Академический Документы

Профессиональный Документы

Культура Документы

Hira Ball Mill Line Replacemen

Загружено:

ananthu.u0 оценок0% нашли этот документ полезным (0 голосов)

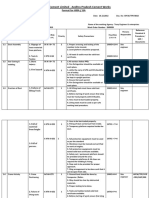

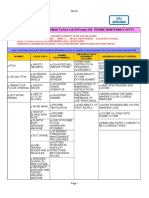

187 просмотров2 страницы1. The document identifies risks associated with ball mill liner replacement at the HIRA MIILL process area and existing controls to mitigate those risks.

2. Key risks include exposure to noise and dust, falling/moving object impacts, improper brake use, overloading, non-tested lifting equipment, and shutdown procedure non-compliance. Controls involve use of PPE, lifting tool testing, brake monitoring, authorized crane use, and permit to work systems.

3. The residual risks involve potential exposure to fumes and gases. Additional controls like ventilation fans and insulated lug connections are recommended to further reduce risks.

Исходное описание:

5t

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ1. The document identifies risks associated with ball mill liner replacement at the HIRA MIILL process area and existing controls to mitigate those risks.

2. Key risks include exposure to noise and dust, falling/moving object impacts, improper brake use, overloading, non-tested lifting equipment, and shutdown procedure non-compliance. Controls involve use of PPE, lifting tool testing, brake monitoring, authorized crane use, and permit to work systems.

3. The residual risks involve potential exposure to fumes and gases. Additional controls like ventilation fans and insulated lug connections are recommended to further reduce risks.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

187 просмотров2 страницыHira Ball Mill Line Replacemen

Загружено:

ananthu.u1. The document identifies risks associated with ball mill liner replacement at the HIRA MIILL process area and existing controls to mitigate those risks.

2. Key risks include exposure to noise and dust, falling/moving object impacts, improper brake use, overloading, non-tested lifting equipment, and shutdown procedure non-compliance. Controls involve use of PPE, lifting tool testing, brake monitoring, authorized crane use, and permit to work systems.

3. The residual risks involve potential exposure to fumes and gases. Additional controls like ventilation fans and insulated lug connections are recommended to further reduce risks.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

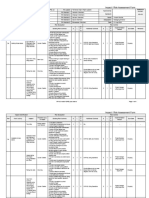

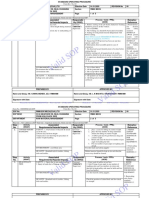

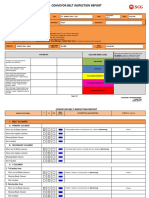

HIRA MIILL( BALL MILL LINER REPLACEMENT)

Risk Additional Residua Person

Process/Are Existing Severit

Hazard Likelihoo Ratin Actions/Control l Risk Responsibl

a Controls y (1 to

d (1 to 5) g s Required Rating e

5)

Administartive

Exposure to

Use of PPE's 3 3 9 control for the 6 RL Saini

noise

use of PPE.

Administartive

Exposure to

Use of PPE's 2 1 2 control for the 1 RL Saini

dust

use of PPE.

Falling Use proper Tested lifting

object lifting tools 3 4 12 tools and tackles 6 RL Saini

impact & tackles to be used.

Moving Use proper Tested lifting

object lifting tools 3 4 12 tools and tackles 6 RL Saini

impact & tackles to be used.

Trolley Brake

Condition

improper checking 3 3 9 4 RL Saini

monitoring .

brake regularly

Only authorised

Overloadin Avoid

3 3 9 persons to use 4 RL Saini

g Overloading

crane.

Physical

Non tested

condition should

Lifting Periodical

3 2 6 be checked 4 RL Saini

equipment testing

before every

s

use.

Ball Mill

Liner Testing to be

replacement Use of performed by

Periodical

tested tools 3 1 3 authorised and 2 RL Saini

testing

& tackles competent

person.

Use of

Slippage of Standard tool

proper tools 3 1 3 1 RL Saini

tools should be used.

& tackles

Continuous

Shutdown permit to training should

4 2 8 4 RL Saini

procedures work system be provided for

PTW.

