Академический Документы

Профессиональный Документы

Культура Документы

Alidrain AD250 PVD Method Statement - Revision 0

Загружено:

Roziman Hj HajonИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Alidrain AD250 PVD Method Statement - Revision 0

Загружено:

Roziman Hj HajonАвторское право:

Доступные форматы

PROJEK MEMBINA JALAN DARI SIBU JAYA KE JALAN KONG YIT KHIM,

SIBU, SARAWAK.

PWD/HO/B011/2019 Method Statement - Prefabricated Vertical Drain

(PVD) PREFABRICATED

TABLE OF CONTENT

Section Description

1.0 OBJECTIVE

2.0 SCOPE

3.0 REFERENCES

4.0 RESPONSIBILITIES

5.0 MATERIALS

6.0 MACHINERY

7.0 WORK SEQUENCE

8.0 SAFETY AND ENVIRONMENT

APPENDIXES

APPENDIX 1 - FORM SJKYK - QC/21(a)

APPENDIX 2 - FORM SJKYK - QC/21(b)

KACC Construction Sdn. Bhd Page 1 of 5

PROJEK MEMBINA JALAN DARI SIBU JAYA KE JALAN KONG YIT KHIM,

SIBU, SARAWAK.

PWD/HO/B011/2019 Method Statement - Prefabricated Vertical Drain (PVD)

PREFABRICATED VERTICAL

1.0 OBJECTIVE

This method statement is to describe the activities which will be used to carry out

the construction of prefabricated vertical drain (PVD) and to outline the resources

needed for the operations of PROJEK MEMBINA JALAN DARI SIBU JAYA KE

JALAN KONG YIT KHIM, SIBU, SARAWAK.

. 2.0 SCOPE

This method statement shall apply for Geotechnical Work as per bill of

quantities for embankment founded on soft area and it requires the Ground

Treatment Works which also referred in the drawing as “Special Embankment

Construction for Type B4N”.

3.0 REFERENCES

a) Construction Drawings

b) Tender Specification, Section 16 Geotextile Specifications, and item 16.7

Prefabricated Vertical Drain.

4.0 RESPONSIBILITIES

a) Site Safety Officer/Supervisor

b) QA/QC Officer/Supervisor

c) Site Engineer

d) Site Supervisor

e) Land Surveyor

f) Plant Operator

g) General Workers

5.0 MATERIALS

5.1. Alidrain AD250 PVD

KACC Construction Sdn. Bhd Page 2 of 5

PROJEK MEMBINA JALAN DARI SIBU JAYA KE JALAN KONG YIT KHIM,

SIBU, SARAWAK.

PWD/HO/B011/2019 Method Statement - Prefabricated Vertical Drain (PVD)

PREFABRICATED VERTICAL

6.0 MACHINERY

6.1. P&H320 Crawler Crane

7.0 WORK SEQUENCE

7.1. General

7.1.1. The PVD layout drawing comprising of numbered square grid box for the

PVD ground treatment shall be based on the construction layout drawing.

7.1.2. The limit of the location of the area to be treated and depth of the PVD to be

installing shall be as specification and engineer requirement.

7.1.3. Sample of PVD shall be taken at site and tested on the required properties

shall be witnessed by client and consultants representative.

7.2. Equipment and accessories

7.2.1. Cable Pull type PVD installation machine with a structural frame (Drain

mast)

7.2.2. Mandrel (rectangular tube approximately 125mm x 50mm x 6mm). The

length of mandrel shall not be less than the maximum length of drain.

7.2.3. Metal shoe ( steel plate approximately 160mm x 85mm x 0.7mm)

7.3. Site preparation

7.3.1. Platform preparation works to the required drainage blanket level shall be

prepared and geotextile (type referred to the construction drawing) shall be

installed prior to PVD installation.

7.3.2. The working platform shall be able to provide stable platform for the

required PVD rigs to move around.

7.4. Setting out of PVD location

7.4.1. Setting out and pegging of PVD corner control point.

7.4.2. PVD point and pattern will be established according to the spacing as

specified.

7.4.3. After setting out has been done, the PVD point shall be marked by placing

steel metal shoes on the ground in accordance to interval as specified in

the drawings. This is to provide visual guide and ease machine operator’s

aiming point and checking.

KACC Construction Sdn. Bhd Page 3 of 5

PROJEK MEMBINA JALAN DARI SIBU JAYA KE JALAN KONG YIT KHIM,

SIBU, SARAWAK.

