Академический Документы

Профессиональный Документы

Культура Документы

152 C - Fire Service Week Observance Fire Safetay

Загружено:

Ows Anish0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров1 страницаfire service week

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документfire service week

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров1 страница152 C - Fire Service Week Observance Fire Safetay

Загружено:

Ows Anishfire service week

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

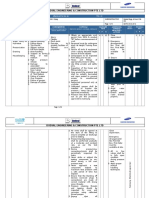

RJ Oil Production - Projects

SPEARHEADING HEALTH, SAFETY & ENVIRONMENT

Fire Service Week Observance & Fire Safety

Background

On 14th April 1944, a major explosion took place on board ship S.S. Fort Stikline carrying explosives and other combustibles

and berthed at Bombay Docks. The explosion and the fire that followed had resulted in massive destruction of ships, port

facilities, and residential area in the neighbourhood besides claiming lives of over 68 fire service personnel, about 150 port

personnel and unaccounted number of civilians. In commemoration of the precious lives lost in the event. April 14 is being

observed as the Fire Service Day and the following the Day as the Fire Service Week (FSW).

The FSW is a grim reminder of the destructive potential of fire and need for fire prevention efforts. Every year fires take a

heavy toll in terms of human lives and property loss. The risk of damage due to fire depends on the combustible available,

the physical arrangement, the geometry of the work location, likelihood of ignition etc. The risk is also controlled by fire

protection measures in place, which related to both fire prevention and fire control. Statistic reveals that nearly 8 – 10% of all

fatalities in industries are due to fire and explosion.

Fire prevention is intended to reduce sources of ignition, to educate the people, to take steps and action to prevent

occurrence of fires and is a protective method in reducing emergencies and the damage caused by fire.

Common Work Place Fire Result From

Combustible & flammable materials in work area due to Poor housekeeping standards.

Lack of hazard / risk awareness of task supervisors and personnel

Release of flammable gas in the vicinity of ignition sources

Oxygen enriched or saturated atmospheres. (Normally available in air approx. 21%).

Presence of vapours of flammable liquids.

Failure to implement specific PTW control measures.

Poor work planning and multiple tasks.

Inadequate fire blanket enclosure for the hot work locations.

Faulty electrical connections, damage equipment, poor workman ship.

Unauthorised operations.

Work Place Fire Prevention Methods

Always maintain good housekeeping at work locations which includes the removal of combustible material, cleaning

of hydrocarbon traces from cellar pits & X’mas trees, valves & flanges nearby.

Inspect the work location and complete the Hot Work check list. Verify inspection sticker/colour coding to verify the

integrity of all hand and power tools and equipment prior to use.

Store, use and handle gas cylinders, related appliances and other flammable material as per safety rules.

Obtain PTW and conduct Gas Testing prior to performing hot or spark potential works in any process area. Also

ensure relevant certificates for all mobile equipment.

Conduct continuous gas monitoring when required. Ensure fire watch man for all hot work.

Implement and maintain all PTW and JSA stated control measures at site. Communicate with team task specific

safety requirements.

Provide proper fire blanket enclosure for the Hot Work locations. Ensure 100% spark containment.

Ensure fire extinguishers, charged fire hose and trained fire watch assigned for all hot work locations at process area.

Be aware of potential for fire blanket contamination by hydrocarbons or other flammable material.

Conduct Toolbox meeting on fire safety and enhance awareness. Implement SIMOP recommendations.

Plan tasks to avoid/reduce same time multiple activities inside confined space (such as cellar pits).

In-case of any fire emergency – STOP the work, Switch off the equipment, Inform Supervisor / Radio room / fire

department and go the nearest assembly point as per wind direction.

