Академический Документы

Профессиональный Документы

Культура Документы

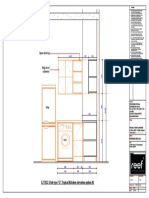

Produced by An Autodesk Student Version: Sheet Content: Cad By: Sheet No: Project Title

Загружено:

Rachelle AtienzaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Produced by An Autodesk Student Version: Sheet Content: Cad By: Sheet No: Project Title

Загружено:

Rachelle AtienzaАвторское право:

Доступные форматы

PRODUCED BY AN AUTODESK STUDENT VERSION

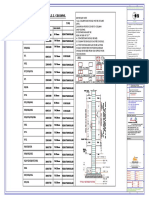

H. NOTES ON COLUMNS

A. GENERAL D. NOTES ON MASONRY

1. Confinement ties shall be provided on all columns at beam column intersection, unless otherwise

1. Construction notes and typical details apply to all drawings unless otherwise shown or 1. All non-load bearing type of concrete blocks shall have a unit weight not to exceed 80 pcf. For

shown in structural plans.

noted. Modify typical details as directed to meet special conditions. non-load bearing type concrete blocks, a minimum compressive strength of 2.76 MPa (400psi) and

5.17 MPa (750 psi) for load bearing type shall be developed. 2. Column ties shall be protected everywhere by covering of concrete cast monolithically with the core

2. Shop drawings with erection and placing diagrams of all structural steel, miscellaneous iron, of minimum thickness of 40mm.

pre-cast concrete, etc. shall be submitted for Engineer's approval before fabrication. 2. Provide 1-Ø16 extra vertical bars at corners, intersections, end of walls, and each side of openings

as shown. 3. Splices should be made within the center half of the column length.

3. Contractor shall verify all dimensions before all work s to begin. Check with mechanical an 4. Splices to be confined by a minimum of 3 links. Top most link to be at top of lower splice bar.

3. Lintel beams or mintel blocks shall bear at least 8 inches (200mm) on each side of masonry wall

electrical contractors for conduits, pipe sleeves, etc. to be embedded in concrete.

opening. 5. No more than half of bars may be spliced at any one section. Splices must be at least 1.00 meter

4. It shall be the contractor's responsibility to provide adequate shorings and bracings of the 4. Wall reinforcements shall be as follows: apart from each other.

structure for all loads that maybe imposed during construction. 6. Welded splice for longitudinal bars with coupling can be considered subject to final approval by

VERTICAL HORIZONTAL

WALL THICKNESS Structural Engineer.

REINFORCEMENT REINFORCEMENT

PRODUCED BY AN AUTODESK STUDENT VERSION

B. CONCRETE & REINFORCEMENT 8 in. Ø12 400mm Ø10 600mm 7. Splices shall be confined by hoops 100mm in spacing through the splice length.

PRODUCED BY AN AUTODESK STUDENT VERSION

6 in. Ø10 400mm Ø10 600mm

1. All materials and workmanship shall conform with the latest building code of American

4 in. Ø10 400mm Ø10 600mm

Concrete Institute (ACI-318).

LAP SPLICE & ANCHORAGE

2. All concrete shall develop a minimum compressive strength at the end of twenty eight (28) 5. Block wall reinforcing bars shall be lapped a minimum of 30 bar diameters where spliced, LAP SPLICE (m) MIN. LAP SPLICE

days with corresponding maximum size aggregate and slumps as follows: horizontal/vertical dowels from footings, column/walls, or slabs shall extend into the block wall a BAR

STANDARD HOOK (m)

UNIT

LENGTH OF COL.