Tool Box Talk

Refresher and refresher

Lack of

training 3 2 6 training should 2 RL Saini

knowledge

continuous be provided

continuously.

Regular

Poor

checking of Standard quality

quality of

cables & 4 3 12 cables should be 6 RL Saini

welding

replacing used.

cables.

faulty cables

Emmission Use of PPE's

Ventilation Fan

of fumes and gas 4 3 12 6 RL Saini

should be used.

and gases detectors.

Insulated lug

Loose Preventive

should be used

connection maintenanc 3 3 9 4 RL Saini

for joint

s e

connections.

Additional

Inadequate Proper

3 1 3 action not 1 RL Saini

lighting illumination

required

Вам также может понравиться

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Документ3 страницыZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilОценок пока нет

- 1.SOP-Castable Refractory Work at Pre-Heater. Kiln Inlet, TAD & CoolerДокумент2 страницы1.SOP-Castable Refractory Work at Pre-Heater. Kiln Inlet, TAD & CoolerJCSОценок пока нет

- SOP of Pump Changing JobДокумент11 страницSOP of Pump Changing JobDwitikrushna Rout100% (1)

- Ayoki Safety Monthly Initiative 27.11.21slideДокумент19 страницAyoki Safety Monthly Initiative 27.11.21slideAltafОценок пока нет

- 731-CC-8 Gear Box Oil Seal Changing From Hold Back SideДокумент5 страниц731-CC-8 Gear Box Oil Seal Changing From Hold Back SideBuddy HartОценок пока нет

- HIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionДокумент26 страницHIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionkrishnaengineeringhilОценок пока нет

- SOP 15 - Hopper Cleaning ActivityДокумент6 страницSOP 15 - Hopper Cleaning Activityfaraz ahmed100% (2)

- Risk Assesment Form - Ball MillingДокумент6 страницRisk Assesment Form - Ball Millingbc150Оценок пока нет

- HIRA JSA For Duct Assembly & ErectionДокумент4 страницыHIRA JSA For Duct Assembly & ErectionRaju100% (2)

- 621-CC#09 Idler and Frame ChangingДокумент4 страницы621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)

- NTPC Integrated Management System (Identification of Ohs Hazards and Risk) Tstps KanihaДокумент11 страницNTPC Integrated Management System (Identification of Ohs Hazards and Risk) Tstps KanihaSamrin Naaz100% (3)

- HIRA 003 Welding and Cutting.Документ4 страницыHIRA 003 Welding and Cutting.srinibas mohapatraОценок пока нет

- How To Ensure Safety For Castable MixingДокумент4 страницыHow To Ensure Safety For Castable MixingNaelОценок пока нет

- SMP For For Mill Girth Gear ReplacementДокумент3 страницыSMP For For Mill Girth Gear Replacementananthu.uОценок пока нет

- 19.hydro Pressure Testing.Документ8 страниц19.hydro Pressure Testing.Mohammad Fazal KhanОценок пока нет

- SOP For Cleaning of Clinker Cooler DischargeДокумент3 страницыSOP For Cleaning of Clinker Cooler Dischargeayaskant751001Оценок пока нет

- Job Safety Analysis: (Risk Assessment)Документ8 страницJob Safety Analysis: (Risk Assessment)Ped KapedОценок пока нет

- SWMS-Pipe Instalation Work at Utility 25.01.21Документ10 страницSWMS-Pipe Instalation Work at Utility 25.01.21Ansari FaisalОценок пока нет

- 02-070302 JSA For Relocation of Monkey Ladder For Construction of Phase-I Tranformer Bay in Brown Zone.Документ4 страницы02-070302 JSA For Relocation of Monkey Ladder For Construction of Phase-I Tranformer Bay in Brown Zone.Mohammed MinhajОценок пока нет

- JSA For The Conveyor BeltДокумент1 страницаJSA For The Conveyor BeltSaklain MustakОценок пока нет

- Jsa Fan Coil Unites MaintenanceДокумент5 страницJsa Fan Coil Unites MaintenanceASLAM MULANIОценок пока нет

