Академический Документы

Профессиональный Документы

Культура Документы

Feasiblity Review 1 1 HD Bucket

Загружено:

Sandeep KumarИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Feasiblity Review 1 1 HD Bucket

Загружено:

Sandeep KumarАвторское право:

Доступные форматы

Doc.

No:

Revision No/Date Rev0/

LIUGONG INDIA Issue no /Date: 1

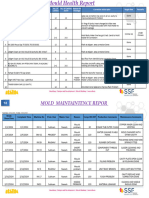

MANUFACTURING FEASIBILITY STUDY REPORT FOR 1.1 HD Bucket

Category ( Process/

Sl no Part Number/ part Name Feasibility issues Current process Suggested process design/inspection Responsibility Status ( GYR) LIPL Updates

/testing/ Facility

1 TORQUE VALUE NOT DEFINED - NEED TO DEFINE THE TORQUE VALUE PROCESS LIPL Torque Value

In drawing the given R20 weld to

2 WELD IS NOT FEASIBLE AS GIVEN IN WE DO THE FILLET WELD AND FILL THE make smooth weld in hatch mark

- PROCESS LIPL

DRAWING R20 AT CORNERS SQUARE WELD WHERE IT REQUIRED area.

SECTION K11 IN REMARK MENTIONED WELD WE WILL FINISH THE WELD IN INCLINED The finishing of 45°±10° acceptable.

3 FINISH WITH 45°. THIS FINISH IS NOT FEASIBLE - PROCESS MEPL This is the weoding to reduce stress

MANNER

IN REGULAR BATCH EXACTLY 45° of welding

IN SECTION C-C WELD SIZE GIVEN IN 8X18 welding should be always '+' side is

4 &16X18, WHICH IS NOT FEASIBLE TO WELD - WE WILL WELD OF FILLET SIZE 16MM PROCESS MEPL accaptable '-'

EXACTLY not accaptable.

5 IN SECTION ALSO GIVEN REMARK IS NEED TO CONFIRM EITHER TO BE LIPL Weld smooth to be make by grinding.

- PROCESS

SMOOTH THE WELD SMOOTH BY GRINDING OR KEEP AS IT IS

IN PORTION E5 IT SEEMS MORE GAP BASED ON 1 ST SAMPLE WE WILL

6 Proto can be make as per Matchwell

BETWEEN RIB AND SIDE PLATE WHICH - MAINTAIN SYMMETRICALLY 12 MM GAP PROCESS MEPL suggetation

CAUSES EXCESS FILL UP OF WELD BETWEEN ALL PLATES TO FILL THE WELD

WALL GAP BETWEEN SIDE PLATE REQUIRED UPDATED DRAWING & CAD Gap can be mailtan 20 MM from Top

7 (97A3085&97A3086) AND SEAT ASSLY - FACILITY LIPL

DRAWING OR 3D MODEL to Seat assembly top plate

(33D1710) TOP NOT GIVEN

8

WALL GAP BETWEEN SIDE PLATE(02G1693) REQUIRED UPDATED DRAWING & CAD Maintain same as 0.95GP Bucket

- FACILITY LIPL

AND BOTTOM PLATE (69A4239) NOT GIVEN DRAWING OR 3D MODEL

9 THICKNESS OF PLATE GIVEN IN 28 MM - NEED DEVIATION TO USE IN 30MM PROCESS LIPL R&D

10 DIM 753 IS NOT FEASIBLE - TO BE CONFIRM EXACT DIMENSION DESIGN LIPL R&D

11 DIM R150, 59 & 96 ARE NOT FEASIBLE TO

DRAFT

- TO BE CONFIRM EXACT DIMENSION DESIGN LIPL R&D

12 WIDTH OF CUTTIONG EDGE PLATE NOT

DEFINED

- TO BE CONFIRM EXACT DIMENSION DESIGN LIPL R&D

Name

PD Supplier

Sign Sign Sign MATCHWELL

ENGG PVT LTD

Date Date Date

Вам также может понравиться

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingОт EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingОценок пока нет

- Torque Mang HidraulicasДокумент2 страницыTorque Mang HidraulicasMauricio Alexis Cubillos LaraОценок пока нет

- Shutdown Valve: B224 323 HPCL Rajasthan Refinery Limited Rajasthan Refinery Project OffsitesДокумент1 страницаShutdown Valve: B224 323 HPCL Rajasthan Refinery Limited Rajasthan Refinery Project OffsitesMirhasan GaziОценок пока нет

- Maintenance Switch Cut Sheet UL LISTEDДокумент2 страницыMaintenance Switch Cut Sheet UL LISTEDgemcom8828Оценок пока нет