REINF. INDIVIDUAL

ANCHORAGE BARS

DIAMETER TENSION BAR COMPRESSION BAR WEIGHT

LENGTH (m)

minimum of 30 bars diameters or a minimum of 400 mm whichever is longer and dowels to match (mm) (Kg/m)

LOCATION 28 DAYS STRENGTH MAX. SIZE AGGREGATE MAX SLUMP vertical reinforcements of wall. 90° 180° 135° TOP BAR OTHERS TOP BAR OTHERS W/ TIES W/ SPIRAL

Curbs & Slab on Grade 3000 psi (210kg/cm)2 1 in. (25mm) 4 in. (100mm) 6. All cells containing reinforcing vars or inserts shall be solidly filled with concrete grout. (Refer to 10 0.5000 0.1500 0.1300 0.1000 0.4200 0.3000 0.4200 0.3000 0.6170 0.3000 0.3000

(except Found) Specifications) 12 0.5000 0.2000 0.1500 0.1200 0.4200 0.3000 0.4200 0.3000 0.8890 0.3000 0.3000

Foundation 3000 psi (210kg/cm)2 ¾ in. (19mm) 4 in. (100mm)

E. TYPICAL RC WALL REINFORCEMENT

Columns & Walls 3000 psi (210kg/cm)2 ¾ in. (19mm) 4 in. (100mm) 16 0.6000 0.2500 0.1800 0.1400 0.7300 0.5200 0.8700 0.6200 1.5800 0.5200 0.4700

Beams & Slabs 3000 psi (210kg/cm)2 ¾ in. (19mm) 4 in. (100mm) 1. RC Wall Reinforcement shall be as follows: 20 0.6000 0.3000 0.2000 0.2000 0.9100 0.6500 1.1000 0.7800 2.4690 0.6500 0.5800

VERTICAL HORIZONTAL 25 0.6800 0.4000 0.2800 0.2600 1.1500 0.8200 1.4000 1 3.8580 0.8000 0.7300

2.1Light weight concrete shall have a unit weight of 110 pcf, Fc' =3000 psi at 28 days. Submit a WALL THICKNESS

REINFORCEMENT REINFORCEMENT

brochure and material sample for Engineer's approval. 28 0.8600 0.4800 0.3800 - 1.4500 1.0300 1.5300 1.0900 4.8400 0.9000 0.8200

8 in. Ø10 300mm E.F. Ø10 300mm E.F.

1. Reinforcing bars shall be grade 40 and diameter 10 and smaller, grade 60 for diameter 12 and larger, 6 in. Ø10 250mm E.F. Ø10 300mm E.F. 32 1.1200 0.6100 0.4300 - 1.9000 1.3500 1.7400 1.2400 6.3270 1.0300 0.9300

and conform to ASTM A706M (PNS 49). 5 in. Ø10 300mm Ø10 400mm 36 1.4300 0.6100 0.4800 - 2.4000 1.7000 2.0000 1.4000 8 1.2000 1.0500

2. In general, the latest edition of ACI-315, Manual standard practice detailing reinforced concrete 4 in. Ø10 400mm Ø10 400mm NOTES:

structures hall be adhered to, unless otherwise shown or noted. 2. Vertical Reinforcing shall be continuous from structural level to structural level unless noted 1. ACI SECTION 12.4 STATES THAT DEVELOPMENT LENGTH OF INDIVIDUAL BARS W/ IN A BUNDLE, IN TENSION

OR COMPRESSION, SHALL BE THAT FOR THE INDIVIDUAL BAR, INCREASED 20% FOR THREE BAR BUNDLE,

AND 33% FOR FOUR BAR BUNDLE.

otherwise. 2. FOR COLUMNS, AT ANY LEVEL NO MORE THAN ALTERNATE BARS SHOULD BE SPLICED. NOT MORE THAN

33% OF THE BARS SHALL BE SPLICED W/ IN THE REQUIRED LAP LENGTH. MINIMUM DISTANCE BETWEEN

3. Maintain minimum concrete cover for reinforcing steel as follows: 3.

TWO ADJACENT BAR SPLICES SHALL BE 600MM.

TOP BARS ARE HORIZONTAL BARS W/ MORE THAN 300 MM DEPTH OF CONCRETE CAST BELOW THE

REINFORCEMENT.

3. Horizontal spacing shall start and end from not more than1/2 the schedule spacing. 4. AS MUCH AS POSSIBLE, SPLICES SUBJECTED TO TENSILE STRESSES ARE DISCOURAGE, THERE SHOULD

i. Suspended slabs ………………………………………………………………...........………….. ¾ in. (19mm) BE AVOIDED OR PROVIDED W/ STANDARD HOOKS.

