Академический Документы

Профессиональный Документы

Культура Документы

Astm D1004

Загружено:

Hernando Andrés Ramírez GilОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Astm D1004

Загружено:

Hernando Andrés Ramírez GilАвторское право:

Доступные форматы

Designation: D1004 − 13

Standard Test Method for

Tear Resistance (Graves Tear) of Plastic Film and Sheeting1

This standard is issued under the fixed designation D1004; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This test method covers the determination of the tear 2.1 ASTM Standards:3

resistance of flexible plastic film and sheeting at very low rates D618 Practice for Conditioning Plastics for Testing

of loading, 51 mm (2 in.)/min. and is designed to measure the D882 Test Method for Tensile Properties of Thin Plastic

force to initiate tearing. The specimen geometry of this test Sheeting

method produces a stress concentration in a small area of the D883 Terminology Relating to Plastics

specimen. The maximum stress, usually found near the onset of D4000 Classification System for Specifying Plastic Materi-

tearing, is recorded as the tear resistance in newtons (or als

pounds-force). The method is not applicable for film or D5947 Test Methods for Physical Dimensions of Solid

sheeting material where brittle failures occur during testing or Plastics Specimens

where maximum extension is greater than 101.6 mm (4 in.). D6988 Guide for Determination of Thickness of Plastic Film

1.1.1 Although resistance to tear can be expressed in new- Test Specimens

tons per microns, (pounds-force per mil) of specimen E4 Practices for Force Verification of Testing Machines

thickness, this is only advisable where correlation for the E691 Practice for Conducting an Interlaboratory Study to

particular material being tested has been established. In most Determine the Precision of a Test Method

cases, comparison between films of dissimilar thickness is not 2.2 ASTM Adjuncts:

valid. Die Drawings4

NOTE 1—Film has been arbitrarily defined as sheeting having nominal

thickness not greater than 0.25 mm (0.010 in.). 3. Terminology

1.2 Constant-Rate-of-Grip Separation Test—This test 3.1 Definitions:

method employs a constant rate of separation of the grips Definitions of terms applying to this test method appear in

holding the test specimen. Terminology D883.

1.2.1 Specimen extension may be measured in this test

method by grip separation. 4. Summary of Test Method

1.3 The values stated in SI units are to be regarded as the 4.1 The force to initiate tearing across a specific geometry

standard. The values given in parentheses are provided for of a film or sheeting specimen is measured using a constant-

information only. rate-of-grip separation machine. The force necessary to initiate

1.4 This standard does not purport to address all of the the tear is calculated from the load-time or load-displacement

safety concerns, if any, associated with its use. It is the data.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 5. Significance and Use

bility of regulatory limitations prior to use. 5.1 Tear resistance of plastic film or sheeting is a complex

NOTE 2—There is no known ISO equivalent to this standard. function of its ultimate resistance to rupture. The specimen

geometry and speed of testing in this test method are controlled

1

to produce tearing in a small area of stress concentration at

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

Molded Products.

3

Current edition approved April 1, 2013. Published April 2013. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1949. Last previous edition approved in 2009 as D1004 – 09. DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/D1004-13. Standards volume information, refer to the standard’s Document Summary page on

2

The following reference may be of interest in connection with this test method: the ASTM website.

4

Graves, F. L., “The Evaluation of Tear Resistance in Elastomers,” India Rubber Available from ASTM International Headquarters. Order Adjunct No.

World, Vol 111, No. 3, December 1944, pp. 305–308. ADJD1004.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

D1004 − 13

rates far below those usually encountered in service. Experi-

ence has shown the test to have its best reliability for materials

which do not have brittle failure or do not elongate greater than

two hundred percent during testing.

5.2 The data from this test method furnish comparative

information for ranking the tearing resistance of plastic speci-

mens of similar composition. Actual use performance in

tearing of some plastics may not necessarily correlate with data

from this test method.

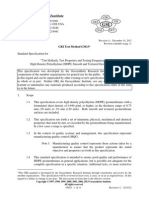

Tolerance ± 0.5°

5.3 The resistance to tear of plastic film and sheeting, while Table of Metric Equivalents

partly dependent upon thickness, has no simple correlation in. mm

4.0 101.60

with specimen thickness. Hence, tearing forces measured in 0.750 19.05

newtons (or pounds-force) cannot be normalized over a wide 1.061 26.95

range of specimen thickness without producing misleading 1.000 25.40

1.118 28.40

data as to the actual tearing resistance of the material. Data 2.0 50.80

from this test method are comparable only from specimens, 0.002 0.051

which vary by no more than 610 % from the nominal or 0.500 12.70

average thickness of all specimens tested. Therefore, the FIG. 1 Die for Tear Test Specimen

tearing resistance is expressed in maximum newtons (or

pounds-force) of force to tear the specimen.

