Академический Документы

Профессиональный Документы

Культура Документы

TechTip GC Liners 1

Загружено:

bnechitaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TechTip GC Liners 1

Загружено:

bnechitaАвторское право:

Доступные форматы

Technical Help Desk

Technical Tip

GC Liner Labyrinth - How to choose the right Injector insert

J. Kuipers, N. Reuter*, E. de Witte, Technical Helpdesk Europe, Middelburg, The Netherlands

Injections and vaporization in gas chromatography are influenced by a number of variables. The liner always

plays a significant role. The most important ones are liner design and volume, sample composition, injector

heat capacity, heat transfer and adsorption effects. These factors together with the type of injection deter-

mine for a large extent the choice of liner.

Liner Types

Three major types of injection based on flash vaporization of the sample can be distinguished:

1. Direct injection

After flash vaporization the entire sample is transferred to the column. The sample transfer speed in

the injector is determined by column flow and volume of the injector liner. This injection type is most

commonly applied for 0.53 mm ID columns or packed columns. Injection volumes usually do not ex-

ceed 1 µl. This maximum in injection volume is related to the internal volume of the liner.

2. Split injection

After flash vaporization the sample is divided into two streams. One directed towards the column, the

other to the split vent. Here, the sample transfer speed in the injector is mainly determined by the flow

of the split vent and the liner volume. The column flow plays an insignificant role. A high transfer speed

of the sample is critical for the quick introduction of the compounds into the capillary column maintain-

ing the columns separation efficiency Split injections are used for all capillary columns with ID‘s rang-

ing from 100 µm to 530 µm. The maximum injection volume for split injections is about 1 µl.

3. Split/Splitless

During the initial splitless period the vaporized sample is transferred to the column. The capillary col-

umn flow and the liner volume determine the speed and efficiency of this process. Larger injection vol-

umes are possible for splitless type injections; volumes up to 5 µl are not uncommon. These large in-

jection volumes can never be injected at once because of possible liner overload but must be careful

introduced at a rate of about 1 µl/sec.

Liner volume

The sample gas volume, which at one time resides in the injector, should in all cases be smaller than the

internal volume of the liner. If not, the liner is overloaded and back flash of the sample into various (metal)

parts of the injector may occur. This phenomenon will cause poor injection profiles, bad peak shapes, ad-

sorption and possible sample carry over. Many liners used for direct and split injection have dimensions of

about 80 mm x 4 mm resulting in an internal volume of ca. 1ml. The effective volume available for the sample

Varian Analytical Instruments Page 1 of 4

Technical Help Desk

Technical Tip

is however significantly lower as part of the liner volume will always be filled with carrier gas. The list below

indicates the solvent expansion volume per µl at 250 °C and 50 kPa

Methanol 0.65 ml

n-hexane 0.2 ml

Isopropanol 0.34 ml

Water 1.46 ml

Dichloromethane 0.41 ml

It is clear from the above that water and methanol in particular quickly can cause liner overload and some

care must taken if these solvents are used. For these solvents smaller injection volumes than 1 µl are to be

recommended.

Injector heat capacity

The efficient and quick evaporation of the sample is influenced by the following factors:

• sample volume

• type of solvent and sample components

• injector temperature

• injector and liner geometry and design

• presence of quartz wool or other liner fillings

The last three determine the heat capacity of the injector and its ability for heat transfer to the sample. The

below list compares the amount of energy needed for evaporation of methanol and water relative to cyclo-

hexane.

Water 5.22

Methanol 3.29

Cyclohexane 1.00

Solvents like methanol and water require much more energy than other common solvents for their evapora-

tion therefore they need a larger heat capacity and better heat transfer system for a quick evaporation.

This can be accomplished by using higher injector temperatures (>275 °C) and larger liner surface areas.

Glass or quartz wool is often used to increase the injectors heat transfer capacity. The evaporation of higher

boiling compounds also requires more energy and also in those cases quartz wool is often used. Besides

benefits glass or quartz wool also has a few disadvantages. The wool can become adsorptive especially if

some fibers are broken or when it has become dirty. It should be exchanged at a regular basis to prevent

chromatographic problems

Discrimination effects

The main aim and challenge of injections is to maintain sample integrity and sample composition during its

transition from the liquid to the gaseous state and also during the sample transfer from injector to the column.

