Академический Документы

Профессиональный Документы

Культура Документы

Sample WPS OQR

Загружено:

avgpaulАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sample WPS OQR

Загружено:

avgpaulАвторское право:

Доступные форматы

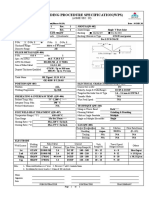

CANADOIL ASIA LTD.

Page 1 of 3

AMATA CITY INDUSTRIAL ESTATE

7/204 MOO 6 TUMBOL MARBYANGPORN

AMPHUR PLUAKDAENG RAYONG, THAILAND

21140 TEL: 66-3865-0120-7 FAX: 66-3865-0123

http:// www.canadoilasia.com

Procedure Qualification Record (PQR)

PQR No. F-8-TM-1L(P) Date February 4, 2010

Welder Name Mr. Sri Jitsanthia Welding Process GTAW & SMAW

Welder ID GTAW & SMAW : 129FB Process Type Manual

BASE METAL ( QW-403 )

Material Spec./ Grade SA-240 TP321H To SA-240 TP321H

ASME P No. / Group No. P-No.8 Gr. No.1 To P-No.8 Gr. No.1

Coupon Dimension 150 mm.X 500 mm.X W.T. 25 mm To 150 mm.X 500 mm.X W.T. 25 mm

Manufacturer INDUSTEEL GROUP ARCELOR To INDUSTEEL GROUP ARCELOR

Heat No. 0461A (Mfg. Heat no.F4638) To 0461A (Mfg. Heat no.F4638)

Carbon content 0.045% To 0.045%

FILLER METAL ( QW-404 )

Electrode Classification 1) ER 347 2) E 347-16 Flux Classification (SAW) 1) N/A 2) N/A

AWS Specification 1) A 5.9 2) A5.4 Flux Type (Active,Neutral,Alloyed) 1) N/A 2) N/A

Filler Size 1) 2.4 mm. 2) 3.2 mm. Manufacturer / Trade Name 1) N/A 2) N/A

A No. 1) 8 2) 8 Batch Number 1) N/A 2) N/A

F No 1) 6 2) 5 Filler Type

Manufacturer / Trade Name 1) RODDACCIAI RW 347 2) ELETTRODO FROINOX E 347-16 (Solid/Metal or Flux Cored/Powder) 1) Solid 2) N/A

Batch No. 1) 459630 2) A005Q26 Weld Metal Thickness 1) 8.0 mm. 2) 17.0 mm.

POSITION ( QW-405 ) GAS ( QW-408 )

Welding Position 3G Shielding Gas / Composition Ar 99.9 %

Welding Progression Uphill Shielding Gas Flow Rate 15-20 L/min.

Backing Gas / Composition Ar 99.9 %

Backing Gas Flow Rate 15-20 L/min.

PREHEAT ( QW-406 ) HEAT TREATMENT ( QW-407 )

Preheat Temp (Min) 100 ˚C Heat treatment Method N/A

Preheat Method N/A Soaking Temp N/A

Preheat Check N/A Soaking Time N/A

Interpass Temp (Max) 150 ˚C Heating Rate N/A

Cooling Rate N/A

ELECTRICAL CHARACTERISTICS ( QW-409 )

Current 1) DC 2) DC Polarity 1) EN 2) EP

Amps 1) 118.6 - 180.4 A 2) 80.4 - 89.4 A Volts 1) 9.9 - 11.6 V 2) 25.6 - 28.6 V

TECHNIQUE ( QW-410 )

Single or Multiple Pass 1) Multiple Pass 2) Multiple Pass Single / Multiple Electrode 1) Single Electrode 2) Single Electrode

Stringer Bead 1) N/A 2) N/A Weave Bead 1) Weave Bead 2) Weave Bead

Tungsten Electrode Type 1) EWTh-2 2) N/A Tungsten Electrode Size 1) 2.4 mm. 2) N/A

Mode of Metal Transfer 1) N/A 2) N/A Wire Feed Speed 1) N/A 2) N/A

Orifice Gas Cup Size 1) No.6 2) N/A Oscillation 1) N/A 2) N/A

Method of Back Gouging 1) N/A 2) N/A Peening 1) N/A 2) N/A

Contact Tube to Work Distance 1) N/A 2) N/A Other 1) N/A 2) N/A

PREPARED BY REVIEWED BY APPROVED BY

Canadoil Asia Ltd. Canadoil Asia Ltd. Canadoil Asia Ltd.

