Академический Документы

Профессиональный Документы

Культура Документы

Barapullah Bridge, India: Enclosure 12

Загружено:

JkkhyhОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Barapullah Bridge, India: Enclosure 12

Загружено:

JkkhyhАвторское право:

Доступные форматы

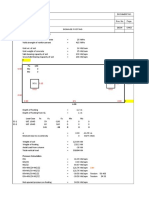

Enclosure 12

Barapullah Bridge, India

Basic Data

Project: Barapullah Bridge, India

Cable No.: LR2 S3(R)-UP

Cable Type: DG-P 55

Strand: EN 10337-Y1860S7+Z-15.7-B

No. of Strands: n= 52

Cross-Section of Strand: A= 150 mm²

Modulus of Elasticity of Strands: E= 195000 N/mm²

Weight of Strand: gS = 1.30 kg/m

Weight of PE-Tube: gT = 3.88 kg/m

Weight of Winch Rope (if necessary): gW = 0.00 kg/m

Coordinate System

Coordinates of Bearing Plate Global

Chord

Stressing

at Deck at Pylon Tensile

Step per

X XAP1 ZAP1 XAP2 ZAP2 Force

Pylon

[m] [m] [m] [m] [kN]

Before first Stressing 0.000 0.000 30.316 12.072 0.0

5

After first Stressing 0.000 0.000 30.314 12.053 2466.0

Before second Stressing 0.000 0.000 30.314 12.063 2598.0

6

After second Stressing 0.000 0.000 30.313 12.046 4933.0

Before third Stressing 0.000 0.000 30.308 12.059 4960.0

15

After third Stressing 0.000 0.000 30.308 12.053 6093.0

Before fourth Stressing 0.000 0.000 30.299 12.025 5271.0

23

After fourth Stressing 0.000 0.000 30.299 12.015 6674.0

Rev.: 0 Date: 13-Mar-19 Doc.-No.: 15 05 01 - 220 Page 1 of 8

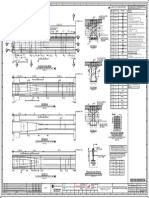

Enclosure 12

Calculation of Strand Elongation and Stressing Force for ConTen Method

Barapullah Bridge, India LR2 S3(R)-UP Type DG-P 55

Strand Type: EN 10337-Y1860S7+Z-15.7-B Weight of Monostrand: gS = 1.30 kg/m s: No. of stressed Strands

Modulus of Elasticity of Strands: E = 195000 N/mm² Weight of PE - Tube: gT = 3.88 kg/m u: No. of unstressed Strands

Cross-Section of Monostrand: A= 150 mm² Weight of winch rope: gW = 0.00 kg/m w: No. of winch ropes

Cable-

Deck Coordinates Deck Coordinates Pylon Chord Tensile Force unl. Cable Chord Elongation max Sag Stressing Force

Chord

s u w XAP1 ZAP1 XAP2 ZAP2 Z Z/s Lcab=Lx-L1 Lch L1 L2 d Sdeck Spylon

[m] [m] [m] [kN] [kN] [m] [m] [mm] [mm] [m] [kN] [kN]

52 0 0 0.000 0.000 30.314 12.053 2466.0 47.4 32.56964 32.622 53 0.1 0.036 47.3 47.5

0 0 0 0.000 0.000 30.316 12.072 0.0 32.631 0.0 0.000 0.0 0.0

1 0 0 0.000 0.000 30.316 12.071 55.8 55.8 32.56964 32.631 62 1.1 0.115 55.7 55.9

2 0 0 0.000 0.000 30.316 12.071 110.1 55.1 32.56964 32.631 61 0.4 0.073 55.0 55.1

3 0 0 0.000 0.000 30.316 12.071 164.2 54.7 32.56964 32.630 61 0.3 0.059 54.7 54.8

4 0 0 0.000 0.000 30.316 12.070 218.1 54.5 32.56964 32.630 61 0.2 0.051 54.4 54.6

5 0 0 0.000 0.000 30.316 12.070 271.6 54.3 32.56964 32.630 61 0.2 0.047 54.2 54.4

6 0 0 0.000 0.000 30.316 12.069 324.9 54.1 32.56964 32.630 60 0.2 0.044 54.1 54.2

7 0 0 0.000 0.000 30.316 12.069 377.8 54.0 32.56964 32.630 60 0.1 0.042 53.9 54.0

8 0 0 0.000 0.000 30.316 12.069 430.3 53.8 32.56964 32.630 60 0.1 0.041 53.7 53.9

9 0 0 0.000 0.000 30.316 12.068 482.6 53.6 32.56964 32.629 60 0.1 0.040 53.5 53.7