The evaporation process of low boiling compounds is always quicker than that of high molecular weight

ones. This difference accounts for the often-mentioned discrimination effects caused by injections. In gen-

eral, the quicker and more complete the evaporation of the sample, the less discrimination effects will be ob-

served. Higher injector temperatures, special liner design and quartz wool will help to minimize these effects.

Inconsistent discrimination profiles will result in poorer repeatability.

Varian Analytical Instruments Page 2 of 4

Technical Help Desk

Technical Tip

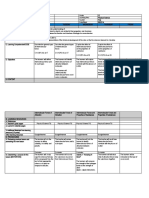

Liners for splitless injections

Straight liner

These are low cost liners for samples with a narrow boiling point range and little risk of ther-

mal decomposition. Can be packed with quartz wool to aid evaporation, limit discrimination

and trap non-volatile materials. Do not use for high boiling samples. Comes usually in 2 or 4

mm ID. Use the 4 mm version for sample volumes > 2 µl to prevent liner overload.

Gooseneck

Minimizes breakdown of active compounds and improves the splitless efficiency. The

gooseneck prevents the sample from reaching metal injector parts, which could cause de-

composition of sensitive compounds. The gooseneck is positioned at the top of the injector.

It is generally regarded as the best splitless liner.

Gooseneck with wool

The single gooseneck can be easily packed with quartz or glass wool to minimize

discrimination. Wool is also a risk as it can become active and adsorptive due to the trapping

of non-volatile residues. Replace it at regular intervals.

Double Gooseneck

The two goosenecks isolate the sample vaporization cloud from any metal injector parts.

The risk of catalytic breakdown is reduced. This type of liner can not packed with glass wool.

Recessed Gooseneck

This model has the same advantages as the other goosenecks but in addition it can be

packed with glass wool at the top. It can also be used for dual column analysis

Varian Analytical Instruments Page 3 of 4

Technical Help Desk

Technical Tip

Liners for split injections

Frit Splitter

The ceramic frit will prevent dirt and non-volatiles from reaching the column. The frit can be-

come active. The gooseneck prevents back flash.

Inverted -or Laminar Cup Splitter

The cup will promote evaporation and mixing of the sample with the carrier gas. It is the best

splitter for higher molecular weight compounds. Slightly larger injection volumes are possible

because the cup will hold the sample liquid until it vaporizes. It is difficult to clean and is rela-

tively expensive.

Baffle Splitter

The baffle creates a turbulent flow, which results in more reproducible injections. Not well

suited for higher boiling compounds because of incomplete vaporization and thus subject to

discrimination.

Liners for direct injections

Straight tube

This type of liner is more suited for packed columns than it is for 0.53 mm ID columns. The

wide-bore column should be positioned at the bottom of the liner just piercing through the

ferrule. This will minimize the effects of possible dead volume during injections although in-

jector parts, which are swept poorly with carrier gas will result in poor injection profiles.

Gooseneck

This is a different type of gooseneck liner where the gooseneck holds the wide-bore column

in position. This design effectively eliminates any dead volume in the injector and provides

the best possible injection profile for wide-bore columns. In reversed position it can also be

used for on-column injections on 0.53 mm columns.

Varian Analytical Instruments Page 4 of 4

Вам также может понравиться

- Distillation ColumnДокумент59 страницDistillation Columnfurqankausarhaider100% (5)

- Basic Filtration ConceptsДокумент3 страницыBasic Filtration ConceptsAFLAC ............Оценок пока нет

- Simple Shear Connection DesignДокумент2 страницыSimple Shear Connection DesignElvin SandajanОценок пока нет

- General Aviation Airport Pavement Design PDFДокумент12 страницGeneral Aviation Airport Pavement Design PDFNaved ShahОценок пока нет

- Arbor - Making An Easy ArborДокумент5 страницArbor - Making An Easy ArbordaniellourencoОценок пока нет

- Color Coding The Periodic TableДокумент4 страницыColor Coding The Periodic TableClaire O'MahonyОценок пока нет

- Chromatography IVДокумент55 страницChromatography IVRussell ChuaОценок пока нет

- Analyzer Sample Cond Basic MT I atДокумент3 страницыAnalyzer Sample Cond Basic MT I atAnonymous dPUUgoОценок пока нет