4. Splices n horizontal reinforcement shall be staggered, splices in two curtains shall not focus in the

ii. Slab on grade ……………………………………………………………………............………... 1 ½ in. (38mm)

same location.

iii. Walls about grade ……………………………………………….………………….……. 1 in. (25mm)

5. This table applies to walls which are architecturally exposed to view.

iv. Beam stirrups and Column ties ……………………………….………………….... 1 ½ in. (38mm)

6. Tension splices shall be as for seismic tension splices.

v. Where concrete is exposed to earth but poured against forms …...… 2 in. (50mm) 12MM Ø VERTICAL REINFORCEMENT

SPCD @ 0.60M

vi. Where concrete is deposited directly against earth ……………….……… 3 in. (75 mm) F. NOTES ON CONSTRUCTION SLAB

4. Splices shall be securely wired together and shall lap or extend in accordance to table 1 (Table of lap 1. All Slab reinforcement shall be at least 25mm clear minimum fom bottom and top of slab.

splice and anchorage length) unless otherwise shown on drawings, splices shall be staggered

whenever possible. 2. If slab are reinforced bothways, bars along the short span shall be place below those along the long

span at the center and over the longer span bars near the supports. 12MMØ HORIZONTAL REINFORCEMENT

5. All anchor bolts, dowels, and other inserts shall be properly positioned and secured in place prior to

3. Temperature bars for slabs shall be generally placed near the face in tension and shall not be less @EVERY THREE LAYERS

placing of concrete.

than 0.002 bt for Grade 40 & 0.0018 for Grade 60.

6. Contractor shall note and provide all miscellaneous curbs, sills, stools, equipment, and mechanical

bases that are required by the architectural, electrical, and mechanical drawings. MASONRY

7. All concrete shall be kept moist for a minimum of seven (7) consecutive days immediately after G. NOTES ON REINFORCED CONCRETE BEAMS AND GIRDERS 1. ALL CONCRETE HOLLOWBLOCKS

pouring by the use of wet burlap, fog spraying, curing componds or other approved methods. 1. If beam reinforcing bars end in wall, the clear distance from the bar to the farther face of the wall WALL SHALL BE LAID IN RUNNING

BOND (INTERLOCKING COURSE) WITH

8. Stripping of forms and shores: shall not be less than 5 bar diameters. The reinforcing bars shall terminate on a standard 90° hook,

FULL MORTAR BEDDING,

a.Foundation……………………………………………………………………..………......24 hrs. 2. If there are two or more layers of reinforcing bars, use 25mm separator between layers of bars at STACK BOND SHALL BE USED ONLY

900mm O.C. In no case shall there be less than two separators between layers of bars. WHEN SPECIFIED.

b.Suspended Slab except when additional loads are

imposed…………………….……………….……….………...................................8 days 3. When a beam crosses a girder, girder bars shall be on top of beam bars. 2. ALL CELLS SHALL BE SOLIDLY FILL

THE CONCRETE GROUT.

c. Columns & Walls…………………………….…………………….……………………….18 hrs. 4. Generally, no splice shall be permitted on beans at points where critical bending stresses occur.

Welded splices shall develop on tension at least 125 percent of the specified yield strength of the

d.Beams………………………………………………………………………….………….……14 days bar. Not more than 50 percent of the bars at any section shall be splice therein.

C. FOUNDATION 5. Pipes are allowed to cross beams in a transverse manner only within the middle third of the span

1. Foundation is designed for a soil bearing capacity of 140 KPa (2800 psf) and should be placed 50mm below the beam mid-depth. The pipes should be encased.

2. Foundation shall rest on natural soil unless otherwise noted by the Engineer. No part of the

foundation shall rest on a fill.

3. The contractor shall notify the Engineer after footing excavation have been completed and prior to

concreting to confirm the design SBC.