10 0 0 0.000 0.000 30.316 12.068 534.6 53.5 32.56964 32.629 60 0.1 0.039 53.4 53.5

11 0 0 0.000 0.000 30.316 12.067 586.2 53.3 32.56964 32.629 59 0.1 0.038 53.2 53.4

12 0 0 0.000 0.000 30.315 12.067 637.5 53.1 32.56964 32.629 59 0.1 0.038 53.1 53.2

13 0 0 0.000 0.000 30.315 12.066 688.6 53.0 32.56964 32.629 59 0.1 0.037 52.9 53.0

14 0 0 0.000 0.000 30.315 12.066 739.3 52.8 32.56964 32.628 59 0.1 0.037 52.7 52.9

15 0 0 0.000 0.000 30.315 12.066 789.7 52.6 32.56964 32.628 59 0.1 0.037 52.6 52.7

16 0 0 0.000 0.000 30.315 12.065 839.8 52.5 32.56964 32.628 59 0.1 0.036 52.4 52.6

17 0 0 0.000 0.000 30.315 12.065 889.7 52.3 32.56964 32.628 58 0.1 0.036 52.3 52.4

18 0 0 0.000 0.000 30.315 12.065 939.2 52.2 32.56964 32.628 58 0.1 0.036 52.1 52.3

19 0 0 0.000 0.000 30.315 12.064 988.4 52.0 32.56964 32.628 58 0.1 0.036 51.9 52.1

20 0 0 0.000 0.000 30.315 12.064 1037.4 51.9 32.56964 32.627 58 0.1 0.036 51.8 51.9

21 0 0 0.000 0.000 30.315 12.063 1086.1 51.7 32.56964 32.627 58 0.1 0.035 51.6 51.8

22 0 0 0.000 0.000 30.315 12.063 1134.5 51.6 32.56964 32.627 58 0.1 0.035 51.5 51.6

23 0 0 0.000 0.000 30.315 12.063 1182.6 51.4 32.56964 32.627 57 0.1 0.035 51.3 51.5

24 0 0 0.000 0.000 30.315 12.062 1230.4 51.3 32.56964 32.627 57 0.1 0.035 51.2 51.3

25 0 0 0.000 0.000 30.315 12.062 1278.0 51.1 32.56964 32.627 57 0.1 0.035 51.0 51.2

26 0 0 0.000 0.000 30.315 12.062 1325.3 51.0 32.56964 32.626 57 0.1 0.035 50.9 51.1

27 0 0 0.000 0.000 30.315 12.061 1372.3 50.8 32.56964 32.626 57 0.1 0.035 50.7 50.9

28 0 0 0.000 0.000 30.315 12.061 1419.0 50.7 32.56964 32.626 57 0.1 0.035 50.6 50.8

29 0 0 0.000 0.000 30.315 12.060 1465.5 50.5 32.56964 32.626 56 0.1 0.035 50.5 50.6

30 0 0 0.000 0.000 30.315 12.060 1511.7 50.4 32.56964 32.626 56 0.1 0.035 50.3 50.5

31 0 0 0.000 0.000 30.315 12.060 1557.7 50.2 32.56964 32.626 56 0.1 0.035 50.2 50.3

32 0 0 0.000 0.000 30.315 12.059 1603.4 50.1 32.56964 32.625 56 0.1 0.035 50.0 50.2

33 0 0 0.000 0.000 30.315 12.059 1648.8 50.0 32.56964 32.625 56 0.1 0.035 49.9 50.0

34 0 0 0.000 0.000 30.315 12.059 1694.0 49.8 32.56964 32.625 56 0.1 0.035 49.7 49.9

35 0 0 0.000 0.000 30.315 12.058 1738.9 49.7 32.56964 32.625 55 0.1 0.035 49.6 49.8

36 0 0 0.000 0.000 30.315 12.058 1783.6 49.5 32.56964 32.625 55 0.1 0.035 49.5 49.6

Rev.: 0 Date: 13-Mar-19 Doc.-No.: 15 05 01 - 220 Page 2 of 8

Enclosure 12

Calculation of Strand Elongation and Stressing Force for ConTen Method

Barapullah Bridge, India LR2 S3(R)-UP Type DG-P 55

Strand Type: EN 10337-Y1860S7+Z-15.7-B Weight of Monostrand: gS = 1.30 kg/m s: No. of stressed Strands

Modulus of Elasticity of Strands: E = 195000 N/mm² Weight of PE - Tube: gT = 3.88 kg/m u: No. of unstressed Strands

Cross-Section of Monostrand: A= 150 mm² Weight of winch rope: gW = 0.00 kg/m w: No. of winch ropes

Cable-

Deck Coordinates Deck Coordinates Pylon Chord Tensile Force unl. Cable Chord Elongation max Sag Stressing Force

