Академический Документы

Профессиональный Документы

Культура Документы

RO System Quotation 20m3/h 73% Recovery

Загружено:

tata_77Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RO System Quotation 20m3/h 73% Recovery

Загружено:

tata_77Авторское право:

Доступные форматы

Reverse Osmosis System

Quotation

For RO system 20m3/h

Recovery rate 73%

no Product Description UNIT

1 Feed pump GRUNDFOS MTBE 50-200( Denmark) 1

2 FBR Multimedia Filter 42"*72" 1

3 Panel- with PLC AND HMI 1

4 Cartride Housing OF SS 304 (5 micron) 1

5 GRUNDFOS High Pressure Pump CRN 32(Denmark) 1

6 RO Membrane Housing 8"*5 membrane 450 PSI 4

7 Membrane Hydranautics CP3 (USA) 20

8 Post Cartride Housing OF SS 304 (1 micron) 1

9 UV sterilizer 48 GPM with control 2

10 Post Cartride Housing OF SS 304 (0.22 micron) 1

11 AQUA Dosing Pump(ITALY) (chlorine ,SMBS,3 chemical 6

dose)

Pressure Gauge 8

12 Internal Piping SS

13 SS 404 frame

14 Consumable Spare For Year 1 Set Of Cartridge Filters

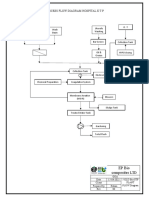

PROCESS FOR WATER PURIFIATION SYSTEM

CHLORINE DOSING SYSTEM

Raw water may contain living micro-organisms and

organics which are objection a Membrane as it may

cause fouling to deteriorate the performance. Even

water may contains ferrous which can be oxidized to

ferric oxide which is settle down in storage tank. We

have offered a Hypo chlorite dosing system for this

purpose. About 3-4 ppm of sodium hypo chlorite

solution is dosed in raw water storage tank. This reacts

with water to form a hypo chlorite acids which acts as

disinfecting agent.

RAW WATER STORAGE TANK

One No. of Raw water is required in for storage of

chlorinated water having appropriate capacity. The tank

is fitted with PVC pipe work & isolation valves and

suitable type of level indicator

Feed pump GRUNDFOS MTBE 50-200

A Horizontal Centrifugal type of pump has been

provided for supplying Raw water to Pressure Sand

Filter Unit. Necessary Suction / discharge pipe work in

s.s construction with isolation valves are also provided

up to PSF Unit

FBR Multimedia Filter 42"*72"

Raw Water is first filtered by filtration unit in series

prior feeding R.O.Plant. pressure Sand Filter Unit is

provided for removal of suspended matters & turbidity

from raw water. vertical Pressure Vessel. Internally, it

is fitted with bottom collecting system. A uniform

grades silica quartz sand is charged on the supporting

media of pebbles and gravels. This unit is fitted with SS

frontal pipe work and Multiport Valve externally. During

service cycle

SMBS DOSING SYSTEM

The Chlorinated water may oxidize the membrane and

to avoid the same precautionary we have provided

Sodium MetaBiSulphite dosing system Dosage rate is

4-5 mg/liter. A HDPE chemical preparation tank with an

electronics diaphragm type dosing pump is provided for

this.

ANTI SCALENT DOSING

The hardness salts of calcium & magnesium are likely

to be precipitated if concentration exceeds its solubility

limit & it may faults the membranes resulting into

scaling which ultimately leads to poor treated water

quality from R.O. System. To prevent this a anti

Scalent dosing (scale inhibitor) dosing system is

provided. Normally a scale inhabitator like Perma care

191 or equivalent chemical is dosed in feed water.

Dosage rate is 4-5 mg/liter

CARTRIDGE FILTER

This kind of Micron Cartridge Filter having Series of

filtration with the 5 Micron Nominal & Absolute Micron

Cartridge. This is a Consumable Cartridge and should

replace it after Days of operation. This for Extra Safety

of your Product water as it comes through the followed

filtration and there are some chances to slippages for

any particles which can be stop through the Cartridge

PLC ELECTRICAL TO CONTROL RO PLANT

When multiple Reverse Osmosis trains are provided

then we will supply identical control systems for each

RO train. Typically, each of these control packages will

utilize an OMRON PLC for R/O train control, and

communication with the water treatment plant SCADA.