5.4 The tear resistance of plastic film may be a specification frequently fail at the edge of the grips, the radius of curvature of the edges

that requires the use of this test method, but with some of the grips may be increased slightly at the point where they come in

procedural modifications that take precedence when adhering contact with the specimen.

to the specification. Therefore, it is advisable to refer to that 6.1.4 Drive Mechanism—A drive mechanism capable of

material specification before using this test method. Table 1 of separating the movable member (grip) from the stationary

Classification System D4000 lists the ASTM materials stan- member (grip) at a controlled velocity of 51 mm (2 in.) 6

dards that currently exist. 5 %/min.

6.1.5 Load Indicator—A suitable load-indicating mecha-

6. Apparatus nism capable of showing the total tensile load carried by the

6.1 Testing Machine—A testing machine of the constant test specimen held by the grips. The testing machine shall be

rate-of crosshead-movement type and comprising essentially essentially free from inertial lag at the specified rate of testing

the following: and shall indicate the load with an accuracy of 61 %. The

6.1.1 Fixed Member—A fixed or essentially stationary accuracy of the testing machine shall be verified in accordance

member carrying one grip. with Practices E4.

6.1.2 Movable Member—A movable member carrying a 6.1.6 Crosshead Extension Indicator—A suitable extension-

second grip. indicating mechanism capable of showing the amount of

6.1.3 Grips—Preferably, a set of self-aligning grips for change in the separation of the grips (crosshead movement).

holding the test specimen between the fixed member and the 6.2 Thickness—Measure the specimen thickness in accor-

movable member of the testing machine. The grips should dance with Test Methods D5947 or Guide D6988 as appropri-

minimize both slippage and uneven stress distribution. ate.

6.1.3.1 Fixed grips are rigidly attached to the fixed and 6.3 Die4—A die having the dimensions shown in Fig. 1 shall

movable members of the testing machine. Fixed grips may be be used to cut all specimens. The 90° angle shall be honed

used if extreme care is taken to ensure that the test specimen is sharp with no radius or have a minimum practical radius. The

inserted and clamped so that the long axis of the test specimen cutting edge of the die shall have a 5° negative rake, and shall

coincides with the direction of pull through the center line of be kept sharp and free from nicks to avoid leaving ragged

the grip assembly. edges on the specimen. Wetting the surface of the sample and

6.1.3.2 Self-aligning grips are attached to the fixed and the cutting edges of the die with water may facilitate cutting.

movable member of the testing machine in such a manner that The sample shall rest on the smooth, slightly yielding surface

they will move freely into alignment as soon as any load is that will not damage the die blade. Lightweight cardboard or a

applied so that the long axis of the test specimen will coincide piece of leather belting is suitable. Care should be taken that

with the direction of the applied pull through the center line of the cut edges of the specimen are perpendicular to its other

the grip assembly. surfaces and that the edges have a minimum of concavity.

NOTE 3—The specimens should be aligned as perfectly as possible with

the direction of pull so that no rotary motion that may induce slippage will 7. Test Specimens

occur in the grips; there is a limit to the amount of misalignment

self-aligning grips will accommodate. 7.1 The test specimens shall be cut out with a die conform-

NOTE 4—Grips lined with thin rubber have been used successfully. ing to the dimensions shown in Fig. 1 and shall not vary by

Grips may be of the self-tightening type. In cases where specimens more than 0.5 % from these dimensions. The cutting edges of

Copyright by ASTM Int'l (all rights reserved); 2

D1004 − 13

the die shall be kept sharp and free of all nicks to avoid leaving TABLE 1 Initial Tear Resistance (Graves Tear) Machine Direction

ragged edges on the specimens. Values Expressed in Units of Grams-Force

Material

Average Sr A SR B rC RD

NOTE 5—Caution should be used to ensure all samples are the same

dimension if multiple specimens are cut at one time by stacking (layering) LDPE—LD 104 314.6 31.98 55.79 89.53 156.2

LLDPE 384.9 7.80 41.73 21.84 116.8

film.