Chord

s u w XAP1 ZAP1 XAP2 ZAP2 Z Z/s Lcab=Lx-L1 Lch L1 L2 d Sdeck Spylon

[m] [m] [m] [kN] [kN] [m] [m] [mm] [mm] [m] [kN] [kN]

37 0 0 0.000 0.000 30.315 12.058 1828.0 49.4 32.56964 32.625 55 0.1 0.035 49.3 49.5

38 0 0 0.000 0.000 30.315 12.057 1872.2 49.3 32.56964 32.624 55 0.1 0.035 49.2 49.3

39 0 0 0.000 0.000 30.315 12.057 1916.1 49.1 32.56964 32.624 55 0.1 0.035 49.1 49.2

40 0 0 0.000 0.000 30.315 12.057 1959.8 49.0 32.56964 32.624 55 0.1 0.035 48.9 49.1

41 0 0 0.000 0.000 30.315 12.056 2003.3 48.9 32.56964 32.624 54 0.1 0.035 48.8 48.9

42 0 0 0.000 0.000 30.315 12.056 2046.5 48.7 32.56964 32.624 54 0.1 0.035 48.6 48.8

43 0 0 0.000 0.000 30.315 12.056 2089.5 48.6 32.56964 32.624 54 0.1 0.035 48.5 48.7

44 0 0 0.000 0.000 30.315 12.055 2132.2 48.5 32.56964 32.624 54 0.1 0.035 48.4 48.5

45 0 0 0.000 0.000 30.314 12.055 2174.7 48.3 32.56964 32.623 54 0.1 0.035 48.2 48.4

46 0 0 0.000 0.000 30.314 12.055 2217.0 48.2 32.56964 32.623 54 0.1 0.036 48.1 48.3

47 0 0 0.000 0.000 30.314 12.054 2259.1 48.1 32.56964 32.623 54 0.1 0.036 48.0 48.1

48 0 0 0.000 0.000 30.314 12.054 2300.9 47.9 32.56964 32.623 53 0.1 0.036 47.9 48.0

49 0 0 0.000 0.000 30.314 12.054 2342.5 47.8 32.56964 32.623 53 0.1 0.036 47.7 47.9

50 0 0 0.000 0.000 30.314 12.053 2383.9 47.7 32.56964 32.623 53 0.1 0.036 47.6 47.8

51 0 0 0.000 0.000 30.314 12.053 2425.0 47.5 32.56964 32.623 53 0.1 0.036 47.5 47.6

52 0 0 0.000 0.000 30.314 12.053 2465.9 47.4 32.56964 32.622 53 0.1 0.036 47.3 47.5

Rev.: 0 Date: 13-Mar-19 Doc.-No.: 15 05 01 - 220 Page 3 of 8

Enclosure 12

st

STRESSING RECORD FOR STAY CABLES WITH CONTEN METHOD 1 STRESSING

Project: Barapullah Bridge, India Page

Cable no. LR2 S3(R)-UP Cable type DG-P 55 Length of cable 32.622 m No. of strands 52

Construction stage Length of jack 900 mm Relieve 8 mm Slip 3 mm

Jack type ConTen 210 kN Jack no. CJ-2016-11 Piston area 31 cm² Friction 1.2%

Tensioning side Deck Date of tensioning Person resp. for tensioning works Owner's representative

Temperature of 1st strand

Gauge pressure

Strand number for Required Elongation Strand protrusion Partial elongation

before relieve

Se- Working Controll force at theoretical actual theoretical at pressure at final actual theoretical Remark

quence jack Unit anchorage before of 50 pressure

after relieve relieve kg/cm²

[kN] [bar] [bar] [mm] [mm] [mm] [mm] [mm]

