Академический Документы

Профессиональный Документы

Культура Документы

QMP-13 Production Control

Загружено:

om cncАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

QMP-13 Production Control

Загружено:

om cncАвторское право:

Доступные форматы

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.

: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 1 of 9

ASWINI GROUP

REVISION CONTROL

The Revision Control format given below is used for updating revisions in the Procedures and issued along with the

document.

DETAILS

REV. REV. ISSUE

TOTAL NO. REVIEW DATE

NO. DATE DESCRIPTION OF REVIEW NO.

OF PAGES PAGE NO.

0.0 04.09.13 6 All New release 1.0 04.09.13

0.0 04.01.17 6 All In line with IATF Requirements 2.0 04.01.17

1.0 07.01.19 8 All Input-process-output introduced 2.0 07.01.19

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 2 of 9

ASWINI GROUP

EFFECTIVE

NAME SIGNATURE DATE

DATE

PREPARD &

RELEASED 07.01.2019

BY

07.01.2019

APPROVED H.GIRI

07.01.2019

BY (CEO)

1.0 Purpose

To establish, implement and manage a process for standardization of work, production planning, execution and process

monitoring and control online.

2.0 Scope

This Process is applicable to all products manufacturing within ASW, including outsourced processes.

3.0 Reference

IATF 16949:2016 Clause 8.5.1 (8.5.1.1, 8.5.1.2, 8.5.1.3 & 8.5.1.7), 8.5.6 (8.5.6.1, 8.5.6.1.1) and 9.1.1.1

4.0 Definition / Abbreviations

WI - Work instruction, SPC - Statistical process control, SOP – Standard Operating Procedure, RM – Raw Material, FG –

Finished Goods, QA – Quality Assurance, UCL – Upper Control Limit, LCL – Lower Control Limit, CP – Process Capability,

Cpk – Process Capability index, USL – Upper Specification Limit, LSL – Lower Specification Limit, UOM – Unit of

Measurement.

5.0 Responsibility

HOD: Production Head

Team: Production, Quality & Stores

6.0 Input – Process – Output

Input Process (Activity) Output

Process Flow, Control Plan & SOP, Work Instructions &

Operation Standardization

PFMEA Visual Standards

Monthly Production Plan, RM

Production Capacity, Customer

Requirement Plan, Weekly

Schedule, RM Stock and FG Production Planning & Control

Production Plan and Daily

Stock

Machine Loading Plan

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 3 of 9

ASWINI GROUP

Monthly Production Plan, Finished Product, Daily

Weekly Production Plan and Production Report and In-

Production Run

Daily Machine Loading Plan & process Inspection Report –

Resources Operator Observation

Defect Prevention and Variation

Production Run Statistical Process Control

Reduction

Production Run Temporary Change of Process Controls Process Deviation Report

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 4 of 9

ASWINI GROUP

6.1 Work Instruction

Identifies the processes needed for the product and prepare Standard Operating Procedure (SOP). The process instructions

for the Standard Operating Procedure should be posted and should include set-up parameters such as machine speeds,

feeds, cycle time, etc., setting procedures, safety instructions, operator responsibilities, part application, process control

methods, in-house and customer complaints. It should be accessible to the operators and supervisors. These instructions

should be developed from the following inputs;

PFMEAs

Control plan(s)

Process flow chart

Floor plan layout

Characteristics matrix

Handling requirements

Customer inputs

Past experience

Engineering drawings, performance specifications, material specifications, visual standards and industry

standards.

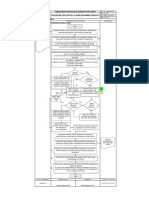

6.2 Production Planning & Control

Input Production Planning - Activity Output

Production Capacity, Prepare monthly production plan based on Monthly production

Customer monthly the customer schedule, enquiry and oral order plan & RM

schedule, RM stock received from customer relation requirement plan.

and FG stock

Communicate to purchase/quality and

maintenance departments.

A

Monthly production Prepare Weekly machine loading plan for Weekly machine

plan & RM stock upcoming week. loading plan.

Weekly machine Daily machine loading

Prepare daily machine loading plan &

loading plan. plan

communicate to shop floor.