- "KAIZEN" Event On Establishing 1S & 2S in Logistics Area For Accomodating Super ACE & Venture PartsДокумент32 страницы"KAIZEN" Event On Establishing 1S & 2S in Logistics Area For Accomodating Super ACE & Venture PartsSaurabh JoshiОценок пока нет

- Repport UT CS - 7Документ1 страницаRepport UT CS - 7daemsalОценок пока нет

- 01/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectДокумент2 страницы01/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectdaemsalОценок пока нет

- Work Instruction Type RII IK-FBI-PROJ-PR-14-006 Rev.01. Englis...Документ1 страницаWork Instruction Type RII IK-FBI-PROJ-PR-14-006 Rev.01. Englis...Hudzaifah AbdussalamОценок пока нет

- Kaizen - Esp02 221B4 DamperДокумент4 страницыKaizen - Esp02 221B4 DamperRakesh Kumar Singh (Phase 1B)Оценок пока нет

- Mounting Face TappingДокумент1 страницаMounting Face TappingChiller PartyОценок пока нет

- Laporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukДокумент4 страницыLaporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukBrata IvanОценок пока нет

- Dj150e PDFДокумент19 страницDj150e PDFDody AnggahОценок пока нет

- MAINTENANCEДокумент6 страницMAINTENANCEshaktiОценок пока нет

- Adjustment: 2-1 Operation Without Housing AssemblyДокумент9 страницAdjustment: 2-1 Operation Without Housing AssemblyMekkati MekkatiОценок пока нет

- Repport UT CS - 11Документ4 страницыRepport UT CS - 11daemsalОценок пока нет

- Drawing Work Load As On 29.09.2021: Exide-TalojaДокумент20 страницDrawing Work Load As On 29.09.2021: Exide-Talojasandesh sadvilkarОценок пока нет

- 06 May 2022 Daily Manpower ArrangementДокумент1 страница06 May 2022 Daily Manpower Arrangementsurya1392Оценок пока нет

- Roofing System - Liquid PlasticДокумент13 страницRoofing System - Liquid PlasticdamindaОценок пока нет

- Gad PSVДокумент1 страницаGad PSVNARAYAN DESAIОценок пока нет

- MLT03 Wi2Документ2 страницыMLT03 Wi2Bami-more AbiolaОценок пока нет

- Flame Arrestor TBEДокумент8 страницFlame Arrestor TBEsudjonoОценок пока нет

- Flange FacingДокумент1 страницаFlange FacingChiller PartyОценок пока нет

- 10/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectДокумент4 страницы10/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectdaemsalОценок пока нет

- Adobe Scan 18 Jul 2023Документ1 страницаAdobe Scan 18 Jul 2023Anish Krishna AniОценок пока нет

- Elektor Electronics USA 1991 06Документ80 страницElektor Electronics USA 1991 06Patrik1968Оценок пока нет

- PPE MATRIX Hazard MappingДокумент1 страницаPPE MATRIX Hazard MappingSaurabh SinghОценок пока нет

- 11 Steps Capacity Enhacement LACV JSRДокумент14 страниц11 Steps Capacity Enhacement LACV JSRAmiya KumarОценок пока нет

- OptimДокумент8 страницOptimVIP VIDEOОценок пока нет

- Data SheetsДокумент5 страницData Sheetshector cano moraОценок пока нет

- PDF 3944 1Документ1 страницаPDF 3944 1maxijuarez20Оценок пока нет

- Discipline Prepared by Reviewed by Approved by Date (Dd-Mm-Yy) Code Lthe Approval Employer App ProvalДокумент7 страницDiscipline Prepared by Reviewed by Approved by Date (Dd-Mm-Yy) Code Lthe Approval Employer App ProvalVinay YadavОценок пока нет

- Drawing Work Load As On 16.09.2021: Exide-TalojaДокумент18 страницDrawing Work Load As On 16.09.2021: Exide-Talojasandesh sadvilkarОценок пока нет

- Evo LPGДокумент2 страницыEvo LPGAbo AnasОценок пока нет

- Low SupportДокумент1 страницаLow SupportMDhana SekarОценок пока нет

- Supplier Quality Issues Report: Stud Tilt MoldedДокумент5 страницSupplier Quality Issues Report: Stud Tilt MoldedJ P ENTERPRISESОценок пока нет

- Notes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Документ1 страницаNotes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Orchie DavidsonОценок пока нет

- T781D CASEADO CompactadoДокумент64 страницыT781D CASEADO CompactadoAlexОценок пока нет

- Update JSS Ex 1805Документ2 страницыUpdate JSS Ex 1805Ilham biocinОценок пока нет