PWD/HO/B011/2019 Method Statement - Prefabricated Vertical Drain (PVD)

7.5. PVD installation PREFABRICATED VERTICAL

7.5.1. Trial PVD installation will be carried out to determine PVD installation

depth.

7.5.2. The roll of PVD is fixed on the drain feed mechanism into the mandrel.

7.5.3. PVD roll will be hanged at the bar hanger on the rig to ensure smooth and

uninterrupted PVD deployment during the installation works.

7.5.4. The PVD installation machine will be driven to PVD marked point

7.5.5. Steel plate with fixture will be placed at the base of the mandrel. PVD shall

be wrapped around the fixture on the anchor and folded back. Mandrel will

be pulled back until the plate cap the mandrel base.

7.5.6. The mandrel is injected into the ground to the required depth and

subsequently retracted. The steel metal place which is held in place at the

toe of the mandrel will then anchor the PVD at the installed depth.

7.5.7. Upon full extraction of the mandrel, the PVD is cut off neatly at the

approximately 150mm above the platform level.

7.5.8. The PVD installation machine is the driven and repositioned over the next

point and the above cycle is repeated.

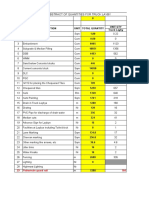

7.6. Recording Sheet for PVD installation

7.6.1. The depth of PVD installed is recorded manually which incorporate:

7.6.1.1. Date of installation

7.6.1.2. Grid and point location

7.6.1.3. Depth of each drain measured from working platform based on the depth

markings on the rig and 150mm above ground.

7.6.1.4. Refer Forms in the Appendixes.

7.7. Splicing of PVD

7.7.1. This is carried by sheaving and tying the PVD together so as to ensure the

structural and hydraulic continuity of the drain.

7.7.2. At the splice, the upper portion of the jacket shall be extended to cover the

lower portion. The jacket and core shall be overlapped at a minimum of

150mm at any splice.

8.0 Safety & Environments

8.1. Safety, Health & Environmental Issues

KACC Construction Sdn. Bhd Page 4 of 5

PROJEK MEMBINA JALAN DARI SIBU JAYA KE JALAN KONG YIT KHIM,

SIBU, SARAWAK.

PWD/HO/B011/2019 Method Statement - Prefabricated Vertical Drain (PVD)

PREFABRICATED

8.1.1 All staff involved with the project shall be inducted VERTICAL

on the safety, health and

environmental issues associated with the work. Before entering the site, all

staff must wear Personal Protective Equipment (PPE).

8.1.2 Only trained personnel with relevant experience shall be allowed to handle

heavy machinery. Construction machineries and plants must maintain

regularly. Ensure machine to inspect before start work by

Safety Officer. All the movement of the construction machineries has to

regulate.

8.1.3 Care will be taken to ensure that dust and air pollution are kept to a

minimum. Temporary earth drains will be constructed where necessary to

prevent water ponding and flooding. Using water browser (if necessary) to

control dust dispersal at site and maintain the schedule. Existing roads and

all project construction sites need to keep clean.

8.1.4 In term of emergency, person in charge at site at that time (site

engineer/safety officer/traffic management officer/site supervisor) must follow

emergency response plan flowchart.

KACC Construction Sdn. Bhd Page 5 of 5

Вам также может понравиться

- 2.hydroseeding by - BhoomiДокумент1 страница2.hydroseeding by - BhoomiShivendra KumarОценок пока нет

- Method Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)Документ11 страницMethod Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)MAYMODERN STEEL100% (1)

- RD - PROTECTION WORKДокумент34 страницыRD - PROTECTION WORKMuthusamy ArumugamОценок пока нет

- Construction Defects in Deep Excavation and Their RemediesДокумент4 страницыConstruction Defects in Deep Excavation and Their Remediesvenkateswara rao pothinaОценок пока нет

- BOQ of 3 SitesДокумент25 страницBOQ of 3 SitesJampani HymavathiОценок пока нет

- List of Works Live in MarketДокумент15 страницList of Works Live in MarketAayush Goel grr XI100% (1)

- Shri Sai Gabion & Fencing: LimitedДокумент2 страницыShri Sai Gabion & Fencing: LimitedShivendra KumarОценок пока нет