FIRE PREVENTION IS BETTER THAN FIRE FIGHTING

आग की रोकथाम आग से लड़ने से बेहतर है

Bulletin- April 2019

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Record Notes of Discussion: Project Name Meeting No. Meeting Type Meeting Date 23Документ2 страницыRecord Notes of Discussion: Project Name Meeting No. Meeting Type Meeting Date 23Ows AnishОценок пока нет

- Lummus Global: RA STATEMENT: Generic RA - Performing Hot WorkДокумент2 страницыLummus Global: RA STATEMENT: Generic RA - Performing Hot WorkOws AnishОценок пока нет

- Pre Erection Scaffolding Inspection: Document Number: D10-PMC-HSE-001Документ2 страницыPre Erection Scaffolding Inspection: Document Number: D10-PMC-HSE-001Ows AnishОценок пока нет

- 5-OHSEMS-PP09-12-FM Inspection Report Each Month Minimum 2 TimesДокумент1 страница5-OHSEMS-PP09-12-FM Inspection Report Each Month Minimum 2 TimesOws AnishОценок пока нет

- Lummus Global: RA STATEMENT: Generic RA - Excavating & ExcavationsДокумент2 страницыLummus Global: RA STATEMENT: Generic RA - Excavating & ExcavationsOws AnishОценок пока нет

- JSA - Installation of U G PipingДокумент11 страницJSA - Installation of U G PipingOws Anish100% (1)

- Rse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerДокумент2 страницыRse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerOws Anish100% (1)

- Quantity Summary Sheet: D10 TONДокумент7 страницQuantity Summary Sheet: D10 TONOws AnishОценок пока нет

- FORM Compliance With LSLawДокумент5 страницFORM Compliance With LSLawOws AnishОценок пока нет

- FATCA-CRS Annexure For Individual Accounts (Including Sole Proprietor) Details Under FATCA and CRSДокумент2 страницыFATCA-CRS Annexure For Individual Accounts (Including Sole Proprietor) Details Under FATCA and CRSOws AnishОценок пока нет

- Hydrotest & Pneumatic Test - TRAДокумент6 страницHydrotest & Pneumatic Test - TRAOws Anish100% (3)

- Finishing Material Status Rev.6Документ2 страницыFinishing Material Status Rev.6Ows AnishОценок пока нет

- MR MR MR: CO2 Project CO2 Project CO2 Project Ssa/Sa Ssa/Sa Ssa/SaДокумент1 страницаMR MR MR: CO2 Project CO2 Project CO2 Project Ssa/Sa Ssa/Sa Ssa/SaOws AnishОценок пока нет

- Architectural Equipment Check List: Doc No: IMF 160-18 DateДокумент1 страницаArchitectural Equipment Check List: Doc No: IMF 160-18 DateOws AnishОценок пока нет

- DG Inspection Check List - 복사본Документ1 страницаDG Inspection Check List - 복사본Ows AnishОценок пока нет

- Competent Person Designation FormДокумент2 страницыCompetent Person Designation FormOws AnishОценок пока нет

- Congratulations: Learning To Coach Online CourseДокумент3 страницыCongratulations: Learning To Coach Online CourseOws AnishОценок пока нет

- WHMIS Definitions: HS1 - 1 Health and SafetyДокумент3 страницыWHMIS Definitions: HS1 - 1 Health and SafetyOws AnishОценок пока нет

- HSE Policy StatementДокумент2 страницыHSE Policy StatementOws AnishОценок пока нет

- Oil Gas CatalogДокумент21 страницаOil Gas CatalogOws AnishОценок пока нет

- HSQE Policy - English PDFДокумент1 страницаHSQE Policy - English PDFOws AnishОценок пока нет

- Hot Work ProcedureДокумент10 страницHot Work ProcedureOws AnishОценок пока нет

- Risk Assessment For 4600002029Документ213 страницRisk Assessment For 4600002029Ows Anish50% (2)

- 437-001-0760 Rules For All Workplaces: General AdministrationДокумент4 страницы437-001-0760 Rules For All Workplaces: General AdministrationOws AnishОценок пока нет

- 437-001-0765 Safety Committees and Safety Meetings: General AdministrationДокумент6 страниц437-001-0765 Safety Committees and Safety Meetings: General AdministrationOws AnishОценок пока нет

- Lock Out and Tag Out Procedures B1Документ12 страницLock Out and Tag Out Procedures B1Ows AnishОценок пока нет

- SRP-Waste Management Plan-G225IEX-SRP-R-PLN-003Документ10 страницSRP-Waste Management Plan-G225IEX-SRP-R-PLN-003Ows AnishОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Practitioners Guide For Business Development Planning in FPOsДокумент70 страницPractitioners Guide For Business Development Planning in FPOsMythreyi ChichulaОценок пока нет