- Physical Science DLP Q1W3Документ7 страницPhysical Science DLP Q1W3junar asentistaОценок пока нет

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsОт EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Distillation Column Tray Selection & Sizing - 1 - Separation Technologies PDFДокумент22 страницыDistillation Column Tray Selection & Sizing - 1 - Separation Technologies PDFmehul10941100% (1)

- Water Pollution, Causes and EffectsДокумент28 страницWater Pollution, Causes and EffectsRuchir Gupta67% (3)

- GRCA 2015 Congress - The International Glassfibre Reinforced Concrete Association (GRCA) For All Your GRC - GFRC InformationДокумент2 страницыGRCA 2015 Congress - The International Glassfibre Reinforced Concrete Association (GRCA) For All Your GRC - GFRC InformationselcuksivaciОценок пока нет

- Anh văn chuyên ngành hóa học và thực phẩmДокумент1 784 страницыAnh văn chuyên ngành hóa học và thực phẩmTìm Nơi Bình YênОценок пока нет

- Choosing The Right Conformal Coating The Facts & MythsДокумент4 страницыChoosing The Right Conformal Coating The Facts & Mythssdfdfs7253Оценок пока нет

- Chapter 5Документ70 страницChapter 5Husnain AliОценок пока нет

- Split and Splitless InjectionДокумент44 страницыSplit and Splitless InjectionBishoy F. YoussefОценок пока нет

- Astm C1567 - 13 PDFДокумент6 страницAstm C1567 - 13 PDFAnonymous SBjNS7Gw0qОценок пока нет

- A Guide To Optimizing In-Tank Agitation and Mixing Using EductorsДокумент12 страницA Guide To Optimizing In-Tank Agitation and Mixing Using EductorsCarlos DiazОценок пока нет

- Orsat ApparatusДокумент7 страницOrsat ApparatusTejas Desai100% (1)

- Design of AbsorberДокумент18 страницDesign of AbsorberAdeel Ahmed100% (2)

- FRI Internal Design Vol4Документ55 страницFRI Internal Design Vol4syamsudin2006Оценок пока нет

- Study of Corrosion Rate in Water Treatment Plant in OilfieldДокумент12 страницStudy of Corrosion Rate in Water Treatment Plant in OilfieldJose Barret0Оценок пока нет

- Chromatography: Reagent ChemicalsДокумент9 страницChromatography: Reagent ChemicalsRonaldo JanglinОценок пока нет

- HPX 87c ManualДокумент22 страницыHPX 87c ManualSharini_Mu_oz_137Оценок пока нет

- Bresle Test Kit PDFДокумент4 страницыBresle Test Kit PDFmuthukumarОценок пока нет

- Filter Water Separator ElementsДокумент28 страницFilter Water Separator Elementslimhockkin3766Оценок пока нет

- How To Choose A Wine Crossflow Microfiltration SystemДокумент4 страницыHow To Choose A Wine Crossflow Microfiltration SystemEugen OdainiiОценок пока нет

- ALPS Application Note - Leak Testing Injection Blow Molded BottlesДокумент5 страницALPS Application Note - Leak Testing Injection Blow Molded BottlesgovindОценок пока нет

- Spray ChamberДокумент5 страницSpray ChamberAristy MirandaОценок пока нет

- S-Flow Houillon Viscometer - UpdatedДокумент31 страницаS-Flow Houillon Viscometer - UpdatedAlamin Saj EngineeringОценок пока нет

- Droplet Formation in A Microchannel NetworkДокумент3 страницыDroplet Formation in A Microchannel Network章昊Оценок пока нет

- Agilent - GC VialsДокумент26 страницAgilent - GC Vialsalchemist90Оценок пока нет

- BW Spray Pump SP-25 EN 2020 GL 070 PreviewДокумент2 страницыBW Spray Pump SP-25 EN 2020 GL 070 PreviewJavi LegaОценок пока нет

- Crossflow Filtration: HandbookДокумент20 страницCrossflow Filtration: HandbookAlgirdas BaranauskasОценок пока нет