Polystyrene 459.8 98.06 261.6 274.6 732.3

7.2 Machine direction specimens are cut perpendicular to HDPE No. 2 474.0 19.82 55.42 55.51 155.2

Polypropylene 503.9 29.87 77.45 83.64 216.9

the machine direction and transverse direction specimens are HDPE No. 1 570.9 36.35 78.20 101.8 219.0

cut perpendicular to the transverse direction. Polyester 2494.0 6407.9 599.2 1142.0 1678.0

A

7.3 At least ten specimens shall be tested for each sample, in S r = within-laboratory standard deviation for the material stated. It is obtained by

pooling the standard deviations of the test results from each laboratory:

the case of isotropic materials.

1

7.4 Test a minimum of ten specimens each in the machine S r 5 ff o sS d

1

2

1sS 2 d2 {1 s S n d 2 g /n g 2

direction and in the transverse direction for each anisotropic B

S R = between-laboratories standard deviation for the material stated. It is a

test sample. pooling of the amounts by which the average of the test results for each laboratory

deviate from the overall average for that material.

7.5 Data from specimens which break at some obvious flaw C

r = within-laboratory repeatability limit = 2.8 × Sr.

D

or which break in or at the edges of the grips shall be discarded R = between-laboratories reproducibility limit = 2.8 × SR.

and additional specimens tested, unless such failures constitute

a variable whose effect is being studied.

7.6 Data from specimens which deviate markedly from the 9.4 After complete rupture of the specimen, the maximum

mean value of all tests shall be rejected if the deviation of the tearing load in newtons (pounds-force), and the maximum

doubtful value is more than five times the standard deviation extension in mm (in.) shall be recorded.

from the mean value obtained by excluding the doubtful

results. 10. Calculation

NOTE 6—For certain materials whose properties vary considerably

10.1 Calculate the mean maximum resistance to tearing, and

throughout the film or sheeting, as many as 50 specimens cut from random the maximum extension for all specimens tested in each

portions of the sheet must be tested if reliable tear resistance data are principal direction of orientation. Record maximum tear resis-

desired. tance expressed in newtons (pounds-force) to three significant

figures and maximum extension expressed in mm (in.) to two

8. Conditioning significant figures.

8.1 Conditioning—Condition the test specimens at 23 6 10.2 Calculate standard deviation.

2°C (73.4 6 3.6°F) and 50 6 10 % relative humidity for not

less than 40 h prior to test in accordance with Procedure A of 11. Report

Practice D618, for those tests where conditioning is required.

11.1 Report the following information:

In cases of disagreement, the tolerances shall be 61°C

11.1.1 Complete identification of the material tested, includ-

(61.8°F) and 65 % relative humidity.

ing type, source, manufacturer’s code number, form, principal

8.2 Test Conditions—Conduct tests in the standard labora- dimensions, previous history, and orientation of sample with

tory atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 6 10 % respect to anisotropy, if any.

relative humidity, unless otherwise specified in the applicable 11.1.2 Average thickness of each test specimen and average

ASTM material specification. In cases of disagreements, the thickness of all test specimens.

tolerances shall be 61°C (61.8°F) and 65 % relative humid- 11.1.3 Type of testing machine used.

ity. 11.1.4 Number of specimens tested in each principal direc-

tion.

9. Procedure 11.1.5 Average value of tear resistance calculated in new-

9.1 An initial jaw separation of 25.4 mm (1 in.) shall be tons (pounds-force) and the maximum extension in mm (in.).

used. The rate of travel of the power activated grip shall be 11.1.6 Standard deviation from the averaged values ob-

51-mm (2-in.)/min. tained for specimens tested in each principal direction.

NOTE 7—In this test method, resistance to tear is calculated from the 12. Precision and Bias5

maximum load recorded. In testing most plastics, this maximum load is

generated at the onset of tearing across the 13-mm (0.5-in.) testing width 12.1 Table 1 and Table 2 are based on a round robin

of the specimen. conducted between 1986 and 1990 in accordance with Practice

9.2 Measure the thickness of the specimen at several points E691, involving seven materials tested by seven laboratories.

in the notched area to the accuracy limits of the measuring For each material, all the samples were prepared at one source,

devices specified in 6.2. Record the average thickness in and randomized sections of film were sent to each of the

microns (mil). laboratories which prepared the test specimens and tested

9.3 Place the specimen in the grips of the testing machine so

that the long axis of the enlarged ends of the specimen is in line 5

Supporting data have been filed at ASTM International Headquarters and may

with the center line of the grip assembly. be obtained by requesting Research Report RR:20-1177.

