Академический Документы

Профессиональный Документы

Культура Документы

Elcometer 266 DC High Voltage Holiday Detector Data Sheet

Загружено:

pbalawin4390Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Elcometer 266 DC High Voltage Holiday Detector Data Sheet

Загружено:

pbalawin4390Авторское право:

Доступные форматы

Page 1 of 3

266 DC Portable Holiday Detector

Can be used in accordance with: ISO 2746,

ANSI/AWWA C 213, AS3894.1, ASTM D4787, ASTM D5162, ASTM G 6, ASTM G 62, BS1344-11,

EN14430, JIS G3491, JIS G3492, NACE RP0274, NACE RP 04901, NACE RP0188

The premature corrosion of a substrate is often due to the failure of it's coating. Major causes of failure are flaws in the

finished coating, these include pinholes, holidays, inclusions, thin spots and bubbles. The consequent

cost of repairs, loss of production and contamination of the process can be considerable. Early inspection of coating flaws

will prevent the expense and inconvenience of failure.

At a glance:

• Safer, easier & more reliable testing than ever

before

• Avoids coating damage by limiting current

• Ideal for field, site or laboratory testing

Features

The Elcometer 266 has been specifically designed to revolutionise high voltage DC testing of coatings by making it safer,

easier and more reliable than previously possible.

• Current limiting to avoid coating damage: When the Elcometer 266 detects a flaw, and sparks, the current

flow reduces to a low level, minimising risk to both the user & the coating.

• Automatic voltage calculator: No need for lookup tables, simply enter the coating thickness value and select

the standard & the gauge will automatically set the voltage.

• Safety hand grip: Ensures that high voltage can only be generated when the handle is being held.

o Specialised ribbing provides superior protection while an optional second hand grip is ideal for two

handed use.

o Dual safety switch on handle to avoid accidental switch on

• Voltage adjustable using the keypad: No need for screwdriver:

o 0.5kV - 1kV in 50V steps

o 1kV to 30kV in 100V steps

• Internal jeep tester: Removing the need for 2 gauges. The closed loop system with internal voltmeter

guarantees the voltage output at all times.

• Specialised handle design: Extended ribbing on the handle provides an effective barrier between the high

voltage and the user.

• Rugged and waterproof to IP65: Rugged, waterproof IP65 case is sealed against the elements.

• Accurate sensitivity adjustment: Allows use on metallised or slightly damp coatings.

• Rechargeable & replaceable battery packs: Battery packs can be charged inside or outside the gauge for

continued use

• Interchangeable handles: 0.1–5kV, 0.1–15kV or 0.1–30kV adjustable in 0.1kV steps.

• Adapter as an accessory: Enables use of accessories from other manufacturers

BAMR (Pty) Ltd, PO Box 23973, Claremont, 7735, South Africa

Ph : 27 (0)21 683 2100, Fax : 27 (0)21 674 1485

Email : sales@bamr.co.za Web : www.bamr.co.za

Page 2 of 3

Features displayed visually

No need to use look up tables with the Adjust voltage via keypad on the gauge, no

integrated voltage calculator. Enter the test need for screwdrivers.

standard and the coating thickness and the Sensitivity to current can be manually preset or

gauge will automatically program the correct automatically adjusted by the gauge for

voltage. partially conductive coatings.

Interchangeable Probe Handles: Elcometer 266 can be used with the

• 500 - 5,000 Volts accessories from the following gauges:

• 500 - 15,000 Volts • Elcometer 236 & Elcometer 136

• 500 - 30,000 Volts • Models AP, APS, AP/S1 & AP/S2

• Models 780, 785 & 790

• Models 10/20 & 14/20

Large, backlit display enables easy viewing Rechargeable battery packs can be charged

even in dark environments. When a flaw is inside or outside the gauge. Batteries are fully

detected the backlight also flashes. charged within 4 hours and provide up to 40

hours continuous use between charges.