Form No.12B Rev.1, Date 29 Nov. 2007

CANADOIL ASIA LTD.

Page 2 of 3

AMATA CITY INDUSTRIAL ESTATE

7/204 MOO 6 TUMBOL MARBYANGPORN

AMPHUR PLUAKDAENG RAYONG, THAILAND

21140 TEL: 66-3865-0120-7 FAX: 66-3865-0123

http:// www.canadoilasia.com

Procedure Qualification Record (PQR)

PQR No. : F-8-TM-1L (P) Welder ID. GTAW & SMAW :129FB

Date : February 4, 2010 Welding Machine No. F-A-R400-025

Tensile Test ( QW-150 ) : Results as per attached report No. PQR 001/2010

Ultimate Unit

Width Thickness Area Ultimate total load Type of Failure &

Specimen No. Stress

(mm.) (mm.) (mm.2) (N.) Location

(N./mm.2)

PL-TT-WM1 19.1 21.32 407.21 246274.7 604.78 Base Metal

PL-TT-WM2 18.9 21.34 403.33 245632.5 609.02 Base Metal

Guided - Bend Tests (QW - 160) : Results as per attached report No. PQR 001/2010

Specimen No. Type of Bend ( Transverse or Longitudinal, Root, Face or Side Bend ) Result

PL-GB-FB1 Side Bend Accepted, No open discontinuity

PL-GB-FB2 Side Bend Accepted, No open discontinuity

PL-GB-RB1 Side Bend Accepted, No open discontinuity

PL-GB-RB2 Side Bend Accepted, No open discontinuity

Toughness Tests (QW - 170) : N/A

Specimen Test Impact Values ( Joules )

Specimen Notch Average

Size Temp.

No. Location 1 2 3 ( Joules )

( mm.) ( oC )

Other Test Result : Radiographic Examination Accepted (Ref. Report No.RT-PQR-002/2010)

Macro Examination Accepted (Ref. Report No.M100002)

Test conducted by Canadoil Asia Laboratory

We certify that the statements in this record are correct and that the test welds were prepared, welded and tested in accordance with

the requirements of Section IX of the ASME code.

PREPARED BY REVIEWED BY APPROVED BY

Form No.12B Rev 1, Date 29 Nov 2007

Page 2 of 3

Canadoil Asia Ltd. Canadoil Asia Ltd. Canadoil Asia Ltd.

Form No.12B Rev 1, Date 29 Nov 2007

CANADOIL ASIA LTD. Page 3 of 3

AMATA CITY INDUSTRIAL ESTATE

7/204 MOO 6 TUMBOL MARBYANGPORN

AMPHUR PLUAKDAENG RAYONG, THAILAND

21140 TEL: 66-3865-0120-7 FAX: 66-3865-0123

http:// www.canadoilasia.com

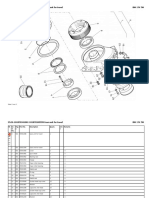

Procedure Qualification Record (PQR)

PQR NO F-8-TM-1L (P) Welder ID GTAW & SMAW :129FB

Date February 4, 2010 Welding Machine No F-A-R400-025

JOINT CONFIGURATION WELD SEQUENCE

θ =55

Outside

8 9 10

T = 25 mm T = 25 mm 6 7

f=0 5 SMAW

4

3

2 GTAW

H 0461A H 0461A

R=4 1

Inside

PL 300 X 500 X 25 t

WELDING PARAMETERS

Filler Metal Welding Current

Wire Feed Inter pass

Layer Weld Welding Travel Speed Heat Input

Type / Volt Speed

No. Pass Process AWS Class Trade Name Dia. (mm) Amp (cm/min) (kJ/cm)

Polarity (mm/sec) Temp( oC )