Copyright by ASTM Int'l (all rights reserved); 3

D1004 − 13

TABLE 2 Initial Tear Resistance (Graves Tear) Transverse representative of other lots, conditions, materials, or laborato-

Direction ries. Users of this test method should apply the principles

Values Expressed in Units of Grams–Force outlined in Practice E691 to generate data specific to their

Material

Average Sr A SR B rC RD laboratory and materials, or between specific laboratories. The

LDPE—LD 104 325.1 15.24 34.63 42.67 96.96 principles of 12.2-12.2.3 would then be valid for such data. If

LLDPE 366.6 20.52 28.53 57.45 79.89

HDPE No. 2 411.1 31.70 82.06 88.76 229.8

Sr and SR have been calculated from a large enough body of

Polypropylene 468.0 33.94 86.73 95.02 242.8 data and for test results that were the result of testing ten

Polystyrene 481.4 101.7 263.7 284.7 738.2 specimens:

HDPE No. 1 523.9 46.02 97.75 128.9 273.7

Polyester 2341.0 317.2 443.2 888.1 1241.0 12.2.1 Repeatability Limit, r—(Comparing two test results

A

S r = within-laboratory standard deviation for the material stated. It is obtained by

for the same material, obtained by the same operator using the

pooling the standard deviations of the test results from each laboratory: same equipment on the same day.) The two test results should

1 be judged not equivalent if they differ by more than the “r”

S r 5 ff o sS d

1

2

1sS 2 d2 {1 s S n d 2 g /n g 2

value for that material.

B

S R = between-laboratories standard deviation for the material stated. It is a 12.2.2 Reproducibility Limit, R—(Comparing two test re-

pooling of the amounts by which the average of the test results for each laboratory

deviate from the overall average for that material. sults for the same material, obtained by different operators

C

r = within-laboratory repeatability limit = 2.8 × Sr. using different equipment in different laboratories.) The two

D

R = between-laboratories reproducibility limit = 2.8 × SR. test results should be judged not equivalent if they differ by

more than the “R” value for that material.

12.2.3 Any judgment in accordance with 12.2.1 or 12.2.2

them. Each “test result” was the average of ten determinations.

would have an approximate 95 % (0.95) probability of being

Each laboratory obtained two test results for each material.

correct.

12.2 Concept of r and R—Warning—The following expla-

nations of r and R (12.2-12.2.3) are only intended to present a 12.3 There are no recognized standards to estimate bias of

meaningful way of considering the approximate precision of this test method.

this test method. The data in Table 1 and Table 2 should not be

rigorously applied to acceptance or rejection of material, as 13. Keywords

those data are specific to the round robin and may not be 13.1 Graves; plastic film; tear; tear initiation; thin sheeting

SUMMARY OF CHANGES

Committee D20 has identified the location of selected changes to this standard since the last issue (D1004 - 09)

that may impact the use of this standard. (April 1, 2013)

(1) Updated the conditioning statement in Section 8. (3) Updated Note 2, the ISO equivalency statement.

(2) Clarified subsection 1.1 with the addition of subsection

1.1.1 to address normalization of results to film thickness and

the deletion of corresponding Note 8.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 4

Вам также может понравиться

- Static and Kinetic Coefficients of Friction of Plastic Film and SheetingДокумент6 страницStatic and Kinetic Coefficients of Friction of Plastic Film and SheetingMartin AndradeОценок пока нет

- Astm-D 5748-95 PDFДокумент4 страницыAstm-D 5748-95 PDFcalidadcdokepОценок пока нет

- Tensile Properties of Thin Plastic Sheeting: Standard Test Method ForДокумент11 страницTensile Properties of Thin Plastic Sheeting: Standard Test Method ForAsyrof hibatullahОценок пока нет

- Astm D 3801Документ5 страницAstm D 3801Boris AguilarОценок пока нет

- Water Vapor Transmission of Materials: Standard Test Methods ForДокумент12 страницWater Vapor Transmission of Materials: Standard Test Methods Formailtorubal2573Оценок пока нет

- GRI Test Method GT12 (B) - ISO VersionДокумент7 страницGRI Test Method GT12 (B) - ISO VersionGILBERTO YOSHIDAОценок пока нет

- C363C363M-09 (2015) Standard Test Method For Node Tensile Strength of Honeycomb Core MaterialsДокумент4 страницыC363C363M-09 (2015) Standard Test Method For Node Tensile Strength of Honeycomb Core MaterialsShico1983Оценок пока нет

