİNÇОценок пока нет

- Dynamic Factor FormulaeДокумент15 страницDynamic Factor FormulaeShubham More0% (1)

- Agma 914 b04Документ45 страницAgma 914 b04Nursena SEVİNÇОценок пока нет

- Design of Bearings & Miscellaneous ElementsДокумент14 страницDesign of Bearings & Miscellaneous ElementsjvanandhОценок пока нет

- ANSI Replaces AGMA Gear Accuracy StandardsДокумент5 страницANSI Replaces AGMA Gear Accuracy StandardsCarlosQuelartОценок пока нет

- Iso 13282013Документ15 страницIso 13282013Kailas KatharОценок пока нет

- Kisssoft Tut 003 E KeyДокумент11 страницKisssoft Tut 003 E KeyJorge Ronald Cabrera ÑaupaОценок пока нет

- A Kinematic Analysis of Meshing Polymer Gear TeethДокумент16 страницA Kinematic Analysis of Meshing Polymer Gear TeethsandeepОценок пока нет

- Agma 927 A01pdfДокумент38 страницAgma 927 A01pdfNursena SEVİNÇОценок пока нет

- DIN-58405-3-1972 Spur Gear Drives For Fine Mechanics - Indication in Drawings, Examples For Calculation PDFДокумент20 страницDIN-58405-3-1972 Spur Gear Drives For Fine Mechanics - Indication in Drawings, Examples For Calculation PDFthaivinhtuyОценок пока нет

- GB/T 10095.2-2008 Cylindrical Gears Accuracy StandardДокумент5 страницGB/T 10095.2-2008 Cylindrical Gears Accuracy StandardtaghdirimОценок пока нет

- KISSsoft Tutorial - Cylindrical Gear Fine SizingДокумент20 страницKISSsoft Tutorial - Cylindrical Gear Fine SizingLuis TestaОценок пока нет

- TechnicalData KGSTOCKGEARS PDFДокумент171 страницаTechnicalData KGSTOCKGEARS PDFChetan PrajapatiОценок пока нет

- Cone Tolerance PDFДокумент21 страницаCone Tolerance PDFPopoaia MarianОценок пока нет

- Design and Analysis Procedures For Shafts and Splines: Paul E. BurkeДокумент21 страницаDesign and Analysis Procedures For Shafts and Splines: Paul E. BurkeBalasrinivasan Murugan100% (3)

- Cycloid Drive - Replaced by Planocentric Involute GearingДокумент6 страницCycloid Drive - Replaced by Planocentric Involute GearingMax GrandeОценок пока нет

- Agma 906 A94Документ22 страницыAgma 906 A94Nursena SEVİNÇОценок пока нет

- Σχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAДокумент1 страницаΣχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAkstayroskОценок пока нет

- IS 3428 Relief GrooveДокумент12 страницIS 3428 Relief Grooveshunmu_scribОценок пока нет

- Accuracy Standards: and ISOIДокумент4 страницыAccuracy Standards: and ISOIali_yy2003100% (1)

- A Crowning Achievement For Automotive ApplicationsДокумент10 страницA Crowning Achievement For Automotive ApplicationsCan CemreОценок пока нет

- Straight Sided Serrations SpecificationsДокумент2 страницыStraight Sided Serrations SpecificationsMarcel Dandaro100% (1)

- ISO Standardisation of Bevel Gears: Overview and Ideas On Method A"Документ28 страницISO Standardisation of Bevel Gears: Overview and Ideas On Method A"vincemugnaioОценок пока нет

- Bac Cau Din Iso 12240.1Документ67 страницBac Cau Din Iso 12240.1Nguyen hanhОценок пока нет

- Tseng 2004 Mechanism and Machine TheoryДокумент15 страницTseng 2004 Mechanism and Machine TheoryKhanh VqОценок пока нет

- Contact Stress Analysis of Spur Gear Teeth Pair PDFДокумент6 страницContact Stress Analysis of Spur Gear Teeth Pair PDFCan CemreОценок пока нет

- Parallel Key Calculation According To DIN 6892Документ21 страницаParallel Key Calculation According To DIN 6892zahirshah1436923Оценок пока нет

- Calculation of Load Capacity of Spur and Helical Gears - Calculation of Tooth Bending StrengthДокумент2 страницыCalculation of Load Capacity of Spur and Helical Gears - Calculation of Tooth Bending StrengthКирилл0% (1)

- AGMA Gear Documents from 1988-1993Документ13 страницAGMA Gear Documents from 1988-1993Rizky MahendraОценок пока нет

- Agma 930-A05Документ86 страницAgma 930-A05Mehul Bansal100% (1)

- Agma Grade 5 Smpe Grade 10Документ25 страницAgma Grade 5 Smpe Grade 10er_winwibowoОценок пока нет