1 47 - 55.7 203 - -

2 48 - 55.0 200 74.9 56.2

3 46 48 54.7 199 74.1 55.5

4 39 48 54.4 198 73.8 55.2

5 45 48 54.2 198 73.5 54.9

6 33 48 54.1 197 73.3 54.7

7 22 48 53.9 197 73.1 54.5

8 34 45 53.7 196 72.9 54.3

9 23 45 53.5 196 72.7 54.1

10 40 45 53.4 195 72.5 53.9

11 24 45 53.2 194 72.3 53.7

12 16 45 53.1 194 72.1 53.5

13 9 45 52.9 193 71.9 53.3

14 38 47 52.7 193 71.7 53.1

15 21 47 52.6 192 71.5 52.9

16 15 47 52.4 192 71.3 52.8

17 49 47 52.3 191 71.2 52.6

18 25 47 52.1 191 71.0 52.4

19 10 47 51.9 190 70.8 52.2

20 4 47 51.8 190 70.6 52.0

21 44 47 51.6 189 70.4 51.9

22 20 47 51.5 189 70.3 51.7

23 8 47 51.3 188 70.1 51.5

24 3 47 51.2 188 69.9 51.3

25 35 47 51.0 188 69.8 51.2

26 17 47 50.9 187 69.6 51.0

27 5 47 50.7 187 69.4 50.8

28 1 47 50.6 186 69.2 50.6

29 32 47 50.5 186 69.1 50.5

30 14 47 50.3 185 68.9 50.3

31 2 47 50.2 185 68.7 50.1

32 50 47 50.0 184 68.6 50.0

33 26 47 49.9 184 68.4 49.8

Rev.: 0 Date: 13-Mar-19 Doc.-No.: 15 05 01 - 220 Page 4 of 8

Enclosure 12

st

STRESSING RECORD FOR STAY CABLES WITH CONTEN METHOD 1 STRESSING

Project: Barapullah Bridge, India Page

Cable no. LR2 S3(R)-UP Cable type DG-P 55 Length of cable 32.622 m No. of strands 52

Construction stage Length of jack 900 mm Relieve 8 mm Slip 3 mm

Jack type ConTen 210 kN Jack no. CJ-2016-11 Piston area 31 cm² Friction 1.2%

Tensioning side Deck Date of tensioning Person resp. for tensioning works Owner's representative

Temperature of 1st strand

Gauge pressure

Strand number for Required Elongation Strand protrusion Partial elongation

before relieve

Se- Working Controll force at theoretical actual theoretical at pressure at final actual theoretical Remark

quence jack Unit anchorage before of 50 pressure

after relieve relieve kg/cm²

[kN] [bar] [bar] [mm] [mm] [mm] [mm] [mm]

34 11 47 49.7 183 68.3 49.6

35 6 47 49.6 183 68.1 49.5

36 55 47 49.5 182 67.9 49.3

37 31 47 49.3 182 67.8 49.2

38 13 47 49.2 182 67.6 49.0

39 7 47 49.1 181 67.5 48.8

40 41 47 48.9 181 67.3 48.7

41 27 47 48.8 180 67.1 48.5

42 18 47 48.6 180 67.0 48.4

43 12 47 48.5 179 66.8 48.2

44 43 47 48.4 179 66.7 48.1

45 30 47 48.2 179 66.5 47.9

46 19 47 48.1 178 66.4 47.7

47 51 47 48.0 178 66.2 47.6

48 36 47 47.9 177 66.1 47.4

49 28 47 47.7 177 65.9 47.3

50 54 47 47.6 176 65.8 47.1

51 37 47 47.5 176 65.6 47.0

52 29 47 47.3 176 65.5 46.8

Rev.: 0 Date: 13-Mar-19 Doc.-No.: 15 05 01 - 220 Page 5 of 8

Enclosure 12

Calculation of Strand Elongation and Stressing Force for

ConTen Method

2. Stressing

Barapullah Bridge, India

LR2 S3(R)-UP

Cable Type: DG-P 55

Strand Type: EN 10337-Y1860S7+Z-15.7-B

Modulus of Elasticity of Strands: E= 195,000 N/mm²

Cross-Section of Mon Deck A= 150 mm²

No. of strands n= 52

Weight of Monostrand: gS = 1.30

Weight of PE - Tube: gT = 3.88 kg/m

Coordinates Deck Coordinates Pylon Chord Tensile Force

XAP1 ZAP1 XAP2 ZAP2 Z Z/n

[m] [m] [m] [m] [kN] [kN]

Before 2. stressing 0.000 0.000 30.314 12.063 2598.0 49.96

After 2. stressing 0.000 0.000 30.313 12.046 4933.0 94.87

unl. Cable Chord Elongation Cable-Chord max Sag Stressing Force

Lcab Lch L1 L2 d Sdeck Spylon

[m] [m] [mm] [mm] [m] [kN] [kN]

Before 2. stressing 32.57028 32.626 55.7 0.1 0.034 49.88 50.04

After 2. stressing 32.51250 32.618 105.8 0.0 0.018 94.79 94.94

Elongation Chord Stressing Force

Tensile

total additional Force Sdeck Spylon

[mm] [mm] [kN] [kN] [kN]

First strand: 113.5 57.8 101.77 101.61 101.93

Last strand: 105.8 57.8 94.87 94.79 94.94

Rev.: 0 Date: 13-Mar-19 Doc.-No.: 15 05 01 - 220 Page 6 of 8

Enclosure 12

STRESSING RECORD FOR STAY CABLES WITH CONTEN METHOD 2nd STRESSING

Project: Barapullah Bridge, India Page

Cable no. LR2 S3(R)-UP Cable type DG-P 55 Length of cable 32.626 m No. of strands 52