Internal calibrated jeep tester and closed Bright LEDs on the handle, as well as a loud

loop system ensures that the generated test audible alarm, clearly indicate if the gauge is

voltage is accurately measured and on (Red) and when a spark is detected (Blue).

continuously controlled, regardless of climatic

conditions.

The optional second hand grip is designed for The easy to use menu driven displays can be

two handed use without compromising its viewed in multiple languages for optimum

safety. Ideal for testing pipes and tank floors. versatility.

Safety Features

2-stage safety switch ensures that if the The extended ribbing provides extra

Elcometer 266 handle is not gripped, the protection to the user and has been

handle will switch off. specifically designed to meet standard

EN61010. High voltage testing has never

been safer.

The speaker on the gauge clearly emits a A loud audible alarm is activated when a

ticking noise to indicate that there is voltage at spark is detected. The beep volume can also

the handle. be adjusted to ensure it can be heard - even

in noisy environments.

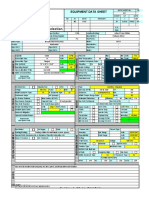

Technical Specifications

Model D266----2

Voltage Range of Coating Thickness

0 - 5kV handle 0 – 1.6 mm

0 - 15kV handle 0 – 3.75 mm

0 - 30kV handle 0 – 7.5 mm

Waterproof IP65 case

High voltage output accuracy ±5% or ±50V below 1000 Volts

Measured current flow accuracy ±5% of full scale

Display resolution 100 Volts, 1µA

Output current 0 - 100 µA maximum

Operating temperature 0°C to 50°C

Power supply Internal rechargeable lithium ion battery, fully charged within 4 hours

Typical battery life (backlight off) DC5: 40 hours DC15: 20 hours DC30: 10 hours

Typical battery life (backlight on) DC5: 20 hours DC15: 15 hours DC30: 8 hours

Instrument case High impact ABS

Earth lead length 10m

Dimensions 520 x 370 x 125mm

Weight Base unit (including battery pack): 1.2kg

Handle: 0.6kg

BAMR (Pty) Ltd, PO Box 23973, Claremont, 7735, South Africa

Ph : 27 (0)21 683 2100, Fax : 27 (0)21 674 1485

Email : sales@bamr.co.za Web : www.bamr.co.za

Page 3 of 3

Packing list

Elcometer 266 DC Holiday Detector including :

• lithium battery

• curly connection cable for high voltage handle

• 10m earth signal return lead with crocodile clip

• battery charger and mains cable

• band brush

• shoulder strap

• tough plastic carrying case

• operating instructions

The Elcometer 266 DC Holiday Detector does not include the handle, select the part number for your required handle

voltage from the part numbers listed below.

Part Numbers

Model Description Part Number

Elcometer 266 Elcometer 266 DC Holiday Detector D266----2

Handles Elcometer 266 DC5 Handle T26620033-1

Elcometer 266 DC15 Handle T26620033-2

Elcometer 266 DC30 Handle T26620033-3

Typical Applications

The Elcometer 266 is ideal instrument to use when testing :

• Insulating coating on oil, gas and water pipelines made from metal or concrete.

• Bitumen or epoxy on concrete eg. storage tanks, water and sewage treatment facilities.

• Flexible membranes on concrete bridge decks

• Vitreous enamel on steel eg. chemical reactors or storage tanks

• High voltage testing of insulation

The sensitivity can be adjusted to ignore stray current flow so that only the flaws are detected.

Test Method - High Voltage Holiday Detection

The High Voltage Detection Technique locates flaws in insulating coatings on conductive substrates. A power supply

within the instrument generates a high DC Voltage which is supplied to a suitable probe. An earth voltage return lead from

the instrument is connected to an uncoated area of the metal of the test substrate.

As the probe is passed over the coated surface, a flaw is indicated by a spark at the contact point with an audible alarm in

the detector and a visual alarm in the probe handle.

Note: This principle uses the principle of an electric current conducting through a material. When a spark occurs, the

circuit is closed and the alarm sounds indicating a flaw. Varying the DC Voltage varies the distance a spark will "jump" to

the metal substrate. The maximum distance a spark will jump is dependant on the dialectric strength of free air.