- 615-Hydraulic Pipe Changing of SCR#3Документ5 страниц615-Hydraulic Pipe Changing of SCR#3Buddy HartОценок пока нет

- Cement Processing Hol CimДокумент1 страницаCement Processing Hol CimShailesh RaneОценок пока нет

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisДокумент11 страницThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh kumar yadav100% (1)

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechДокумент3 страницыJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidОценок пока нет

- Check List Rotary Packer: Packing Plant General StatusДокумент3 страницыCheck List Rotary Packer: Packing Plant General StatusTITUS YUSUF100% (1)

- MTA2018-JHA-012 Air Compressor OperationДокумент10 страницMTA2018-JHA-012 Air Compressor OperationKelvin TanОценок пока нет

- HIRA For Work at HeightДокумент4 страницыHIRA For Work at Heightdinesattri100% (1)

- SOP 11 - Lime Stone Circuit OprationДокумент9 страницSOP 11 - Lime Stone Circuit Oprationfaraz ahmedОценок пока нет

- Tube Expanders CatalogДокумент20 страницTube Expanders Catalognathanielek1989Оценок пока нет

- 1370323828p - TRX 2319Документ2 страницы1370323828p - TRX 2319Anonymous e3yfLHTBv100% (1)

- 02 HIRA-JSA-Coal Mill Operation.Документ10 страниц02 HIRA-JSA-Coal Mill Operation.saji kumarОценок пока нет

- JSA - Main Turbine Lub Oil Pumps - OHДокумент2 страницыJSA - Main Turbine Lub Oil Pumps - OHShubham Gupta0% (1)

- Jha For Painting Works Repainting of Control Room and Guard House at Switchyard (External)Документ1 страницаJha For Painting Works Repainting of Control Room and Guard House at Switchyard (External)Jonas GonzalesОценок пока нет

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelДокумент3 страницыRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed ElnagdyОценок пока нет

- Weekly 1/G1J06 OkДокумент9 страницWeekly 1/G1J06 OkWisnu NugrahaОценок пока нет

- Complete ProjectДокумент79 страницComplete ProjectMithun RajОценок пока нет

- How To Ensure Safety For Brick CuttingДокумент5 страницHow To Ensure Safety For Brick CuttingNael67% (3)

- On-Site Emergency Plan: Captive Power Plant Angul, OdishaДокумент67 страницOn-Site Emergency Plan: Captive Power Plant Angul, OdishaANILОценок пока нет

- SOP of Conveyor Belt Re-JointingДокумент9 страницSOP of Conveyor Belt Re-JointingDwitikrushna RoutОценок пока нет

- Case Study - Maintenance ManagementДокумент27 страницCase Study - Maintenance ManagementDuke Maher SalemОценок пока нет

- ExcavationДокумент3 страницыExcavationprasanna ok100% (1)

- Lifting Fixing of GI SheetДокумент1 страницаLifting Fixing of GI SheetJack PОценок пока нет

- WORK at HEIGHT Job Hazard AnalysisДокумент3 страницыWORK at HEIGHT Job Hazard Analysistosin babayomi0% (1)

- 11.pneumatic Pressure Testing.Документ7 страниц11.pneumatic Pressure Testing.Mohammad Fazal KhanОценок пока нет

- 08-SOP For Belt Conveyor 6ABДокумент14 страниц08-SOP For Belt Conveyor 6ABTamil VananОценок пока нет

- General Civil Works Risk AssessmentДокумент8 страницGeneral Civil Works Risk AssessmentsufiyanОценок пока нет

- Job Safety Analysis MDC Cylinder ReplacementДокумент2 страницыJob Safety Analysis MDC Cylinder ReplacementMaxi Pro100% (2)

- Belt Conveyor Troubleshooting: HGRS MASTER - MaintenanceДокумент7 страницBelt Conveyor Troubleshooting: HGRS MASTER - MaintenanceJerry HukyОценок пока нет

- Compulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 17 - Wool Press OperationДокумент2 страницыCompulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 17 - Wool Press OperationUlviyye ElesgerovaОценок пока нет

- HIRA MechanicalДокумент6 страницHIRA Mechanicalsufiyan sskОценок пока нет

- Job Safety Analysis: Cooling Tower OperationДокумент2 страницыJob Safety Analysis: Cooling Tower OperationVi VekОценок пока нет

- Builder Hoist Erection JSA HSE ProfessionalsДокумент2 страницыBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDOОценок пока нет

- Pulley Lagging Rubber Sheet PDFДокумент1 страницаPulley Lagging Rubber Sheet PDFSanatha AgungОценок пока нет

- SOP of Idler ChangeДокумент9 страницSOP of Idler ChangeDwitikrushna RoutОценок пока нет

- TTEC Fencing RAДокумент7 страницTTEC Fencing RAGeml TrinidadОценок пока нет

- HIRA - MS Staircase ErectionДокумент7 страницHIRA - MS Staircase ErectionRamОценок пока нет

- Hazard Identification & Risk Assessment Sheet ForДокумент6 страницHazard Identification & Risk Assessment Sheet Forasathish.eee100% (1)

- Hira Mill (Measuring Bunker Liner Replacement)Документ2 страницыHira Mill (Measuring Bunker Liner Replacement)ananthu.uОценок пока нет

- Testing and Inspection Intervals For Electrical Equipment (Extracted From As3760 - 2003)Документ1 страницаTesting and Inspection Intervals For Electrical Equipment (Extracted From As3760 - 2003)Anonymous QE45TVC9e3Оценок пока нет

- Top Safety Measures at Construction SitesДокумент3 страницыTop Safety Measures at Construction Sitesananthu.uОценок пока нет

- Calculating The Time Weighted Average TWA Noise Level and Noise Dose Levels PDFДокумент1 страницаCalculating The Time Weighted Average TWA Noise Level and Noise Dose Levels PDFananthu.uОценок пока нет

- SOPs-Craning and Rigging StandardДокумент37 страницSOPs-Craning and Rigging Standardananthu.u100% (1)

- Week 2 - Element 4: Electrical Hazards and ControlДокумент33 страницыWeek 2 - Element 4: Electrical Hazards and Controlananthu.u100% (2)

- Event Tree Analysis: SverdrupДокумент13 страницEvent Tree Analysis: Sverdrupananthu.u100% (1)

- CoBDiploma OHP 1E3.Rev1Документ38 страницCoBDiploma OHP 1E3.Rev1ananthu.uОценок пока нет

- Tata Projects Limited: Hazard Identification and Risk Assessment (HIRA)Документ7 страницTata Projects Limited: Hazard Identification and Risk Assessment (HIRA)ananthu.u100% (3)

- ISO 14001 2015 Audit Checklist. DQSДокумент19 страницISO 14001 2015 Audit Checklist. DQSananthu.u100% (3)

- CoBDiploma OHP 1C5.Rev1Документ71 страницаCoBDiploma OHP 1C5.Rev1ananthu.uОценок пока нет

- CoBDiploma OHP 1E4.Rev1Документ65 страницCoBDiploma OHP 1E4.Rev1ananthu.uОценок пока нет

- Job Hazard Analysis: IP-OPS-066Документ9 страницJob Hazard Analysis: IP-OPS-066ananthu.uОценок пока нет

- BSI Standards PublicationДокумент14 страницBSI Standards Publicationananthu.uОценок пока нет

- Smoke Alarm Maintenance ChecklistДокумент2 страницыSmoke Alarm Maintenance Checklistananthu.u100% (2)

- Near Miss ReportingДокумент14 страницNear Miss Reportingananthu.u100% (4)

- Blood Anatomy and Physiology ReviewДокумент20 страницBlood Anatomy and Physiology ReviewStacey CamilleОценок пока нет

- Evaluation and Comparison of Highly Soluble Sodium Stearyl Fumarate With Other Lubricants in VitroДокумент8 страницEvaluation and Comparison of Highly Soluble Sodium Stearyl Fumarate With Other Lubricants in VitroSvirskaitė LaurynaОценок пока нет