Each R/O control panel will also have a color touch

screen operator interface (HMI). This will give the

operator full access to monitor and control all aspects

of each respective Reverse Osmosis train.

Each of the PLCs will communicate over an OMRON

based Ethernet network with the water treatment plant

SCADA. The plant SCADA will then be able to

communicate with all pre and post ancillary equipment

as well as each RO train independently or collectively

using message block transfers of data.

GRUNDFOS High Pressure Pump CRN 32

For Reverse Osmosis Process to take place feed

pressure of water need to be raised. For this purpose a

Vertical Multistage Centrifugal High Pressure Pump in

S.S construction is provided R.O. System requires

operating pressure of about 14-16 kg/cm². High-

pressure pump is fitted with S.S. discharge pipe work

with necessary control valves. Necessary instruments

like a High Pressure Switch, Pressure Gauge and re-

circulation valves are provided for safer operation of

system.

REVERSE OSMOSIS SYSTEM

Reverse Osmosis System rejects 97 – 99% of total

dissolved solids by the principle of `Osmosis’. This

system consists of a R.O. Module assembly mounted on

M.S.Skid. High pressure rating FRP Pressure Vessel is

fitted on the skid which houses spirally wound

membrane elements in series.

In RO System feed soften water is divided into two

streams viz Product & Reject water. Product water is

treated water having lesser TDS. Reject water is highly

concentrated water, which is not to be used for any

purpose but drained. Feed water at elevated pressure is

first fed to first Pressure Vessel treated water is

collected in center core tube. Treated water from each

membrane is collected jointly in a common product

water storage tank and reject is drained

For safe operation of system following instruments are

provide on Panel

Feed & Reject Pressure Gauge : To indicate respective

pressure of R.O. System.

Feed & Reject Flow Indicator : To indicate respective

flow of R.O. System.

T.D.S Meter : To measure TDS of Raw & Treated water.

High Pressure Switch : For tripping high pressure pump

in case of excessive feed pressure of R.O. System.

chemical dosing system

after water come from RO system water is very low

salinity so that system is for additive of chemicals to

rise TDS of water to be acceptable for consumers and to

government rules for bottled water

PRODUCT WATER STORAGE TANK

One No. of Treated water from R.O. System is stored in

a storage tank constructed storage tank of appropriate

capacity. The tank is fitted with S.S. pipe work &

isolation valves and suitable type of level indicator. One

no. of transfer pump is provided in S.S. material of

construction to feed the water in MCF

Post Cartride Housing OF SS 304 (1 micron)

During storage, atmospheric or any other contamination

may take place in treated water. Hence, after passing

water from R.O. System, water is once again passed

through a micron cartridge filter. This is a S.S.304

Vessel fitted internally with P.P spun micron cartridge

elements having absolute ratings of 1.0 micron which

removes all impurities present in the water and make

the water free of particulates

ULTRA VIOLET STERILIZER

Through R.O. treated water is free from all the micro-

biological impurities like Bacteria, Virus, etc. it may

redevelop again in water during prolonged storage. For

disinfections of water is essential for Reverse Osmosis

Application before Filling & Sealing in bottle. Hence, a

online Ultra Violet Sterilizer is provided for disinfections

of R.O. treated water before filling in pre-cleaned PET

Bottles. The water to be disinfected, is passed through

U.V. System , which consists of U.V. Tubes which

radiates high intensity Ultra Violet Rays, which in turn

kills the microorganisms. This systems consists of a S.S

finished surface housing with Ultraviolet Lamps fitted in

it. The water to be treated is surroundings this tubes

during treatment. An electrical systems is provided for

production of high voltage required for U.V. Rays

generation.

Post Cartride Housing OF SS 304 (0.22

micron)

after passing water from U.V System, water is once

again passed through a micron cartridge filter. This is a

S.S.304 Vessel fitted internally with P.P spun micron

cartridge elements having absolute ratings of 0.22

micron which removes all bacterial impurities present in

the water and make the water free of particulates

chemical dosing system

after water come from RO system water is very low

salinity so that system is for additive of chemicals to

rise TDS of water to be acceptable for consumers and to

government rules for bottled water

price 17000

RO

Вам также может понравиться

- Municipal Wastewater Treatment: Evaluating Improvements in National Water QualityОт EverandMunicipal Wastewater Treatment: Evaluating Improvements in National Water QualityОценок пока нет