Communicate to production supervisor,

setters and operators

Monitor and update the actual production in

` the daily production report

Monthly production

plan, Weekly machine Review production plan every day with Changes of production

loading plan & Daily Production Head planning A

machine loading plan

Review production plan every month with

MD

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 5 of 9

ASWINI GROUP

6.3 Production Run

Input Production Execution - Activity Output

Daily machine loading Organize manpower as per daily machine

plan and resources as loading plan and allocate job

necessary (plant layout)

Daily machine loading Job setup / job change / run the machine as

plan / SOP per the daily machine loading plan

SOP Inspect the setup samples and get approval First off Inspection

from line inspector.

No

Is approved by line Adjust / correct setting

inspector? and take new samples

Yes

Monitor production & inspect as per operator

SOP instruction plan mentioned in the SOP and

record the results in the operator observation

page of the in-process inspection report

No Stop Production and

Yes

Is the results are as per adjust / correct setting

specifications? And refer corrective

action procedure

Record the actual shift production in the daily

production report and machine loading plan and file it.

Record all the down times in the daily production

report and file it.

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 6 of 9

ASWINI GROUP

6.4 Statistical Process Control

Input Statistical Process Control - Activity Output

Safety and Significant, Open new X bar R control chart for safety

Characteristics and significant characteristics mentioned in

mentioned in the SOP the SOP by the symbol <SC> and <CC>

Draw the control limits from the previous

control chart

Select 5 consecutive samples measure and

record the values in the X bar R control chart

up to job change. Frequency – 1 Hour.

Calculate average, range and plot the value in

the X bar R control chart

Average = Sum of the subgroup value

divided by 5

Range = Maximum – Minimum value of

the subgroup.

Yes No Stop Production and

Is the plotted points are adjust / correct setting

with in the control and refer corrective

limits? action procedure

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 7 of 9

ASWINI GROUP

Input Statistical Process Control - Activity Output

Yes

Collect and file control chart after job change

and continue with the same chart whenever

the part is running.

Once the chart completed calculate control

limit, Cp and Cpk from the following

formulas.

Constants for sub group No. 5

A2 = 0.577, d2 = 2.326, D3 = 0, D4 = 2.114

X double bar (X dbar) = Average of X bar

R bar = Average of R

X bar Control limits,

UCL = Xbbar + A2*Rbar

LCL = Xbbar – A2*Rbar

R bar Control Limit

UCL = D4*Rbar

LCL = D3*Rbar

Sigma (S) = Rbar / d2

CP = Total Tolerance / (6*S)

Cpk = Min{( USL – Xdbar)/( 3*S), (Xdbar – LSL)/(3*S)

Are the Cp & Cpk value No Take CAPA to

>= 1.67 improve the process

Yes

Draw a new control limit and continue to

monitor the process again.

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 8 of 9

ASWINI GROUP

6.5 Temporary Change of Process Controls

Input Temporary Change Process Control - Activity Output

Temporary change in process Identify change/deviation

controls (operator, machine, against control plan in ongoing

tools, gauge, process control production process controls

parameters, location, etc.)

Stop the production and restore

Process Flow, PFMEA, Control Analyze the the process controls (as per the

Plan, CSR & Customer Risk control plan)

Feedback/Complaints (PFMEA)?

Prepare work instruction,

Alternate process controls

inspection/test, identification

(4Ms), inspection, test, etc.

and traceability requirements

methods/techniques

Prepare process deviation permit

with all necessary supporting

details

QA and/or Stop the production and restore

Customer the process controls (as per the

Approval? control plan)

Run the production process with

deviation permit and as per the

plan and instructions

Conduct inspection, testing,

verification, audit, etc. as per the

plan & instructions

QA and/or Stop the production, and recall

Customer the products in all stages, and

Approval? treat with control of NC product

Identify the lot with suitable Control on process deviation

means for easy identification and traceability at all

and traceability stages/Process Deviation Report

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No.: QMP-13

Issue/Rev. No.: 2.0/1.0

AQMS PROCEDURE

Date: 07.01.2019

PRODUCTION CONTROL Page 9 of 9

ASWINI GROUP

7.0 Further Reference

7.1 Documented Information

As per List of Documented Information to be maintained – RD-ASW-01

As per List of Documented Information to be retained – RD-ASW-02

Вам также может понравиться

- QMP-18 Initial Production ControlДокумент5 страницQMP-18 Initial Production Controlom cncОценок пока нет

- QMP-05 - Corrective ActionДокумент5 страницQMP-05 - Corrective Actionom cnc100% (1)

