Академический Документы

Профессиональный Документы

Культура Документы

WP

Загружено:

Umeshchandra PatilОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WP

Загружено:

Umeshchandra PatilАвторское право:

Доступные форматы

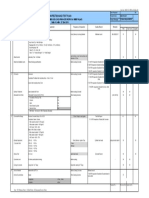

CI/SfB Vn6

PRODUCT DATASHEET

integritank

®

STRUCTURAL WATERPROOFING MEMBRANE

DESCRIPTION TECHNICAL DATA

Integritank is a liquid applied, fully reactive, elastomeric PROPERTY1 VALUE

membrane based on Methyl Methacrylate (MMA) resins that cure

rapidly to provide a tough impermeable waterproof membrane. Application Temperature Range 2

-5 to +40°C

It is available in both spray and hand grades.

Typical Overcoating Time ~ 60 minutes

USES

Typical Tensile Strength

Integritank is designed to retain, exclude or protect structures 13 MPa

(BS903: A2: 1995, ISO37: 1994; ASTM D412)

from water, oils, fuels and many aggressive chemicals. With the

spray grade outputs in excess of 2,000m² per day can be Typical Elongation at Break

130%

achieved. The hand grade version was specifically developed for (BS 903: A2: 1995, ISO 37: 1994; ASTM - D412)

application in small areas or where restrictive access prevents

Low Temperature Flexibility

spray application. Typical applications include: (Mandrel Test MOAT 27: 5.4.2 1983)

Unaged Pass at -25°C

Tunnels

56 days heated at 70°C Pass at -20°C

Balconies

28 days water soak at 23°C Pass at -25°C

Podium Decks

Static Crack Bridging @ 0°C

Basement tanking

(DTp Appendix B: Technical Memorandum BE27 Pass

Roofs Tested To 2mm)

Concrete, masonry, asphalt or steel substrates requiring a

chemical and/or abrasion resistant coating Typical Elongation at Break

> 130%

(BS 903: A2: 1995, ISO 37: 1994; ASTM - D412)

Storage tanks and silos.

Secondary containment - bund lining or earthen Heat Ageing at 70°C for 1 year.

containment bunds (using a fabric carrier for the coating) (Equivalent to 32 years ageing at 20°C

BS 903: A2: 1995, ISO 37: 1994)

No significant

Silage units change

Tensile Strength

Canals and culverts

Elongation at Break

Sewage and sludge tanks

Hardness (2mm Application)

Low-level radiation tanking and roofing applications. Shore D 51

Shore A 90 – 95

FEATURES (BS 2782: Part 3 Method 365B: 1992 ISO 868:

1985)

Approved by British Board of Agrément (UK), British Nuclear

Fuels (UK) and CEMETE (France) Dimensional Stability

+0.23%

(MOAT 27: 5.1.6.1 1983)

Unaffected by high humidity and rapid cure even at low

temperatures enabling all year round application on all Methane Resistance 0.03ml/m²/day/

continents (Wimpey Environmental Method) atmosphere

Fast track and weather tolerant application all year round

Fully reactive and does not contain solvents Water Vapour Permeability

@ 25°C, 75% RH 3.36g/m2/day

Able to carry load or traffic after one hour (BS 3177: 1959)

Resistant to ballast and backfill materials

Long and effective life Resistance to Aggregate Indentation

No damage

(DTp Appendix B: Technical Memorandum BE27)

Impermeable to chloride ions

Excellent chemical, abrasion and impact resistance Chisel Impact at 23° and 0°C

No damage

Excellent UV and weather resistance (DTp Appendix B: Technical Memorandum BE27)

Can bridge shrinkage cracks in concrete over a wide

Dynamic Ballast Resistance No damage or

temperature range

(181 kN/2x106 cycles, SNCF) leaks

High bond strength to substrate

Excellent intercoat adhesion Resistance to Static Indentation

Overcoating time not critical (MOAT 27: 5.1.10 1983) L4

Can be applied to verticals and overhead

Resistance to Dynamic Indentation

On site quality assurance programme (MOAT 27: 5.1.10 1983) I3

Applied only by authorised and trained contractors

Water Vapour Resistance @ 25°C, 75% RH

61 MNsg-1

(BS 3177: 1959)

1

Property values range in accordance with normal statistical test variation. Please

consult the relevant standard or contact us for further advice.

2

For temperatures outside this application range please contact us.

MA066 Integritank Datasheet Issue 9

Page 1 of 3

CI/SfB Vn6

PRODUCT DATASHEET

integritank

®

STRUCTURAL WATERPROOFING MEMBRANE

Resistance to Water Pressure Coverage rates are based on a smooth substrate and will vary

6 metre head of water no leak with surface texture and porosity.