Pinhole & Porosity Detection

Premature corrosion of a substrate is usually due to the failure of the coating. A major cause of failure is the presence of

flaws in the finished coating.

Collectively referred to as a coating’s porosity the main types of flaw are described below:

Runs & Sags : The wet coating moves under gravity leaving a thin dry film.

Cissing : Occurs when a coating does not re-flow to cover the voids generated by air bubbles being released

from the surface of the coating.

Cratering : Occurs when the substrate is wet or if the coating has poor flow characteristics, thus creating voids in

the coating.

Pinholes : Caused either by air entrapment which is then released from the surface, or by the entrapment of

particulates (dust, sand etc) which do not stay in place.

Over Coating : If too much coating is applied to a substrate, as the coating cures it can crack from internal stresses

of the coating.

Under Coating : Areas not coated, or the coating flows away from the particular edges, corners or a substrate and

welds. Furthermore over a rough surface profile, insufficient coating may leave the profile’s peaks

exposed.

NB : The High Voltage Technique can be used to locate flaws in coatings on concrete. As most

concrete conducts electricity (due to moisture inherent in concrete), the Elcometer 266 can be used.

BAMR (Pty) Ltd, PO Box 23973, Claremont, 7735, South Africa

Ph : 27 (0)21 683 2100, Fax : 27 (0)21 674 1485

Email : sales@bamr.co.za Web : www.bamr.co.za

Вам также может понравиться

- Elcometer 266 DC Portable Holiday DetectorДокумент3 страницыElcometer 266 DC Portable Holiday DetectorkhuramluckОценок пока нет

- Surge Arrester Buyers Guide Ed5 - S - EXCOUNT-A (English)Документ2 страницыSurge Arrester Buyers Guide Ed5 - S - EXCOUNT-A (English)nguyenngocdienОценок пока нет

- 300 Series Photoelectric Smoke Detector SystemДокумент4 страницы300 Series Photoelectric Smoke Detector SystemgeoffffОценок пока нет

- User CompassДокумент7 страницUser CompassRolando LoayzaОценок пока нет

- Belimo S2A Datasheet En-UsДокумент3 страницыBelimo S2A Datasheet En-UsNam NguyễnОценок пока нет

- Vanguard Auto Ohm 100Документ4 страницыVanguard Auto Ohm 100juan primoОценок пока нет

- Let 2000 RD - IДокумент2 страницыLet 2000 RD - Iheri fauziОценок пока нет

- Megger PDF - MIT330Документ4 страницыMegger PDF - MIT330HugoiggОценок пока нет

- DM200 ManualДокумент2 страницыDM200 ManualJuan Alonso Garcia ArmentaОценок пока нет

- Megger-Mjolner-600 Ds enДокумент5 страницMegger-Mjolner-600 Ds enAmit Kumar KandiОценок пока нет

- Electricians Testers MIT 300 Series Insulation and Continuity TestersДокумент4 страницыElectricians Testers MIT 300 Series Insulation and Continuity TestersSamastha Nair SamajamОценок пока нет

- Megger-Vidar Ds en v03Документ3 страницыMegger-Vidar Ds en v03Hashim Othman IIОценок пока нет

- 3SK11201AB40 Datasheet enДокумент5 страниц3SK11201AB40 Datasheet enkosicenetflixОценок пока нет

- PANASONIC TX-21AT2P (CP-521P) (WWW - Pieseelectronice.net)Документ17 страницPANASONIC TX-21AT2P (CP-521P) (WWW - Pieseelectronice.net)tipudelacablutvОценок пока нет

- Omega Acb Catalogue PDFДокумент135 страницOmega Acb Catalogue PDFUmesh kumar100% (1)

- MD5060e - Catalogo - POДокумент2 страницыMD5060e - Catalogo - PORafael Moreira CunhaОценок пока нет

- Vanguard DatasheetДокумент4 страницыVanguard DatasheetAndrea AlvarezОценок пока нет

- Fluke 1630 Clamp Meter DatasheetДокумент3 страницыFluke 1630 Clamp Meter DatasheetMakassar TeknikОценок пока нет

