Академический Документы

Профессиональный Документы

Культура Документы

Heat Exchanger: Micro Projet:-Thermal Engineering

Загружено:

Shubham0 оценок0% нашли этот документ полезным (0 голосов)

48 просмотров16 страницThis document provides an overview of heat exchangers. It discusses that heat exchangers transfer heat from one medium to another and are widely used in industries like power generation, refrigeration, and chemical plants. It classifies heat exchangers as parallel flow, counter flow, or cross flow based on the flow direction of fluids. Common types are shell and tube and plate heat exchangers. Selection factors for heat exchangers include pressure limits, temperature ranges, materials of construction, and efficiency. The document concludes that counter flow designs provide better efficiency and material selection is important to prevent corrosion in heat exchangers.

Исходное описание:

Mm

Оригинальное название

Som

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides an overview of heat exchangers. It discusses that heat exchangers transfer heat from one medium to another and are widely used in industries like power generation, refrigeration, and chemical plants. It classifies heat exchangers as parallel flow, counter flow, or cross flow based on the flow direction of fluids. Common types are shell and tube and plate heat exchangers. Selection factors for heat exchangers include pressure limits, temperature ranges, materials of construction, and efficiency. The document concludes that counter flow designs provide better efficiency and material selection is important to prevent corrosion in heat exchangers.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

48 просмотров16 страницHeat Exchanger: Micro Projet:-Thermal Engineering

Загружено:

ShubhamThis document provides an overview of heat exchangers. It discusses that heat exchangers transfer heat from one medium to another and are widely used in industries like power generation, refrigeration, and chemical plants. It classifies heat exchangers as parallel flow, counter flow, or cross flow based on the flow direction of fluids. Common types are shell and tube and plate heat exchangers. Selection factors for heat exchangers include pressure limits, temperature ranges, materials of construction, and efficiency. The document concludes that counter flow designs provide better efficiency and material selection is important to prevent corrosion in heat exchangers.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 16

HEAT EXCHANGER

Micro projet :- Thermal

Engineering

INDEX

1.INTRODUCTION

2.PRINCIPALS OF HEAT EXCHANGERS

3.CLASSIFICATIONS OF HEAT EXCHANGERS

4.TYPES OF HEAT EXCHANGER

5.APPLICATION OF HEAT EXCHANGERS

6.MATERIALS USED FOR HEAT EXCHANGER

7.SELECTION CRITERIA FOR HEAT EXCHANGER

8.CONCLUSION

9.RESUIT

10.REFERENCES

INTRODUCTION

• A heat exchanger is a piece of equipment built for

efficient heat transfer from one medium to another

• They are widely used in space hea ng,

refrigera on, air condi oning, power plants,

chemical plants, petrochemical plants, petroleum

refineries, natural gas processing, and sewage

treatment

PRINCIPLES OF HEAT

EXCHANGER

• Heat transferred from hot fluid to cold fluid

• Heat transferred through the wall Q = U. A.LMTD

CLASSIFICATIONS OF HEAT

EXCHANGERS

1 parallel flow heat exchanger :-

In parallel flow heat exchangers, the two

fluids enter the exchanger at the same end,

and travel in parallel to one another to the

other side.

2 counter flow heat exchanger :-

In counter flow heat exchangers the fluids

enter the exchanger from opposite ends. The

counter current design is the most efficient, in

that it can transfer the most heat from the

heat medium due to the fact that the average

temperature difference along any unit length

is greater.

3 cross flow heat exchanger :-

In a cross flow heat exchanger, the fluids

travel roughly perpendicular to one another

through the exchanger.

TYPES OF HEAT EXCHANGER

1 Shell and tube heat exchanger :-

It consist of a large number of a parallel

tubes enclosed in a rela vely closed fi ng

cylindrical Shell.

Shell and tube heat exchangers are typically

used for high pressure applica on.