- Bulk Properties of PowdersДокумент15 страницBulk Properties of Powderslhphong021191Оценок пока нет

- Major Well Services ProviderДокумент8 страницMajor Well Services ProviderPraneet MathurОценок пока нет

- DST Tools CatalogДокумент103 страницыDST Tools CatalogSikander Mushtaq100% (1)

- Module 4 Annex Part 1 MKДокумент95 страницModule 4 Annex Part 1 MKtata_77Оценок пока нет

- SCIENCE IV 3rd Quarter TestДокумент2 страницыSCIENCE IV 3rd Quarter Test엘라엘라100% (5)

- Techno Commercial Offer For 20 KLD Army Cantonment .Документ9 страницTechno Commercial Offer For 20 KLD Army Cantonment .Anshika RaiОценок пока нет

- Basics For Small Water Systems in Oregon: Storage Tank ChlorinationДокумент2 страницыBasics For Small Water Systems in Oregon: Storage Tank Chlorinationtata_77Оценок пока нет

- Design Calculations: Design Calculation For 97.5 M /HR WTP 1Документ6 страницDesign Calculations: Design Calculation For 97.5 M /HR WTP 1JASON SANJAYОценок пока нет

- MBR System Process ControlДокумент3 страницыMBR System Process ControluemaaplОценок пока нет

- ROYAL WATER SOLUTION PROPOSAL FOR 500LPH RO PLANTДокумент7 страницROYAL WATER SOLUTION PROPOSAL FOR 500LPH RO PLANTSubhajit BorgohainОценок пока нет

- Seapak Series: Integrated Ultrafiltration and Seawater Reverse Osmosis Platform For 1,000 - 10,000 M /dayДокумент2 страницыSeapak Series: Integrated Ultrafiltration and Seawater Reverse Osmosis Platform For 1,000 - 10,000 M /dayadalcayde2514100% (1)

- 2000 LPDДокумент5 страниц2000 LPDACTS TECHNO SOLUTIONSОценок пока нет

- Package Bumhan Water Co.Документ40 страницPackage Bumhan Water Co.ReyОценок пока нет

- EmulsionДокумент8 страницEmulsiontata_77Оценок пока нет

- Sewage Treatment PlantДокумент9 страницSewage Treatment PlantRohit NegiОценок пока нет

- Diligent Etp 1000m3Документ18 страницDiligent Etp 1000m3Prabhakar DhamaleОценок пока нет

- MBRДокумент9 страницMBRAuspicious MuthuОценок пока нет

- 1) STP 500 LTR (Lal Pathlabs)Документ16 страниц1) STP 500 LTR (Lal Pathlabs)raj enterprise100% (1)

- Hyflux Standard Membrane Systems Brochure - Ver5.1 - ENДокумент40 страницHyflux Standard Membrane Systems Brochure - Ver5.1 - ENIGNyomanAnomWijayaОценок пока нет

- SBR Sewage Treatment Plant Clear WaterДокумент12 страницSBR Sewage Treatment Plant Clear WaterAndreea CalcanОценок пока нет

- Multiorganics 50 KLDДокумент24 страницыMultiorganics 50 KLDArjun KrishnakumarОценок пока нет

- STP Design Report - IndiqubeДокумент20 страницSTP Design Report - IndiqubeRajkishore NayakОценок пока нет

- ECE4453 Physical Chemical Treatment I Week 4Документ113 страницECE4453 Physical Chemical Treatment I Week 4Mohsen Mohammad0% (1)

- STP BioshaftДокумент54 страницыSTP BioshaftImran KhanОценок пока нет

- Techno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridДокумент9 страницTechno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridTech MongerОценок пока нет

- Techno-Commercial Offer For 150 KLD STP, Based Upon MBBR.Документ9 страницTechno-Commercial Offer For 150 KLD STP, Based Upon MBBR.Anshika RaiОценок пока нет

- 0.90 MLD MechanicalДокумент8 страниц0.90 MLD Mechanicalkiran raghukiranОценок пока нет

- DesignДокумент3 страницыDesigntata_77Оценок пока нет

- Gravity - Rapid Sand FiltrationДокумент12 страницGravity - Rapid Sand FiltrationBrudel_c100% (1)

- DM Plant RevisedДокумент47 страницDM Plant RevisedSai Krishna MummalaneniОценок пока нет