- Joystick Station Juliet-PKДокумент8 страницJoystick Station Juliet-PKmhafizanОценок пока нет

- OMEGA Air Circuit Breaker DetailsДокумент137 страницOMEGA Air Circuit Breaker DetailsSIVA NAGA SUDHEER SIDDANIОценок пока нет

- AC Hipots 15-200kVДокумент4 страницыAC Hipots 15-200kVferiОценок пока нет

- Elma Instrument Full Cat 2014Документ40 страницElma Instrument Full Cat 2014Steve TaylorОценок пока нет

- Fluke 1630 DatasheetДокумент3 страницыFluke 1630 Datasheetpavan kumarОценок пока нет

- 14.-Sistemadepuestaatierra Agosto-2010 000Документ2 страницы14.-Sistemadepuestaatierra Agosto-2010 000joseОценок пока нет

- Fluke 1621: Technical Data Basic Earth Ground TesterДокумент2 страницыFluke 1621: Technical Data Basic Earth Ground TesterHector Zenteno RodriguezОценок пока нет

- 5a192733ad8bc 6CP AC Hipots 15-200kV 0 0Документ4 страницы5a192733ad8bc 6CP AC Hipots 15-200kV 0 0Equitec CalibrationОценок пока нет

- Electrical Test and Measurement Solutions For Railway IndustryДокумент16 страницElectrical Test and Measurement Solutions For Railway Industrymochammad syariefОценок пока нет

- BM80 2 DS en V11Документ4 страницыBM80 2 DS en V11ajaydce05Оценок пока нет

- AG230 Datasheet En-GbДокумент3 страницыAG230 Datasheet En-GbTrai Nhà NôngОценок пока нет

- Amprobe ACF3000 AK: AC Current ProbeДокумент63 страницыAmprobe ACF3000 AK: AC Current ProbetrebeardОценок пока нет

- DB GB NC56Документ4 страницыDB GB NC56ciocioi iancuОценок пока нет

- M4100 WebДокумент2 страницыM4100 WebKinhОценок пока нет

- NCVT-1P Web ManualДокумент4 страницыNCVT-1P Web Manualjose.erraizОценок пока нет

- Kyoritsu 2500Документ2 страницыKyoritsu 2500abdalrhman alqatawnehОценок пока нет

- Kyoritsu 2500Документ2 страницыKyoritsu 2500abdalrhman alqatawnehОценок пока нет

- I Series: Photoelectric Smoke DetectorsДокумент2 страницыI Series: Photoelectric Smoke DetectorsthienОценок пока нет

- Electronic Pressure and Temperature Switches: FeaturesДокумент16 страницElectronic Pressure and Temperature Switches: Featuresmanjunath blОценок пока нет

- M4100 Web-2Документ2 страницыM4100 Web-2IVE IVEОценок пока нет

- BEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke DetectorДокумент14 страницBEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke Detectorluisrruiz_123Оценок пока нет

- PPTДокумент23 страницыPPTyashОценок пока нет

- Multi MeterДокумент10 страницMulti MeterMoolaramОценок пока нет

- Sharp 19C140 Chasis+CD AДокумент24 страницыSharp 19C140 Chasis+CD ADale MccleanОценок пока нет

- Analog Insulation Resistance Tester: An ISO 9001:2008 CompanyДокумент8 страницAnalog Insulation Resistance Tester: An ISO 9001:2008 Companyrohitsingh2909Оценок пока нет

- 9619 LG Flatron L1917S Chassis CL-82 Monitor LCD Manual de ServicioДокумент26 страниц9619 LG Flatron L1917S Chassis CL-82 Monitor LCD Manual de ServicioPa PlastireОценок пока нет

- 10 Best Multimeters For Home Use and Professional WorkДокумент16 страниц10 Best Multimeters For Home Use and Professional WorkOluwafemi Olarinde0% (1)

- BM235 Manual EEVblog PDFДокумент30 страницBM235 Manual EEVblog PDFRavenSpyОценок пока нет