RODDACCIAI

1 Root GTAW ER 347 2.4 DC-EN 118.6 9.9 6.0 - 11.7 70

RW 347

RODDACCIAI

2 Hot GTAW ER 347 2.4 DC-EN 167.1 11.1 9.5 - 11.7 86

RW 347

RODDACCIAI

3 Fill GTAW ER 347 2.4 DC-EN 180.4 11.6 10.3 - 12.2 90

RW 347

FROINOX E

4 Fill SMAW E 347-16 3.2 DC-EP 87.4 28.6 10.5 - 14.3 104

347-16

FROINOX E

5 Fill SMAW E 347-16 3.2 DC-EP 89.3 28.1 9.7 - 15.5 121

347-16

FROINOX E

6 Fill SMAW E 347-16 3.2 DC-EP 88.3 27.6 9.2 - 15.9 129

347-16

FROINOX E

7 Fill SMAW E 347-16 3.2 DC-EP 89.4 27.3 9.1 - 16.1 74

347-16

FROINOX E

8 Cap SMAW E 347-16 3.2 DC-EP 82.9 26.7 8.1 - 16.4 86

347-16

FROINOX E

9 Cap SMAW E 347-16 3.2 DC-EP 83.3 25.6 8.5 - 15.1 92

347-16

FROINOX E

10 Cap SMAW E 347-16 3.2 DC-EP 80.4 25.7 8.4 - 14.8 107

347-16

PREPARED BY REVIEWED BY APPROVED BY

Canadoil Asia Ltd. Canadoil Asia Ltd. Canadoil Asia Ltd.

Form No.12B Rev.1, Date 29 Nov. 2007

Вам также может понравиться

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Pwps Jo Wps Asme 016 Rev.001Документ2 страницыPwps Jo Wps Asme 016 Rev.001Bagandi ManurungОценок пока нет

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Документ2 страницыASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONДокумент3 страницыWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- WPS-ASME-009-1 Rev1Документ1 страницаWPS-ASME-009-1 Rev1Ahmed LepdaОценок пока нет

- WPS Vessel 1Документ4 страницыWPS Vessel 1Naqqash SajidОценок пока нет

- Proposed WPSДокумент2 страницыProposed WPSChisom Ikengwu100% (2)

- Form Wps JBL09-2011Документ2 страницыForm Wps JBL09-2011fawad aliОценок пока нет

- WELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTДокумент1 страницаWELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTAhmed LepdaОценок пока нет

- Asme IxДокумент1 страницаAsme IxAxel Navarro AlbinesОценок пока нет

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCДокумент5 страницJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148Оценок пока нет

- WPS, PQR & WPQ - Duplex 2205Документ20 страницWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- GMCo - WPSДокумент8 страницGMCo - WPSMohamed AtefОценок пока нет

- WPS 05Документ4 страницыWPS 05Naqqash SajidОценок пока нет

- WPS for Gas Field Development WeldingДокумент2 страницыWPS for Gas Field Development WeldingAhmed LepdaОценок пока нет

- Asme PQRДокумент4 страницыAsme PQRHong Dae Yoon100% (2)

- Manual Standard WeldingДокумент192 страницыManual Standard WeldingGEORGE IVAN0% (1)

- PQR (52a) ModelДокумент1 страницаPQR (52a) ModelSIDDHARTH BEHERAYОценок пока нет

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ3 страницыWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ1 страницаWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaОценок пока нет

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaДокумент5 страницBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaОценок пока нет

- Tips Wps FormatДокумент5 страницTips Wps FormatWaqas WaqasОценок пока нет

- WPS-ASME-007-1 Rev0Документ1 страницаWPS-ASME-007-1 Rev0Ahmed LepdaОценок пока нет

- Joints (Qw-402) DetailsДокумент3 страницыJoints (Qw-402) DetailsNaqqash SajidОценок пока нет

- Stainless steel welding procedure qualification recordДокумент1 страницаStainless steel welding procedure qualification recordchandraОценок пока нет

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFДокумент11 страницEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- PRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWДокумент8 страницPRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWmegantara maromОценок пока нет