2 Plate types heat exchanger :-

Heat exchanger is the Plate heat

exchanger. One is composed of mul ple,

thin, slightly separated plates that have

very large surface areas and fluids flow

passage for heat transfer.

APPLICATION OF HEAT

EXCHANGER

1 These are used in food industries

2 These are used in dairy product industry

3 They are large used where even the slightest

contamina on of the products due to leakage

cannot be tolerated

4 In gasket and brazing technology made these heat

exchanger in HVAC applica on

5 They are used in refrigera on applica on in close loop

MATERIALS USED FOR HEAT

EXCHANGER

1 Carbon steel

2 C-Mo steel

3 Low alloy steel (less then 6% chromium)

4 Alloy steel (less then 17% chromium)

5 Cast iron

6 Brass

7 Austeni c Cr-Ni steel

SELECTION CRITERIA FOR

HEAT EXCHANGER

1 High/low pressure limits

2 Thermal performance

3 Temperature ranges

4 Fluid flow capacity

5 Cleanability, maintenance and repair

6 Ability and ease of future expansion

7 pressure drops across the exchanger

CONCLUSION

1 Heat exchangers are widely used in industries for

both hea ng and cooling.

2 Proper selec on required sufficient knowledge of

heat exchangers types and opera ng requirements.

3 Mostly used heat exchangers are Shell and tube

heat exchangers.

4 For any types of heat exchangers counter flow

pa ern has be er efficiency.

RESULT

Erosion which removes metals rapidly because of

fric on which produce erosion as well as corrosion

use stainless steel, aluminum, Carbon steel tubes

there which are easily available and less effec ve to

chemistry of fluid

This all opera on can improve the effec veness of

heat exchanger

Less expansion of tube decrease overall cost of heat

exchanger

REFERENCES

Coulson, J. and Richardson, J (1999). Chemical

Engineering- Fluid Flow. Heat Transfer and Mass

Transfer- Volume 1; Reed Educa onal & Professional

Publishing LTD

Dogan Eryener (2005), ‘Thermoeconomic

op miza on of baffle spacing for shell and tube heat

exchangers’, Energy Conserva on and Management,

Volume 47, Issue 11–12, Pages 1478–1489.

G.F.Hewi , G.L.Shires, T.R.Bo (1994) Process Heat

Transfer, CRC Press, Inc, United States Of America.

THANK YOU

Вам также может понравиться

- Injection MouldingДокумент20 страницInjection MouldingSumanta Das100% (1)

- 2nd Physical Science ExamДокумент3 страницы2nd Physical Science ExamJokaymick LacnoОценок пока нет

- 1-Classification of Heat Exchangers & Selection CriteriaДокумент56 страниц1-Classification of Heat Exchangers & Selection CriteriaShahid_Rao786100% (1)

- Clay TilesДокумент5 страницClay Tilesprashmce100% (1)

- Heat Exchanger Design: Table of ContentДокумент18 страницHeat Exchanger Design: Table of ContenthellopaОценок пока нет

- Cryogenic Heatexchanger Unit LNG PlantДокумент6 страницCryogenic Heatexchanger Unit LNG Plantrissa100% (1)

- WASA Design Manual Final Mar 09 PDFДокумент234 страницыWASA Design Manual Final Mar 09 PDFrealchicОценок пока нет

- AP Government GATE Online Classes: Heat TransferДокумент88 страницAP Government GATE Online Classes: Heat TransferRohan lallОценок пока нет

- 2017 Gas Lift CatalogДокумент28 страниц2017 Gas Lift CatalogHìnhxămNơigóckhuấtTimAnhОценок пока нет

- Mechanical Design of Shell and Tube Heat ExchangerДокумент69 страницMechanical Design of Shell and Tube Heat ExchangerFazil HassanОценок пока нет

- Heat Exchanger ASSUIETДокумент229 страницHeat Exchanger ASSUIETعبدوخطابОценок пока нет

- Heat Exchanger Important DocumentДокумент126 страницHeat Exchanger Important DocumentUsamaAli100% (1)

