Академический Документы

Профессиональный Документы

Культура Документы

PSDV-11803 Installation Procedure - Rev.b (Per Cms Comment)

Загружено:

IsaalexОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PSDV-11803 Installation Procedure - Rev.b (Per Cms Comment)

Загружено:

IsaalexАвторское право:

Доступные форматы

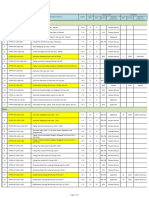

INSTALLATION AND PRECOMM NO: ID-PCK-PB-IBP-7011022

PROCEDURE PAGE: 1 OF 3

PCK 7A MWP-B DATE: REV: B

PECIKO 03/06/2010

PSDV-11803

INITIAL STATE

Fuel gas line on shutdown condition

New PSDV-11803 ready in position

New LCP PSDV-11803 ready in position

100. PREPARATION: Location Action by

110. Team Organization. MWP-B

111.ENG/PJC: 1 person. ENG/PJC

112. BSP/MNP/IS: 1 person BSP/MNP

113. BSP/PRD : 2 person BSP/PRD

114. PJT/CMS : 2 person PJT/CMS

115. Contractor: 3 person. IBP

120. Work Permit. IBP

130. Material and Tools.

131. Common tools (multi-tester, screw driver, spanner)

132. Gas Driven Hydraulic pump.

133. Radios.

134. Nitrogen.

135. Valve and Tubing plug.

200. INHIBITION Field

Close ball Valve Z-51 in new WHCP (see DWG. ID-PCK-PB-IBP- MWP-B IBP

7002104 sht.6)

Push PB CC-1 in new WHCP (see DWG. ID-PCK-PB-IBP-7002104

IBP

sht.6)

300. TIE IN Field

Check accumulator precharge already 85 barg MWP-B IBP

IBP

Blown supply & return tube using Nitrogen

Flush & circulate hydraulic oil TOTAL Azzola ZS-32 NAS 6 through IBP

new installed tube (5 minutes)

IBP

Connect LP hydraulic supply & return, MP-2 supply & return tube to

new LCP PSDV-11803

IBP

Install ball new valve & tubing as LP hydraulic return line

INSTALLATION AND PRECOMM NO: ID-PCK-PB-IBP-7011022

PROCEDURE PAGE: 2 OF 3

PCK 7A MWP-B DATE: REV: B

PECIKO 03/06/2010

PSDV-11803

400. LEAK TEST Field

Disconnect the tubing at LP hydraulic supply & return line to new LCP MWP-B IBP

PSDV-11803 and Pressurize with flushed hydraulic oil TOTAL Azolla

ZS-32 using gas driven hydraulic pump until reach it’s 150% of

working pressure (7 barg).

IBP

Hold for 30 minutes, ensure no leakage happened

Re-connect the tubing at LP hydraulic supply & return line to new LCP IBP

PSDV-11803

Ensure all connection have tighten already IBP

Disconnect the tubing at MP-2 supply & return line to new LCP PSDV-

IBP

11803 and Pressurize with flushed hydraulic oil TOTAL Azolla ZS-32

using gas driven hydraulic pump until reach it’s 150% of working

pressure (210 barg).

IBP

Hold for 30 minutes, ensure no leakage happened

IBP

Re-connect the tubing at MP-2 supply & return line to new LCP PSDV-

11803

IBP

Ensure all connection have tighten already

500. COMPLETION : Field

Open hydraulic supply ball valve V-1 to LCP PSDV-11803 (see DWG. MWP-B BSP/MNP

ID-PCK-GP-IBP-7002004 HOOK UP DRAWING sheet 39A)

Open hydraulic return ball valve V-2 to LCP PSDV-11803 (see DWG.

BSP/MNP

ID-PCK-GP-IBP-7002004 HOOK UP DRAWING sheet 39A)

Open hydraulic return ball valve V-3 to LCP PSDV-11803 (see DWG.

BSP/MNP

ID-PCK-GP-IBP-7002004 HOOK UP DRAWING sheet 39A)

Open ball Valve Z-51 in new WHCP (see DWG. ID-PCK-PB-IBP- BSP/MNP

7002104 sht.6)

BSP/MNP

SOV-11803 shall be opened first prior to open PSDV-11803

Push PB CC-1 in new WHCP (see DWG. ID-PCK-PB-IBP-7002104 BSP/MNP

sht.6) and record traveling time from close to open position

Pull PB CC-1 in new WHCP (see DWG. ID-PCK-PB-IBP-7002104 BSP/MNP

sht.6) and record traveling time from open to close position

INSTALLATION AND PRECOMM NO: ID-PCK-PB-IBP-7011022

PROCEDURE PAGE: 3 OF 3

PCK 7A MWP-B DATE: REV: B

PECIKO 03/06/2010

PSDV-11803

FINAL STATE

Fuel gas line on shutdown condition

New PSDV-11803 ready to be used and all associate tag shall be

installed (WHCP & RTU)