- QMP 15 Identification and TraceabilityДокумент6 страницQMP 15 Identification and Traceabilityom cncОценок пока нет

- QMP-10 New Product DevelopmentДокумент15 страницQMP-10 New Product Developmentom cnc100% (1)

- 15 (QSP-QA - 07) Process & Product AuditДокумент3 страницы15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- QMP 07 TrainingДокумент10 страницQMP 07 Trainingom cncОценок пока нет

- QMP-02 - Control of RecordДокумент5 страницQMP-02 - Control of Recordom cncОценок пока нет

- QMP-06 - Preventive ActionДокумент5 страницQMP-06 - Preventive Actionom cnc100% (1)

- Procedure: Measurement System Analysis ExecutionДокумент1 страницаProcedure: Measurement System Analysis Executionaslam100% (1)

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Документ1 страницаQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- Quality Control Process Chart (Machining)Документ7 страницQuality Control Process Chart (Machining)mani317Оценок пока нет

- Customer ComplientДокумент1 страницаCustomer Complientom cncОценок пока нет

- Production Process: Standard Operating Procedure (SOP)Документ3 страницыProduction Process: Standard Operating Procedure (SOP)abu naymОценок пока нет

- Ref Flow Charts Layout InspectionДокумент1 страницаRef Flow Charts Layout Inspectionrajesh.bОценок пока нет

- Supplier Rating ProcedureДокумент4 страницыSupplier Rating ProcedureAmine Chahi100% (1)

- Top Management, Stores and DispatchДокумент4 страницыTop Management, Stores and DispatchBibhudutta mishraОценок пока нет

- Process Audit - Sheet New ......Документ1 страницаProcess Audit - Sheet New ......MUKESH KUMARОценок пока нет

- 14-QSP - 59 Procedure For Temporary Change of Process Controls PDFДокумент1 страница14-QSP - 59 Procedure For Temporary Change of Process Controls PDFsahyadri engineersОценок пока нет

- 3.6 Initial SupplyДокумент2 страницы3.6 Initial SupplySunil Kumar92% (12)

- Product Audit Check SheetДокумент3 страницыProduct Audit Check SheetLakshmanan Venkatesan100% (1)

- QP Nonconforming Product Sample 2014Документ2 страницыQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Rework & Repair ProcedureДокумент1 страницаRework & Repair ProcedureManu Sharma100% (4)

- (As Per IS 2500, ISO 2859-1 & DIN 40080) : Sampling PlanДокумент1 страница(As Per IS 2500, ISO 2859-1 & DIN 40080) : Sampling PlanLOGANATHAN V100% (1)

- Centurion Power Cables (P) LTD.: 1.0 PurposeДокумент4 страницыCenturion Power Cables (P) LTD.: 1.0 PurposetriveshОценок пока нет

- P13-Process For APQPДокумент6 страницP13-Process For APQPBangali Singh100% (1)

- Customer Specific Requirement Check ListДокумент2 страницыCustomer Specific Requirement Check ListMuthu100% (2)

- Iatf ActivitiesДокумент6 страницIatf ActivitiesWizard tube and Engineered componentОценок пока нет

- RD ASW 22 Masterlist of APQPДокумент1 страницаRD ASW 22 Masterlist of APQPom cncОценок пока нет

- Product Audit ReportДокумент2 страницыProduct Audit ReportManoharar R100% (2)

- .013-00-Checking AidsДокумент3 страницы.013-00-Checking Aidsdaniel_sasikumarОценок пока нет

- Apqp - DR SHFTДокумент60 страницApqp - DR SHFTrajesh5000100% (2)

- MSIL Audit Cheklist 16Документ22 страницыMSIL Audit Cheklist 16Pravin Balasaheb GunjalОценок пока нет

- QSP Format Product SafetyДокумент4 страницыQSP Format Product Safetydhir.ankurОценок пока нет

- Gate Check Review FormsДокумент7 страницGate Check Review FormsKamardeen Nazurudeen100% (1)

- MFG Process Audit ReportДокумент1 страницаMFG Process Audit ReportBASAVA ENGINEERINGОценок пока нет

- Customer Complaint HandlingДокумент7 страницCustomer Complaint HandlingpapplionОценок пока нет

- Evidences To Be Maintained As Per APQP For PMДокумент3 страницыEvidences To Be Maintained As Per APQP For PMSachin RamdurgОценок пока нет