- Plasma TV: Service ManualДокумент16 страницPlasma TV: Service Manualoswald parraОценок пока нет

- Manual Mas345Документ31 страницаManual Mas345Eibar016Оценок пока нет

- AcuRev 2100 Multi Circuit Power Energy Meter InstallationДокумент11 страницAcuRev 2100 Multi Circuit Power Energy Meter InstallationDiogo RomeroОценок пока нет

- Series: Quite Simply, The Best in Insulation!Документ4 страницыSeries: Quite Simply, The Best in Insulation!MOHAMMAD YASSIRОценок пока нет

- 2CDC110004C0210 CM RangeДокумент128 страниц2CDC110004C0210 CM RangeIrfan AshrafОценок пока нет

- Fluke 279FC Infrared CameraДокумент5 страницFluke 279FC Infrared CameraNavinderjit SinghОценок пока нет

- SYNERGY - Profile (Electricals)Документ9 страницSYNERGY - Profile (Electricals)kuraimundОценок пока нет

- EN VEGASWING 61 63 N ElectronicsДокумент20 страницEN VEGASWING 61 63 N ElectronicsPvalpОценок пока нет

- Multifunction Digital: Clamp MeterДокумент9 страницMultifunction Digital: Clamp MeterAgung DuemilanoveОценок пока нет

- 20MU14Документ24 страницы20MU14Philbert TaylorОценок пока нет

- File 1574958586 PDFДокумент4 страницыFile 1574958586 PDFINSPECCIONES TECNICAS ALBACETE S.L.Оценок пока нет

- SCI Ductile Iron Flanged FittingДокумент12 страницSCI Ductile Iron Flanged FittingJose Angel GonzalezОценок пока нет

- 1list of Procedures & Records As Required by API Q1 (9th Edition) Rev.01Документ5 страниц1list of Procedures & Records As Required by API Q1 (9th Edition) Rev.01pbalawin43900% (2)

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsДокумент24 страницыPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishОценок пока нет

- 266 DC Portable Holiday Detector: o o o oДокумент3 страницы266 DC Portable Holiday Detector: o o o opbalawin4390Оценок пока нет

- Checklist of OHSAS 18001 Mandatory DocumentationДокумент11 страницChecklist of OHSAS 18001 Mandatory DocumentationCarla BaraybarОценок пока нет

- Amaidhiyum Aarokiyamum (Monthly Magazine) - March Month 2015Документ32 страницыAmaidhiyum Aarokiyamum (Monthly Magazine) - March Month 2015pbalawin4390Оценок пока нет

- What Did The November 2008 Amendments To ISO 9001 Mean To You?Документ20 страницWhat Did The November 2008 Amendments To ISO 9001 Mean To You?vmachamrajОценок пока нет

- Health Safety Work - GuideДокумент107 страницHealth Safety Work - Guidepbalawin4390Оценок пока нет

- Jokes Collection As On 191108Документ111 страницJokes Collection As On 191108jinu245Оценок пока нет

- 5 S - A PresentationДокумент38 страниц5 S - A Presentationpbalawin43900% (1)

- C6140-0060 - Control Cabinet Industrial PC: VariantsДокумент2 страницыC6140-0060 - Control Cabinet Industrial PC: Variantsdarinel88Оценок пока нет

- G120 CU240BE2 BA6 0414 Eng en-USДокумент380 страницG120 CU240BE2 BA6 0414 Eng en-USAnonymous xjn66H1Оценок пока нет

- Power Industry in Vidarbha RegionДокумент10 страницPower Industry in Vidarbha RegionKetan PoddarОценок пока нет

- Electrical Schematic DiagramДокумент1 страницаElectrical Schematic DiagramMary CindyОценок пока нет

- PUTДокумент15 страницPUTDaisuke NiwaОценок пока нет

- Advanced Digital Speedometer For Vehicles and Machinaries (Used As Odometer Too)Документ27 страницAdvanced Digital Speedometer For Vehicles and Machinaries (Used As Odometer Too)Shanky Kumar100% (2)