Construction stage Length of jack 900 mm Relieve 8 mm Slip 1 mm

Jack type ConTen 210 kN Jack no. CJ-2016-11 Piston area 31 cm² Friction 1.1%

Tensioning side Deck Date of tensioning Person resp. for tensioning works Owner's representative

Temperature of 1st strand

Gauge pressure

Strand number for Required Elongation Strand protrusion Partial elongation

before relieve

Se- force at theoretical

Remark

quence Working Controll anchorage theoretical actual before before at final actual theoretical

jack Unit after relieve relieve stressing pressure

[kN] [bar] [bar] [mm] [mm] [mm] [mm] [mm]

1 47 - 101.6 350 69.9 69.9

2 45 47 101.5 350 69.9 69.9

3 33 47 101.3 349 69.9 69.9

4 38 47 101.2 349 69.9 69.9

5 21 47 101.1 348 69.9 69.9

6 15 47 100.9 348 69.9 69.9

7 44 47 100.8 347 69.9 69.9

8 20 47 100.7 347 69.9 69.9

9 8 47 100.5 347 69.9 69.9

10 32 47 100.4 346 69.9 69.9

11 14 47 100.3 346 69.9 69.9

12 46 38 100.1 345 69.9 69.9

13 39 38 100.0 345 69.9 69.9

14 48 38 99.9 344 69.9 69.9

15 34 38 99.7 344 69.9 69.9

16 23 38 99.6 344 69.9 69.9

17 22 38 99.5 343 69.8 69.8

18 40 38 99.3 343 69.8 69.8

19 24 38 99.2 342 69.8 69.8

20 16 38 99.1 342 69.8 69.8

21 9 38 98.9 341 69.8 69.8

22 49 38 98.8 341 69.8 69.8

23 25 38 98.7 341 69.8 69.8

24 10 38 98.5 340 69.8 69.8

25 4 38 98.4 340 69.8 69.8

26 3 38 98.3 339 69.8 69.8

27 35 38 98.1 339 69.8 69.8

28 17 38 98.0 338 69.8 69.8

29 5 38 97.9 338 69.8 69.8

30 1 38 97.7 338 69.8 69.8

31 2 38 97.6 337 69.8 69.8

32 50 38 97.5 337 69.8 69.8

33 26 38 97.3 336 69.8 69.8

Rev.: 0 Date: 13-Mar-19 Doc.-No.: 15 05 01 - 220 Page 7 of 8

Enclosure 12

STRESSING RECORD FOR STAY CABLES WITH CONTEN METHOD 2nd STRESSING

Project: Barapullah Bridge, India Page

Cable no. LR2 S3(R)-UP Cable type DG-P 55 Length of cable 32.626 m No. of strands 52

Construction stage Length of jack 900 mm Relieve 8 mm Slip 1 mm

Jack type ConTen 210 kN Jack no. CJ-2016-11 Piston area 31 cm² Friction 1.1%

Tensioning side Deck Date of tensioning Person resp. for tensioning works Owner's representative

Temperature of 1st strand

Gauge pressure

Strand number for Required Elongation Strand protrusion Partial elongation

before relieve

Se- force at theoretical

Remark

quence Working Controll anchorage theoretical actual before before at final actual theoretical

jack Unit after relieve relieve stressing pressure

[kN] [bar] [bar] [mm] [mm] [mm] [mm] [mm]

34 11 38 97.2 336 69.8 69.8

35 6 38 97.1 335 69.8 69.8

36 7 38 96.9 335 69.8 69.8

37 13 38 96.8 335 69.8 69.8

38 31 38 96.7 334 69.8 69.8

39 55 38 96.5 334 69.8 69.8

40 41 38 96.4 333 69.8 69.8

41 27 38 96.3 333 69.7 69.7

42 18 38 96.1 332 69.7 69.7

43 12 38 96.0 332 69.7 69.7

44 19 38 95.9 332 69.7 69.7

45 30 38 95.7 331 69.7 69.7

46 43 38 95.6 331 69.7 69.7

47 51 38 95.5 330 69.7 69.7

48 36 38 95.3 330 69.7 69.7

49 28 38 95.2 329 69.7 69.7

50 29 38 95.1 329 69.7 69.7

51 37 38 94.9 329 69.7 69.7

52 54 38 94.8 328 69.7 69.7

Rev.: 0 Date: 13-Mar-19 Doc.-No.: 15 05 01 - 220 Page 8 of 8

Вам также может понравиться

- Barapullah Bridge, India: Enclosure 98Документ5 страницBarapullah Bridge, India: Enclosure 98JkkhyhОценок пока нет

- Appendix 3 30m RC Box-Girder DesignДокумент21 страницаAppendix 3 30m RC Box-Girder DesignebsiОценок пока нет