- Methodology For PQC (00) Toll Plaza L&TДокумент4 страницыMethodology For PQC (00) Toll Plaza L&TDeven PatleОценок пока нет

- Nitobond EP03 - 0911 ENG - Concrete AdhesifДокумент2 страницыNitobond EP03 - 0911 ENG - Concrete AdhesifFadi HОценок пока нет

- DLC Methodology - Nagpur MumbaiДокумент13 страницDLC Methodology - Nagpur MumbaiGanesh Kumar TulabandulaОценок пока нет

- Quotation Tree Plantation - 3Документ1 страницаQuotation Tree Plantation - 3Shivendra KumarОценок пока нет

- S.O.R. Bridge WorksДокумент48 страницS.O.R. Bridge WorksUmar KarimiОценок пока нет

- GP209 - Method Statement For Soil Preparation and Natural Grass InstallationДокумент5 страницGP209 - Method Statement For Soil Preparation and Natural Grass Installationatef ghazyОценок пока нет

- Cube Test ReportДокумент1 страницаCube Test ReportShubham MareОценок пока нет

- Mainmark - Permeation PDFДокумент4 страницыMainmark - Permeation PDFAndrea David RodriguesОценок пока нет

- Annexure 1 PDFДокумент32 страницыAnnexure 1 PDFDushyant JadaunОценок пока нет

- BoqДокумент22 страницыBoqDheeraj ThakurОценок пока нет

- A Case Study of Soft Ground Improvement by DynamicДокумент13 страницA Case Study of Soft Ground Improvement by DynamicZOUABIОценок пока нет

- During Tremie Concreting The Following Precautions Are To Be Taken While Doing The WorkДокумент2 страницыDuring Tremie Concreting The Following Precautions Are To Be Taken While Doing The WorkRaghavendraОценок пока нет

- Geotextile Installation PDFДокумент4 страницыGeotextile Installation PDFthadikkaranОценок пока нет

- Mos Survey WorkДокумент4 страницыMos Survey Workaniesbaek100% (1)

- MOS Main Truss Bridge Rev 01Документ35 страницMOS Main Truss Bridge Rev 01Ami ShafiОценок пока нет

- Gabions Product Specifications and Quality Control GroundtechДокумент2 страницыGabions Product Specifications and Quality Control GroundtechRajeev SharanОценок пока нет

- Post Tensioned I-Beam RB011, RBO12Документ13 страницPost Tensioned I-Beam RB011, RBO12MAYMODERN STEELОценок пока нет

- BOQ Estimate PKG 01 Modified On 30.09.21Документ18 страницBOQ Estimate PKG 01 Modified On 30.09.21surendra KumarОценок пока нет

- Method of Statement - Junction ChamberДокумент9 страницMethod of Statement - Junction ChamberLaksri JayathilakeОценок пока нет

- COS - 01 Hawamore PDFДокумент9 страницCOS - 01 Hawamore PDFrao shoaibОценок пока нет

- Method Statement For ExcavationДокумент7 страницMethod Statement For ExcavationAbideen RaheemОценок пока нет

- Abstract of Quantities For Truck LaybyДокумент3 страницыAbstract of Quantities For Truck LaybyStephen Rajkumar JayakumarОценок пока нет

- Morth Section 700Документ3 страницыMorth Section 700Psrawat RawatОценок пока нет

- WRD Water ResourcesДокумент32 страницыWRD Water ResourcesatgsganeshОценок пока нет

- Geo in HighwayДокумент13 страницGeo in HighwayPradeepBansalОценок пока нет

- CRRI Presentation On GeosyntheticsДокумент51 страницаCRRI Presentation On GeosyntheticsGautam RaiОценок пока нет

- A Lecture Notes 2012 Dda2132 CHP 3b Pile TestДокумент13 страницA Lecture Notes 2012 Dda2132 CHP 3b Pile Testmkpasha55mpОценок пока нет

- Method Statement Horizontal DrainДокумент1 страницаMethod Statement Horizontal DrainAlsonChin100% (1)

- Geogrid-Techgrid Technical LiteratureДокумент13 страницGeogrid-Techgrid Technical Literaturesachindagrawal90440% (1)

- Solcourse - Polythene DPM DatasheetДокумент2 страницыSolcourse - Polythene DPM DatasheetkibzeamОценок пока нет

- Part S22 Soil Nailing Nov 2014Документ7 страницPart S22 Soil Nailing Nov 2014Anonymous ECNRVD0RОценок пока нет