- Optimal Design of IPM Motors With Different Cooling Systems and WДокумент18 страницOptimal Design of IPM Motors With Different Cooling Systems and WjalilemadiОценок пока нет

- Cálculo de EngranajesДокумент18 страницCálculo de EngranajesJose Luis HernandezОценок пока нет

- Bonfiglioli Geared MotorДокумент584 страницыBonfiglioli Geared MotorProdip SarkarОценок пока нет

- Plastic Spur Gear Pair FailureДокумент14 страницPlastic Spur Gear Pair FailureDan Wolf100% (1)

- Ansi Agma 2000 A88Документ4 страницыAnsi Agma 2000 A88vijaykumarn0% (1)

- Din 5480-2 - 2006-05Документ40 страницDin 5480-2 - 2006-05Luiz Munari100% (2)

- Home Search Collections Journals About Contact Us My IopscienceДокумент8 страницHome Search Collections Journals About Contact Us My IopscienceCan CemreОценок пока нет

- Iso TC 60 SC 1WG 7 N 308Документ76 страницIso TC 60 SC 1WG 7 N 308Sandip PatelОценок пока нет

- Load Sharing Methods of Backstops 2004 01Документ10 страницLoad Sharing Methods of Backstops 2004 01Ruben SalgadoОценок пока нет

- The Application of Bevel GearsДокумент6 страницThe Application of Bevel GearsPrasanth ThiagarajanОценок пока нет

- Translated Copy of Translated Copy of DIN 58405-1Документ30 страницTranslated Copy of Translated Copy of DIN 58405-1venkatОценок пока нет

- Semi-Topping Shaper CuttersДокумент4 страницыSemi-Topping Shaper CuttersalemarlonstosОценок пока нет

- American Gear ManufacturersДокумент20 страницAmerican Gear Manufacturerssimone.castagnetti100% (1)

- ANL TruckДокумент162 страницыANL Truckmail_krkОценок пока нет

- Nasa RP 1152 PDFДокумент76 страницNasa RP 1152 PDFPaul WallsОценок пока нет

- Gear Grinding: SoftwareДокумент68 страницGear Grinding: SoftwareTungОценок пока нет

- R.drago Publications ListДокумент14 страницR.drago Publications Listidontlikeebooks100% (1)

- Diseños de EngranajesДокумент26 страницDiseños de EngranajesTarja Turunen MexicoОценок пока нет

- Influence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationДокумент7 страницInfluence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationsamanaveenОценок пока нет

- Bearing Load Rating GuidelineДокумент4 страницыBearing Load Rating GuidelineAnand kumarОценок пока нет

- Catalogo AgmaДокумент52 страницыCatalogo AgmaNursena SEVİNÇОценок пока нет

- Characteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesДокумент14 страницCharacteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesJohn FelemegkasОценок пока нет

- A Comparison of Current AGMA ISO API Gear Rating Methods PDFДокумент84 страницыA Comparison of Current AGMA ISO API Gear Rating Methods PDFNARENDRASINH PARMARОценок пока нет

- Loads Acting On Crane Structure During TravelДокумент11 страницLoads Acting On Crane Structure During Travelaiyubi2Оценок пока нет

- Structural Health MonitoringОт EverandStructural Health MonitoringDaniel BalageasОценок пока нет

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987От EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonОценок пока нет

- Nordel Pulley Tambor FalhaДокумент17 страницNordel Pulley Tambor FalhaJoseph SilvaОценок пока нет

- Zw3ds Application in Shoemaking IndustryДокумент11 страницZw3ds Application in Shoemaking IndustryTms ArnОценок пока нет

- Enjoy Flexible Product Design With zw3dДокумент11 страницEnjoy Flexible Product Design With zw3dTms ArnОценок пока нет

- Chapters 1 3 Solid Edge Synchronous Technology Ebook PDFДокумент43 страницыChapters 1 3 Solid Edge Synchronous Technology Ebook PDFTms ArnОценок пока нет

- Master ModelhobДокумент1 страницаMaster ModelhobTms Arn100% (1)

- Scientific Calculator Model Instruction ManualДокумент51 страницаScientific Calculator Model Instruction ManualTms ArnОценок пока нет

- Turner 250Документ41 страницаTurner 250Tms ArnОценок пока нет

- General Machinist HandbookДокумент320 страницGeneral Machinist HandbookHakuna Matata100% (7)

- Cholesterol Mortality Chart PDFДокумент1 страницаCholesterol Mortality Chart PDFTms Arn100% (1)

- Mini Lathe Users GuideДокумент35 страницMini Lathe Users GuidequirxiОценок пока нет

- Cholesterol Mortality ChartДокумент1 страницаCholesterol Mortality ChartTms ArnОценок пока нет

- Vivax Assist 2016 Product CatalogueДокумент24 страницыVivax Assist 2016 Product CatalogueTms ArnОценок пока нет