New LCP & it`s new connection is READY FOR COMMISSIONING

CAUTION

IN CASE OF OPERATING ANOMALY OR IF THIS PROCEDURE IS NOT

APPLICABLE FOR WHATEVER REASON, REPORT IMMEDIATELY TO

SUPERVISOR

Вам также может понравиться

- Overhauling Boiler 3 Valve Technical ProposalДокумент41 страницаOverhauling Boiler 3 Valve Technical Proposaltimothy100% (2)

- Qatar Transmission System Expansion - Phase 10 Substations Package S5 & S8 CONTRACT No. GTC/371C/2010Документ20 страницQatar Transmission System Expansion - Phase 10 Substations Package S5 & S8 CONTRACT No. GTC/371C/2010Vijai PrasathОценок пока нет

- 11 Proportional Valve Mini CatalogДокумент104 страницы11 Proportional Valve Mini CatalogInnov8 OilОценок пока нет

- Pump Control PW200 220-7Документ21 страницаPump Control PW200 220-7Teknik Makina100% (1)

- Cable Gland, Cable & Wire Installation ProcedureДокумент14 страницCable Gland, Cable & Wire Installation ProcedureIsaalexОценок пока нет

- IC-8 Chilled Water SequenceДокумент4 страницыIC-8 Chilled Water Sequencevirtech0% (1)

- Adani Power's Goal of 20,000 MW by 2020Документ43 страницыAdani Power's Goal of 20,000 MW by 2020Vara BikkinaОценок пока нет

- Flyaudio in An 08 Is250 With Factory Nav InstructionsДокумент2 страницыFlyaudio in An 08 Is250 With Factory Nav InstructionsAndrewTalfordScottSr.Оценок пока нет

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Marcel Breuer: Hungarian-American Designer, Architect and Bauhaus PioneerДокумент8 страницMarcel Breuer: Hungarian-American Designer, Architect and Bauhaus PioneerYosaphat Kiko Paramore DiggoryОценок пока нет

- 5 KVA UPS Docs (HI-REL) PDFДокумент53 страницы5 KVA UPS Docs (HI-REL) PDFMohan Kulkarni75% (4)

- Book 2Документ36 страницBook 2vijaysatawОценок пока нет

- Pressure Transmitter Elec: Instrument Calibration ResultДокумент2 страницыPressure Transmitter Elec: Instrument Calibration ResultIsaalexОценок пока нет

- RA 8042 and RA 10022 ComparedДокумент37 страницRA 8042 and RA 10022 ComparedCj GarciaОценок пока нет

- Performance Testing Procedure Rev 0 PDFДокумент36 страницPerformance Testing Procedure Rev 0 PDFIsaalexОценок пока нет

- CV Ipan PurnamaДокумент7 страницCV Ipan PurnamaIsaalexОценок пока нет

- CV Ipan PurnamaДокумент7 страницCV Ipan PurnamaIsaalexОценок пока нет

- CV Ipan PurnamaДокумент7 страницCV Ipan PurnamaIsaalexОценок пока нет

- Power Cable ScheduleДокумент40 страницPower Cable ScheduleAnupam0103Оценок пока нет

- 244256-Exabeam Security Content in The Legacy Structure-Pdf-EnДокумент142 страницы244256-Exabeam Security Content in The Legacy Structure-Pdf-EnYoussef MohamedОценок пока нет

- 500mw Checking and Setting of Hydraulic and ElectroДокумент15 страниц500mw Checking and Setting of Hydraulic and Electrothangarajm1984Оценок пока нет

- Schedue IFS Metal 1Документ1 страницаSchedue IFS Metal 1IsaalexОценок пока нет

- Control Philosophy - DM PlantДокумент11 страницControl Philosophy - DM Plantnileshwarke100% (1)

- Introduction To Management: Planning & Goal SettingДокумент31 страницаIntroduction To Management: Planning & Goal SettingMaisarah NorzihanОценок пока нет

- Binder 4Документ68 страницBinder 4Sunil KОценок пока нет

- LPG Storage & Transfer ProceduresДокумент26 страницLPG Storage & Transfer ProceduresKuldeepsingh Chandel100% (1)

- Appendix-4 Fabrication Sequences TopSide AДокумент2 страницыAppendix-4 Fabrication Sequences TopSide AIsaalexОценок пока нет