(DTp Appendix B: Technical Memorandum BE27) CLEANING

For information about the chemical resistance of Integritank All tools and equipment should be cleaned with Stirling Lloyd

please consult our Customer Services Department. Solvent No.1 (Acetone) before the material is allowed to cure.

SURFACE PREPARATION PACKAGING & STORAGE

It should be stressed that the success of any waterproofing Primer refer to separate datasheets

system is dependent on the thoroughness of the surface Spray Grade Membrane 48kg & 400kg kits

preparation.

3

Hand Grade Membrane 20kg kits

Concrete

Catalyst 20kg kits for on-site addition

New concrete substrates should be a minimum of seven days

old. The substrate must be clean, dry and structurally sound. It All components of the Integritank system should be stored in

must be free from laitance, oils and all other surface cool, dry, protected conditions, out of direct sunlight and in

contaminants. Where the use of a non-structural screed or a accordance with the relevant site Health & Safety regulations.

lightweight concrete substrate is proposed, please seek our Storage temperature must not exceed 25oC. Do not store near

advice as these materials often have low cohesive strength or naked flames or foodstuffs. Stored in unopened containers,

retain water in open pores. under these conditions, the components have a shelf life of six

months.

Repairs to damaged concrete can be made using Metaset® Rapid

Repair Mortar. ANCILLARIES

Steel Stirling Lloyd produces a range of products to compliment the

Integritank system. These include:

On steel surfaces all rust, dirt and contamination should be

removed to expose bright metal to achieve a surface finish to Metaset® – a range of resin based rapid repair mortars.

comply with Swedish standard Sa 2.5. SL Smoothing Primer - an MMA levelling primer.

For compatibility with other construction materials or where

Sealants – a range of flexible sealants for all joints and

cracks.

additives, cement replacement or curing compounds have been

used please contact us.

HEALTH & SAFETY

APPLICATION

The Material Safety Data Sheet must be read, understood and

Primer available on site before commencing work.

The substrate must be primed with an appropriate Stirling Lloyd It is the Company’s policy to take all reasonable steps to prevent

primer prior to application of the Integritank membrane. A injury to all property and personnel from foreseeable hazards.

choice of primers is available depending on the type of substrate This extends to the public in so far as they come into contact

and weather conditions. They are usually applied using a brush with the Company or its products.

or roller. Please consult the appropriate datasheets.

GENERAL INFORMATION

Membrane

Integritank is part of a wide range of specialist waterproofing,

Both grades of Integritank are applied in two colour-coded surfacing and repair materials manufactured and supplied by

coats. Stirling Lloyd. If you require any further information on this or

any other of our products, please do not hesitate to contact us

Integritank Spray Grade is metered, mixed and spray applied or visit www.stirlinglloyd.com.

using plural component spray equipment to give a minimum dry

film thickness of 1mm per coat.

An Integritank Hand Grade is also available. The mixed material

is poured onto the substrate and spread using a trowel and / or

brush. For vertical surfaces the material should be applied by

brush. The material should be applied in two even coats to give

a minimum dry film thickness of 1mm per coat.

Both spray and hand grade can be trafficked or loaded once fully

cured.

COVERAGE

3

Integritank Hand Grade is supplied in both winter and summer and tropical grades.

Primer refer to separate datasheet The winter grade is automatically supplied in the UK between October 1st and March

31st. It has additional cold cure accelerator added at the manufacturing stage to

Membrane (Spray & Hand Grade) 1.4kg/m²/coat increase the speed of cure at temperatures below 10oC. The catalyst levels should be

adjusted in accordance with the ambient temperature during application.

MA066 Integritank Datasheet Issue 9

Page 2 of 3

CI/SfB Vn6

PRODUCT DATASHEET

integritank

®

STRUCTURAL WATERPROOFING MEMBRANE

® INTEGRITANK & METASET are registered trademarks of Stirling Lloyd

Polychem Ltd.

© 2010 Stirling Lloyd Polychem Ltd.

The information presented herein is accurate to the best of our knowledge.

We pursue a progressive research and development policy and reserve the

right to alter any of the details herein without notice. The information given

must not be taken in any way to form a specification. All technical

properties quoted are from laboratory prepared samples. We will not

accept liability whatsoever arising out of the use of the information

contained herein.