- Grammar9practise PDFДокумент2 страницыGrammar9practise PDFTms ArnОценок пока нет

- Open-sided RAIN CAP (8.4Документ1 страницаOpen-sided RAIN CAP (8.4Tms ArnОценок пока нет

- iHUDforRFactor Install ManualДокумент14 страницiHUDforRFactor Install ManualTms ArnОценок пока нет

- GearCalc ManualДокумент127 страницGearCalc ManualTms ArnОценок пока нет

- Workshop Manual MPIДокумент372 страницыWorkshop Manual MPIPhil ProfiliОценок пока нет

- R Factor ManualДокумент80 страницR Factor ManualFabio FilippinОценок пока нет

- Cutting ToolsДокумент143 страницыCutting ToolsTone RatanalertОценок пока нет

- ZF Transmission Service Manual ExplainedДокумент25 страницZF Transmission Service Manual ExplainedJose Rafael Ramos ChiquilloОценок пока нет

- Reeeeeeeeeeeeeport 2Документ27 страницReeeeeeeeeeeeeport 2Mahantesh ValiОценок пока нет

- GN - 8-02 - Protective Treatment of FastenersДокумент5 страницGN - 8-02 - Protective Treatment of Fastenersachus2000Оценок пока нет

- Mailstar 775Документ399 страницMailstar 775PostmasterstestОценок пока нет

- Huck C50LДокумент4 страницыHuck C50LchristianОценок пока нет

- Probset 1Документ3 страницыProbset 1John Zedrick MacaisaОценок пока нет

- Gates Tb035 enДокумент6 страницGates Tb035 enMLentingОценок пока нет

- Wireless Heat Cost AllocatorsДокумент8 страницWireless Heat Cost AllocatorsCrni202Оценок пока нет

- Sliding Gate Operator Manual (WJKMB201&202)Документ13 страницSliding Gate Operator Manual (WJKMB201&202)Ricardo FajardoОценок пока нет

- Section 6 - Assembly ManualДокумент170 страницSection 6 - Assembly ManualLuis Torres100% (1)

- Construction Estimate for Medical CollegeДокумент1 страницаConstruction Estimate for Medical CollegeNarayan BhosekarОценок пока нет

- A90.1 Safety Standard For Belt ManliftДокумент36 страницA90.1 Safety Standard For Belt ManliftYadi KusmayadiОценок пока нет

- Bucket Control Lever - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsДокумент3 страницыBucket Control Lever - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsashraf elsayedОценок пока нет

- Ubom Ahc 3 - 21Документ36 страницUbom Ahc 3 - 21Victor PATIÑOОценок пока нет

- E3D-V4 Assembly ManualДокумент3 страницыE3D-V4 Assembly Manuale3donline100% (1)

- SogavДокумент39 страницSogavGalih YugaОценок пока нет

- Transfer Gearbox AssemblyEW145BДокумент101 страницаTransfer Gearbox AssemblyEW145Bសុខ ប៊ុនណារ៉ង់Оценок пока нет

- Sheet: Reducing Falls in Construction: Safe Use of Extension LaddersДокумент3 страницыSheet: Reducing Falls in Construction: Safe Use of Extension LaddersjefhdezОценок пока нет

- Product Data: Heradesign Superfi NeДокумент6 страницProduct Data: Heradesign Superfi NeP. IulianОценок пока нет

- Vedanta Limited Integrated Field Plan Inspection ReportsДокумент23 страницыVedanta Limited Integrated Field Plan Inspection ReportsPRAKASH PANDEYОценок пока нет

- Series 1204: Orange Research IncДокумент3 страницыSeries 1204: Orange Research IncWilson VelásquezОценок пока нет

- Capstan Winch PDFДокумент54 страницыCapstan Winch PDFChristian BourkeОценок пока нет

- Awning Bracket Pioneer Platform/ Tray: ControlledДокумент2 страницыAwning Bracket Pioneer Platform/ Tray: ControlledAnonymous lfw4mfCmОценок пока нет

- Catalogo Tolco FPS12Документ128 страницCatalogo Tolco FPS12Cesar Romero100% (1)

- Bracing and Tie Down DetailsДокумент7 страницBracing and Tie Down DetailsKristin MunozОценок пока нет

- Laboratory Glassware CatalogueДокумент52 страницыLaboratory Glassware CatalogueashkansoheylОценок пока нет

- Vetrolux Din 28120 28121Документ4 страницыVetrolux Din 28120 28121Brian RobertsОценок пока нет

- 3S AWD Trans Service Manual SearchableДокумент103 страницы3S AWD Trans Service Manual SearchableTim ZimmerОценок пока нет

- Price BrakeupДокумент168 страницPrice BrakeupNityanand DasОценок пока нет