- IADC CodesДокумент5 страницIADC CodesShahab Khan YousafzaiОценок пока нет

- Manual: Version 1.0 / 2018Документ35 страницManual: Version 1.0 / 2018LUD TECHОценок пока нет

- Feb 2024 MRM, TRДокумент2 страницыFeb 2024 MRM, TRajayaimaОценок пока нет

- Notes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Документ1 страницаNotes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Orchie DavidsonОценок пока нет

- Elektor Electronics USA 1991 04Документ72 страницыElektor Electronics USA 1991 04Patrik1968Оценок пока нет

- Notes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Документ1 страницаNotes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Orchie DavidsonОценок пока нет

- H 623500meu71 Sa00pb 01 - CДокумент9 страницH 623500meu71 Sa00pb 01 - CMarcoОценок пока нет

- Working Breakdown Structure - WBS - Updated 12.02.12Документ1 страницаWorking Breakdown Structure - WBS - Updated 12.02.12Sohail Khan100% (1)

- Gear Data For 71400418Документ2 страницыGear Data For 71400418Pratap ThakurОценок пока нет

- Hoja de Datos XV-5025Документ1 страницаHoja de Datos XV-5025dgii.oftec.car2Оценок пока нет

- Kaizen - Battery RoomДокумент4 страницыKaizen - Battery RoomRakesh Kumar Singh (Phase 1B)Оценок пока нет

- Notes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Документ1 страницаNotes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Orchie DavidsonОценок пока нет

- CIGRE2008 G1IF4 Rev0.6Документ2 страницыCIGRE2008 G1IF4 Rev0.6QUANGTUNGHTDОценок пока нет

- E After: New Design Method For Valves Internals (Trim), To Optimize ProcessДокумент4 страницыE After: New Design Method For Valves Internals (Trim), To Optimize ProcessIan MannОценок пока нет

- Daily Progress Drumshell 03.01.23Документ3 страницыDaily Progress Drumshell 03.01.23kehlmathias07Оценок пока нет

- Manual Mitutoyo Digimatic CaliperДокумент1 страницаManual Mitutoyo Digimatic CaliperPubcrawl100% (1)

- csb722 Manual3Документ9 страницcsb722 Manual3said.khamissssОценок пока нет

- Kick Off Meeting InternalДокумент26 страницKick Off Meeting Internaldeden ibnuОценок пока нет

- Advance Intimation Note (Format No. 7fo3 (A) ) : Project TitleДокумент29 страницAdvance Intimation Note (Format No. 7fo3 (A) ) : Project TitleBALACHANDAR SОценок пока нет

- Sample Feedback-Tracking SheetДокумент1 страницаSample Feedback-Tracking SheetJitendra NathОценок пока нет

- Caterpillar Annual Repor - 022Документ103 страницыCaterpillar Annual Repor - 022Sandeep KumarОценок пока нет

- Excavator: Tough World. Tough EquipmentДокумент2 страницыExcavator: Tough World. Tough EquipmentSandeep KumarОценок пока нет

- 970E IIIA 20 PG A4 Broch - 03 - 2020Документ11 страниц970E IIIA 20 PG A4 Broch - 03 - 2020Sandeep Kumar100% (1)

- IN Company Kobelco November 2020 PDFДокумент32 страницыIN Company Kobelco November 2020 PDFSandeep KumarОценок пока нет

- Liugong Large Wheel Loader BrochureДокумент17 страницLiugong Large Wheel Loader BrochureSandeep KumarОценок пока нет

- Liugong 922E PDFДокумент11 страницLiugong 922E PDFSandeep Kumar80% (5)

- Cummins QSM11 272 KW (370 HP) at 1,800 RPM 258 KW (351 HP) at 1,800 RPM 25,300 KG 4.5 M 220 KN 3,300 MMДокумент2 страницыCummins QSM11 272 KW (370 HP) at 1,800 RPM 258 KW (351 HP) at 1,800 RPM 25,300 KG 4.5 M 220 KN 3,300 MMSandeep KumarОценок пока нет

- Bosch Fip Exlpoded ViewДокумент3 страницыBosch Fip Exlpoded ViewSandeep KumarОценок пока нет

- Delhi IndoreДокумент2 страницыDelhi IndoreSandeep KumarОценок пока нет

- Team Development Interventions: Evidence-Based Approaches For Improving TeamworkДокумент15 страницTeam Development Interventions: Evidence-Based Approaches For Improving TeamworkSandeep KumarОценок пока нет

- Liugong Global Product PosterДокумент2 страницыLiugong Global Product PosterSandeep Kumar100% (2)

- Ashutosh Das - Technical Marketing ResumeДокумент3 страницыAshutosh Das - Technical Marketing ResumeSandeep KumarОценок пока нет