- 4.4.4 High-Performance Liquid Chromatography (HPLC) : Using The Microscale Chromatography ColumnsДокумент2 страницы4.4.4 High-Performance Liquid Chromatography (HPLC) : Using The Microscale Chromatography ColumnsJuanОценок пока нет

- Fluid Power Fluid Power Equipment Tutorial - Hydraulic Filters and ReservoirsДокумент0 страницFluid Power Fluid Power Equipment Tutorial - Hydraulic Filters and ReservoirsvelavansuОценок пока нет

- HPTLCДокумент46 страницHPTLCVedha K Chalam100% (1)

- Cross Flow Filtration HandbookДокумент21 страницаCross Flow Filtration Handbooksahar vahdatifarОценок пока нет

- Bioreactor Engineering Module-1 Basic Design and Construction of A Fermentor and Its AncillariesДокумент23 страницыBioreactor Engineering Module-1 Basic Design and Construction of A Fermentor and Its AncillariesssfoodtechОценок пока нет

- Recent Advances in Spiral WoundДокумент6 страницRecent Advances in Spiral WoundIndyОценок пока нет

- Aseptic Processing: Sterilization by FiltrationДокумент10 страницAseptic Processing: Sterilization by FiltrationEjaj SumitОценок пока нет

- FLEXO June2012Документ4 страницыFLEXO June2012Dani MakersОценок пока нет

- Design of Absorber PDF FreeДокумент18 страницDesign of Absorber PDF FreeANGELINA NITA WIDIYAWATIОценок пока нет

- Guidelines For Use and Care of Aminex Resin-Based ColumnsДокумент22 страницыGuidelines For Use and Care of Aminex Resin-Based Columns黃英婷Оценок пока нет

- Volumetric GlasswareДокумент17 страницVolumetric Glasswaremaduche1234Оценок пока нет

- Test Bench Preventative Maintenance and Operational GuideДокумент4 страницыTest Bench Preventative Maintenance and Operational GuideKeron TrotzОценок пока нет

- Life Sciences46Документ10 страницLife Sciences46Siyanda DubeОценок пока нет

- FILMTEC Membranes Interconnector Technology For 8-Inch Diameter FILMTEC ElementsДокумент4 страницыFILMTEC Membranes Interconnector Technology For 8-Inch Diameter FILMTEC ElementsGonzalo MijaresОценок пока нет

- Obturation of Root Canal System: Ass. Prof. Dr. Anas F MahdeeДокумент33 страницыObturation of Root Canal System: Ass. Prof. Dr. Anas F MahdeeThin TranphuocОценок пока нет

- Fluid Power Fluid Power Equipment Tutorial - Hydraulic Filters and ReservoirsДокумент10 страницFluid Power Fluid Power Equipment Tutorial - Hydraulic Filters and ReservoirsBhushan Verma100% (1)

- HPTLCДокумент46 страницHPTLCFree Escort Service0% (1)

- Sample Preparation and Assaying: G E. G, E V. P, W E. H, JДокумент6 страницSample Preparation and Assaying: G E. G, E V. P, W E. H, JBrunno AndradeОценок пока нет

- DialysisДокумент27 страницDialysisalen19819072Оценок пока нет

- Plant Design MCQ PDFДокумент12 страницPlant Design MCQ PDFKapilSahuОценок пока нет

- 11mm ColumnДокумент3 страницы11mm Columnpepecolon123Оценок пока нет

- Nickel MPS 300 1Документ12 страницNickel MPS 300 1Francisco BocanegraОценок пока нет

- RVDFДокумент8 страницRVDFSiska MilalaОценок пока нет

- Electrocoat 101 105Документ5 страницElectrocoat 101 105Sy Nguyen VietОценок пока нет

- Enhancing The Performance of Rotary Vacuum Drum FilterДокумент8 страницEnhancing The Performance of Rotary Vacuum Drum FilterBernardo RodriguesОценок пока нет

- Ai Hempadur 87540 EnglishДокумент2 страницыAi Hempadur 87540 EnglishAmilcar BolagОценок пока нет

- Dnvps Line Sampler: (Marpol Annex Vi-Compliant)Документ6 страницDnvps Line Sampler: (Marpol Annex Vi-Compliant)dassi99Оценок пока нет

- Macherey Nagel TLCДокумент45 страницMacherey Nagel TLCRia Doloking SituruОценок пока нет

