Академический Документы

Профессиональный Документы

Культура Документы

Drill Press Table & Fence

Загружено:

gmand68Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Drill Press Table & Fence

Загружено:

gmand68Авторское право:

Доступные форматы

DRILL PRESS

TABLE

AND FENCE

© 2009 August Home Publishing Co.

Feature

Project

Drill Press Table & Fence

Sometimes simple is best. This drill press table with an adjustable fence

is the perfect example.

A n auxiliary table and an adjust-

able fence. Those are the first

two improvements I’d make

to a “bare bones” drill press.

Take this table for instance.

It’s much larger than the metal

drill press table it’s attached to. So

it offers plenty of support when

working with long pieces.

The table also lays the ground-

work for an adjustable fence. To

position the fence quickly and accu-

rately, it slides along two T-shaped

slots in the table. And a built-in

clamp locks it in place.

TABLE 3⁄ "-thick

4 plywood on the bottom. There’s also another advantage

The table is made up of two layers. And a top layer of 1⁄4" hardboard cre- to this double-layered table. The top

To add rigidity, there’s a layer of ates a flat, durable worksurface. layer has a removable center insert,

see Fig. 1. When this insert gets

1 chewed up with use, simply slide it in

or out to expose a “fresh” drilling sur-

face. Or replace it with a new insert.

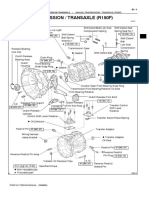

BASE. I started on the table by

making the plywood base (A), as

shown in Fig. 2. To form the first

half of the T-slots, you’ll need to

cut two dadoes in the base, see Fig.

2a. Later, each of these dadoes will

accept the head of a flange bolt that

guides the fence in the slot.

INSTALL T-NUTS. The next step is to

install a set of T-nuts that are used

to attach the base to the metal drill

a. press table. To locate the holes for

these T-nuts, start by setting the

base on the drill press table. Then,

after marking the location of the

holes from underneath the table,

b. drill counterbored shank holes and

tap the T-nuts into place.

TOP. Now you can concentrate on

the top of the table. It consists of two

top (B) pieces and the hardboard

insert, see Figs. 1 and 2. Note: It’s

FLANGE BOLT best to cut the top pieces oversize

and trim them flush later.

1 www.Woodsmith.com © 2009 August Home Publishing Co. All Rights Reserved.

The insert fits into a dovetail-shaped

2

opening in the top of the table. This

opening is formed by cutting a

bevel on the inside edge only of the

top pieces, see Fig. 2b.

To prevent the insert from binding,

the beveled edges of the top pieces

need to be parallel to each other. A

simple solution is to use a spacer

when gluing on the top pieces.

After trimming the edges flush, a. b.

you can complete the second half of

the T-slots. This is just a matter of

cutting dadoes in the top pieces, as

shown in Figs. 3 and 3a.

Now all that’s left is to cut an insert

(C) to fit the opening in the table.

To do this, you’ll need to bevel both

edges of the insert. While you’re at

it, it’s a good idea to make several

3

inserts so you’ll have a few spares.

FENCE

After attaching the drill press table

with bolts, the next step is to add the

fence to the top of the table. a.

The thing I like best about this

fence is you can adjust it without { A waxed “key”

having to coax first one end and ensures proper

then the other. The reason has to do alignment when

with a narrow slot in each end of the gluing up the

fence. These slots form openings for fence pieces.

the flange bolts that guide the fence.

Why not just drill holes for the But there’s clearance between see Fig. 4. The slot for the flange

bolts? After all, it would be quicker. the bolt and the ends of the slot. So bolts is formed by first cutting a pair

The only problem is if you don’t even if both ends of the fence aren’t of dadoes in each fence piece, then

move both ends of the fence the same perfectly aligned, it still slides nice gluing the pieces together,

amount when making an adjustment, and smooth into place. as shown in the margin.

the bolts would jam in the holes and FENCE PIECES. To make the fence, NOTCH. Before installing

hardware

cause the fence to bind. start by cutting two fence pieces (D), the fence, I cut a shallow • (2) !/4" Threaded Knobs

notch in the bottom edge. In • (2) !/4" Washers

4 use, this notch straddles the • (2) !/4" x 3!/4" Flange Bolts

• (4) %/16" T-Nuts

insert in the table, see Figs.

• (4) %/16" Washers

1 and 4. This way, when the

• (4) !/4" Wing Nuts

fence is tightened down, it Note: You’ll also need (4)

won’t apply pressure on the !/4" bolts to mount table to

insert. So you’ll still be able drill press (length will vary)

to slide the insert in or out.

ATTACH FENCE. Now all that’s

left is to attach the fence to the

table. After slipping the flange bolts

in place, set the fence down over

them. Tightening knobs on the

ends of the bolts locks the fence

securely in place.

2 www.Woodsmith.com © 2009 August Home Publishing Co. All Rights Reserved.