NOTE: PROJECT TITLE: SUBMITTED BY SECTION CAD BY: SHEET CONTENT: SHEET NO:

REPUBLIC ACT 9266: This drawing is an instrument of DESIGN BY:

service is the property of the Architect, registered Architect

and as such must not be reproduced or copied in part or in PROPOSED 5 STOREY RESIDENTIAL AND ATIENZA, RACHELLE CHECKED BY:

whole without permission. All drawings are to be returned CE182-1L / E03 ENGR. WYNDELL ALMENOR

COMMERCIAL BLDG. W/ DECK MAYUGA, DANIEL APPROVED BY:

when no longer in use. PRESIDENTIAL DECREE NO. 49:

"Protection of Intellectual Property" Works of Art, NAKPIL KEILAH

REG. NO. - PTR. NO. - PRODUCED BY AN AUTODESK STUDENT VERSION

Architecture, Model and Designs are creative works and

REVISION:

TIN NO. DATE: PLACE: considered as part of the intellectual property of the author. LOCATION: 638 TOMAS MAPUA ST., STA. CRUZ, MANILA DATE:

Вам также может понравиться

- Viper 560XV InstallДокумент55 страницViper 560XV InstallFUCK YOUОценок пока нет

- Building Quantities ExplainedДокумент12 страницBuilding Quantities ExplainedAxn Nyama38% (26)

- Freelander 1 MY01 - Electrical Circuit Diagrams (LRL0364ENX 2nd Edition)Документ132 страницыFreelander 1 MY01 - Electrical Circuit Diagrams (LRL0364ENX 2nd Edition)Riahi Rezeg100% (5)

- 03 - Par A - Bridges PDFДокумент161 страница03 - Par A - Bridges PDFAnonymous s01ruAIОценок пока нет

- PSY10 PowerpointДокумент134 страницыPSY10 PowerpointRachelle Atienza100% (1)

- Piping Drawing (Macmac)Документ15 страницPiping Drawing (Macmac)Mark Joseph Nambio Nieva100% (2)

- DD43.1 Assembly GuideДокумент17 страницDD43.1 Assembly Guideohsweet jeremyОценок пока нет

- General Notes: Masonry Option Notes (Cont.) :: FDOT 2014 Design Standards FDOT 2014Документ10 страницGeneral Notes: Masonry Option Notes (Cont.) :: FDOT 2014 Design Standards FDOT 2014Arjie alimОценок пока нет

- Column GwaliorДокумент1 страницаColumn Gwaliorvs consultantОценок пока нет

- MR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFДокумент1 страницаMR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFMr. SinghОценок пока нет

- RUBENДокумент1 страницаRUBENmaeglin_elendilОценок пока нет

- Purchaser Name: Andrew Henderson Revision Initial Date: ACN: 610 855 260 TNC Engineering Pty LTDДокумент18 страницPurchaser Name: Andrew Henderson Revision Initial Date: ACN: 610 855 260 TNC Engineering Pty LTDSwaminathan VivekananthamОценок пока нет

- PD 0158 SM 01Документ1 страницаPD 0158 SM 01FAIZAN AHMEDОценок пока нет

- Sydney Simon Mungala EAAQ/06354P/2014 Project: Multi Use Development Nairobi CBDДокумент1 страницаSydney Simon Mungala EAAQ/06354P/2014 Project: Multi Use Development Nairobi CBDNehemiah KoechОценок пока нет

- L (73) 20 Unit Type 'G' Typical Kitchen Plan Option 01 PDFДокумент1 страницаL (73) 20 Unit Type 'G' Typical Kitchen Plan Option 01 PDFJeremiah MangeniОценок пока нет

- General construction notes for reinforced concrete wallsДокумент1 страницаGeneral construction notes for reinforced concrete wallsalezandro del rossiОценок пока нет

- General Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port S-01 24-59Документ1 страницаGeneral Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port S-01 24-59alezandro del rossiОценок пока нет

- CULVERT DRAWING BINDERДокумент5 страницCULVERT DRAWING BINDERAhmed Nader KhurshidОценок пока нет

- L (73) 25 Unit Type 'G' Typical Kitchen Elevation (Option 02)Документ1 страницаL (73) 25 Unit Type 'G' Typical Kitchen Elevation (Option 02)Jeremiah MangeniОценок пока нет