- PP Aaa PP1 132Документ20 страницPP Aaa PP1 132Rabah Amidi100% (1)

- PP10CC 00 6LBB Yr Abc 001 PDFДокумент26 страницPP10CC 00 6LBB Yr Abc 001 PDFanbesivam87Оценок пока нет

- Procedure For Condenser Vacuum PullingДокумент4 страницыProcedure For Condenser Vacuum PullingPulkit AgarwalОценок пока нет

- Electricity Flow Diagram Generator SupplyДокумент1 страницаElectricity Flow Diagram Generator SupplyjokoОценок пока нет

- CW Pump House Instrumentation WiringДокумент14 страницCW Pump House Instrumentation Wiringmukesh_kht1Оценок пока нет

- A Shift-15.02.2024 ReportДокумент1 страницаA Shift-15.02.2024 ReportShiavm PatelОценок пока нет

- Equipment List Senbal-05 Feb 23Документ1 страницаEquipment List Senbal-05 Feb 23R.A. AbriantoОценок пока нет

- ES0153-75440100-DBR-0003 Dust ExtractionДокумент19 страницES0153-75440100-DBR-0003 Dust Extractionraaj bharathОценок пока нет

- Boiler MCC 7aДокумент3 страницыBoiler MCC 7aMisbahul AnwarОценок пока нет

- UntitledДокумент2 страницыUntitledNguyễn Duy HảiОценок пока нет

- 5 Buffer Hopper D-PumpДокумент4 страницы5 Buffer Hopper D-PumpMithun Singh RajputОценок пока нет

- BDB - SCHДокумент4 страницыBDB - SCHmartonoscribОценок пока нет

- TG-PM ChecklistДокумент106 страницTG-PM Checklistsudhansu8beheraОценок пока нет

- USPL storage tank docsДокумент1 страницаUSPL storage tank docsaravind grandhiОценок пока нет

- Karam-12 Unsecuring ProgramДокумент2 страницыKaram-12 Unsecuring ProgramAhmed AliОценок пока нет

- Spreadsheet-Based Process Group SoftwareДокумент10 страницSpreadsheet-Based Process Group SoftwareHendy ArmantoОценок пока нет

- System NamelistДокумент4 страницыSystem Namelisthafiz sungchangОценок пока нет

- PLTU SEKAYAN 1X7,5 MW Maintenance ReportДокумент4 страницыPLTU SEKAYAN 1X7,5 MW Maintenance ReportAlbert NathanОценок пока нет

- A Shift-12.02.2024 Report1Документ1 страницаA Shift-12.02.2024 Report1Shiavm PatelОценок пока нет

- Unassigned Problem - 25 - SolutionsДокумент7 страницUnassigned Problem - 25 - Solutionsธนลักษณ์ งามปัญจะОценок пока нет

- Wa0000Документ60 страницWa0000Radha Raman Mishra100% (1)

- ICSS To WHCP 13 Sequence OPEN-CLOSEДокумент4 страницыICSS To WHCP 13 Sequence OPEN-CLOSECường Đặng ViếtОценок пока нет

- ICSS To WHCP 13 Sequence OPEN-CLOSE PDFДокумент4 страницыICSS To WHCP 13 Sequence OPEN-CLOSE PDFCường Đặng ViếtОценок пока нет

- Datasheet 3 Pcs 01Документ24 страницыDatasheet 3 Pcs 01StarburstОценок пока нет

- SBS Tech ChillerДокумент1 страницаSBS Tech ChillerYang John (Rich-Tech1688)Оценок пока нет

- Updated Meter Id With Flow Mwter and Ip Address of Link 150 UflexДокумент26 страницUpdated Meter Id With Flow Mwter and Ip Address of Link 150 Uflexambitquality01Оценок пока нет

- PID Temperature Batch Counter Controller Operating ManualДокумент4 страницыPID Temperature Batch Counter Controller Operating ManualBalaso GaikwadОценок пока нет

- Process Group Spreadsheet-Based Software ValidationДокумент10 страницProcess Group Spreadsheet-Based Software ValidationAnonymous iCFJ73OMpDОценок пока нет

- 4.STC TRS Conventional 02 e AuxiliariesДокумент39 страниц4.STC TRS Conventional 02 e Auxiliariesmikkumar5100% (1)

- NCCR 3G 002 Swap Ericsson Borneo Covrel Cpich WPC 201511013Документ2 страницыNCCR 3G 002 Swap Ericsson Borneo Covrel Cpich WPC 201511013NangОценок пока нет