- Page No: 01: SA 240 GR 304 SA 240 GR 304Документ5 страницPage No: 01: SA 240 GR 304 SA 240 GR 304jobertОценок пока нет

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectДокумент2 страницыPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungОценок пока нет

- Welding Procedure Specification for Stainless SteelДокумент5 страницWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- Wps FormatДокумент12 страницWps FormatGohilakrishnan ThiagarajanОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Twi LTD: Welding Procedure Specification (WPS) - Page 1Документ2 страницыTwi LTD: Welding Procedure Specification (WPS) - Page 1joehodohОценок пока нет

- WPS 6G CS Pipe CorrectДокумент4 страницыWPS 6G CS Pipe CorrectAla ReguiiОценок пока нет

- According To ASME IX: Welding Procedure Specification (W.P.S)Документ4 страницыAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehОценок пока нет

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeДокумент2 страницыWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- PQR Procedure Qualification Records for GMAW and SAW WeldingДокумент3 страницыPQR Procedure Qualification Records for GMAW and SAW WeldingKumawat PrakashОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- PQR 03 2014Документ2 страницыPQR 03 2014vinuОценок пока нет

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCДокумент7 страницJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCTrường Tùng LýОценок пока нет

- GTAW Welding Procedure for ASTM A53 PipeДокумент2 страницыGTAW Welding Procedure for ASTM A53 PipeS. K. M. ShujonОценок пока нет

- GMAW welding parameters for SS400 pipeДокумент2 страницыGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- WPS 03 2014Документ2 страницыWPS 03 2014vinuОценок пока нет

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Документ6 страниц(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpОценок пока нет

- Welding Procedure SpecificationДокумент27 страницWelding Procedure SpecificationGopakumar K100% (2)

- Final - WPS PQR 86Документ4 страницыFinal - WPS PQR 86Parag WadekarОценок пока нет

- Wps PQR Welder Qualification Certification ConsultancyДокумент2 страницыWps PQR Welder Qualification Certification ConsultancyEmam SayedОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- WELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928Документ2 страницыWELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928duyanhОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Premier Limited Plate Data SheetДокумент14 страницPremier Limited Plate Data SheetGurbir SinghОценок пока нет

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDДокумент5 страницWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriОценок пока нет

- Q-Chem Ethylene Project Welding Procedure SpecificationДокумент1 страницаQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaОценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Industrial retail prices slashed by Rs3/scm for Gujarat GasДокумент9 страницIndustrial retail prices slashed by Rs3/scm for Gujarat GasavgpaulОценок пока нет

- Understanding Rice Husk As A Biomass Fuel EN V1 2013.9.4Документ8 страницUnderstanding Rice Husk As A Biomass Fuel EN V1 2013.9.4Nuc LeusОценок пока нет

- Top Indian Business PublicationsДокумент1 страницаTop Indian Business PublicationsavgpaulОценок пока нет

- HDFC Bank Merger Clarification Remains PositiveДокумент4 страницыHDFC Bank Merger Clarification Remains PositiveavgpaulОценок пока нет

- Understanding Rice Husk As A Biomass Fuel EN V1 2013.9.4Документ8 страницUnderstanding Rice Husk As A Biomass Fuel EN V1 2013.9.4Nuc LeusОценок пока нет

- Bioresources.: Greaseproof Paper Products: A Review Emphasizing Ecofriendly ApproachesДокумент27 страницBioresources.: Greaseproof Paper Products: A Review Emphasizing Ecofriendly ApproachesavgpaulОценок пока нет

- Boiler Retrofit Improves Efficiency and Increases Biomass Firing RatesДокумент12 страницBoiler Retrofit Improves Efficiency and Increases Biomass Firing RatesavgpaulОценок пока нет

- P-1100-Wc-A4 Air Tube Disc Clutches and BrakesДокумент48 страницP-1100-Wc-A4 Air Tube Disc Clutches and BrakesavgpaulОценок пока нет

- PNG 520 - Course On Phase RelationsДокумент173 страницыPNG 520 - Course On Phase RelationsavgpaulОценок пока нет