- 2000 LPH Reverse Osmosis Plant FRPДокумент20 страниц2000 LPH Reverse Osmosis Plant FRPt m murshedОценок пока нет

- Waterflooding BL PETE482 SP 14Документ62 страницыWaterflooding BL PETE482 SP 14joduro1Оценок пока нет

- Disinfection Methods for Water TreatmentДокумент6 страницDisinfection Methods for Water TreatmentAriff JasniОценок пока нет

- Bill of Quantities: Project: Sewage Treatment Plant (0.90 MLD) Location: Pochampally Consultant: Mep ConsultantДокумент7 страницBill of Quantities: Project: Sewage Treatment Plant (0.90 MLD) Location: Pochampally Consultant: Mep Consultantsubramanyam kumarОценок пока нет

- 1000LPH RO System HinadaДокумент5 страниц1000LPH RO System HinadaBrenda HaroОценок пока нет

- WTE-ENDOM2021001505-R12-AS Cooling-SSF and DSДокумент26 страницWTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDeepak Patil100% (1)

- Sewage Treatment Plant Components and ProcessДокумент64 страницыSewage Treatment Plant Components and ProcessPankaj Gogoi100% (1)

- 5011) QUOTATION FOR R O PLANT 4000 LPH FOR Multan Chemical (Faisalabad) 27-07-2015Документ5 страниц5011) QUOTATION FOR R O PLANT 4000 LPH FOR Multan Chemical (Faisalabad) 27-07-2015shahbaz shahОценок пока нет

- ROДокумент71 страницаROMohamed MahmoudОценок пока нет

- Potassium Permanganate As Oxidant in The Cod Test For Saline Water SamplesДокумент11 страницPotassium Permanganate As Oxidant in The Cod Test For Saline Water SampleskomodobutaОценок пока нет

- Hydromagx 1Документ19 страницHydromagx 1Jeya KumarОценок пока нет

- GM Infinite 410kld FBBR Quote 26.08.16Документ14 страницGM Infinite 410kld FBBR Quote 26.08.16karthikeyanОценок пока нет

- LPH RO ManualДокумент28 страницLPH RO ManualAnil UnechaОценок пока нет

- 2000 LPH Ro PlantДокумент17 страниц2000 LPH Ro PlantKamatchi NathanОценок пока нет

- MBR Wastewater Treatment: Membrane Bioreactors ExplainedДокумент16 страницMBR Wastewater Treatment: Membrane Bioreactors ExplainedAgus WitonoОценок пока нет

- Techno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteДокумент9 страницTechno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteTech MongerОценок пока нет

- Compact Wastewater Treatment: An Introduction to Membrane BioreactorsДокумент16 страницCompact Wastewater Treatment: An Introduction to Membrane BioreactorsDhananjay Khadse100% (3)

- Catalogue Absorption Chillers ENG FДокумент80 страницCatalogue Absorption Chillers ENG FBubai111100% (1)

- Project Execution PlanДокумент20 страницProject Execution Planprabhu rajendranОценок пока нет

- Bill of Quantities Sewage Treatment PlanДокумент11 страницBill of Quantities Sewage Treatment PlanMiguel ChanОценок пока нет

- 02.12.21 90m3hr Euroclean-DHV MaithonДокумент16 страниц02.12.21 90m3hr Euroclean-DHV MaithonSagnik DasОценок пока нет

- STP Presentation - SBRДокумент51 страницаSTP Presentation - SBRNoriel LunaОценок пока нет

- Trehan STPДокумент2 страницыTrehan STPsoma_sharadОценок пока нет

- MBR - Industrial WW AE 02Документ12 страницMBR - Industrial WW AE 02transilvanpopОценок пока нет

- Membrane Treatment Processes Offer Versatility and Physical Barrier for Contaminant RemovalДокумент8 страницMembrane Treatment Processes Offer Versatility and Physical Barrier for Contaminant RemovalbazediОценок пока нет

- Exp 3Документ15 страницExp 3mjunaidОценок пока нет

- Buxar STPДокумент333 страницыBuxar STPPradeep SharmaОценок пока нет

- Saadiyat Sewage Treatment Plant, UAE-Abu Dhabi: A Case StudyДокумент4 страницыSaadiyat Sewage Treatment Plant, UAE-Abu Dhabi: A Case StudyLexОценок пока нет