- 001 - Index Drawing - Mechanical ElectricalДокумент2 страницы001 - Index Drawing - Mechanical Electricalana astutiОценок пока нет

- Raw water 6.6Kv switchgear and DM Plant 415V MCC single line diagramsДокумент2 страницыRaw water 6.6Kv switchgear and DM Plant 415V MCC single line diagramsrpshvjuОценок пока нет

- 24-00-00 PB 001 CONF 00 - ELECTRICAL POWER - General - Description and OperationДокумент18 страниц24-00-00 PB 001 CONF 00 - ELECTRICAL POWER - General - Description and OperationKshitiz RastogiОценок пока нет

- Specifications For Pressure SwitchesДокумент1 страницаSpecifications For Pressure SwitchesVirgilioОценок пока нет

- Update to As Built Documents on 2 Mar 2023Документ5 страницUpdate to As Built Documents on 2 Mar 2023ekyyyОценок пока нет

- Bom Uss1Документ15 страницBom Uss1superthambiОценок пока нет

- CSS 1250kva & 800kvaДокумент9 страницCSS 1250kva & 800kvaDarshit VyasОценок пока нет

- 1e V09 MPGB 00043Документ10 страниц1e V09 MPGB 00043mohamed abourayaОценок пока нет

- LS Compensating Valve Tech NoteДокумент4 страницыLS Compensating Valve Tech NoteDeutsch themeОценок пока нет

- P&I Diagram For Butane and Propane Transfer From Ship To IPPL TankДокумент1 страницаP&I Diagram For Butane and Propane Transfer From Ship To IPPL TankPrakash JoshiОценок пока нет

- P&I Diagram For Butane and Propane Transfer From Ship To IPPL TankДокумент1 страницаP&I Diagram For Butane and Propane Transfer From Ship To IPPL TankPrakash JoshiОценок пока нет

- Infineon-Design Guide Boost Type CCM PFC ICE3PCSxx-AN-v02 00-EN PDFДокумент26 страницInfineon-Design Guide Boost Type CCM PFC ICE3PCSxx-AN-v02 00-EN PDFThai Anh NguyenОценок пока нет

- Log Book February 23Документ43 страницыLog Book February 23INDFAB PROJECTS100% (1)

- Petronas Carigali Sdn. BHD.: Objective Programme (Routine Wireline)Документ2 страницыPetronas Carigali Sdn. BHD.: Objective Programme (Routine Wireline)Rick Raynold ClaudiusОценок пока нет

- UntitledДокумент2 страницыUntitledNguyễn Duy HảiОценок пока нет

- PT. DTBAMUTIAABAI'I Price Quote for Air Compressor Spare PartsДокумент1 страницаPT. DTBAMUTIAABAI'I Price Quote for Air Compressor Spare PartsIsaalex100% (1)

- CV: Experienced Project PlannerДокумент3 страницыCV: Experienced Project PlannerIsaalexОценок пока нет

- CV SetiyoДокумент2 страницыCV SetiyoIsaalexОценок пока нет

- CV: Experienced Project PlannerДокумент3 страницыCV: Experienced Project PlannerIsaalexОценок пока нет

- It Modern App GuideДокумент38 страницIt Modern App GuideManuel ChuquimarcaОценок пока нет

- High Performance HMI for Vale Mine AutomationДокумент3 страницыHigh Performance HMI for Vale Mine AutomationIsaalexОценок пока нет

- Hydraulic Flushing ProcedureДокумент6 страницHydraulic Flushing ProcedureIsaalexОценок пока нет

- Appendix-4 Fabrication SequencesДокумент4 страницыAppendix-4 Fabrication SequencesIsaalexОценок пока нет

- It Modern App GuideДокумент38 страницIt Modern App GuideManuel ChuquimarcaОценок пока нет

- Appendix-2 Schedule Lv2Документ1 страницаAppendix-2 Schedule Lv2IsaalexОценок пока нет

- Input Output: Form 3 - Function TestДокумент52 страницыInput Output: Form 3 - Function TestIsaalexОценок пока нет

- ID-PCK-GP-IBP-2011007 Support Installation Procedure Rev.C (AFC)Документ10 страницID-PCK-GP-IBP-2011007 Support Installation Procedure Rev.C (AFC)IsaalexОценок пока нет

- Id PCK Pa Ibp 7011026 - Rev.c CoverДокумент2 страницыId PCK Pa Ibp 7011026 - Rev.c CoverIsaalexОценок пока нет

- Tray ProcedureДокумент27 страницTray ProcedureIsaalexОценок пока нет

- Performance Testing Procedure Rev D1Документ12 страницPerformance Testing Procedure Rev D1IsaalexОценок пока нет