- Ohe Fitting GuidelineДокумент56 страницOhe Fitting Guidelinepretha56Оценок пока нет

- Corrosion Under InsulationДокумент25 страницCorrosion Under InsulationNaqib Nordin33% (3)

- 418 Heat Ex ChangersДокумент57 страниц418 Heat Ex ChangersRanjit_Prakash_653100% (1)

- Lecture 1 - Classification of Heat ExchangersДокумент47 страницLecture 1 - Classification of Heat ExchangersAhmed HelmiОценок пока нет

- Weight Fixed Cone ValveДокумент9 страницWeight Fixed Cone ValveJohn TLОценок пока нет

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsОт EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsРейтинг: 4 из 5 звезд4/5 (6)

- Double Pipe Heat ExchangerДокумент6 страницDouble Pipe Heat ExchangerKhaqan Amin50% (8)

- Requisitions IndexДокумент13 страницRequisitions IndexKarnan ThirugnanamОценок пока нет

- Shell and Tube Heat Exchanger: Research TitleДокумент10 страницShell and Tube Heat Exchanger: Research TitleDimas SatriaОценок пока нет

- Heat ExchangersДокумент56 страницHeat ExchangersGeeva Prasanth AОценок пока нет

- Unit IДокумент133 страницыUnit IShubhamОценок пока нет

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersОт EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersРейтинг: 4 из 5 звезд4/5 (13)

- Double Pipe Heat ExchangerДокумент6 страницDouble Pipe Heat ExchangerharisОценок пока нет

- 1 418 Heat ExchangersДокумент58 страниц1 418 Heat ExchangersoperationmanagerОценок пока нет

- Heat Exchanger.Документ10 страницHeat Exchanger.RajarajeswariОценок пока нет

- Life Cycle AssessmentДокумент11 страницLife Cycle AssessmentAsniIbrahimОценок пока нет

- Intercambiador de CalorДокумент55 страницIntercambiador de Calorandy pandaОценок пока нет

- Intercambiador de CalorДокумент54 страницыIntercambiador de CalorCristian NipasОценок пока нет

- FINAL Project VivaДокумент20 страницFINAL Project VivaHem KumarОценок пока нет

- Plate Heat ExchANGER Final ProposalДокумент18 страницPlate Heat ExchANGER Final ProposalShanil SahaiОценок пока нет

- Amit Chogale ThermalДокумент11 страницAmit Chogale ThermalAditya MhatreОценок пока нет

- Seminar Topic: Compact Heat ExchangerДокумент20 страницSeminar Topic: Compact Heat ExchangerPankaj DohaleОценок пока нет

- Heat Exchanger Design (Theory)Документ20 страницHeat Exchanger Design (Theory)Iqra MubeenОценок пока нет

- High Temperature Heat ExchangersДокумент13 страницHigh Temperature Heat ExchangersuvsarathiОценок пока нет

- Classification of Heat Exchangers-1Документ55 страницClassification of Heat Exchangers-1PraveenОценок пока нет

- HE 04 Oct 21Документ11 страницHE 04 Oct 21Abir RahmanОценок пока нет

- Lecture 18 Heat Exchangers Part IДокумент18 страницLecture 18 Heat Exchangers Part Iquik silvaОценок пока нет

- Heat Exchangers: Prepared by ׃Документ11 страницHeat Exchangers: Prepared by ׃alslmani97.blogspot.comОценок пока нет

- HEAT ExchangersДокумент27 страницHEAT ExchangersBeatriceОценок пока нет

- Keynote Lecture: High Temperature Heat Exchangers: January 2005Документ14 страницKeynote Lecture: High Temperature Heat Exchangers: January 2005Md. Azizul HakimОценок пока нет

- ChapterДокумент4 страницыChapterIskandar ZulkarnainОценок пока нет

- Heat Exchangers1Документ34 страницыHeat Exchangers1Saloni.Dhawale Btech2018Оценок пока нет