- M4 ManualДокумент20 страницM4 Manualamit64007Оценок пока нет

- GCTroubleshooting Part One NotesДокумент5 страницGCTroubleshooting Part One NotesSoheil MoghadamОценок пока нет

- Bomba Peristáltica ManualДокумент5 страницBomba Peristáltica ManualEdinson BlancoОценок пока нет

- Zen ThaneДокумент11 страницZen ThaneM CОценок пока нет

- The Basics of Hydraulic FiltrationДокумент3 страницыThe Basics of Hydraulic Filtrationbee1406763181Оценок пока нет

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersОт EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersОценок пока нет

- Parker N2 Compact User Guide - ENДокумент42 страницыParker N2 Compact User Guide - ENbnechitaОценок пока нет

- Das 2Документ265 страницDas 2bnechitaОценок пока нет

- Centri Series BrochureДокумент12 страницCentri Series BrochurebnechitaОценок пока нет

- GC 2008 Simultaneous Analysis Compounds Content Beer HeadspaceДокумент7 страницGC 2008 Simultaneous Analysis Compounds Content Beer HeadspacebnechitaОценок пока нет

- Ebook GC Tips Tricks 5994 4947en AgilentДокумент19 страницEbook GC Tips Tricks 5994 4947en AgilentbnechitaОценок пока нет

- Improve-Sensitivity-for-Antisense-Oligonucleotide-Quantification-in-Plasma Using-MicroLC-MRM-MethodologyДокумент5 страницImprove-Sensitivity-for-Antisense-Oligonucleotide-Quantification-in-Plasma Using-MicroLC-MRM-MethodologybnechitaОценок пока нет

- BR Phenols Smoke Impacted Wines Gcms 5994 3644en AgilentДокумент5 страницBR Phenols Smoke Impacted Wines Gcms 5994 3644en AgilentbnechitaОценок пока нет

- Materials Today Communications: S. Deniz Varsavas, Cevdet KaynakДокумент10 страницMaterials Today Communications: S. Deniz Varsavas, Cevdet KaynakbnechitaОценок пока нет

- Combating The Helium Shortage: Alternative Options For Your GC-VUV TechnologyДокумент52 страницыCombating The Helium Shortage: Alternative Options For Your GC-VUV TechnologybnechitaОценок пока нет

- Java Programming Cheat SheetДокумент2 страницыJava Programming Cheat SheetbnechitaОценок пока нет

- An Introduction To Gas Chromatography - Vacuum Ultraviolet SpectrosДокумент42 страницыAn Introduction To Gas Chromatography - Vacuum Ultraviolet SpectrosbnechitaОценок пока нет

- Juices Enriched With Phenolic Extracts From Grapes: Corresponding Author: Jana - Kulichova@mendelu - CZДокумент7 страницJuices Enriched With Phenolic Extracts From Grapes: Corresponding Author: Jana - Kulichova@mendelu - CZbnechitaОценок пока нет

- W 03540 enДокумент28 страницW 03540 enbnechitaОценок пока нет

- Trace Analysis of Ammonia in Ethylene by Gas Chromatography and Nitrogen Chemiluminescence DetectionДокумент4 страницыTrace Analysis of Ammonia in Ethylene by Gas Chromatography and Nitrogen Chemiluminescence DetectionbnechitaОценок пока нет

- Bautista2015 Article EnvironmentallyInducedChangesIДокумент15 страницBautista2015 Article EnvironmentallyInducedChangesIbnechitaОценок пока нет

- Spiridon p.629-635Документ7 страницSpiridon p.629-635bnechitaОценок пока нет

- Bio-Poly (Butylene Succinate) and Its Composites With Grape Pomace: Mechanical Performance and Thermal PropertiesДокумент12 страницBio-Poly (Butylene Succinate) and Its Composites With Grape Pomace: Mechanical Performance and Thermal PropertiesbnechitaОценок пока нет

- Capillaryapplicationdata PDFДокумент52 страницыCapillaryapplicationdata PDFbnechitaОценок пока нет

- 14 FungopДокумент8 страниц14 FungopbnechitaОценок пока нет

- 2018-2066 Short CommunicationДокумент3 страницы2018-2066 Short CommunicationbnechitaОценок пока нет