- Grease Proof PapersДокумент94 страницыGrease Proof PapersavgpaulОценок пока нет

- Tappijournal202110 DLДокумент58 страницTappijournal202110 DLavgpaulОценок пока нет

- SS - Paper TL Case StudyДокумент2 страницыSS - Paper TL Case StudyavgpaulОценок пока нет

- Extend Roll Covering: Effective Water Cooling Systems PerformanceДокумент3 страницыExtend Roll Covering: Effective Water Cooling Systems PerformanceavgpaulОценок пока нет

- Fenner Drives Full CatalogДокумент124 страницыFenner Drives Full CatalogavgpaulОценок пока нет

- Chemicals Play Key Role in Food Packaging: TechlinkДокумент2 страницыChemicals Play Key Role in Food Packaging: TechlinkavgpaulОценок пока нет

- Novel Bio Based Coating For Barrier PapersДокумент23 страницыNovel Bio Based Coating For Barrier PapersavgpaulОценок пока нет

- Understanding Rice Husk As A Biomass Fuel EN V1 2013.9.4Документ8 страницUnderstanding Rice Husk As A Biomass Fuel EN V1 2013.9.4Nuc LeusОценок пока нет

- Better productivity by controlling web tension profileДокумент8 страницBetter productivity by controlling web tension profileavgpaulОценок пока нет

- Improved Performance and Availability by Use of Intelligent Soot Blowing in Recovery BoilersДокумент11 страницImproved Performance and Availability by Use of Intelligent Soot Blowing in Recovery BoilersavgpaulОценок пока нет

- An Optimization Study On Soot-Blowing of Air Preheaters in Coal-Fired Power Plant BoilersДокумент15 страницAn Optimization Study On Soot-Blowing of Air Preheaters in Coal-Fired Power Plant BoilersavgpaulОценок пока нет

- Vacuum Breakers Brochure (Metric)Документ4 страницыVacuum Breakers Brochure (Metric)avgpaulОценок пока нет

- SS - Paper TL Case StudyДокумент2 страницыSS - Paper TL Case StudyavgpaulОценок пока нет

- Steam Generation Unit in A Simple Version of Biomass Based Small Cogeneration UnitДокумент5 страницSteam Generation Unit in A Simple Version of Biomass Based Small Cogeneration UnitavgpaulОценок пока нет

- In-Situ Measurements of Sootblower Jet Impact in Recovery BoilersДокумент7 страницIn-Situ Measurements of Sootblower Jet Impact in Recovery BoilersavgpaulОценок пока нет

- Low Pressure Sootblowing Technology - The State of DevelopmentДокумент18 страницLow Pressure Sootblowing Technology - The State of DevelopmentavgpaulОценок пока нет

- Increase Power Generation with Black Liquor Recovery Boiler MethodsДокумент11 страницIncrease Power Generation with Black Liquor Recovery Boiler MethodsavgpaulОценок пока нет

- Better productivity by controlling web tension profileДокумент8 страницBetter productivity by controlling web tension profileavgpaulОценок пока нет

- Embedding DWF Files in Word: EOT CranesДокумент5 страницEmbedding DWF Files in Word: EOT CranesavgpaulОценок пока нет

- Inventor 11 ExclusiveДокумент7 страницInventor 11 ExclusiveavgpaulОценок пока нет

- Contoured Keyways: EOT CranesДокумент3 страницыContoured Keyways: EOT CranesavgpaulОценок пока нет

- Gear unit travel parts list BW 174 TWДокумент3 страницыGear unit travel parts list BW 174 TWeshopmanual EnamОценок пока нет

- PEHJ0255-00 - Hydraulic Hammer Paste Data SheetДокумент2 страницыPEHJ0255-00 - Hydraulic Hammer Paste Data SheetOscar Delgado0% (1)

- Mil PRF 83483Документ1 страницаMil PRF 83483JOSEОценок пока нет

- List of TESDA Acc Assessment Centers PDFДокумент119 страницList of TESDA Acc Assessment Centers PDFSollee Montaño FerrerОценок пока нет