- Design Process TurtleДокумент2 страницыDesign Process TurtleBAlaОценок пока нет

- SOP-10 Final Inspection ProcedureДокумент3 страницыSOP-10 Final Inspection ProceduretriveshОценок пока нет

- Control PlanДокумент6 страницControl PlanFahmy Khoerul HudaОценок пока нет

- QAD Procedure - Control of Non-Conforming Products P2Документ2 страницыQAD Procedure - Control of Non-Conforming Products P2sumanОценок пока нет

- Procedure For NPD HandoverДокумент1 страницаProcedure For NPD HandoverTushar Wagh100% (1)

- Induction Training Text Format - StaffДокумент5 страницInduction Training Text Format - StaffJohnОценок пока нет

- COMP-OPP-01 Procedure For Control and Validation of ProductionДокумент4 страницыCOMP-OPP-01 Procedure For Control and Validation of ProductionISODCC DSPIОценок пока нет

- Purpose:: Procedure Manual FifoДокумент3 страницыPurpose:: Procedure Manual FifoartiОценок пока нет

- APQP Matrix Pedal Yl1 at IsgДокумент11 страницAPQP Matrix Pedal Yl1 at Isgkaran singh100% (2)

- TEAM fEASIBILITYДокумент2 страницыTEAM fEASIBILITYPk NimiwalОценок пока нет

- Shriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)Документ5 страницShriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)deepak sharma100% (1)

- QMS Inspection ProcedureДокумент5 страницQMS Inspection ProcedureReyhan MfОценок пока нет

- Product Audit FormДокумент2 страницыProduct Audit Formcong da0% (1)

- 4M Inspection ReportДокумент4 страницы4M Inspection ReportKaran Malhi100% (1)

- Initial Supply ControlДокумент3 страницыInitial Supply ControlKuldeep Chauhan100% (2)

- Supplier Audit Check Sheet.Документ1 страницаSupplier Audit Check Sheet.ALI ASGHARОценок пока нет

- QMS 075 Procedure For Product Identification and Traceability SampleДокумент2 страницыQMS 075 Procedure For Product Identification and Traceability SampleAli Saifullizan Ismail100% (1)

- 4th Edition PPAPДокумент83 страницы4th Edition PPAPTerri Paleno Lebow100% (1)

- Master TimingДокумент4 страницыMaster TimingPk NimiwalОценок пока нет

- Q2-760-01-Control of Monitoring and Measuring DevicesДокумент5 страницQ2-760-01-Control of Monitoring and Measuring DevicesAlineОценок пока нет

- QMP-01 - Control of DocumentДокумент7 страницQMP-01 - Control of Documentom cncОценок пока нет

- ASMI-OSHMS-PR-13 - OSH Performance Monitoring ProcedureДокумент9 страницASMI-OSHMS-PR-13 - OSH Performance Monitoring ProcedureJHUPEL ABARIALОценок пока нет

- Quality Manual - VVRДокумент67 страницQuality Manual - VVRRajamani100% (2)

- QMP-01 - Control of DocumentДокумент7 страницQMP-01 - Control of Documentom cncОценок пока нет

- QMP 07 TrainingДокумент10 страницQMP 07 Trainingom cncОценок пока нет

- QMP-02 - Control of RecordДокумент5 страницQMP-02 - Control of Recordom cncОценок пока нет

- RD ASW 22 Masterlist of APQPДокумент1 страницаRD ASW 22 Masterlist of APQPom cncОценок пока нет

- Xods G8D1Документ75 страницXods G8D1om cncОценок пока нет

- QMP-06 - Preventive ActionДокумент5 страницQMP-06 - Preventive Actionom cnc100% (1)

- Weekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 MarimuthuДокумент10 страницWeekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 Marimuthuom cncОценок пока нет

- Customer ComplientДокумент1 страницаCustomer Complientom cncОценок пока нет

- Top 3 Rejections: Rejected Qty Rej %Документ1 страницаTop 3 Rejections: Rejected Qty Rej %om cncОценок пока нет

- 703 Fmea m3 LatestДокумент24 страницы703 Fmea m3 Latestom cncОценок пока нет

- CMM Statistical Process Control by Hilton RobertsДокумент16 страницCMM Statistical Process Control by Hilton RobertsAnonymous DP6iO3DfQОценок пока нет

- CQEДокумент5 страницCQErajaabid0% (1)