- D 1921 - 01 - Rde5mjeДокумент5 страницD 1921 - 01 - Rde5mjejamaljamal20100% (1)

- Astm d1603Документ4 страницыAstm d1603zeqs9Оценок пока нет

- Astm D2412-11Документ7 страницAstm D2412-11Leudy Utria100% (1)

- Abrasion TaberДокумент2 страницыAbrasion TaberDiego Fernado AvendañoОценок пока нет

- Astm C 907-2008Документ3 страницыAstm C 907-2008zeqs9Оценок пока нет

- Strength Properties of Adhesives in Shear by Tension Loading of Single-Lap-Joint Laminated AssembliesДокумент4 страницыStrength Properties of Adhesives in Shear by Tension Loading of Single-Lap-Joint Laminated AssembliesMarceloОценок пока нет

- E 96 - e 96M - 15Документ13 страницE 96 - e 96M - 15ruben carcamoОценок пока нет

- ASTM D883 - 12e1 Standard Terminology Relating To PlasticsДокумент2 страницыASTM D883 - 12e1 Standard Terminology Relating To PlasticsRenzo POОценок пока нет

- Astm D 695 - 02Документ10 страницAstm D 695 - 02catarinaОценок пока нет

- ASTM D7254 - 07 Standard Specification For Polypropylene (PP) SidingДокумент2 страницыASTM D7254 - 07 Standard Specification For Polypropylene (PP) SidingAndres Fitria FarrelОценок пока нет

- ASTM D 6093 - 97Документ3 страницыASTM D 6093 - 97shgsuhermanОценок пока нет

- D 4073 Â " 94 R03 RDQWNZMДокумент3 страницыD 4073 Â " 94 R03 RDQWNZMdorbarelОценок пока нет

- Astm D635-2006Документ7 страницAstm D635-2006Boris AguilarОценок пока нет

- Astm D 3767Документ8 страницAstm D 3767jackie wang100% (1)

- ASTM D4541 - 17 - Standard Test Method For Pull-Off Strength of Coatings Using Portable Adhesion TestersДокумент18 страницASTM D4541 - 17 - Standard Test Method For Pull-Off Strength of Coatings Using Portable Adhesion TestersFurkan IŞIKОценок пока нет

- Iso 178 PDFДокумент22 страницыIso 178 PDFThiago Torres0% (1)

- Astm D4833.479148-1Документ4 страницыAstm D4833.479148-1Leudy Utria100% (1)

- Astm C 772-2003Документ2 страницыAstm C 772-2003zeqs9Оценок пока нет

- ASTM D1922 03 Standard Test Method For Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method PDFДокумент6 страницASTM D1922 03 Standard Test Method For Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method PDFAnonymous evrlUD100% (1)

- AASHTO T-250 Thermoplastic Traffic Line Material - Test MethodsДокумент13 страницAASHTO T-250 Thermoplastic Traffic Line Material - Test MethodsAn Trang100% (3)

- ASTM D2842 06 Water Absorption Test MethodДокумент10 страницASTM D2842 06 Water Absorption Test MethodAnonymous BXmahb50% (1)

- Astm D3330-D3330M - 04 2010 PDFДокумент6 страницAstm D3330-D3330M - 04 2010 PDFdamaso taracenaОценок пока нет

- Impact Resistance of Plastic Film by The Free-Falling Dart MethodДокумент10 страницImpact Resistance of Plastic Film by The Free-Falling Dart MethoddanoninoОценок пока нет

- D 5101 - 99 Rduxmdetotk - PDFДокумент8 страницD 5101 - 99 Rduxmdetotk - PDFdadadadОценок пока нет

- D5596-03 (Reapproved 2016)Документ3 страницыD5596-03 (Reapproved 2016)Dilip VaradharajanОценок пока нет

- Extension-Recovery and Adhesion of Latex Sealants: Standard Test Method ForДокумент3 страницыExtension-Recovery and Adhesion of Latex Sealants: Standard Test Method Formercab15Оценок пока нет

- 2 Astm D6943Документ16 страниц2 Astm D6943Boris CardenasОценок пока нет

- D624-00 (2012) Standard Test Method For Tear StrengthДокумент9 страницD624-00 (2012) Standard Test Method For Tear StrengthHussein BeqaiОценок пока нет