Union Bank, King Street, Knutsford, Cheshire, WA16 6EF, England

Tel: +44 (0) 1565 633111 Fax: +44 (0) 1565 633555

E-Mail: info@stirlinglloyd.com

www.stirlinglloyd.com

MA066 Integritank Datasheet Issue 9

Page 3 of 3

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Chinese Characters HistoryДокумент85 страницChinese Characters HistoryScribd_Fond_of100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 7H17-28 Clearances and Wear Limits PDFДокумент3 страницы7H17-28 Clearances and Wear Limits PDFDimitris K100% (1)

- Elevation of Control RoomДокумент1 страницаElevation of Control RoomgohilnarendraОценок пока нет

- Lighting SystemДокумент16 страницLighting SystemsyahfendyОценок пока нет

- Method Statement For Chipping and Grouting For All EDI System in PH2Документ6 страницMethod Statement For Chipping and Grouting For All EDI System in PH2vinodhyperОценок пока нет

- A3100 PDFДокумент2 страницыA3100 PDFirfanWPKОценок пока нет

- Soil ExplorationДокумент84 страницыSoil ExplorationK.Mallikarjuna RaoОценок пока нет

- BPG Cooling Towers-Audit GuidelinesДокумент22 страницыBPG Cooling Towers-Audit GuidelinesrikiОценок пока нет

- Electric Diagram PDFДокумент72 страницыElectric Diagram PDFORLANDO VILCHES LOBOSОценок пока нет

- Upheavel Buckling CalculationДокумент8 страницUpheavel Buckling Calculationsaravanakkumar boominahtanОценок пока нет

- Threading 2018.2Документ284 страницыThreading 2018.2Karan VirbhadreОценок пока нет

- Typical Physical Properties of Vermiculite ConcreteДокумент6 страницTypical Physical Properties of Vermiculite ConcreteUmeshchandra PatilОценок пока нет

- GRP Tank Smartage Projects Brochure Low ResДокумент6 страницGRP Tank Smartage Projects Brochure Low ResUmeshchandra PatilОценок пока нет

- Plaster Mesh CatalogueДокумент9 страницPlaster Mesh CatalogueUmeshchandra PatilОценок пока нет

- Roff New Construction Tile Adhesives PDFДокумент2 страницыRoff New Construction Tile Adhesives PDFUmeshchandra PatilОценок пока нет

- Roff New Construction Tile AdhesivesДокумент2 страницыRoff New Construction Tile AdhesivesUmeshchandra PatilОценок пока нет

- MasterEmaco - S 348 v2Документ2 страницыMasterEmaco - S 348 v2Umeshchandra PatilОценок пока нет

- Pushpak Brochure 2018Документ16 страницPushpak Brochure 2018Umeshchandra PatilОценок пока нет

- Sun PU GardДокумент2 страницыSun PU GardUmeshchandra PatilОценок пока нет

- ITP HMMI Project RC Works - (003) - EditedДокумент1 страницаITP HMMI Project RC Works - (003) - EditedVivit Cllu StiaОценок пока нет

- SikaFix®-121 Ground BondДокумент2 страницыSikaFix®-121 Ground BondSisuangly SimamoraОценок пока нет

- Fluid Monitoring Module FMM: Description Technical SpecificationsДокумент8 страницFluid Monitoring Module FMM: Description Technical SpecificationsSamad A BakarОценок пока нет

- Precast IFCДокумент42 страницыPrecast IFCar_raghvendra4151Оценок пока нет

- 16 IbmДокумент6 страниц16 IbmAmul ChiluveruОценок пока нет

- B.S. in Electro Mechanical Technology PDFДокумент2 страницыB.S. in Electro Mechanical Technology PDFHomer Solon PadugaОценок пока нет

- Snapper Blower ManualДокумент3 страницыSnapper Blower ManualcornbreadsoapgirlОценок пока нет

- MEM 516 Machine Tool DesignДокумент2 страницыMEM 516 Machine Tool Designgaurav pathak100% (1)

- Products: Suppliers BuyersДокумент26 страницProducts: Suppliers Buyers12345vinothОценок пока нет

- Weld Cheat SheetДокумент1 страницаWeld Cheat SheetBruce BrownОценок пока нет

- Nuts An364 An365Документ1 страницаNuts An364 An365geoffxyz0Оценок пока нет

- Green Bee Smart BuildingДокумент3 страницыGreen Bee Smart BuildingKatama Raju Bandigari100% (2)

- Pds Hempadur 85671 En-GbДокумент2 страницыPds Hempadur 85671 En-GbPrabath Nilan GunasekaraОценок пока нет

- Tugas 5 RefrigeratorДокумент83 страницыTugas 5 Refrigeratoraa_ahyarОценок пока нет

- Pdtspec4 - 01 (MIB 202) PDFДокумент4 страницыPdtspec4 - 01 (MIB 202) PDFAnonymous LAgHIKY65i100% (1)

- Composite Pavement Virginia Tech 09 Cr2Документ60 страницComposite Pavement Virginia Tech 09 Cr2Dr. Ir. R. Didin Kusdian, MT.Оценок пока нет

- Force One Vs Other SUVsДокумент11 страницForce One Vs Other SUVsarpit_saraswat89Оценок пока нет

- Manual V1000 Wiring AvigilonДокумент1 страницаManual V1000 Wiring AvigilonPrima VDОценок пока нет

- Nordson EFD 615DT 626DT Operating ManualДокумент16 страницNordson EFD 615DT 626DT Operating Manualneri_colin3770Оценок пока нет