Академический Документы

Профессиональный Документы

Культура Документы

Exxon IP 10-10-2 General Purpose Gear Units

Загружено:

Gilvan SilvaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Exxon IP 10-10-2 General Purpose Gear Units

Загружено:

Gilvan SilvaАвторское право:

Доступные форматы

General Purpose Gear Units IP 10-10-2

INTERNATIONAL Page 1 of 3

PRACTICE (This practice is appropriate for attachment to Inquiry or Purchase Document) Rev. 1 March 1998

THE FOLLOWING PARAGRAPH NUMBERS REFER TO API-677,

FIRST EDITION, MARCH 1989, WHICH IS A PART OF THIS PRACTICE.

SECTION 1 - GENERAL

I 1.1 SCOPE

a. (Exception) This practice covers general-purpose, horizontal, enclosed-single and double-helical

one-and two-stage speed increasers and reducers of parallel-shaft design.

b. All requirements specified in this practice are additions to those of API-677 unless specifically

noted as exceptions. Paragraph numbers in this practice which do not appear in API-677 are

new paragraphs.

c. An asterisk () indicates that a decision by the Purchaser is required, or that additional

information is furnished by the Purchaser.

Note: A Bullet () is shown in API-677 indicating that a Purchaser's decision is required.

d. Vendor Qualification. General-purpose gear units shall be supplied by vendors qualified by

experience to manufacture the units proposed. To qualify, the vendor must have manufactured,

at the proposed point of manufacture, at least two gear units of comparable power and speed

rating, pinion speed, speed ratio, and pitch line velocity. These gear units must have been in

service for at least one year and be performing satisfactorily.

I 1.5 REFERENCED PUBLICATIONS

a. Table 1 lists the practices and standard which shall be used with this practice.

b. Table 2 lists the standards which shall be used with this practice as specified by the Purchaser.

TABLE 1

PRACTICES

IP 2-1-1 Plant Noise Design Criteria

IP 20-1-1 Inspection of Equipment and Materials

STANDARD

API Standard

677 General-Purpose Gear Units for Refinery Service

TABLE 2

STANDARDS

ASTM Standards

B 111 / B 111M Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule

Stock

B 169 / B 169M Aluminum Bronze Plate, Sheet, Strip and Rolled Bar

B 171 / B 171M Copper-Alloy Plate and Sheet for Pressure Vessels, Condensers

and Heat Exchangers

B584 Copper Alloy Sand Castings for General Applications

API Standard

671 Special Purpose Couplings for Refinery Services

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY — FLORHAM PARK, N.J.

IP 10-10-2 General Purpose Gear Units

Page 2 of 3 INTERNATIONAL

PRACTICE

Rev. 1 March 1998 (This practice is appropriate for attachment to Inquiry or Purchase Document)

SECTION 2 - BASIC DESIGN

2.1 GENERAL

E 2.1.5 (Exception) Noise. Vendors shall furnish noise emission data for the quoted equipment with their

proposal per IP 2-1-1.

O,R 2.1.14 Gear units and auxiliaries shall be suitable for outdoor installation in the climatic zone specified.

R 2.1.18 When specified, spare rotors shall be furnished for and delivered with each gear unit. If the rotors of

two or more proposed gear units are duplicates, a single spare set will suffice.

R 2.1.19 When specified, a spare bearing set including thrust and radial bearings shall be furnished with each

gear unit. If two or more proposed gear units are duplicates, a single spare bearing set will suffice.

2.5 RATING

O,R 2.5.1.1 For electric motor drivers the gear unit shall also be rated to withstand momentary high torque

overloads equal to or exceeding four times gear power rating to provide for peak torque resulting

from reapplication of voltage after a power interruption. The suitability of this rating shall be

confirmed by the Purchaser after final system characteristics are defined.

In addition, for synchronous motor drives and variable frequency induction motor drives, the

gear unit including the gear teeth and bearing metal shall also be rated to withstand the peak

oscillatory torque values predicted by the system transient torsional analysis of the motor starting

without incurring fatigue damage or failure.

2.10 BEARINGS

2.10.3 THRUST BEARINGS

R 2.10.3.1 Proposed system arrangement for gear units without thrust bearings must be approved by the

Owner's Engineer.