- GPS Responsible Team: Following Action Need To Be Implemented ImmediatelyДокумент2 страницыGPS Responsible Team: Following Action Need To Be Implemented ImmediatelySandeep KumarОценок пока нет

- APppeksit KPI 2Документ1 страницаAPppeksit KPI 2Sandeep KumarОценок пока нет

- Mechatronics MaterialДокумент86 страницMechatronics MaterialKota Tarun ReddyОценок пока нет

- Syllabus (2020) : NTA UGC-NET Computer Science and ApplicationsДокумент24 страницыSyllabus (2020) : NTA UGC-NET Computer Science and ApplicationsDiksha NagpalОценок пока нет

- Worship Aid - May Crowning 2020Документ5 страницWorship Aid - May Crowning 2020Kevin RyanОценок пока нет

- Dispersion Relation of Electromagnetic WavesДокумент2 страницыDispersion Relation of Electromagnetic WavesFidel SouzaОценок пока нет

- Edwards SVV HandoutДокумент2 страницыEdwards SVV HandoutossinОценок пока нет

- Manual Safety Installation Operations Tescom en 123946Документ23 страницыManual Safety Installation Operations Tescom en 123946Karikalan JayОценок пока нет

- Solution Manual For C How To Program 8th Edition Paul J Deitel Harvey DeitelДокумент34 страницыSolution Manual For C How To Program 8th Edition Paul J Deitel Harvey Deiteldryas.czech0gkl100% (47)

- D90KSДокумент1 страницаD90KSAmilton filhoОценок пока нет

- Chapter 3Документ26 страницChapter 3Francis Anthony CataniagОценок пока нет

- Good Data Won't Guarantee Good DecisionsДокумент3 страницыGood Data Won't Guarantee Good DecisionsAditya SharmaОценок пока нет

- Diagnostic Report: Patient Name: Pranav Chauhan PRANM050319990B 0009VA060799Документ2 страницыDiagnostic Report: Patient Name: Pranav Chauhan PRANM050319990B 0009VA060799pranav chauhanОценок пока нет

- Power Systems (K-Wiki - CH 4 - Stability)Документ32 страницыPower Systems (K-Wiki - CH 4 - Stability)Priyanshu GuptaОценок пока нет

- Agribusiness Magazine August 2019 EditionДокумент42 страницыAgribusiness Magazine August 2019 EditiondowntopОценок пока нет

- How Plants SurviveДокумент16 страницHow Plants SurviveGilbertОценок пока нет

- Erp FinalДокумент33 страницыErp FinaltenetchatОценок пока нет

- Price List Printer HP Per November 2017Документ14 страницPrice List Printer HP Per November 2017anthony_prawiraОценок пока нет

- Concordance C Index - 2 PDFДокумент8 страницConcordance C Index - 2 PDFnuriyesanОценок пока нет

- Global Governance and Interstate SystemДокумент25 страницGlobal Governance and Interstate SystemRay Stephen SantosОценок пока нет

- Pursanova IXC ManualДокумент16 страницPursanova IXC ManualHector Serrano MagañaОценок пока нет

- Yealink Meeting Server Administrator Guide V10.23.0.5 PDFДокумент97 страницYealink Meeting Server Administrator Guide V10.23.0.5 PDFFatima PérezОценок пока нет

- (1908) Mack's Barbers' Guide: A Practical Hand-BookДокумент124 страницы(1908) Mack's Barbers' Guide: A Practical Hand-BookHerbert Hillary Booker 2nd100% (1)

- EDUHUBДокумент6 страницEDUHUBishant sharmaОценок пока нет

- Chapter - 01 Geography The Earth in The Solar SystemДокумент10 страницChapter - 01 Geography The Earth in The Solar SystemKarsin ManochaОценок пока нет

- NM Integrative Wellness MRC Public Health Acupuncture JITTДокумент40 страницNM Integrative Wellness MRC Public Health Acupuncture JITTPrince DhillonОценок пока нет

- Umihara Et Al-2017-Chemistry - A European JournalДокумент3 страницыUmihara Et Al-2017-Chemistry - A European JournalNathalia MojicaОценок пока нет

- Lesson 2.4Документ8 страницLesson 2.4Tobi TobiasОценок пока нет

- Negotiation Homework AssignmentДокумент3 страницыNegotiation Homework AssignmentEunice Lourenço TanganeОценок пока нет

- GE Elec 7 UNIT-3 NoДокумент22 страницыGE Elec 7 UNIT-3 NoLyleОценок пока нет

- 3250-008 Foundations of Data Science Course Outline - Spring 2018Документ6 страниц3250-008 Foundations of Data Science Course Outline - Spring 2018vaneetОценок пока нет