- CH - Ash Pond Lining With Geomembrane, NelloreДокумент3 страницыCH - Ash Pond Lining With Geomembrane, NellorePa Dadang0% (1)

- Gabion, Geo Textile & RenomatressДокумент4 страницыGabion, Geo Textile & RenomatressSandun NimanthaОценок пока нет

- 1.8 Method Statement - Soil Nailing and Guniting SursbДокумент5 страниц1.8 Method Statement - Soil Nailing and Guniting SursbfatinОценок пока нет

- Soil Nailing PDFДокумент14 страницSoil Nailing PDFRonald De GuzmanОценок пока нет

- 6 Major Reasons For Failure of Pile Foundation!Документ1 страница6 Major Reasons For Failure of Pile Foundation!Martin GriffinОценок пока нет

- Standard Penetration TestДокумент21 страницаStandard Penetration TestVenkatesh ThumatiОценок пока нет

- Basic Rate UttarakhandДокумент17 страницBasic Rate UttarakhandShivendra KumarОценок пока нет

- Construction of Road With: Geo-TextilesДокумент32 страницыConstruction of Road With: Geo-Textileskutticute_877110165Оценок пока нет

- Monthly Progress Report: Frischmannprabhu (India) Pvt. LTDДокумент54 страницыMonthly Progress Report: Frischmannprabhu (India) Pvt. LTDshravan38Оценок пока нет

- 6sec.600 (Concrete Pavement)Документ35 страниц6sec.600 (Concrete Pavement)aalignup arc & const. pvt ltdОценок пока нет

- Methodology For Soil Geotechnical InvestigationДокумент4 страницыMethodology For Soil Geotechnical InvestigationShyama Prasad SamantaОценок пока нет

- Installing GeotextilesДокумент2 страницыInstalling GeotextilesAbdullah MofarrahОценок пока нет

- Base Grouting of Bored Cast-In-Situ Piles at The Railway Bridge Over The River Rupsha, Bangladesh: A Case StudyДокумент10 страницBase Grouting of Bored Cast-In-Situ Piles at The Railway Bridge Over The River Rupsha, Bangladesh: A Case StudyRaja RajanОценок пока нет

- PileДокумент5 страницPileSuman NakarmiОценок пока нет

- 140224-DeepExcavation Design WebinarДокумент83 страницы140224-DeepExcavation Design WebinarAnonymous qEPNPwAОценок пока нет

- (MS) Slope Protection For SlopeДокумент14 страниц(MS) Slope Protection For SlopeUniversal CollabОценок пока нет

- SI-BQ6 - Laboratory Testing (JKR's Rate)Документ3 страницыSI-BQ6 - Laboratory Testing (JKR's Rate)Ir Ahmad AfiqОценок пока нет

- Earthworks Subfolder PK 61.30 - PK 75 - 14th July 2021 En.Документ546 страницEarthworks Subfolder PK 61.30 - PK 75 - 14th July 2021 En.Adrian FrantescuОценок пока нет

- 300mm Microhtbar RevДокумент2 страницы300mm Microhtbar RevAlsonChinОценок пока нет

- K&J Quotation For Geotechnical - OLEOДокумент4 страницыK&J Quotation For Geotechnical - OLEORamakrishnaОценок пока нет

- CONSTRUCTION METHODOLOGY Embankment RailwaysДокумент5 страницCONSTRUCTION METHODOLOGY Embankment Railwaysvenkateswara rao PothinaОценок пока нет

- Underck Insulation MSTДокумент8 страницUnderck Insulation MSTmahesh naikОценок пока нет

- 002-Rock BlastingДокумент5 страниц002-Rock BlastingRoziman Hj HajonОценок пока нет

- Lampiran B-Keputusan Ujian Campuran Cement Grout PDFДокумент5 страницLampiran B-Keputusan Ujian Campuran Cement Grout PDFRoziman Hj HajonОценок пока нет

- Paper 8 - Road Construction On Peat Soil May 2014 (Rev)Документ16 страницPaper 8 - Road Construction On Peat Soil May 2014 (Rev)Roziman Hj HajonОценок пока нет

- Road Works Method StatementДокумент3 страницыRoad Works Method StatementRoziman Hj HajonОценок пока нет

- Proposed Bridges To Replace Existing Ferry ServicesДокумент25 страницProposed Bridges To Replace Existing Ferry ServicesRoziman Hj Hajon100% (1)