- Effect of Standard Costing On Profitability of Manufacturing Companies: Study of Edo State NigeriaДокумент7 страницEffect of Standard Costing On Profitability of Manufacturing Companies: Study of Edo State Nigeriadanial haziqОценок пока нет

- Turnaround at Preston Plant Assignment 3Документ5 страницTurnaround at Preston Plant Assignment 3melinda fahrianiОценок пока нет

- Lecture 10 - Control Charts For VariableДокумент16 страницLecture 10 - Control Charts For VariableMuhazam Khan Sherbaz KhanОценок пока нет

- Control ChartsДокумент29 страницControl Chartsmbstutextile100% (1)

- ASTM-E2587-Standard Practice For Use of Control Charts in Statistical Process ControlДокумент29 страницASTM-E2587-Standard Practice For Use of Control Charts in Statistical Process ControlDaniel Carchi100% (2)

- Mil STD 1916Документ33 страницыMil STD 1916Gabriel BeloqueОценок пока нет

- CPK - Vs PPMДокумент21 страницаCPK - Vs PPMazadsingh1100% (1)

- Lean Six Sigma Green BeltДокумент5 страницLean Six Sigma Green BeltMadhavaKrishna0% (1)

- 420C19Документ42 страницы420C19Al Arafat Rumman100% (2)

- MBA Operation Project Download Project Report On Analysis of The Quality Procedures at M S WheelДокумент94 страницыMBA Operation Project Download Project Report On Analysis of The Quality Procedures at M S WheelWhatsapp stutsОценок пока нет

- Acceptance Sampling and Control ChartДокумент43 страницыAcceptance Sampling and Control Chartnimit jhambОценок пока нет

- Lean Six Sigma Project - A Beginner's Guide: - NilakantasrinivasanДокумент8 страницLean Six Sigma Project - A Beginner's Guide: - NilakantasrinivasanZeeshan AliОценок пока нет

- Mistake Proofing and Poka-YokeДокумент75 страницMistake Proofing and Poka-YokeadamОценок пока нет

- Quality Progress Magazine (June-2007)Документ92 страницыQuality Progress Magazine (June-2007)Ghulam Mustafa100% (1)

- Statistical Process ControlДокумент77 страницStatistical Process ControlMahender KumarОценок пока нет

- Quality Book LectureДокумент23 страницыQuality Book Lectureikolev57Оценок пока нет

- Krajewski OM13 PPT 03Документ84 страницыKrajewski OM13 PPT 03Nadeen YehiaОценок пока нет

- GM 1927-30 QSB Audit Master - Final011811Документ16 страницGM 1927-30 QSB Audit Master - Final011811Mohammad GadОценок пока нет

- Answers To 10 Common Questions About Capsule FillingДокумент5 страницAnswers To 10 Common Questions About Capsule Fillingluismanolo09Оценок пока нет

- Statistical Process Control.Документ26 страницStatistical Process Control.foofoolОценок пока нет

- CertBus ASQ CSSBB Study Materials Braindumps With Real Exam PDFДокумент18 страницCertBus ASQ CSSBB Study Materials Braindumps With Real Exam PDFafreen timberwalla100% (1)

- Module 1 Understanding QualityДокумент32 страницыModule 1 Understanding QualityJordan Loren MaeОценок пока нет

- 1033079-KSS 050-Product Characteristic ClassificationДокумент9 страниц1033079-KSS 050-Product Characteristic ClassificationvkmsОценок пока нет

- Six Sigma Quality at Flyrock TiresДокумент3 страницыSix Sigma Quality at Flyrock TiresAbeyОценок пока нет

- Applying Some Quality Control Charts To Study The Strength of Building Concrete Blocks and Clay Building Brricks PDFДокумент44 страницыApplying Some Quality Control Charts To Study The Strength of Building Concrete Blocks and Clay Building Brricks PDFTran Huynh NamОценок пока нет

- Magnetimarelli Qa Doc 0001 A Rev Mar 2010Документ35 страницMagnetimarelli Qa Doc 0001 A Rev Mar 2010DinsdinsdinsОценок пока нет

- Chapter 10-Control (Am)Документ27 страницChapter 10-Control (Am)Yeshna GunnooОценок пока нет

- Lesson Plan TQM-NewДокумент7 страницLesson Plan TQM-Newtmuthu123Оценок пока нет