- Fpubh 10 1079779Документ10 страницFpubh 10 1079779Dona WirdaningsiОценок пока нет

- TDS-PE-102-UB5502H (Provisional) 2019Документ2 страницыTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraОценок пока нет

- TOCДокумент14 страницTOCAthirah HattaОценок пока нет

- Using Oxidation States To Describe Redox Changes in A Given Reaction EquationДокумент22 страницыUsing Oxidation States To Describe Redox Changes in A Given Reaction EquationkushanОценок пока нет

- DexaДокумент36 страницDexaVioleta Naghiu100% (1)

- Clinical Crown Lengthening in The Esthetic Zone2028Документ12 страницClinical Crown Lengthening in The Esthetic Zone2028AchyutSinhaОценок пока нет

- (R#1) XQ-450 - 600-800VДокумент121 страница(R#1) XQ-450 - 600-800VFrancisco PestañoОценок пока нет

- Field Study 1-Act 5.1Документ5 страницField Study 1-Act 5.1Mariya QuedzОценок пока нет

- Corrosion Short Courses - Environmental CrackingДокумент8 страницCorrosion Short Courses - Environmental CrackingMario SalayaОценок пока нет

- PackageДокумент3 страницыPackagegvspavan67% (3)

- Kristen Swanson's Theory of CaringДокумент12 страницKristen Swanson's Theory of CaringAlexandria David50% (2)

- Complete Prerequisite Program v2Документ78 страницComplete Prerequisite Program v2Ramasubramanian Sankaranarayanan100% (1)

- Cruz v. CA - G.R. No. 122445 - November 18, 1997 - DIGESTДокумент2 страницыCruz v. CA - G.R. No. 122445 - November 18, 1997 - DIGESTAaron Ariston80% (5)

- Parle G ReportДокумент7 страницParle G ReportnikhilОценок пока нет

- Hygold 5000Bs: Base Oil Marketing SpecificationДокумент1 страницаHygold 5000Bs: Base Oil Marketing Specificationsamsoon80100% (1)

- Pinoy Ree - EeДокумент138 страницPinoy Ree - EeChilvin ChipmunkОценок пока нет

- Chapter 2 - Alkanes PDFДокумент54 страницыChapter 2 - Alkanes PDFSITI NUR ALISSA BINTI AHMAD RASMANОценок пока нет

- Tutorial Slides - Internal Forced Convection & Natural ConvectionДокумент31 страницаTutorial Slides - Internal Forced Convection & Natural ConvectionVivaan Sharma75% (4)

- OxygendemandДокумент12 страницOxygendemandAllenОценок пока нет

- The Man S Bible 50 Essential Tips For Success With Your Mind Body and WomenДокумент155 страницThe Man S Bible 50 Essential Tips For Success With Your Mind Body and WomenDonStemple100% (4)

- 04 TitrimetryДокумент7 страниц04 TitrimetryDarwin Fetalbero ReyesОценок пока нет

- Imperial SpeechДокумент2 страницыImperial SpeechROJE DANNELL GALVANОценок пока нет

- 19.-Solid Waste TreatmentДокумент108 страниц19.-Solid Waste TreatmentShaira Dale100% (1)

- Maintenance Service Procedure Document For AMC: Scada &telecom System For Agcl Gas Pipeline NetworkДокумент17 страницMaintenance Service Procedure Document For AMC: Scada &telecom System For Agcl Gas Pipeline NetworkanupamОценок пока нет

- Jose de Villa National School: Home Visitation FormДокумент3 страницыJose de Villa National School: Home Visitation FormNoli AsuroОценок пока нет

- Filipino Concept of Health and IllnessДокумент43 страницыFilipino Concept of Health and IllnessFelisa Lacsamana Gregorio50% (2)

- Blockchain Deck PDFДокумент65 страницBlockchain Deck PDFsankhaОценок пока нет

- digiPHONENT UG enДокумент44 страницыdigiPHONENT UG enIrving Javier Leal OrtizОценок пока нет