- ME 478: Heat Exchanger Design .: CH-1: Heat Exchangers Introduction, Classification, and SelectionДокумент5 страницME 478: Heat Exchanger Design .: CH-1: Heat Exchangers Introduction, Classification, and SelectionalawyОценок пока нет

- Chapter 3 Heat ExchangerДокумент66 страницChapter 3 Heat ExchangerramskokyОценок пока нет

- Final 1Документ22 страницыFinal 1Sampath MechОценок пока нет

- Helical Heat Exchanger (Autosaved)Документ20 страницHelical Heat Exchanger (Autosaved)Rahul VinnyОценок пока нет

- Topics To Be Covered: - Introduction-Heat ExchangersДокумент13 страницTopics To Be Covered: - Introduction-Heat ExchangersAniruddhaОценок пока нет

- Act 3 ConclusionДокумент13 страницAct 3 ConclusionVon A. DamirezОценок пока нет

- Heat ExchangerДокумент5 страницHeat ExchangerAtta ur Rehman BhattiОценок пока нет

- Design, Analysis and Fabrication of Shell and Tube Heat ExchangerДокумент13 страницDesign, Analysis and Fabrication of Shell and Tube Heat Exchangerabel siudОценок пока нет

- Design of Double Pipe Heat Exchanger: Mrs. Kirti B.Zare, Ms. Dipika Kanchan, Ms. Nupur PatelДокумент14 страницDesign of Double Pipe Heat Exchanger: Mrs. Kirti B.Zare, Ms. Dipika Kanchan, Ms. Nupur PatelFranceОценок пока нет

- Classification, Construction & Manufacture of Heat ExchangerДокумент56 страницClassification, Construction & Manufacture of Heat ExchangerMochammad ReshaОценок пока нет

- Test of A Tubular CondenserДокумент9 страницTest of A Tubular CondenserDevin Bea0% (1)

- Heat ExchangerДокумент20 страницHeat ExchangerankitОценок пока нет

- Heat ExchangerДокумент37 страницHeat Exchangerdhairya1725100% (5)

- Shell - Tube Heat ExchangerДокумент28 страницShell - Tube Heat ExchangersachingirОценок пока нет

- Heat Transfer Assignment 1Документ13 страницHeat Transfer Assignment 1Abhinav mothaОценок пока нет

- Parametric Analysis OF The Performance OF Heat PipeДокумент18 страницParametric Analysis OF The Performance OF Heat PipeSandeep Pathak0% (1)

- DMCДокумент7 страницDMCFares NasserОценок пока нет

- Suez University Faculty of Petroleum & Mining Engineering: Prepared ByДокумент17 страницSuez University Faculty of Petroleum & Mining Engineering: Prepared ByitezazahsanОценок пока нет

- Thermo DynamicsДокумент16 страницThermo DynamicsEmmanuel IsiayinekifeОценок пока нет

- Project HMTДокумент13 страницProject HMTBra Sello RMОценок пока нет

- Type of Vessels: 1.1. Open-End and Closed-End VesselДокумент7 страницType of Vessels: 1.1. Open-End and Closed-End VesselHoàng Hữu QuốcОценок пока нет

- Waste Heat Recovery Considering Environmental FactorsДокумент7 страницWaste Heat Recovery Considering Environmental FactorsrvnesariОценок пока нет

- Plate Type Heat ExchangerДокумент5 страницPlate Type Heat ExchangerLaxmi PrasannaОценок пока нет

- Heat Exchanger and Its Classification: Dr. Liaquat Ali KhanДокумент34 страницыHeat Exchanger and Its Classification: Dr. Liaquat Ali KhanKhalil AhmadОценок пока нет

- Unit 2. Heat Exchangers: Professional Course in English "Process Technology. Equipment and Systems"Документ20 страницUnit 2. Heat Exchangers: Professional Course in English "Process Technology. Equipment and Systems"Nathalia DelgadoОценок пока нет