- PFD FileДокумент11 страницPFD FileNaveen MahawarОценок пока нет

- 10 KLD Civil Based MBR STP - Perspective ViewДокумент4 страницы10 KLD Civil Based MBR STP - Perspective ViewVivek KapadiaОценок пока нет

- Raw WaterДокумент41 страницаRaw WaterEzhil Vendhan PalanisamyОценок пока нет

- Cooling Tower RO SystemДокумент7 страницCooling Tower RO SystemAbdul SamadОценок пока нет

- Air Reverse OsmosisДокумент12 страницAir Reverse Osmosisirdawan100% (2)

- Process Flow Diagram Hospital E.T.P: EP Bio CompositesДокумент2 страницыProcess Flow Diagram Hospital E.T.P: EP Bio CompositesRohan Chaugule100% (1)

- MBBR DesignДокумент5 страницMBBR Designsaurabh kushwahaОценок пока нет

- 46 07 13 - Packaged Water Treatment Equipment PDFДокумент9 страниц46 07 13 - Packaged Water Treatment Equipment PDFmasoodaeОценок пока нет

- Aqua BaseДокумент8 страницAqua BasejpfamiliabОценок пока нет

- Bike Wash ETP OfferДокумент11 страницBike Wash ETP OfferMuhammadHanifaОценок пока нет

- Microbiology CourseДокумент132 страницыMicrobiology Coursetata_77Оценок пока нет

- Shock Chloro CalcДокумент2 страницыShock Chloro Calctata_77Оценок пока нет

- Water Microbiology Quality Assurance ProgramДокумент74 страницыWater Microbiology Quality Assurance Programtata_77Оценок пока нет

- EPA WWT Factsheet - Ozone Disinfection 9-1999Документ7 страницEPA WWT Factsheet - Ozone Disinfection 9-1999kkdaОценок пока нет

- Water Sources and Potential Contamination of Taps and Water SystemsДокумент26 страницWater Sources and Potential Contamination of Taps and Water Systemstata_77Оценок пока нет

- 03 Lewabrane Manual System Design 03Документ13 страниц03 Lewabrane Manual System Design 03zamijakaОценок пока нет

- Microbiology CourseДокумент129 страницMicrobiology Coursetata_77Оценок пока нет

- Homogenizer: Standard Operating ProcedureДокумент1 страницаHomogenizer: Standard Operating ProcedureDermedic phar este0% (1)

- Lecture 2. Water Quality ParametersДокумент52 страницыLecture 2. Water Quality ParametersAbo-Khaled MohammedОценок пока нет

- Determain SulphateДокумент13 страницDetermain SulphateNalita Aurelia AuritaОценок пока нет

- Bromate Prove Ulr en 2016-01-06 HintДокумент3 страницыBromate Prove Ulr en 2016-01-06 Hinttata_77Оценок пока нет

- 03 Lewabrane Manual System Design 03Документ13 страниц03 Lewabrane Manual System Design 03zamijakaОценок пока нет

- Calcium TestДокумент7 страницCalcium Testtata_77Оценок пока нет

- وجية جرجس جزء 1Документ207 страницوجية جرجس جزء 1Anonymous mghI7I7pОценок пока нет

- Water Quality MicrobiologyДокумент56 страницWater Quality MicrobiologyEva Pa'e OОценок пока нет

- CH Lori NationДокумент11 страницCH Lori NationihllhmОценок пока нет

- Pseudomona in Hot TubsДокумент2 страницыPseudomona in Hot Tubstata_77Оценок пока нет

- CH Lori NationДокумент11 страницCH Lori NationihllhmОценок пока нет

- Permeate Recycle Improves RO PerformanceДокумент8 страницPermeate Recycle Improves RO Performancetata_77Оценок пока нет

- Cepacia From Respiratory Secretions of Patients With Cystic Fibrosis. J.Clin - Microbiol. 22 (1) 5-8Документ1 страницаCepacia From Respiratory Secretions of Patients With Cystic Fibrosis. J.Clin - Microbiol. 22 (1) 5-8tata_77Оценок пока нет

- Technical Service Bulletin: Procedure For Measuring Silt Density Index (SDI)Документ3 страницыTechnical Service Bulletin: Procedure For Measuring Silt Density Index (SDI)JC PinoОценок пока нет

- Technical Service Bulletin: Procedure For Measuring Silt Density Index (SDI)Документ3 страницыTechnical Service Bulletin: Procedure For Measuring Silt Density Index (SDI)JC PinoОценок пока нет