Вам также может понравиться

- Furniture of Yesterday and Today (1937)Документ68 страницFurniture of Yesterday and Today (1937)gmand68Оценок пока нет

- Kristin Marciniak - The Salem Witch Trials. A History Perspectives Book (2013,)Документ36 страницKristin Marciniak - The Salem Witch Trials. A History Perspectives Book (2013,)gmand68Оценок пока нет

- Lessons in Chess Strategy - W.H. CozensДокумент114 страницLessons in Chess Strategy - W.H. Cozensgmand68Оценок пока нет

- Billy Connolly - Billy Connolly's Route 66 - The Big Yin On The Ultimate American Road Trip - Little, Brown Book Group (2011)Документ301 страницаBilly Connolly - Billy Connolly's Route 66 - The Big Yin On The Ultimate American Road Trip - Little, Brown Book Group (2011)gmand68Оценок пока нет

- Shop CartДокумент3 страницыShop Cartgmand68Оценок пока нет

- Router Table Micro-AdjusterДокумент2 страницыRouter Table Micro-Adjustergmand68100% (1)

- Portable Dovetail Jig WorkcenterДокумент8 страницPortable Dovetail Jig Workcentergmand6850% (2)

- Sliding Lid BoxesДокумент7 страницSliding Lid Boxesgmand68100% (1)

- Tupia - 17 Molduras Com 3 BitsДокумент5 страницTupia - 17 Molduras Com 3 Bitsleocadio_01100% (1)

- Portable Sandpaper StorageДокумент3 страницыPortable Sandpaper Storagegmand68100% (1)

- 5 Router Table UpgradesДокумент3 страницы5 Router Table Upgradesgmand68100% (3)

- Table Saw Ripping JigДокумент5 страницTable Saw Ripping Jiggmand68100% (1)

- Cutting Perfect TapersДокумент3 страницыCutting Perfect Tapersgmand68100% (1)

- Classy Cutting BoardsДокумент6 страницClassy Cutting Boardsgmand68Оценок пока нет

- Adjustable Taper Ripping JigДокумент6 страницAdjustable Taper Ripping Jiggmand68Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- RHC0234 014013MДокумент2 страницыRHC0234 014013Mpearl ikebuakuОценок пока нет

- Tivyside Classified 290915Документ3 страницыTivyside Classified 290915Digital MediaОценок пока нет

- Frister Cub 7Документ51 страницаFrister Cub 7Ian Black87% (15)

- 5e Advanced Ravnica SupplementДокумент41 страница5e Advanced Ravnica SupplementdurgenspessОценок пока нет

- FCE - Key Word Transformations (For, Since, Ago)Документ2 страницыFCE - Key Word Transformations (For, Since, Ago)alex100% (1)

- Book 1Документ9 страницBook 1Star HealthОценок пока нет

- Manual Transmission (R150F)Документ3 страницыManual Transmission (R150F)daniel_gustavo_2002100% (4)

- Burn Case StudyДокумент5 страницBurn Case Studycaryl100% (1)

- Legendary Monk FullДокумент23 страницыLegendary Monk FullAnto MagaОценок пока нет

- All of me-John-LegendДокумент3 страницыAll of me-John-Legendredouane redОценок пока нет

- 2007 Txtpro PartlistДокумент70 страниц2007 Txtpro PartlistdemoracingeduОценок пока нет

- The 6 Simple Machines: Wedge Screw Inclined PlaneДокумент27 страницThe 6 Simple Machines: Wedge Screw Inclined Planefiey_ra100% (3)

- WWW Learnit3dДокумент2 страницыWWW Learnit3dDanielОценок пока нет

- Medicus Golf Student Manual 2008Документ93 страницыMedicus Golf Student Manual 2008hedonistic770% (1)

- Entertainment: ELE Syllabus EntryДокумент9 страницEntertainment: ELE Syllabus EntryKari Kristine Hoskins Barrera100% (1)

- UntitledДокумент8 страницUntitledBurcu YÜNEKОценок пока нет

- P.E. Mapeh 3Документ4 страницыP.E. Mapeh 3Valencia RaymondОценок пока нет

- Technical Service Information 12-59Документ8 страницTechnical Service Information 12-59Planta Damiana2100% (1)

- Terrain and BuildingДокумент9 страницTerrain and BuildingAde MarkusОценок пока нет

- Crypts of RavenloftДокумент17 страницCrypts of Ravenloftevandro souza0% (2)

- Compliance Statement For SCPsДокумент2 страницыCompliance Statement For SCPsmengineeringОценок пока нет

- OK! Magazine Australia - December 16, 2019 PDFДокумент86 страницOK! Magazine Australia - December 16, 2019 PDFAdam C BmkОценок пока нет

- Nce Upon A Time, in The Quaint Village of LumariaДокумент1 страницаNce Upon A Time, in The Quaint Village of LumariaAdamu KassieОценок пока нет

- FOCGB3 Utest VG 2AДокумент1 страницаFOCGB3 Utest VG 2AVesna ObradovićОценок пока нет

- Yamaha Yzf r15 Version 2-0-2015 User ManualДокумент62 страницыYamaha Yzf r15 Version 2-0-2015 User ManualAswin Lovez Candy's100% (1)

- What To Do in Bosnia HerzegovinaДокумент1 страницаWhat To Do in Bosnia HerzegovinaDenis KajicОценок пока нет

- Kokichi OmaSprite Gallery Danganronpa Wiki FДокумент3 страницыKokichi OmaSprite Gallery Danganronpa Wiki Fmzcvxf9fwpОценок пока нет

- Product Technical Application Guide: Volvo RemanДокумент49 страницProduct Technical Application Guide: Volvo RemanJonah RagleОценок пока нет

- All Euro Data 2021 2022Документ320 страницAll Euro Data 2021 2022Joe Guerby FlarissaintОценок пока нет

- Lesson 1:: Aerobic, Muscle-Strengthening, and Bone-Strengthening ActivitiesДокумент6 страницLesson 1:: Aerobic, Muscle-Strengthening, and Bone-Strengthening ActivitiesJerwin SamsonОценок пока нет