- A Guide On Geometric Design of RoadДокумент93 страницыA Guide On Geometric Design of RoadRoziman Hj Hajon100% (2)

- Samalaju Onshore - (2) MPR December 2013Документ59 страницSamalaju Onshore - (2) MPR December 2013Roziman Hj HajonОценок пока нет

- Full Paper-Professional Ethics in Construction QualityДокумент10 страницFull Paper-Professional Ethics in Construction QualityRoziman Hj HajonОценок пока нет

- Install Base in R12Документ3 страницыInstall Base in R12Hai Duc NguyenОценок пока нет

- Devireg 530Документ1 страницаDevireg 530Mohammed Al-kawakОценок пока нет

- Lab ManualДокумент10 страницLab ManualtheОценок пока нет

- As 2159 2009 Piling Design and InstallationДокумент9 страницAs 2159 2009 Piling Design and InstallationKinson LowОценок пока нет

- HIO KeypadДокумент4 страницыHIO KeypadMaitry ShahОценок пока нет

- OBJECTIVES RationaleДокумент1 страницаOBJECTIVES RationaleKylah Joy BautistaОценок пока нет

- Order Fulfilment PDFДокумент21 страницаOrder Fulfilment PDFSaikumar SelaОценок пока нет

- Implementing Global Human Resources PDFДокумент486 страницImplementing Global Human Resources PDFme.atulОценок пока нет

- ENG DS OSA Series Relay Data Sheet E 0411Документ3 страницыENG DS OSA Series Relay Data Sheet E 0411Klisman Rafael Santi RamosОценок пока нет

- Somerset West Tattersalls CC: Trading As Vegas BetsДокумент8 страницSomerset West Tattersalls CC: Trading As Vegas BetsBereng SekОценок пока нет

- 4ipnet Solution HotelДокумент27 страниц4ipnet Solution HotelAdrian Gamboa MarcellanaОценок пока нет

- GCC 5241PДокумент16 страницGCC 5241Pboating1997Оценок пока нет

- Module 1 Introduction To ElectronicsДокумент4 страницыModule 1 Introduction To ElectronicsAldrin VillanuevaОценок пока нет

- Zero Cross90003138AДокумент11 страницZero Cross90003138AJeremiasPereiraОценок пока нет

- Book IELTS Test Online Booking WizardДокумент4 страницыBook IELTS Test Online Booking WizardNilza BackesОценок пока нет

- Waste SegregationДокумент14 страницWaste SegregationTrexy HerederoОценок пока нет

- Frizz Dual ManualДокумент2 страницыFrizz Dual ManualManuel Francisco de PereaОценок пока нет

- Lisa Kleypas Un Strain Frumos PDF 1 PDFPDF CompressДокумент360 страницLisa Kleypas Un Strain Frumos PDF 1 PDFPDF CompressIlinca100% (1)

- Working Together ApartДокумент8 страницWorking Together ApartIzo SeremОценок пока нет

- User Manual Flenex FW 1.3.Документ64 страницыUser Manual Flenex FW 1.3.ClaudiОценок пока нет

- ACA UNIT-5 NotesДокумент15 страницACA UNIT-5 Notespraveennegiuk07Оценок пока нет

- DTN NS3Документ4 страницыDTN NS3Mirza RizkyОценок пока нет

- CyberOps Skills Assessment - Student TRNG - ExamДокумент4 страницыCyberOps Skills Assessment - Student TRNG - ExamIsabella Leon67% (3)

- AsfqДокумент3 страницыAsfqKuzaki VileОценок пока нет

- Technical Specification: ConfigurationДокумент7 страницTechnical Specification: ConfigurationAhmedRamadanОценок пока нет

- AWS Academy Cloud Foundations Module 05 Student GuideДокумент75 страницAWS Academy Cloud Foundations Module 05 Student GuidevalzОценок пока нет

- Energy Efficient BuildingДокумент11 страницEnergy Efficient BuildingSantosh Basnet100% (2)

- Integrating Microsoft Access With Autocad VbaДокумент19 страницIntegrating Microsoft Access With Autocad VbaLuiz Paulo Cruz JrОценок пока нет

- CV Iqbal 2016Документ3 страницыCV Iqbal 2016Muhammad Iqbal ImaduddinОценок пока нет

- HTML FormДокумент5 страницHTML Formshivam ashishОценок пока нет