- General Construction Notes: Schedule of Minimum Slab ReinforcementДокумент2 страницыGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinОценок пока нет

- General Construction Notes: Schedule of Minimum Slab ReinforcementДокумент1 страницаGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinОценок пока нет

- S-1 RevisedДокумент1 страницаS-1 Revisedbernard1agoncillioОценок пока нет

- RoofSpecДокумент1 страницаRoofSpeccaleb nyamoraОценок пока нет

- Tek 17-04B PDFДокумент4 страницыTek 17-04B PDFGérard PIERRE LOUISОценок пока нет

- L (73) 22 Unit Type 'G' Typical Kitchen Elevation Option 01 PDFДокумент1 страницаL (73) 22 Unit Type 'G' Typical Kitchen Elevation Option 01 PDFJeremiah MangeniОценок пока нет

- Design Manual Ceiling SystemДокумент9 страницDesign Manual Ceiling SystemMuhammad SheboksheОценок пока нет

- Joska Muchelle WambuaДокумент2 страницыJoska Muchelle Wambuamutisoshadrack082Оценок пока нет

- North West View 1 North East View 2: ClientДокумент1 страницаNorth West View 1 North East View 2: ClientCSEC Uganda Ltd.Оценок пока нет

- NWSC Bunga WDДокумент2 страницыNWSC Bunga WDPIUSОценок пока нет

- Drawing Sheet 4Документ1 страницаDrawing Sheet 4Kunal SharmaОценок пока нет

- L (73) 23 Unit Type 'G' Typical Kitchen Plan (Option 02) PDFДокумент1 страницаL (73) 23 Unit Type 'G' Typical Kitchen Plan (Option 02) PDFJeremiah MangeniОценок пока нет

- GENERAL NOTESДокумент1 страницаGENERAL NOTESmcbluedОценок пока нет

- Details of RCC ColumnДокумент1 страницаDetails of RCC ColumnRavi Kumar RaiОценок пока нет

- Summary Layout For DrawingДокумент1 страницаSummary Layout For DrawingSuhail AhamedОценок пока нет

- Omnia Bridge DeckДокумент7 страницOmnia Bridge DeckKsenia ProtcenkoОценок пока нет

- PROPOSED CHURCH BUILDING ArchitectureДокумент30 страницPROPOSED CHURCH BUILDING Architecturesyedstructures3Оценок пока нет

- SS 01Документ1 страницаSS 01eno khanОценок пока нет

- Construction JointДокумент1 страницаConstruction JointAbbas FarisОценок пока нет

- Notes For Structural DrawingsДокумент3 страницыNotes For Structural DrawingsQaiser KhanОценок пока нет

- Complete A Helical Pile Prelim Using These PlansДокумент6 страницComplete A Helical Pile Prelim Using These PlansBrielle RendoraОценок пока нет

- Sample Precast SpecificationsДокумент3 страницыSample Precast SpecificationsRJSQОценок пока нет

- B-WALL-09-RДокумент1 страницаB-WALL-09-Rp.tooconstructionltdОценок пока нет

- Technical Specs of PoleДокумент22 страницыTechnical Specs of Poleanon_237992751Оценок пока нет

- General construction notes and requirementsДокумент4 страницыGeneral construction notes and requirementsGrachelle Tan100% (1)

- Moment Connection TipsДокумент7 страницMoment Connection TipsManoj JaiswalОценок пока нет

- Constructability of Embedded Steel Plates in CIP ConcreteДокумент7 страницConstructability of Embedded Steel Plates in CIP ConcreteimranОценок пока нет

- 247110006_Two_storey_General_Specifications_1.docxДокумент6 страниц247110006_Two_storey_General_Specifications_1.docxEmmanОценок пока нет

- Block PlanДокумент1 страницаBlock PlanJade Atkinson PhellaineОценок пока нет

- Concrete SW Design Guide 2009 IBCДокумент15 страницConcrete SW Design Guide 2009 IBCadfadОценок пока нет

- C10487-04 Revb PDFДокумент1 страницаC10487-04 Revb PDFjinesh shahОценок пока нет