- Temperature GaugeДокумент2 страницыTemperature GaugeIsaalexОценок пока нет

- PSDV-11803 Installation Procedure - Rev.b (Per Cms Comment)Документ3 страницыPSDV-11803 Installation Procedure - Rev.b (Per Cms Comment)IsaalexОценок пока нет

- Input Output: Form 3 - Function TestДокумент52 страницыInput Output: Form 3 - Function TestIsaalexОценок пока нет

- Input Output: Form 3 - Function TestДокумент52 страницыInput Output: Form 3 - Function TestIsaalexОценок пока нет

- Id PCK Pa Ibp 7011026 - Rev.c CoverДокумент3 страницыId PCK Pa Ibp 7011026 - Rev.c CoverIsaalexОценок пока нет

- Hydraulic Flushing ProcedureДокумент6 страницHydraulic Flushing ProcedureIsaalexОценок пока нет

- MunnarДокумент5 страницMunnarvisujinuОценок пока нет

- Section - I: Cover Page Section - II:: IndexДокумент21 страницаSection - I: Cover Page Section - II:: Indexamit rajputОценок пока нет

- EasementДокумент10 страницEasementEik Ren OngОценок пока нет

- Alcalel-Lucent WLAN OmniAcces StellarДокумент6 страницAlcalel-Lucent WLAN OmniAcces StellarJBELDОценок пока нет

- Rural Perception of SUV CarsДокумент29 страницRural Perception of SUV CarsritusinОценок пока нет

- OFW Dependent Scholarship AssessmentДокумент3 страницыOFW Dependent Scholarship AssessmentJosebeth CairoОценок пока нет

- Basic Accounting Principles and Budgeting FundamentalsДокумент24 страницыBasic Accounting Principles and Budgeting Fundamentalskebaman1986Оценок пока нет

- Foreign Direct Investment in Mongolia An Interactive Case Study (USAID, 2007)Документ266 страницForeign Direct Investment in Mongolia An Interactive Case Study (USAID, 2007)Oyuna Bat-OchirОценок пока нет

- Open Recruitment Member Kejar Mimpi Periode 2023 (Responses)Документ22 страницыOpen Recruitment Member Kejar Mimpi Periode 2023 (Responses)Sophia Dewi AzzahraОценок пока нет

- What Is Propaganda DeviceДокумент3 страницыWhat Is Propaganda DeviceGino R. Monteloyola100% (1)

- Brexit Essay - Jasraj SinghДокумент6 страницBrexit Essay - Jasraj SinghJasraj SinghОценок пока нет

- Nippon Metal Primer Red Oxide TDSДокумент2 страницыNippon Metal Primer Red Oxide TDSPraveen KumarОценок пока нет

- Recognition & Derecognition 5Документ27 страницRecognition & Derecognition 5sajedulОценок пока нет

- Human Computer InteractionДокумент12 страницHuman Computer Interactionabhi37Оценок пока нет

- SUTI Report - Metro ManilaДокумент87 страницSUTI Report - Metro ManilaIvan Harris TanyagОценок пока нет

- B JA RON GAWATДокумент17 страницB JA RON GAWATRon GawatОценок пока нет

- Pabahay Bonanza: Philippine National Bank As of September 30, 2009Документ80 страницPabahay Bonanza: Philippine National Bank As of September 30, 2009ramonlucas700Оценок пока нет

- Đề Số 1 - Đề Phát Triển Đề Minh Họa 2023Документ20 страницĐề Số 1 - Đề Phát Triển Đề Minh Họa 2023Maru KoОценок пока нет

- S-S-, AXXX XXX 008 (BIA Sept. 15, 2017)Документ7 страницS-S-, AXXX XXX 008 (BIA Sept. 15, 2017)Immigrant & Refugee Appellate Center, LLCОценок пока нет

- PartlowControllerCatalog PDFДокумент98 страницPartlowControllerCatalog PDFvinh nguyen theОценок пока нет

- Bridge Ogres Little Fishes2Документ18 страницBridge Ogres Little Fishes2api-246705433Оценок пока нет

- Ed TechДокумент19 страницEd TechAlexie AlmohallasОценок пока нет

- MU0017 Talent ManagementДокумент12 страницMU0017 Talent ManagementDr. Smita ChoudharyОценок пока нет

- Holmes 1993Документ8 страницHolmes 1993Rumaisa KrubaОценок пока нет

- 7 ways to improve energy efficiency of pumpsДокумент1 страница7 ways to improve energy efficiency of pumpsCharina Malolot VillalonОценок пока нет