- Astm D4218 PDFДокумент3 страницыAstm D4218 PDFthlpapОценок пока нет

- Sheehan 06 PDFДокумент8 страницSheehan 06 PDFpalani.djpОценок пока нет

- D 1780 - 99 Rde3odaДокумент4 страницыD 1780 - 99 Rde3odaMarceloОценок пока нет

- ASTM D5420-04 - Gardner - Impact Resistance of Flat Rigid Plastic Specimen PDFДокумент8 страницASTM D5420-04 - Gardner - Impact Resistance of Flat Rigid Plastic Specimen PDFMehdi Gouader0% (1)

- Astm D4603 - IvДокумент4 страницыAstm D4603 - IvramОценок пока нет

- ASTM D 1824 - 95 Reaprovado 2010 PDFДокумент3 страницыASTM D 1824 - 95 Reaprovado 2010 PDFramon0% (1)

- D 4726 - 02 Rdq3mjyДокумент11 страницD 4726 - 02 Rdq3mjyHumberto GutierrezОценок пока нет

- Astm D4060 14Документ5 страницAstm D4060 14hadi ebrahimfathОценок пока нет

- D 6768 - 03Документ3 страницыD 6768 - 03luis-12Оценок пока нет

- Gri GM13Документ11 страницGri GM13Mauricio PerezОценок пока нет

- Astm d747 Pdqv6897Документ5 страницAstm d747 Pdqv6897Nayth Andres GalazОценок пока нет

- ASTM Designation: C 1305 - 08Документ3 страницыASTM Designation: C 1305 - 08Lupita RamirezОценок пока нет

- Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperatureДокумент2 страницыLinear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperaturePyone Ei ZinОценок пока нет

- Astm D4000 2004 PDFДокумент19 страницAstm D4000 2004 PDFHARSHAОценок пока нет

- Etag 002 PT 2 PDFДокумент13 страницEtag 002 PT 2 PDFRui RibeiroОценок пока нет

- Astm D 905 - 03Документ5 страницAstm D 905 - 03Ramon Ferreira OliveiraОценок пока нет

- ASTM D-4060 Abrasion Resistant of Organic CoatingsДокумент5 страницASTM D-4060 Abrasion Resistant of Organic CoatingsArieIndrawan100% (1)

- D1828-01 (2013) Standard Practice For Atmospheric Exposure of Adhesive-Bonded Joints and StructuresДокумент3 страницыD1828-01 (2013) Standard Practice For Atmospheric Exposure of Adhesive-Bonded Joints and Structuresjose floresОценок пока нет

- ElmendorfTear ASTM D1922Документ34 страницыElmendorfTear ASTM D1922Sukrito Kumar MittraОценок пока нет

- Iso 527Документ3 страницыIso 527Vo Truong GiangОценок пока нет

- Astm D1621-00Документ4 страницыAstm D1621-00hegiro1974Оценок пока нет

- Astm D3262-96Документ8 страницAstm D3262-96anish_am2005Оценок пока нет

- ASTM D1004 - 13-Standard Test Method For Tear Resistance (Graves Tear) of Plastic Film and SheetingДокумент4 страницыASTM D1004 - 13-Standard Test Method For Tear Resistance (Graves Tear) of Plastic Film and Sheetingsparrowjack908Оценок пока нет

- Tear Resistance (Graves Tear) of Plastic Film and Sheeting: Standard Test Method ForДокумент4 страницыTear Resistance (Graves Tear) of Plastic Film and Sheeting: Standard Test Method ForPavan KumarОценок пока нет

- ASTM D-1004-08 (Tear Resistance (Graves Tear) of Plastic Film and Sheeting) PDFДокумент4 страницыASTM D-1004-08 (Tear Resistance (Graves Tear) of Plastic Film and Sheeting) PDFT Aaa100% (1)

- Notched, Constant Ligament-Stress (NCLS) Test To Determine Slow-Crack-Growth Resistance of HDPE Resins or HDPE Corrugated PipeДокумент5 страницNotched, Constant Ligament-Stress (NCLS) Test To Determine Slow-Crack-Growth Resistance of HDPE Resins or HDPE Corrugated PipeHernando Andrés Ramírez GilОценок пока нет

- F2785Документ13 страницF2785Hernando Andrés Ramírez Gil100% (1)

- Excess Flow Valves For Natural Gas ServiceДокумент5 страницExcess Flow Valves For Natural Gas ServiceHernando Andrés Ramírez GilОценок пока нет