- Liga NG Mga Barangay: Resolution No. 30Документ2 страницыLiga NG Mga Barangay: Resolution No. 30Rey PerezОценок пока нет

- Gravity Based Foundations For Offshore Wind FarmsДокумент121 страницаGravity Based Foundations For Offshore Wind FarmsBent1988Оценок пока нет

- Introduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions ManualДокумент12 страницIntroduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions Manualethelbertsangffz100% (34)

- Paul Milgran - A Taxonomy of Mixed Reality Visual DisplaysДокумент11 страницPaul Milgran - A Taxonomy of Mixed Reality Visual DisplaysPresencaVirtual100% (1)

- EC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - AДокумент29 страницEC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - AAnonymous bSpP1m8j0n50% (2)

- Steam Source Book PDFДокумент108 страницSteam Source Book PDFJose Levican A100% (1)

- Labor CasesДокумент47 страницLabor CasesAnna Marie DayanghirangОценок пока нет

- Sacmi Vol 2 Inglese - II EdizioneДокумент416 страницSacmi Vol 2 Inglese - II Edizionecuibaprau100% (21)

- IP Based Fingerprint Access Control & Time Attendance: FeatureДокумент2 страницыIP Based Fingerprint Access Control & Time Attendance: FeaturenammarisОценок пока нет

- Defeating An Old Adversary Cement Kiln BallsДокумент5 страницDefeating An Old Adversary Cement Kiln BallsManish KumarОценок пока нет

- YeetДокумент8 страницYeetBeLoopersОценок пока нет

- Binder 1Документ107 страницBinder 1Ana Maria Gálvez Velasquez0% (1)

- Intro S4HANA Using Global Bike Solutions EAM Fiori en v3.3Документ5 страницIntro S4HANA Using Global Bike Solutions EAM Fiori en v3.3Thăng Nguyễn BáОценок пока нет

- Writing Task The Strategy of Regional Economic DevelopementДокумент4 страницыWriting Task The Strategy of Regional Economic DevelopementyosiОценок пока нет

- Switch CondenserДокумент14 страницSwitch CondenserKader GüngörОценок пока нет

- Final Project Report GMS BtechДокумент68 страницFinal Project Report GMS Btech02Musaib Ul FayazОценок пока нет

- Projects: Term ProjectДокумент2 страницыProjects: Term ProjectCoursePinОценок пока нет

- Sun Nuclear 3D SCANNERДокумент7 страницSun Nuclear 3D SCANNERFranco OrlandoОценок пока нет

- CEA 4.0 2022 - Current Draft AgendaДокумент10 страницCEA 4.0 2022 - Current Draft AgendaThi TranОценок пока нет

- Jetweigh BrochureДокумент7 страницJetweigh BrochureYudi ErwantaОценок пока нет

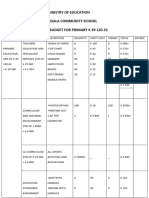

- Ministry of Education Musala SCHДокумент5 страницMinistry of Education Musala SCHlaonimosesОценок пока нет

- Prevalence of Peptic Ulcer in Patients Attending Kampala International University Teaching Hospital in Ishaka Bushenyi Municipality, UgandaДокумент10 страницPrevalence of Peptic Ulcer in Patients Attending Kampala International University Teaching Hospital in Ishaka Bushenyi Municipality, UgandaKIU PUBLICATION AND EXTENSIONОценок пока нет

- Icom IC F5021 F6021 ManualДокумент24 страницыIcom IC F5021 F6021 ManualAyam ZebossОценок пока нет

- Awais Inspector-PaintingДокумент6 страницAwais Inspector-PaintingMohammed GaniОценок пока нет

- Health Informatics SДокумент4 страницыHealth Informatics SnourhanОценок пока нет

- Ficha Tecnica 320D3 GCДокумент12 страницFicha Tecnica 320D3 GCanahdezj88Оценок пока нет

- Aluminium Extrusion Industry in IndiaДокумент3 страницыAluminium Extrusion Industry in Indiakalan45Оценок пока нет

- Business Testimony 3Документ14 страницBusiness Testimony 3Sapan BanerjeeОценок пока нет