2.12 LUBRICATION

R 2.12.10 d. Materials of construction for coolers in fresh water cooling service shall be carbon steel

with admiralty metal tubes and brass tubesheets. Materials for salt water cooling service

shall be as follows:

SHELL CHANNELS AND COVERS TUBESHEETS TUBES

Materials Specification Material Specification Material Specification

Carbon Steel Acid Resisting ASTM B584 Naval brass ASTM B171 Inhibited ASTM B111

Bronze Alloy C92200 Alloy C46400 Admiralty Alloy C44300

or C44400, or

Aluminum ASTM B169 C44500

Bronze Alloy C61400

SECTION 3 - ACCESSORIES

3.2 COUPLINGS AND GUARDS

R 3.2.4 The coupling to shaft juncture shall be capable of transmitting the peak torques due to

acceleration and re-acceleration referenced in Par. 2.5.1.1 above.

SECTION 4 - INSPECTION, TESTING, AND PREPARATION FOR SHIPMENT

4.3 TESTING

4.3.4 OPTIONAL TESTS

R 4.3.4.1 FULL-SPEED/FULL OR PART LOAD TEST

Unless otherwise specified, vibration limits shall not exceed those specified in Par. 2.9.3.

4.4 PREPARATION FOR SHIPMENT

M 4.4.3.1 (Exception) Painting of unmachined exterior surfaces for corrosive or marine atmospheres will be

specified.

SECTION 5 - VENDOR'S DATA

5.1 PROPOSALS

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY — FLORHAM PARK, N.J.

General Purpose Gear Units IP 10-10-2

INTERNATIONAL Page 3 of 3

PRACTICE (This practice is appropriate for attachment to Inquiry or Purchase Document) Rev. 1 March 1998

O,R 5.1.1 p. Experience qualification information to comply with Par. 1.1d above.

5.2 CONTRACT DATA

5.2.3 DATA

R 5.2.3.2 g. If specified, the following additional data shall be provided to the Purchaser for review by the

Owner's Engineer.

1. Input and results of critical speed and rotor unbalance response study including bearing

and support stiffnesses and damping as a function of percent torque load and speed.

2. Dimensioned thrust bearing drawings.

3. Dimensioned radial bearing drawings.

4. Input and results of torsional critical speed analysis and transient torsional analysis.

5. Preliminary curves of allowable radial bearing load versus speed (RPM) for variable

frequency induction motor and synchronous electric motor drives.

Revision Memo

12/90 Revision 0 - Original Issue of Basic Practice

6/95 Revision 0 - Original Issue of International Practice

3/98 Revision 1

Deleted Old Pars. 1.2a, 2.10.2, 3.2.8, 4.4.3.2, and 5.1.1.q as adequately covered by API Standards.

Exxon Research and Engineering Company, 1995, 1998

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY — FLORHAM PARK, N.J.

Вам также может понравиться

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsОт EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahОценок пока нет

- Exxon IP 10-3-4 Axial Compressors For Air ServiceДокумент7 страницExxon IP 10-3-4 Axial Compressors For Air ServiceGilvan SilvaОценок пока нет

- Exxon IP 6-4-1 Air-Cooled Heat ExchangersДокумент6 страницExxon IP 6-4-1 Air-Cooled Heat Exchangershcsharma1967Оценок пока нет

- Packaged, Integrally Geared Centrifugal IP 10-3-2 Air CompressorsДокумент5 страницPackaged, Integrally Geared Centrifugal IP 10-3-2 Air CompressorsGilvan SilvaОценок пока нет

- EXXON IP-10-01-01 Centrifugal PumpsДокумент9 страницEXXON IP-10-01-01 Centrifugal PumpsyerkoОценок пока нет

- MQ SP M 4015 PDFДокумент25 страницMQ SP M 4015 PDFjaseelОценок пока нет

- IP 10-4-1 (Reciprocating Process Compressors)Документ9 страницIP 10-4-1 (Reciprocating Process Compressors)luisОценок пока нет

- E PR 810Документ41 страницаE PR 810anju2718Оценок пока нет

- Packed Tower InternalsДокумент1 страницаPacked Tower Internalspalto1Оценок пока нет

- A10-A-DOC-VE-068274 - 00 离心泵 设计要求Документ14 страницA10-A-DOC-VE-068274 - 00 离心泵 设计要求zhangОценок пока нет

- RESR001Документ34 страницыRESR001ermusatОценок пока нет

- Exxon IP 7-3-1 Sootblowers For Fired EquipmentДокумент3 страницыExxon IP 7-3-1 Sootblowers For Fired EquipmentGilvan SilvaОценок пока нет