- 28 GHZ Millimeter Wave Cellular Communication Measurements For Reflection and Penetration Loss in and Around Buildings in New York CityДокумент5 страниц28 GHZ Millimeter Wave Cellular Communication Measurements For Reflection and Penetration Loss in and Around Buildings in New York CityJunyi LiОценок пока нет

- SGP Question BankДокумент3 страницыSGP Question BankSanjay AgrawalОценок пока нет

- Motor Control Selection GuideДокумент12 страницMotor Control Selection GuideMihaiNeacsuОценок пока нет

- Digital Circuits: EE/CE 3320 / Spring 2020 / Lecture 12Документ82 страницыDigital Circuits: EE/CE 3320 / Spring 2020 / Lecture 12Muhammad MontahaОценок пока нет

- DMD Getting StartedДокумент2 страницыDMD Getting StartedGanjanGОценок пока нет

- Tutorial Sheet FET AmplifierДокумент6 страницTutorial Sheet FET AmplifierGauravKumarОценок пока нет

- STRONG SRT4155Evolution Service Manual PDFДокумент32 страницыSTRONG SRT4155Evolution Service Manual PDFTim SmytheОценок пока нет

- 32ld340h Hotel TV Owners Man PDFДокумент317 страниц32ld340h Hotel TV Owners Man PDFJoel HeinzОценок пока нет

- Pic Microcontroller Based 3 Phase Induction Motor Protection SystemДокумент5 страницPic Microcontroller Based 3 Phase Induction Motor Protection SystemNaveen ChandarОценок пока нет

- 2014-02 TestingCathodicProtectionSystems Slides 508Документ49 страниц2014-02 TestingCathodicProtectionSystems Slides 508shejin R.SОценок пока нет

- Example Pump Selection: Equipment Data SheetДокумент4 страницыExample Pump Selection: Equipment Data SheetMohamed Yassine LahianiОценок пока нет

- Cold Room Evaporator UnitДокумент2 страницыCold Room Evaporator UnitAlex AndersОценок пока нет

- Process Control Concepts, Dynamics and Applications PDFДокумент734 страницыProcess Control Concepts, Dynamics and Applications PDFAfzaalUmair71% (7)

- Dynamic Testing of Machines and StructuresДокумент13 страницDynamic Testing of Machines and Structuresjjiitthhiinn0% (1)

- 27030422-ACOMT2A04 DatasheetДокумент3 страницы27030422-ACOMT2A04 DatasheetJorge VieiraОценок пока нет

- ENA EREC S36 Extract 180902050402Документ5 страницENA EREC S36 Extract 180902050402MehrdadОценок пока нет

- Recloser-Fuse Coordination of Radial Distribution Systems in Presence of DG: Analysis, Simulation Studies, & An Adaptive Relaying SchemeДокумент31 страницаRecloser-Fuse Coordination of Radial Distribution Systems in Presence of DG: Analysis, Simulation Studies, & An Adaptive Relaying SchemeAndres L MencoОценок пока нет

- Dse402 Mkii Data SheetДокумент2 страницыDse402 Mkii Data SheetyanОценок пока нет

- Final DCN Spring 2020 PDFДокумент2 страницыFinal DCN Spring 2020 PDFMUHAMMAD AHMEDОценок пока нет

- R1100RT Elec DiagramДокумент3 страницыR1100RT Elec DiagramDanijel Denial Kurinčič100% (3)

- Colpitts OscillatorДокумент3 страницыColpitts OscillatorBharat SwabhimanОценок пока нет

- 1SFC132057M0201Документ104 страницы1SFC132057M0201Y.a. Ooi100% (1)

- 3.2 RMR-35 Equipment Operation and Maintenance ManualДокумент11 страниц3.2 RMR-35 Equipment Operation and Maintenance Manual021804Оценок пока нет

- Digital Signal Processing (EE-394) : Practical Work BookДокумент13 страницDigital Signal Processing (EE-394) : Practical Work BookHermain Fayyaz KarimОценок пока нет