- Aroma Impact Components of Brazilian Cabernet Sauvignon Wines Using Detection Frequency Analysis (GC-olfactometry) PDFДокумент9 страницAroma Impact Components of Brazilian Cabernet Sauvignon Wines Using Detection Frequency Analysis (GC-olfactometry) PDFbnechitaОценок пока нет

- Journal of Food Engineering: John S. Roberts, David R. Kidd, Olga Padilla-ZakourДокумент6 страницJournal of Food Engineering: John S. Roberts, David R. Kidd, Olga Padilla-ZakourbnechitaОценок пока нет

- Aaac Astm B All Aluminium Alloy ConductorДокумент6 страницAaac Astm B All Aluminium Alloy ConductorIngenieria DyconОценок пока нет

- Mini Labo Flyer PDFДокумент2 страницыMini Labo Flyer PDFSinan ÇağlanОценок пока нет

- PFI Polypropylene High Flow HFCP Series Element Filter CartridgesДокумент2 страницыPFI Polypropylene High Flow HFCP Series Element Filter Cartridgesbennypartono407Оценок пока нет

- (Lec6) Phase EquilibriaДокумент52 страницы(Lec6) Phase EquilibriadinurjОценок пока нет

- AFPA SpanTables 1993Документ52 страницыAFPA SpanTables 1993eaglerjoОценок пока нет

- For Bolstering Concrete: Panicum Maximum Jacq. Ash and Pulverized Corbicula Fluminea As An AdmixtureДокумент4 страницыFor Bolstering Concrete: Panicum Maximum Jacq. Ash and Pulverized Corbicula Fluminea As An AdmixtureKristianKurtRicaroОценок пока нет

- Non-Metallic Expansion Joints: Industries, IncДокумент26 страницNon-Metallic Expansion Joints: Industries, IncMauricio ChucuyaОценок пока нет

- Group 1 (Alkali Metals) - Lithium, Sodium, Potassium QPДокумент8 страницGroup 1 (Alkali Metals) - Lithium, Sodium, Potassium QPRODGERS BANDAОценок пока нет

- Concrete Beam DesignДокумент3 страницыConcrete Beam Designheherson juanОценок пока нет

- 4860 Molenaar IIIДокумент165 страниц4860 Molenaar IIIJhinson BriceñoОценок пока нет

- Improving Mechanical Properties of Alsi10Mg Aluminum Alloy Using Ultrasonic Melt Treatment Combined With T6 Heat TreatmentДокумент11 страницImproving Mechanical Properties of Alsi10Mg Aluminum Alloy Using Ultrasonic Melt Treatment Combined With T6 Heat Treatmentפּואַ פּוגאַОценок пока нет

- Product Data Sheet 3900 3900vp General Purpose PH Orp Sensors Rosemount en 70722Документ20 страницProduct Data Sheet 3900 3900vp General Purpose PH Orp Sensors Rosemount en 70722KishorОценок пока нет

- Drug Product DevelopmentДокумент20 страницDrug Product Developmentducluong28Оценок пока нет

- History of Polyester, Its Uses & ManufacturingДокумент5 страницHistory of Polyester, Its Uses & ManufacturingRezaul Karim TutulОценок пока нет

- Paper - Chevron Natural Gas Carbon Capture Technology Testing ProjectДокумент10 страницPaper - Chevron Natural Gas Carbon Capture Technology Testing ProjectendosporaОценок пока нет

- Pneumatic Structures: The Fascination of Pneumatic Structures Begins With The Fascination of The SkyДокумент9 страницPneumatic Structures: The Fascination of Pneumatic Structures Begins With The Fascination of The SkyTangha Muklom KunchaОценок пока нет

- Pulpling of Wood EditedДокумент6 страницPulpling of Wood EditedMuhammad Omar Khan GhouriОценок пока нет

- SXK New Price ListДокумент5 страницSXK New Price ListidchandraОценок пока нет

- D 3517 - 19 ResinДокумент13 страницD 3517 - 19 ResinNeeraj kumarОценок пока нет

- Chem Topic 8 PracticeДокумент8 страницChem Topic 8 Practicekakahem246Оценок пока нет

- Welded Bridge CodeДокумент32 страницыWelded Bridge CodeProduction Galvano IndiaОценок пока нет