- 015-FH-1002 (Rev.1) PDFДокумент8 страниц015-FH-1002 (Rev.1) PDFarjun PV RaoОценок пока нет

- A 53 - A 53M - 02Документ22 страницыA 53 - A 53M - 02Sourav RobinОценок пока нет

- Compressor Station Optimization Using Simulation-Based OptimizationДокумент10 страницCompressor Station Optimization Using Simulation-Based OptimizationAmbrish SinghОценок пока нет

- Pressure Testing of Unfired Pressure Vessels: ScopeДокумент9 страницPressure Testing of Unfired Pressure Vessels: Scopebenedicto soto mestanzaОценок пока нет

- Bulletin 16 - Conversion of Triple Effect Evaporator With Five Effect EvaporatorДокумент2 страницыBulletin 16 - Conversion of Triple Effect Evaporator With Five Effect EvaporatorSivaram KrishnamoorthyОценок пока нет

- Ga 201Документ31 страницаGa 201JJ WeldingОценок пока нет

- Design and Optimization of The Methanolto-Olefin Process Part IДокумент12 страницDesign and Optimization of The Methanolto-Olefin Process Part IForcus onОценок пока нет

- STP-1000 Basic Engineering Design DataДокумент17 страницSTP-1000 Basic Engineering Design Datanghiemta18100% (2)

- Material Requisition xxxx-MR01/: SRU Thermal Reactor PACKAGE (4137.05-PK-311/321)Документ28 страницMaterial Requisition xxxx-MR01/: SRU Thermal Reactor PACKAGE (4137.05-PK-311/321)saptarshi jashОценок пока нет

- SA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02Документ5 страницSA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02altipatlarОценок пока нет

- G3ir 1000 25 SP 9001 - R1Документ72 страницыG3ir 1000 25 SP 9001 - R1Ramu NallathambiОценок пока нет

- Combustion Design Data: Design Practices Fired Heaters Subsection M Exxon EngineeringДокумент29 страницCombustion Design Data: Design Practices Fired Heaters Subsection M Exxon EngineeringFRANKLIN REVILLAОценок пока нет

- General-Purpose Steam Turbines (Amendments/Supplements To Api 611)Документ27 страницGeneral-Purpose Steam Turbines (Amendments/Supplements To Api 611)BiswasОценок пока нет

- Conventional Type Pressure Relief Valve NumbersДокумент18 страницConventional Type Pressure Relief Valve NumbersswatkoolОценок пока нет

- 2394-000-STC-1391-00 - 0-Welded SeriesДокумент35 страниц2394-000-STC-1391-00 - 0-Welded SeriesvermaccioОценок пока нет

- ExxonДокумент1 страницаExxonAndres Camilo BenitezОценок пока нет

- 6700-EQS-2800-EC-0004 - EC 2802 - Flash Cooler Condenser - R01Документ9 страниц6700-EQS-2800-EC-0004 - EC 2802 - Flash Cooler Condenser - R01balajiОценок пока нет

- 5-16-4 Steam Turbines: Standard SpecificationДокумент3 страницы5-16-4 Steam Turbines: Standard SpecificationzsmithОценок пока нет

- Engineering Standard: IPS-E-PR-330Документ30 страницEngineering Standard: IPS-E-PR-330Akmal ZuhriОценок пока нет

- Pulsation Suppression Device Design For Reciprocating CompressorДокумент9 страницPulsation Suppression Device Design For Reciprocating CompressorFrancis LinОценок пока нет

- Engineering Standard: IPS-E-PR-790Документ36 страницEngineering Standard: IPS-E-PR-790Anonymous M4BGwOkIpОценок пока нет

- 943025-806 Strainers Rev01Документ3 страницы943025-806 Strainers Rev01studyendlessОценок пока нет

- Engineering Standard: IPS-E-PR-700Документ17 страницEngineering Standard: IPS-E-PR-700ssureshkumar85100% (1)

- Sabp Z 018Документ23 страницыSabp Z 018Eagle SpiritОценок пока нет

- Air Cooled Exchangers PDFДокумент18 страницAir Cooled Exchangers PDFRaghav SharmaОценок пока нет