- Design of PurlinsДокумент4 страницыDesign of PurlinsNicole PerezОценок пока нет

- Slab DesignДокумент9 страницSlab Designsuleiman.ahОценок пока нет

- Proposal Stressing JBT Preservasi Jalintim Sumatera Utara H.125 CM - L.16.0 M - CTC.185CmДокумент12 страницProposal Stressing JBT Preservasi Jalintim Sumatera Utara H.125 CM - L.16.0 M - CTC.185CmShetty SyabellaОценок пока нет

- BridgeДокумент8 страницBridgeTuklal Chaudhary100% (1)

- Project: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionДокумент4 страницыProject: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionEr Ravi VishwakarmaОценок пока нет

- Relay - Setting - P443 REV.3Документ29 страницRelay - Setting - P443 REV.3Noptana Tummasit100% (2)

- Given: 3. Purlins DesignДокумент3 страницыGiven: 3. Purlins DesignJake CortezОценок пока нет

- Composites Project: Experimental and Numerical Modelling of Sandwich Composite LaminatesДокумент18 страницComposites Project: Experimental and Numerical Modelling of Sandwich Composite LaminateskhemchandkumarОценок пока нет

- 2-Col Bent On Bored PilesДокумент29 страниц2-Col Bent On Bored PilesHenry DiyokeОценок пока нет

- Isolated Footing DesignДокумент11 страницIsolated Footing DesignPadmanabh Shridhar DesaiОценок пока нет

- Exercise 01Документ9 страницExercise 01Srimonta RoyОценок пока нет

- Design AnalysisДокумент11 страницDesign AnalysisEvello MercanoОценок пока нет

- WRC 297Документ9 страницWRC 297akisdassasОценок пока нет

- End Diaphragm Beam-30.0mДокумент13 страницEnd Diaphragm Beam-30.0mSharath AnumalaОценок пока нет

- WRC 297Документ9 страницWRC 297akisdassas100% (1)

- Pilescarrying Capacity AnalysisДокумент4 страницыPilescarrying Capacity AnalysisGloria IjiomaОценок пока нет

- Appendix - 4AДокумент15 страницAppendix - 4Amoumita mukherjeeОценок пока нет

- Parapet Mounted - 1800 Reach - Post and JibДокумент3 страницыParapet Mounted - 1800 Reach - Post and Jibkiruba shankarОценок пока нет

- 150x100x10UA STANDARD LINTEL 3.6mДокумент9 страниц150x100x10UA STANDARD LINTEL 3.6mTerry CheukОценок пока нет

- Design One Way SlabДокумент22 страницыDesign One Way Slabjohn rey toledoОценок пока нет

- Design of Purlins Revised 2005Документ39 страницDesign of Purlins Revised 2005vidyaОценок пока нет

- 006 - Design of Tension MemberДокумент5 страниц006 - Design of Tension MemberVAIBHAVОценок пока нет

- Beam and Slab Type Combined FootingДокумент6 страницBeam and Slab Type Combined FootingAlphyl BalasabasОценок пока нет

- Larsen & Toubro Ltd. Rev Ltem Structural Design Calculations of Radiant SectionДокумент24 страницыLarsen & Toubro Ltd. Rev Ltem Structural Design Calculations of Radiant SectionAkshay Patil100% (1)

- Dwg. No:: Install Steel Pile Rigging Study and Lifting PlanДокумент21 страницаDwg. No:: Install Steel Pile Rigging Study and Lifting PlanOctavianus LubisОценок пока нет

- Setting Calculation P443Документ27 страницSetting Calculation P443Noptana Tummasit75% (4)

- Grade Beam DesignДокумент2 страницыGrade Beam Designjohnstruct archОценок пока нет

- Trunnion 6 TonДокумент3 страницыTrunnion 6 TonEngr Khurram Jaan RamayОценок пока нет

- Reinforced Soil Retaining Walls-Design and ConstructionДокумент32 страницыReinforced Soil Retaining Walls-Design and ConstructiongauravОценок пока нет

- Base Plate Design PDFДокумент1 страницаBase Plate Design PDFmaheshbandhamОценок пока нет

- Beam Design With Deflection CheckДокумент5 страницBeam Design With Deflection ChecknileshОценок пока нет

- Steel Truss CalculationДокумент15 страницSteel Truss Calculationphong00x3Оценок пока нет

- Deck Girder ExampleДокумент28 страницDeck Girder ExampleEng'r Mohammed HamzaОценок пока нет

- 3-Design For ULS - Shear and Torsion (2016)Документ22 страницы3-Design For ULS - Shear and Torsion (2016)Jin PiaoОценок пока нет