- CLB21003 Process Heat Transfer - Mini Project: Design of Heat ExchangerДокумент21 страницаCLB21003 Process Heat Transfer - Mini Project: Design of Heat ExchangerSiti Hajar Mohamed83% (6)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОт EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОценок пока нет

- Som MCQ For ExamДокумент3 страницыSom MCQ For ExamShubhamОценок пока нет

- Course Name: Mechanical Enginnering (ME) SR No. Registration ID Enroll No Candidate Name GenderДокумент2 страницыCourse Name: Mechanical Enginnering (ME) SR No. Registration ID Enroll No Candidate Name GenderShubhamОценок пока нет

- Crystal Structures With Cubic Unit CellsДокумент8 страницCrystal Structures With Cubic Unit CellsShubhamОценок пока нет

- AXIAL LoadДокумент49 страницAXIAL LoadShubhamОценок пока нет

- Bhutan Higher Secondary Education Certificate Examination December2014 Marking Scheme - ChemistryДокумент3 страницыBhutan Higher Secondary Education Certificate Examination December2014 Marking Scheme - ChemistryTsheyang LhazomОценок пока нет

- Brady&Weil08 Ch03-SoilOrders A5Документ45 страницBrady&Weil08 Ch03-SoilOrders A5Biniam Nega0% (1)

- Soil Freeze-Thaw Effects On Bank Erodibility and Stability: ElecteДокумент23 страницыSoil Freeze-Thaw Effects On Bank Erodibility and Stability: ElecteiliavaОценок пока нет

- Discussion Between Essar Power & FAG Bearings India LTDДокумент2 страницыDiscussion Between Essar Power & FAG Bearings India LTDJay Rameshbhai ParikhОценок пока нет

- RougingДокумент6 страницRougingmarcmanichОценок пока нет

- Isolation and Alkaline Hydrolysis of The Protein GlutenДокумент5 страницIsolation and Alkaline Hydrolysis of The Protein GlutenTiffany EspirituОценок пока нет

- Terrazo Concrete: Characteristics of TerrazzoДокумент8 страницTerrazo Concrete: Characteristics of Terrazzodanishali1090Оценок пока нет

- N Giungas Presentation PДокумент73 страницыN Giungas Presentation PGustavo FuentesОценок пока нет

- CHEM 221/PHY 335 - Molecular Symmetry IДокумент34 страницыCHEM 221/PHY 335 - Molecular Symmetry Ipaul javed0% (1)

- Dirac Notation PM r4Документ19 страницDirac Notation PM r4Andrea BucciОценок пока нет

- EMEA - Summary of The Product CharacteristicsДокумент20 страницEMEA - Summary of The Product CharacteristicskadecОценок пока нет

- Self Cleaning Flow Inverted SiphonsДокумент110 страницSelf Cleaning Flow Inverted SiphonsjcbobedaОценок пока нет

- South Coast Air Quality Management District Rule 1168 Voc Limits - For Estidama Lbi2.1Документ25 страницSouth Coast Air Quality Management District Rule 1168 Voc Limits - For Estidama Lbi2.1AtiqОценок пока нет

- Phy PracticalДокумент45 страницPhy PracticalmuskanОценок пока нет

- Syllabus Diploma ElectricalДокумент136 страницSyllabus Diploma Electricalrjpatil19Оценок пока нет

- Dawlance Report1Документ17 страницDawlance Report1engr_dkОценок пока нет

- CRM47885 Lrac9768Документ5 страницCRM47885 Lrac9768Sergio mauricio sergioОценок пока нет

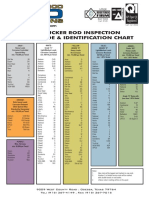

- Permian Rod Operations - Sucker Rod Identification Chart PDFДокумент1 страницаPermian Rod Operations - Sucker Rod Identification Chart PDFMinimaxou78Оценок пока нет

- IMUNOMOD TataneasaДокумент6 страницIMUNOMOD TataneasaminunatОценок пока нет