- Maulana Rosyid Hidayat: Curiculum Vitae 2022Документ2 страницыMaulana Rosyid Hidayat: Curiculum Vitae 2022Ridho ImmahdiОценок пока нет

- Aluminium and Its Alloys: EF420 Lecture 11 John TaylorДокумент48 страницAluminium and Its Alloys: EF420 Lecture 11 John TaylorzorazhrОценок пока нет

- Slitter Knives (Top/Bottom Slitter Knives) 裁切專用刀具-分條圓刀 (上/下圓刀)Документ3 страницыSlitter Knives (Top/Bottom Slitter Knives) 裁切專用刀具-分條圓刀 (上/下圓刀)smartcad60Оценок пока нет

- Stuckey Casing ScrapersДокумент5 страницStuckey Casing ScrapersGeorge Lamey0% (1)

- Amendment No. 1 Hot-Dip Zinc Coatings On Steel and Cast Iron ProductsДокумент2 страницыAmendment No. 1 Hot-Dip Zinc Coatings On Steel and Cast Iron ProductsGMSОценок пока нет

- 1 8159-51CrV4Документ2 страницы1 8159-51CrV4black_absynthОценок пока нет

- A Review of GTAW Gas Tungsten Arc Weldin PDFДокумент8 страницA Review of GTAW Gas Tungsten Arc Weldin PDFMarjorie ManukayОценок пока нет

- NORD-Painting CodeДокумент3 страницыNORD-Painting CodeubabОценок пока нет

- Cold ForgingДокумент12 страницCold Forgingkasana100% (1)

- Dynamic Air ClassifiersДокумент3 страницыDynamic Air Classifierskensley oliveiraОценок пока нет

- This Product Masterspec Section Modifies The Original Masterspec Text and Does Not Include The Full Content of The Original Masterspec SectionДокумент13 страницThis Product Masterspec Section Modifies The Original Masterspec Text and Does Not Include The Full Content of The Original Masterspec SectionEltonОценок пока нет

- Wilson Tool Tapping Tools For TRUMPF MachinesДокумент4 страницыWilson Tool Tapping Tools For TRUMPF MachinesSM TECH SRLОценок пока нет

- DAG LayerДокумент3 страницыDAG LayerSudhansu DashОценок пока нет

- Understanding Lathe Machine Parts, Operations and Tool-Workpiece ContactДокумент12 страницUnderstanding Lathe Machine Parts, Operations and Tool-Workpiece Contactfaizan997Оценок пока нет

- Bondhus CatalogДокумент52 страницыBondhus CatalogCarbide Processors IncОценок пока нет

- Akadi Products Business ProfileДокумент17 страницAkadi Products Business ProfileJayaprakash DОценок пока нет

- Ultra-high Strength Fastener GuideДокумент4 страницыUltra-high Strength Fastener GuidemirosekОценок пока нет

- Binder MCM 001Документ13 страницBinder MCM 001hsemargОценок пока нет

- Korloy Turning InsertsДокумент76 страницKorloy Turning InsertsR AksathОценок пока нет

- Tap-Drill Chart Recommend Tap Drill To Use For 75% Depth of ThreadДокумент1 страницаTap-Drill Chart Recommend Tap Drill To Use For 75% Depth of ThreadPliskinAJОценок пока нет

- Selection & Reference Information: Cutting Orifice Reference Chart - Cutting Tip SizeДокумент5 страницSelection & Reference Information: Cutting Orifice Reference Chart - Cutting Tip SizecarlosОценок пока нет

- Bengalac Red Oxide PrimerДокумент3 страницыBengalac Red Oxide PrimerNagendra BurabattulaОценок пока нет

- Questions CswipДокумент63 страницыQuestions CswipMohamed ElsayedОценок пока нет

- 11.asme CA 360 Nbic Part3Документ50 страниц11.asme CA 360 Nbic Part3udomОценок пока нет

- Fusion Bonded Epoxy Coating: Long Term Corrosion ProtectionДокумент2 страницыFusion Bonded Epoxy Coating: Long Term Corrosion ProtectionLi KLОценок пока нет

- Astm A312Документ12 страницAstm A312EbernalОценок пока нет