- 001 R0 RNT Design of Closed PortionДокумент37 страниц001 R0 RNT Design of Closed PortionrohanZorbaОценок пока нет

- Final Stress SummДокумент3 страницыFinal Stress SummSharyn PolleyОценок пока нет

- Tepo Sole Co., LTD: 1. General InformationДокумент3 страницыTepo Sole Co., LTD: 1. General InformationAlpha ScimathОценок пока нет

- Column Design 300x300Документ7 страницColumn Design 300x3001234 1234Оценок пока нет

- Base Plate Design in LSM by IS Code Revision 2Документ24 страницыBase Plate Design in LSM by IS Code Revision 2Structural SpreadsheetsОценок пока нет

- 8.arch Main MemberДокумент3 страницы8.arch Main MembervibishnanОценок пока нет

- 13-Glulam Beam ColumnДокумент35 страниц13-Glulam Beam Columnnandu523Оценок пока нет

- Full Design Report For Digester SlabДокумент7 страницFull Design Report For Digester SlabFrederick BruceОценок пока нет

- LAGOS DORMITORY-BeamDesignДокумент147 страницLAGOS DORMITORY-BeamDesignadetokunbo fapuroОценок пока нет

- Aerator Tank - Calculation - 1B14Документ2 страницыAerator Tank - Calculation - 1B14abd razak haronОценок пока нет

- 2-Col Bent On Bored PilesДокумент17 страниц2-Col Bent On Bored PileszxcОценок пока нет

- PILE FDN DESIGN For NMD TOWERДокумент12 страницPILE FDN DESIGN For NMD TOWERraj mОценок пока нет

- Cable Geometry and PT Losses1Документ4 страницыCable Geometry and PT Losses1Loziardo KuncayoОценок пока нет

- XX2 PDFДокумент3 страницыXX2 PDFgarysootetОценок пока нет

- Concrete Steel: Selected Design Case: 2Документ25 страницConcrete Steel: Selected Design Case: 2venu manikantaОценок пока нет

- Input Echo, Leg & Lug Item 1, Description: GuideДокумент4 страницыInput Echo, Leg & Lug Item 1, Description: GuideSiri SiriОценок пока нет

- Wall FootingДокумент3 страницыWall FootingFrancis Ko Badongen-Cawi Tabaniag Jr.Оценок пока нет

- Ultimate Strength Analysis Girder-Cross Section: PIER2, Variante: CS1Документ1 страницаUltimate Strength Analysis Girder-Cross Section: PIER2, Variante: CS1Khai HoangОценок пока нет

- Design of Purlins Revised-2005Документ41 страницаDesign of Purlins Revised-2005Ramachandra SahuОценок пока нет

- Design of Purlins Revised-2005Документ45 страницDesign of Purlins Revised-2005Nguyen Duc CuongОценок пока нет

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresОт EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresРейтинг: 4 из 5 звезд4/5 (1)

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesОт EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesРейтинг: 5 из 5 звезд5/5 (3)

- O level Physics Questions And Answer Practice Papers 2От EverandO level Physics Questions And Answer Practice Papers 2Рейтинг: 5 из 5 звезд5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- 303-W1-Rb-0632-1-Rdl-Num Det of Sup STR PDFДокумент1 страница303-W1-Rb-0632-1-Rdl-Num Det of Sup STR PDFJkkhyhОценок пока нет

- 303 w1 RB 0633 1 RDL RC Det of GirdДокумент1 страница303 w1 RB 0633 1 RDL RC Det of GirdJkkhyhОценок пока нет

- PDFДокумент3 страницыPDFdevaОценок пока нет

- LR2 S1 (L) - DN PDFДокумент2 страницыLR2 S1 (L) - DN PDFJkkhyhОценок пока нет

- Is 1343 1980 PDFДокумент68 страницIs 1343 1980 PDFpriyankaОценок пока нет

- Gate NotesДокумент29 страницGate NotesShiv BhatnagarОценок пока нет

- 1 Method Statement For Barapullah Post Tensioning Rev-CДокумент20 страниц1 Method Statement For Barapullah Post Tensioning Rev-CJkkhyhОценок пока нет

- Gate NotesДокумент29 страницGate NotesShiv BhatnagarОценок пока нет

- Wo-Ec546wod7000042 Stay CableДокумент3 страницыWo-Ec546wod7000042 Stay CableJkkhyhОценок пока нет

- Prestressing Note Rev BДокумент1 страницаPrestressing Note Rev BJkkhyhОценок пока нет

- Bridge Engineering by PonnusamyДокумент2 страницыBridge Engineering by PonnusamyJkkhyhОценок пока нет

- Extreme Ocean Waves - 2nd Edition - 2016 Edition (2015) PDFДокумент242 страницыExtreme Ocean Waves - 2nd Edition - 2016 Edition (2015) PDFEstebanAbokОценок пока нет