- Chemical Additve CalculationДокумент2 страницыChemical Additve Calculationtata_77Оценок пока нет

- Biocides For Disinfection and Storage of Hydranautics Membrane ElementsДокумент6 страницBiocides For Disinfection and Storage of Hydranautics Membrane Elementstata_77Оценок пока нет

- Fan Coil Units 2016Документ34 страницыFan Coil Units 2016Zurahid OmeragićОценок пока нет

- Two-third vs Ten-thirteen rules for pressure relief device requirementsДокумент3 страницыTwo-third vs Ten-thirteen rules for pressure relief device requirementsomeshchemОценок пока нет

- Guide To Registration Rev 9 - February 2014Документ5 страницGuide To Registration Rev 9 - February 2014Anton WelgemoedОценок пока нет

- JAFM Engine Nozzle Journal 2018Документ10 страницJAFM Engine Nozzle Journal 2018arslansayaniОценок пока нет

- Brochure Air Application Map Fisher en 138202Документ1 страницаBrochure Air Application Map Fisher en 138202Habib A. IslamОценок пока нет

- 16 LI-Y Modeling SEN Preheating With Fluent and GASEQДокумент20 страниц16 LI-Y Modeling SEN Preheating With Fluent and GASEQSteve WanОценок пока нет

- Experiment 4Документ5 страницExperiment 4mythiliОценок пока нет

- Adaptive Identification of A Pneumatic Pump: Diploma ThesisДокумент86 страницAdaptive Identification of A Pneumatic Pump: Diploma Thesisandreas vavatsikosОценок пока нет

- AP PGECET Chemical Engg 2015 Question Paper - Answer Key DownloadДокумент16 страницAP PGECET Chemical Engg 2015 Question Paper - Answer Key DownloadpavaniОценок пока нет

- 1 s2.0 S0360544218313318 Main PDFДокумент10 страниц1 s2.0 S0360544218313318 Main PDFMohamed KandilОценок пока нет

- Plug Flow Reactor NotesДокумент4 страницыPlug Flow Reactor Notesahmad pidotОценок пока нет

- Shell Corena S4 P 100 (En) TDS v1Документ3 страницыShell Corena S4 P 100 (En) TDS v1Anonymous oAbjbl4HОценок пока нет

- Manual Oc-1Документ12 страницManual Oc-1Engineering WatermasterОценок пока нет

- Discharge through orifices and over weirs under varying headsДокумент9 страницDischarge through orifices and over weirs under varying headsAbdul WahabОценок пока нет

- Open ChannelsДокумент21 страницаOpen ChannelsShlomo GoldbergsteinОценок пока нет

- 10:1 pilot ratio counterbalance valveДокумент2 страницы10:1 pilot ratio counterbalance valveVignesh PandiyanОценок пока нет

- 103-Effect of Hydrocarbon Partial Pressure On Propylene Production in The FCCДокумент10 страниц103-Effect of Hydrocarbon Partial Pressure On Propylene Production in The FCCdonald55555Оценок пока нет

- Topping & Bottoming CycleДокумент28 страницTopping & Bottoming CycleNadeem TanwariОценок пока нет

- Halliburton Nitrogen Services: Worldwide Leader in Nitrogen Applications in Oilfield ServicesДокумент4 страницыHalliburton Nitrogen Services: Worldwide Leader in Nitrogen Applications in Oilfield ServicesAshish AmarОценок пока нет

- Thermodynamics: Mariam El GharibДокумент19 страницThermodynamics: Mariam El GharibAbo Alphotoh GamingОценок пока нет

- This Study Resource Was: Example 11.4-1. A Mixture of Benzene-Toluene Is ToДокумент8 страницThis Study Resource Was: Example 11.4-1. A Mixture of Benzene-Toluene Is ToDicky ANdestaОценок пока нет

- Kul-24.3200 L01 Resistance 001 2015 AutumnДокумент45 страницKul-24.3200 L01 Resistance 001 2015 AutumnBraulyo PimentelОценок пока нет

- Lecture 1 SeriesДокумент43 страницыLecture 1 SerieschetsОценок пока нет

- Heating Help PDFДокумент113 страницHeating Help PDFchaitu348Оценок пока нет

- Heat Load CalculationДокумент6 страницHeat Load Calculationavj278631Оценок пока нет