- Astm D790-17Документ12 страницAstm D790-17Hernando Andrés Ramírez GilОценок пока нет

- F2788 PDFДокумент11 страницF2788 PDFHernando Andrés Ramírez GilОценок пока нет

- Molded Drain, Waste, and Vent (DWV) Short-Pattern Plastic FittingsДокумент6 страницMolded Drain, Waste, and Vent (DWV) Short-Pattern Plastic FittingsHernando Andrés Ramírez GilОценок пока нет

- F2788 PDFДокумент11 страницF2788 PDFHernando Andrés Ramírez GilОценок пока нет

- Butt Heat Fusion Polyethylene (PE) Plastic Fittings For Polyethylene (PE) Plastic Pipe and TubingДокумент6 страницButt Heat Fusion Polyethylene (PE) Plastic Fittings For Polyethylene (PE) Plastic Pipe and TubingHernando Andrés Ramírez GilОценок пока нет

- F2787 PDFДокумент26 страницF2787 PDFHernando Andrés Ramírez Gil100% (1)

- Polyethylene (PE) Plastic Tubing: Standard Specification ForДокумент7 страницPolyethylene (PE) Plastic Tubing: Standard Specification ForHernando Andrés Ramírez GilОценок пока нет

- Polyethylene (PE) Plastic Pipe, Schedule 40: Standard Specification ForДокумент7 страницPolyethylene (PE) Plastic Pipe, Schedule 40: Standard Specification ForHernando Andrés Ramírez GilОценок пока нет

- Aatcc 173-2015 PDFДокумент4 страницыAatcc 173-2015 PDFHernando Andrés Ramírez GilОценок пока нет

- D2729Документ5 страницD2729Hernando Andrés Ramírez Gil100% (1)

- Time-to-Failure of Plastic Pipe Under Constant Internal PressureДокумент4 страницыTime-to-Failure of Plastic Pipe Under Constant Internal PressureHernando Andrés Ramírez GilОценок пока нет

- Resistance To Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and FittingsДокумент3 страницыResistance To Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and FittingsHernando Andrés Ramírez GilОценок пока нет

- Butt Heat Fusion Polyethylene (PE) Plastic Fittings For Polyethylene (PE) Plastic Pipe and TubingДокумент6 страницButt Heat Fusion Polyethylene (PE) Plastic Fittings For Polyethylene (PE) Plastic Pipe and TubingHernando Andrés Ramírez GilОценок пока нет

- D1785 PDFДокумент11 страницD1785 PDFHernando Andrés Ramírez GilОценок пока нет

- Association of Textile, Parel & Matenals Professionals: This Test Method Is Not For ResaleДокумент7 страницAssociation of Textile, Parel & Matenals Professionals: This Test Method Is Not For ResaleHernando Andrés Ramírez GilОценок пока нет

- D1527 PDFДокумент8 страницD1527 PDFHernando Andrés Ramírez GilОценок пока нет

- Association of Textile, Parel & Matenals Professionals: This Test Method Is Not For ResaleДокумент7 страницAssociation of Textile, Parel & Matenals Professionals: This Test Method Is Not For ResaleHernando Andrés Ramírez GilОценок пока нет

- Aatcc 173-2015 PDFДокумент4 страницыAatcc 173-2015 PDFHernando Andrés Ramírez GilОценок пока нет

- Association of Textile, Parel & Matenals Professionals: This Test Method Is Not For ResaleДокумент7 страницAssociation of Textile, Parel & Matenals Professionals: This Test Method Is Not For ResaleHernando Andrés Ramírez GilОценок пока нет

- Association of Textile, Apparel & Materials Professionals: This Test Method Is Not For ResaleДокумент4 страницыAssociation of Textile, Apparel & Materials Professionals: This Test Method Is Not For ResaleHernando Andrés Ramírez GilОценок пока нет

- Aatcc 173-2015 PDFДокумент4 страницыAatcc 173-2015 PDFHernando Andrés Ramírez GilОценок пока нет

- Astm D2538 02Документ6 страницAstm D2538 02Hernando Andrés Ramírez Gil100% (1)

- Astm D2563-08Документ24 страницыAstm D2563-08Dalton Jay Casila100% (1)

- Astm D2582-16Документ5 страницAstm D2582-16Hernando Andrés Ramírez GilОценок пока нет

- Astm D1239 07Документ3 страницыAstm D1239 07Hernando Andrés Ramírez Gil100% (1)