- C10487-04 Revb PDFДокумент1 страницаC10487-04 Revb PDFjinesh shahОценок пока нет

- Gabion retaining wall detailsДокумент1 страницаGabion retaining wall detailsBharat AryalОценок пока нет

- Site Location Plan Scale: NTS: NotesДокумент1 страницаSite Location Plan Scale: NTS: NotesKamagara Roland AndrewОценок пока нет

- Site Location Plan and Development NotesДокумент1 страницаSite Location Plan and Development NotesKamagara Roland AndrewОценок пока нет

- NotesДокумент1 страницаNotesMohammad AlkahteebОценок пока нет

- Structural Notes and DetailsДокумент1 страницаStructural Notes and DetailsMohammad AlkahteebОценок пока нет

- Structural For TenderДокумент18 страницStructural For Tenderrimshabatoool72Оценок пока нет

- General: Structural SteelДокумент1 страницаGeneral: Structural SteelDerf Jayson AdanteОценок пока нет

- Technical Guidance Note: Omnia Wideslab Permanent Formwork Guide To SpecifiersДокумент1 страницаTechnical Guidance Note: Omnia Wideslab Permanent Formwork Guide To SpecifiersBogdanBОценок пока нет

- 150mm Beam & Block Data SheetДокумент2 страницы150mm Beam & Block Data SheetErnie ErnieОценок пока нет

- PT Benefits Concrete StructuresДокумент3 страницыPT Benefits Concrete StructuresAce JokerОценок пока нет

- Reinforcement Detailing Do's and Don'tsДокумент3 страницыReinforcement Detailing Do's and Don'tsmcadsriОценок пока нет

- Cable TraysДокумент6 страницCable TrayssallammohamedОценок пока нет

- 03 - Par A - BridgesДокумент162 страницы03 - Par A - BridgesVivek KumarОценок пока нет

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionОт EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionОценок пока нет

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionОт EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionОценок пока нет

- Methodology for Reinforcing Concrete Footing and ColumnДокумент6 страницMethodology for Reinforcing Concrete Footing and ColumnRachelle AtienzaОценок пока нет

- Microbiology: An Introduction to MicroorganismsДокумент10 страницMicrobiology: An Introduction to MicroorganismsRachelle AtienzaОценок пока нет

- OJTДокумент36 страницOJTRachelle AtienzaОценок пока нет

- Assignment CE159Документ12 страницAssignment CE159Rachelle AtienzaОценок пока нет

- 10-Terrestrial EcosystemДокумент26 страниц10-Terrestrial EcosystemRachelle AtienzaОценок пока нет

- Scaffolding and StagingДокумент26 страницScaffolding and StagingRachelle AtienzaОценок пока нет

- Workout DeflectionsДокумент3 страницыWorkout DeflectionsRachelle Atienza50% (2)

- Activityity On Matlab PDFДокумент2 страницыActivityity On Matlab PDFRachelle AtienzaОценок пока нет

- ESE 150 RA 9275 (Phil Clean Water Act & Its Implementing Rules & Regulations) .Nov13Документ64 страницыESE 150 RA 9275 (Phil Clean Water Act & Its Implementing Rules & Regulations) .Nov13Rachelle Atienza100% (1)

- Activityity On MatlabДокумент2 страницыActivityity On MatlabRachelle AtienzaОценок пока нет

- 5-Environmental Chemistry and MicrobiologyДокумент41 страница5-Environmental Chemistry and MicrobiologyRachelle AtienzaОценок пока нет

- Soil Chemistry: Study of Chemical PropertiesДокумент13 страницSoil Chemistry: Study of Chemical PropertiesRachelle Atienza0% (1)

- Freshwater and Marine Environment ComparisonДокумент29 страницFreshwater and Marine Environment ComparisonRachelle AtienzaОценок пока нет

- 2-ESE150 Group 2Документ21 страница2-ESE150 Group 2Rachelle AtienzaОценок пока нет

- 12-Group 12 Marine PollutionДокумент17 страниц12-Group 12 Marine PollutionRachelle AtienzaОценок пока нет