- Exxon IP 5-3-1 Pressure Testing of Unfired Pressure VesselsДокумент2 страницыExxon IP 5-3-1 Pressure Testing of Unfired Pressure Vesselshcsharma1967Оценок пока нет

- Vents and Drains, Flushing and Cleaning Connections: ScopeДокумент13 страницVents and Drains, Flushing and Cleaning Connections: ScopePanneer BalashanmuganОценок пока нет

- HP Surge ValveДокумент4 страницыHP Surge ValveVee Balaji100% (1)

- Requisitions IndexДокумент13 страницRequisitions IndexKarnan ThirugnanamОценок пока нет

- General Furnace SpecificationДокумент5 страницGeneral Furnace SpecificationswatkoolОценок пока нет

- CHART Cold Box Installation Operation and Maintenance PDFДокумент16 страницCHART Cold Box Installation Operation and Maintenance PDFDana GuerreroОценок пока нет

- Human Factors in Plant Design: ScopeДокумент28 страницHuman Factors in Plant Design: ScopeRajuОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент14 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- Spec SCAPSA Metallic Material Selected StdsДокумент107 страницSpec SCAPSA Metallic Material Selected StdsSwath M MuraliОценок пока нет

- A.1 Job Spec Boiler Package Rev BДокумент30 страницA.1 Job Spec Boiler Package Rev Bprashant937Оценок пока нет

- Sabp Z 032Документ20 страницSabp Z 032Eagle SpiritОценок пока нет

- MQ SP I 7024 PDFДокумент33 страницыMQ SP I 7024 PDFJaseelKanhirathinkalОценок пока нет

- EGE15B5Документ56 страницEGE15B5Jhonny Rafael Blanco CauraОценок пока нет

- Mr. C.H.Park / Project Manager 03-May-06Документ30 страницMr. C.H.Park / Project Manager 03-May-06Ali YassineОценок пока нет

- IPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsДокумент22 страницыIPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsAbdi RahimianОценок пока нет

- Attach 4 RAM Analysis ReportДокумент51 страницаAttach 4 RAM Analysis ReportLisbeth Roos RoosОценок пока нет

- Engineering Manual SPD0027EPN: Pipe Thickness Decision Method Under Asme StandardДокумент9 страницEngineering Manual SPD0027EPN: Pipe Thickness Decision Method Under Asme StandardGabbar SinghОценок пока нет

- Lubrication, Shaft-Sealing and Oil-Control Systems and Auxiliaries (Amendments/Supplements To Iso 10438)Документ42 страницыLubrication, Shaft-Sealing and Oil-Control Systems and Auxiliaries (Amendments/Supplements To Iso 10438)Biswas100% (1)

- Dep 7Документ28 страницDep 7BiswasОценок пока нет

- Castable-Free Fired HeaterДокумент4 страницыCastable-Free Fired HeaterchemengseliemОценок пока нет

- Final Project Report: Uop, LLCДокумент165 страницFinal Project Report: Uop, LLCSiddharth KishanОценок пока нет

- Exxon Ejectors PDFДокумент19 страницExxon Ejectors PDFRitesh Dev MaityОценок пока нет

- Engineering Standard: IPS-E-PR-410Документ19 страницEngineering Standard: IPS-E-PR-410محمد نصیریОценок пока нет

- Practical Guide To Rubber Injection Molding PDFДокумент130 страницPractical Guide To Rubber Injection Molding PDFGilvan Silva100% (3)

- JPCL APP Plural - Plural Component Spray 2012-09Документ50 страницJPCL APP Plural - Plural Component Spray 2012-09Gilvan SilvaОценок пока нет

- JPCL APP Plural - Plural Component Spray 2012-09Документ50 страницJPCL APP Plural - Plural Component Spray 2012-09Gilvan SilvaОценок пока нет

- AWWA - Disinfection of Pipelines and Storage Facilities Field Guide PDFДокумент147 страницAWWA - Disinfection of Pipelines and Storage Facilities Field Guide PDFbureua100% (1)

- Tri-Service Corrosion Conference PDFДокумент1 883 страницыTri-Service Corrosion Conference PDFGilvan SilvaОценок пока нет

- World Pipelines Oct 2018 PDFДокумент84 страницыWorld Pipelines Oct 2018 PDFGilvan SilvaОценок пока нет

- 05 - Phase Transformation in Welding PDFДокумент36 страниц05 - Phase Transformation in Welding PDFIrfan KhanОценок пока нет