- En 12256Документ10 страницEn 12256Hernando Andrés Ramírez GilОценок пока нет

- MYP Overview Integrated ScienceДокумент73 страницыMYP Overview Integrated SciencerowanОценок пока нет

- Computer Simulation of Virtual Cathode Oscillations: Articles You May Be Interested inДокумент8 страницComputer Simulation of Virtual Cathode Oscillations: Articles You May Be Interested inChAmirShokatGujjarОценок пока нет

- Q1 Week 2 - Module 3 Uniform Circular MotionДокумент21 страницаQ1 Week 2 - Module 3 Uniform Circular MotionLullaby GomaОценок пока нет

- Analog Meters-1 PDFДокумент120 страницAnalog Meters-1 PDFSayak DasguptaОценок пока нет

- Eddy Current Inspection 20 Question QuizДокумент4 страницыEddy Current Inspection 20 Question QuizThinesh Shankar ThineshОценок пока нет

- Physics of SportsДокумент24 страницыPhysics of SportsRaj MallickОценок пока нет

- The Basics of Lightning and Surge ProtectionДокумент48 страницThe Basics of Lightning and Surge ProtectionJairo Ramos100% (1)

- Astm F819Документ3 страницыAstm F819edmarrobОценок пока нет

- The Inertia Torque of The Hooke JointДокумент45 страницThe Inertia Torque of The Hooke JointHaridev MoorthyОценок пока нет

- WPH11 01 MSC 20210304Документ14 страницWPH11 01 MSC 20210304Little WizardОценок пока нет

- Devices For Various Applications: 7SV7220 Power Supply UnitДокумент10 страницDevices For Various Applications: 7SV7220 Power Supply UnitWalter Andres Estevez VasquezОценок пока нет

- Exp 4 ABCD Parameters of Transmission LineДокумент8 страницExp 4 ABCD Parameters of Transmission LinePuduru BharathiОценок пока нет

- Modeling of Three Winding Voltage Regulating TransformersДокумент11 страницModeling of Three Winding Voltage Regulating Transformerswvargas926100% (1)

- 3.1 - Infrared Spectroscopy - Chemistry LibreTextsДокумент5 страниц3.1 - Infrared Spectroscopy - Chemistry LibreTextsAhmadulhaqОценок пока нет

- Summative Test 2Документ7 страницSummative Test 2Nicole Bacani100% (1)

- Scope: Specific ApplicationsДокумент29 страницScope: Specific ApplicationsGary CudalОценок пока нет

- Service Manual: SC-TM23Документ124 страницыService Manual: SC-TM23Omar FloresОценок пока нет

- Pulley Problems M1Документ6 страницPulley Problems M1Pratik BhosaleОценок пока нет

- Effect of Handrail Shape On Graspability Preprint ManuscriptДокумент50 страницEffect of Handrail Shape On Graspability Preprint ManuscriptAlbertHerzogОценок пока нет

- Facts 2 MarksДокумент14 страницFacts 2 MarksBharath Raj100% (1)

- M-Line Range Catlogue1 PDFДокумент22 страницыM-Line Range Catlogue1 PDFdip461Оценок пока нет

- Induction Motors Faults and ProtectionДокумент2 страницыInduction Motors Faults and ProtectionMuhammad Ali Khan AwanОценок пока нет

- 8ph0 01 Ms Nov 2021 Edexcel As PhysicsДокумент19 страниц8ph0 01 Ms Nov 2021 Edexcel As PhysicssenseiОценок пока нет

- Mastering Physics - Change of Phase (Temperature), Sound LabДокумент10 страницMastering Physics - Change of Phase (Temperature), Sound LabpalparasОценок пока нет

- EES 612 Course OutlineДокумент5 страницEES 612 Course OutlineJoseph DОценок пока нет

- SubblasterДокумент1 страницаSubblasterkarulovОценок пока нет

- Rail GunДокумент8 страницRail GunSaurabh Sharma100% (1)

- Acceleration Field: - The Acceleration of The Particle Is Ascribable To Two ReasonsДокумент12 страницAcceleration Field: - The Acceleration of The Particle Is Ascribable To Two ReasonsAboo Sdam AL MkahalОценок пока нет

- 271-123 221-BgeДокумент80 страниц271-123 221-Bgecastel100% (8)

- Pressure Drop and Friction Loss Pressure Drop and Friction LossДокумент38 страницPressure Drop and Friction Loss Pressure Drop and Friction LossKatherine PutriОценок пока нет