- 6 MicrobiologyДокумент10 страниц6 MicrobiologyRachelle AtienzaОценок пока нет

- 11 PresentationДокумент26 страниц11 PresentationRachelle AtienzaОценок пока нет

- 7 Chemical BiochemicalДокумент12 страниц7 Chemical BiochemicalRachelle AtienzaОценок пока нет

- Soil Chemistry: Study of Chemical PropertiesДокумент13 страницSoil Chemistry: Study of Chemical PropertiesRachelle Atienza0% (1)

- 8-Fundamentals of Material BalancesДокумент23 страницы8-Fundamentals of Material BalancesRachelle AtienzaОценок пока нет

- MODEL 6505S Control Head (Mighty Mariner System)Документ3 страницыMODEL 6505S Control Head (Mighty Mariner System)pan - panОценок пока нет

- Roof Deck Floor Plan: Bureau of DesignДокумент1 страницаRoof Deck Floor Plan: Bureau of DesignJule LobresОценок пока нет

- General: Knock Sensor (Flat Type)Документ2 страницыGeneral: Knock Sensor (Flat Type)bob loblawОценок пока нет

- Cushcraft: Assembly and Installation InstructionsДокумент16 страницCushcraft: Assembly and Installation InstructionsedualoviОценок пока нет

- Geep 114Документ5 страницGeep 114friendkwtОценок пока нет

- LC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityДокумент2 страницыLC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityAndrei PantaОценок пока нет

- GE Molded Case Circuit BreakersДокумент120 страницGE Molded Case Circuit Breakersdiscovery198Оценок пока нет

- SF6 RMU - Installation & OperationДокумент27 страницSF6 RMU - Installation & Operationeng.mohamad.saadОценок пока нет

- fbm023 DF 8507 2 PDFДокумент2 страницыfbm023 DF 8507 2 PDFayicОценок пока нет

- TH Trouble Code ListДокумент43 страницыTH Trouble Code ListDean mark rey luzonОценок пока нет

- Color OrganДокумент7 страницColor OrganGabeliDurresitОценок пока нет

- KT-1703V Parts List and SpecificationsДокумент22 страницыKT-1703V Parts List and Specificationsvico21hОценок пока нет

- System Neutral Resistance GroundingДокумент7 страницSystem Neutral Resistance GroundingadhyarthaОценок пока нет

- ASHRAE 90.1 Building Envelope RequirementsДокумент51 страницаASHRAE 90.1 Building Envelope RequirementsRam RamisettiОценок пока нет

- Restraint System Diagnostics and DTC ReferenceДокумент88 страницRestraint System Diagnostics and DTC ReferencechrideerОценок пока нет

- Generator & Transformer ProtectionДокумент27 страницGenerator & Transformer ProtectionfriendbceОценок пока нет

- MobileDart Evolution MX8cДокумент16 страницMobileDart Evolution MX8cAbel Chaiña Gonzales100% (1)

- Galleon 1-3K-ISO TX - Manual PDFДокумент19 страницGalleon 1-3K-ISO TX - Manual PDFBeto SanabriaОценок пока нет

- Npt55 Winding Pitch & WaveformДокумент8 страницNpt55 Winding Pitch & Waveformengmohsen.ramadanhotmail.comОценок пока нет

- Ucd Ac005 0013 L100 PRMДокумент5 страницUcd Ac005 0013 L100 PRMArtur ArturowskiОценок пока нет

- Fast Splice Kit III: Type No.: HF FSK3Документ2 страницыFast Splice Kit III: Type No.: HF FSK3odethОценок пока нет

- TAPROOT COMPLETE MAT LIST (Grand Stand)Документ1 страницаTAPROOT COMPLETE MAT LIST (Grand Stand)Abdul HameedОценок пока нет

- Ur E11rev4Документ8 страницUr E11rev4Maan MrabetОценок пока нет

- Architectural Lighting FixturesДокумент50 страницArchitectural Lighting FixturesRonaldОценок пока нет

- 01 Product Datasheet - LuxSpace HE Including Compact PowerДокумент9 страниц01 Product Datasheet - LuxSpace HE Including Compact PowerfacastrofОценок пока нет