- JPCL APP Plural - Plural Component Spray 2012-09Документ50 страницJPCL APP Plural - Plural Component Spray 2012-09Gilvan SilvaОценок пока нет

- Exxon IP 10-9-1 Mechanical AgitatorsДокумент7 страницExxon IP 10-9-1 Mechanical AgitatorsGilvan SilvaОценок пока нет

- X-Ray Film SeminarДокумент40 страницX-Ray Film SeminarGilvan SilvaОценок пока нет

- JPCL APP Plural - Plural Component Spray 2012-09Документ50 страницJPCL APP Plural - Plural Component Spray 2012-09Gilvan SilvaОценок пока нет

- Exxon IP 10-4-1 Reciprocating Process CompressorsДокумент9 страницExxon IP 10-4-1 Reciprocating Process CompressorsGilvan SilvaОценок пока нет

- Exxon IP 7-9-1 Expansion Joints For Fired EquipmentДокумент3 страницыExxon IP 7-9-1 Expansion Joints For Fired EquipmentGilvan SilvaОценок пока нет

- Exxon IP 10-12-1 Vibration, AxialДокумент3 страницыExxon IP 10-12-1 Vibration, AxialGilvan SilvaОценок пока нет

- Exxon IP 9 2 1 Additional RequirementsДокумент8 страницExxon IP 9 2 1 Additional RequirementsGilvan SilvaОценок пока нет

- Exxon IP 10-10-2 General Purpose Gear UnitsДокумент3 страницыExxon IP 10-10-2 General Purpose Gear UnitsGilvan SilvaОценок пока нет

- Exxon IP 7-3-1 Sootblowers For Fired EquipmentДокумент3 страницыExxon IP 7-3-1 Sootblowers For Fired EquipmentGilvan SilvaОценок пока нет

- Exxon IP 15-1-1 Instrumentation For Fired HeatersДокумент14 страницExxon IP 15-1-1 Instrumentation For Fired HeatersGilvan Silva100% (1)

- GP 43-50 31 January 2009 PDFДокумент52 страницыGP 43-50 31 January 2009 PDFGilvan SilvaОценок пока нет

- Vents For Fixed Roof Atmospheric IP 9-7-3 Storage Tanks: ScopeДокумент1 страницаVents For Fixed Roof Atmospheric IP 9-7-3 Storage Tanks: ScopeGilvan SilvaОценок пока нет

- Exxon IP 7-5-1 Coils For Fired Heaters and BoilersДокумент5 страницExxon IP 7-5-1 Coils For Fired Heaters and BoilersGilvan SilvaОценок пока нет

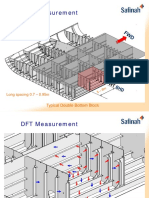

- DFT Measurement: Typical Double Bottom BlockДокумент4 страницыDFT Measurement: Typical Double Bottom BlockGilvan SilvaОценок пока нет

- Corrugated Steel Manhole Assemblies: Standard Specification ForДокумент8 страницCorrugated Steel Manhole Assemblies: Standard Specification ForGilvan SilvaОценок пока нет

- Pregatirea Suprafetelor Pentru VopsireДокумент4 страницыPregatirea Suprafetelor Pentru VopsireValentin GalbenОценок пока нет

- Aspersão Termica - FundamentosДокумент1 страницаAspersão Termica - FundamentosGilvan SilvaОценок пока нет

- Micrometer PDFДокумент5 страницMicrometer PDFAlessandro sergio de souzaОценок пока нет

- Micrometer PDFДокумент5 страницMicrometer PDFAlessandro sergio de souzaОценок пока нет

- Mcqs For MCATДокумент26 страницMcqs For MCATHashir Ahmad KhanОценок пока нет

- GasCalc Module enДокумент2 страницыGasCalc Module ensppramОценок пока нет

- A Method of Identifying The Lightning Strike Location On A Structure Hartono ArticleДокумент6 страницA Method of Identifying The Lightning Strike Location On A Structure Hartono Articlefreddy riveraОценок пока нет

- Matlab Fourier Series Signal & SystemДокумент15 страницMatlab Fourier Series Signal & SystemNik Ahmad FaisalОценок пока нет

- Method To Make Yttrium-Barium-Copper Oxide Superconductor (YBCO)Документ2 страницыMethod To Make Yttrium-Barium-Copper Oxide Superconductor (YBCO)RUBYОценок пока нет