- Wall Treatments and Wall FunctionsДокумент15 страницWall Treatments and Wall FunctionssantiagoОценок пока нет

- Introduction To The Simulation of Mechanical SystemsДокумент15 страницIntroduction To The Simulation of Mechanical SystemsDaniel TriasОценок пока нет

- LCR Lab ReportДокумент5 страницLCR Lab ReportBen BrownОценок пока нет

- (Paperhub Ir) 10 1007@bf02917005Документ11 страниц(Paperhub Ir) 10 1007@bf02917005mostafa shahrabiОценок пока нет

- Input Data: Beam Deflection Check Long Term Deflection ACI CODE - 318-05Документ4 страницыInput Data: Beam Deflection Check Long Term Deflection ACI CODE - 318-05Ral GLОценок пока нет

- Chemistry For First Year FBISE PDFДокумент58 страницChemistry For First Year FBISE PDFMinahil Noor50% (2)

- Vibration Analysis of Cracked BeamДокумент80 страницVibration Analysis of Cracked Beamyq zhangОценок пока нет

- What Do You Mean by Electrical Flux and PotentialДокумент4 страницыWhat Do You Mean by Electrical Flux and PotentialadimeghaОценок пока нет

- ntrcduçtion: - :sed System Does Not Change and The Total Energy of A Closed System Does NotДокумент9 страницntrcduçtion: - :sed System Does Not Change and The Total Energy of A Closed System Does Notklarise asuncionОценок пока нет

- Problem Set 4Документ31 страницаProblem Set 4Joakin Bahamondes100% (1)

- Factors Affecting Acoustics in BuildingsДокумент2 страницыFactors Affecting Acoustics in BuildingsReign JandaОценок пока нет

- Phy Assignment1Документ7 страницPhy Assignment1AakashRajОценок пока нет

- 24945: FISS 011 - Fisica Experimental II - 005: Coulombs Law SimulationДокумент2 страницы24945: FISS 011 - Fisica Experimental II - 005: Coulombs Law SimulationAlberto GMОценок пока нет

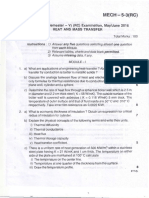

- Heat and Mass Transfer June 2016 PDFДокумент3 страницыHeat and Mass Transfer June 2016 PDFAshwin kumarОценок пока нет

- Lecture 7Документ4 страницыLecture 7minoОценок пока нет

- 1 s2.0 S0263822315001993 MainДокумент10 страниц1 s2.0 S0263822315001993 MainShree BiradarОценок пока нет

- Sciencedirect: Modal Analysis of Functionally Graded Material Plates Using Finite Element MethodДокумент8 страницSciencedirect: Modal Analysis of Functionally Graded Material Plates Using Finite Element MethodMona AwadОценок пока нет

- The ElectronДокумент20 страницThe ElectronJohn Byde100% (1)

- Control System Analysis & Design by Frequency ResponseДокумент38 страницControl System Analysis & Design by Frequency ResponseDozdiОценок пока нет

- Measurement of Viscosity Using Falling Ball ViscometerДокумент3 страницыMeasurement of Viscosity Using Falling Ball ViscometerOsamaОценок пока нет

- Dynamics: Newton's Laws of Motion: Phys101 Lectures 4 & 5Документ25 страницDynamics: Newton's Laws of Motion: Phys101 Lectures 4 & 5Anonymous m8oCtJBОценок пока нет

- Hydrodynamic Characteristics of PropellersДокумент16 страницHydrodynamic Characteristics of Propellerseraz11Оценок пока нет

- SE Prod FM CH 3 Flow in Pipes NumericalsДокумент23 страницыSE Prod FM CH 3 Flow in Pipes NumericalsASHOK SUTHARОценок пока нет

- Lecture07 - Gear Train AnalysisДокумент33 страницыLecture07 - Gear Train Analysis蒲俊雄Оценок пока нет

- 4 MotionOneDimensionFull PDFДокумент38 страниц4 MotionOneDimensionFull PDFmagiclcjОценок пока нет

- Normal Modes TextДокумент13 страницNormal Modes TextVie YaОценок пока нет

- Finite Element Modelling Techniques in MSC NASTRAN and LS DYNAДокумент172 страницыFinite Element Modelling Techniques in MSC NASTRAN and LS DYNAsreejit7777% (13)

- Mechanics of Materials: Engineering Mechanics, Statics TME212, ME211Документ18 страницMechanics of Materials: Engineering Mechanics, Statics TME212, ME211Shahzaib GulОценок пока нет

- Homework Chapter3Документ26 страницHomework Chapter3nxey bonxОценок пока нет