- F 1624 - 99 Rje2mjqtukveДокумент8 страницF 1624 - 99 Rje2mjqtukveJuanОценок пока нет

- NEMA TS2 - OverviewДокумент22 страницыNEMA TS2 - OverviewAdalberto MesquitaОценок пока нет

- Design, Analysis, Fabrication and Testing of A Formula Car ChassisДокумент10 страницDesign, Analysis, Fabrication and Testing of A Formula Car ChassisSavalia HardikОценок пока нет

- Formula Sheet 1Документ4 страницыFormula Sheet 1Abhimanyu DwivediОценок пока нет

- Perhitungan Sabuk Ties TC Potain MCR 225AДокумент15 страницPerhitungan Sabuk Ties TC Potain MCR 225AsuryaОценок пока нет

- HVAC Qualification KanishkДокумент38 страницHVAC Qualification Kanishkk.p.Оценок пока нет

- Buting Senior High School Media and Information Literacy Unit TestДокумент2 страницыButing Senior High School Media and Information Literacy Unit TestGina BundaОценок пока нет

- Cat Apem Ermec Nuevo Catalogo General de Pulsadores Interruptores Apem Big Blue 2011 12Документ589 страницCat Apem Ermec Nuevo Catalogo General de Pulsadores Interruptores Apem Big Blue 2011 12Josue BerzunzaОценок пока нет

- GEC 17 Lesson 1 Introduction To STSДокумент15 страницGEC 17 Lesson 1 Introduction To STSJhupit Ganihay100% (1)

- B SafeunitДокумент4 страницыB SafeunitSabariyantoОценок пока нет

- Hw2 Machining Solutions 2016Документ9 страницHw2 Machining Solutions 2016BARNABAS DOGOОценок пока нет

- Experimental Study of Cuttings Transport in Directional WellsДокумент14 страницExperimental Study of Cuttings Transport in Directional WellsFabian Andrey DiazОценок пока нет

- Priyanka Patel Resume r6Документ2 страницыPriyanka Patel Resume r6api-288092186Оценок пока нет

- Control and Interfacing of BLDC Motor With Labview Using MyrioДокумент5 страницControl and Interfacing of BLDC Motor With Labview Using Myriovasu_koneti5124Оценок пока нет

- Local Buckling Analysis Based On DNV-OS-F101 2000Документ4 страницыLocal Buckling Analysis Based On DNV-OS-F101 2000shervinyОценок пока нет

- 2008 PJC CH H2 P3 PrelimДокумент12 страниц2008 PJC CH H2 P3 PrelimdeadbeanОценок пока нет

- Ujian Nasional Bahasa Inggris SMA Tahun 1994Документ6 страницUjian Nasional Bahasa Inggris SMA Tahun 1994Andhika A. SetiyonoОценок пока нет

- Grade 5 Science Practice Test: Nebraska Department of Education 2012Документ13 страницGrade 5 Science Practice Test: Nebraska Department of Education 2012Ria SihombingОценок пока нет

- GMAT QUANT TOPIC 3 (Inequalities + Absolute Value) SolutionsДокумент46 страницGMAT QUANT TOPIC 3 (Inequalities + Absolute Value) SolutionsBhagath GottipatiОценок пока нет

- 2011 Exam GeotechnicalДокумент9 страниц2011 Exam GeotechnicalAhmed AwadallaОценок пока нет

- Standard Method For Making and Curing Cubes Made From Pre-Bagged Grouts and Polymer Modified Mortars PDFДокумент7 страницStandard Method For Making and Curing Cubes Made From Pre-Bagged Grouts and Polymer Modified Mortars PDFVCОценок пока нет

- Pages From ASME - B31 - 3 - UnlockedДокумент8 страницPages From ASME - B31 - 3 - UnlockedJose Juan GasparОценок пока нет

- Helmreich Cut Up Sonic TransductionДокумент9 страницHelmreich Cut Up Sonic TransductiongrundumОценок пока нет

- 9487-Physics Teachers' Guide Unit 2 - Electricity, Electrons and Energy LevelsДокумент141 страница9487-Physics Teachers' Guide Unit 2 - Electricity, Electrons and Energy LevelsAli AkbarОценок пока нет

- Porirua Harbour Bathymetric SurveyДокумент32 страницыPorirua Harbour Bathymetric SurveyPaul MarlowОценок пока нет