Академический Документы

Профессиональный Документы

Культура Документы

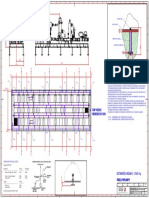

Bar Reinforcement Welded Wire Fabric: Concrete Pavement Jointed Reinforced

Загружено:

garpheetОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bar Reinforcement Welded Wire Fabric: Concrete Pavement Jointed Reinforced

Загружено:

garpheetАвторское право:

Доступные форматы

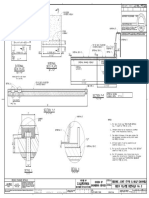

• DOWEL LENGTH CLASS 4, 5, OR 7 JOINT PLASTIC DOWEL CAP GENERAL NOTES

C

L EXPANSION JOINT C

L EXPANSION JOINT SEALING MATERIAL TO FIT DOWEL

WELDED WIRE 1. MULTIPLE PIECE TIE BARS ARE REQUIRED AT LONGITUDINAL CONSTRUCTION JOINTS.

…" …" C

L EXPANSION JOINT

60'-6" • DOWEL LENGTH FABRIC

C

L EXPANSION JOINT USE MULTIPLE PIECE TIE BAR ASSEMBLIES WITH STOP TYPE COUPLINGS AND WITH THREADS

ƒ"

6"

CLASS 4, 5, OR 7 JOINT ƒ" ON THE BARS. ENSURE THE MULTIPLE PIECE TIE BAR ASSEMBLIES DEVELOP A MINIMUM

3" 3" SEALING MATERIAL

ULTIMATE TENSILE STRENGTH EQUAL TO 1.25 TIMES THE YIELD STRENGTH OF THE

2" MIN

TRANSVERSE BARS BEING JOINED. USE DEFORMED REINFORCING BARS FOR TIE BARS.

T/2

1 ‚" 3" 3"

T/2

TIE BAR ASSEMBLIES MADE FROM STEELS OTHER THAN ASTM GRADE 60 AND WITH

D D MIN

DEFORMATIONS OTHER THAN ASTM STANDARD MAY BE USED IF IT CAN BE PROVEN TO THE

LONGITUDINAL

T

D D D D

4" FOR S=12'-2"

T

SAWED JOINT

4" FOR S=11'-8"

2"MIN - 4"MAX

ENGINEER THAT THEY ARE IN EVERY RESPECT THE EQUAL OF THE ASSEMBLIES SPECIFIED.

3" 3" 1 ‚" MIN

LABORATORY TESTING OF THE PROPOSED ASSEMBLIES, AT THE CONTRACTOR'S EXPENSE,

JOINT PLATE 2"MIN MAY BE REQUIRED.

#10 WIRES PLASTIC DOWEL CAP

JOINT PLATE 8"

S

AT 6" TO FIT DOWEL 8" USE A BITUMINOUS 2. FORM CONSTRUCTION JOINTS WITH METAL OR WOOD FORMS EQUAL IN DEPTH TO THE NOMINAL

CASING

CASING MASTIC ON THIS HALF DEPTH OF THE PAVEMENT OR BY OTHER MEANS APPROVED PRIOR TO THEIR USE.

USE A BITUMINOUS

C C SECTION A-A MASTIC ON THIS HALF SECTION A-A

3. SAW LONGITUDINAL AND TRANSVERSE JOINTS AS SOON AS SAWING CAN BE ACCOMPLISHED

BAR REINFORCED WELDED WIRE FABRIC

WITHOUT DAMAGE TO THE PAVEMENT AND BEFORE 24 HOURS AFTER PLACING THE CONCRETE,

Q

TRANSVERSE EXPANSION JOINTS THE EXACT TIME WILL BE APPROVED BY THE ENGINEER. PREFORMED JOINT WITH ASPHALT

STRIP IS NOT ACCEPTABLE.

NOTE: DOWEL BARS CONFORMING TO ASTM A615

8" FOR R=12'-10"

C

2"MIN - 4"MAX

8" FOR R=12'-4"

4. LONGITUDINAL JOINTS ARE SHOWN OFFSET FOUR INCHES FROM THE THEORETICAL LANE

A A C A A

OR A616 GRADE 60 ARE ACCEPTABLE

LINE AND MAY BE OFFSET TO EITHER SIDE IF THE WIDTH OF THE WIRE FABRIC IS

#10 WIRES PROPERLY ADJUSTED.

R

AT 12" MULTIPLE PIECE TIE

5. ONE OF THE LONGITUDINAL JOINTS OF PAVEMENT SLABS WIDER THAN TWO LANES MAY BE A

LONGITUDINAL BARS BARS AT 24" C-C

NO.4 BARS CONSTRUCTION JOINT. FOR PAVEMENT SLABS WIDER THAN 15 FT. PROVIDE A LONGITUDINAL

AT 24" C-C 33D 33D SAWED JOINT UNLESS OTHERWISE DIRECTED.

33D 33D

CLASS 4, 5,

6. FORM THE JOINT SEAL SPACE AT TRANSVERSE EXPANSION JOINTS BY USING A STRAIGHT

6"

CLASS 4, 5, OR 7 JOINT C

L LONGITUDINAL

C

L LONGITUDINAL FORM PLACED BEHIND THE LONGITUDINAL FLOAT. LOOSEN THE FORM AS SOON AS THE

OR 7 JOINT SEALING CONSTRUCTION

SEALING CONSTRUCTION JOINT CONCRETE WILL RETAIN ITS SHAPE AND EDGE WITH AN APPROVED EDGING TOOL. TOOL BOTH

MATERIAL

MATERIAL JOINT

EDGES OF LONGITUDINAL CONSTRUCTION JOINTS TO A „IN. RADIUS AT THE PAVEMENT

15'-3" 15'-0" 15'-0" 15'-3" SURFACE.

T/2

1ST PLACEMENT 2ND PLACEMENT 1ST PLACEMENT 2ND PLACEMENT

T/2

7. DO NOT DISCHARGE CONCRETE FROM THE MIXER DIRECTLY ON TOP OF OR ON THE SIDES

C

L TRANSVERSE JOINT 1„"X20" DOWELS AT 12" C-C

T

NO.4 BARS AT 12" C-C OF THE EXPANSION JOINT ASSEMBLIES.

T

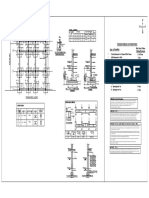

BAR REINFORCEMENT WELDED WIRE FABRIC 8. LAP TRANSVERSE EDGES OF SHEETS OF WELDED WIRE FABRIC 12 INCHES EXCEPT AT

TRANSVERSE EXPANSION JOINTS. LAP LONGITUDINAL EDGES 6 INCHES EXCEPT AT

TWO LANE PAVEMENT PLAN

LONGITUDINAL CONSTRUCTION JOINTS.

3" 3"

WIDTH - Q 3" 3"

TRANSVERSE 9. DOWEL BARS MAY BE COATED WITH STAINLESS STEEL, MONEL METAL, OR IN ACCORDANCE

BARS WELDED WIRE FABRIC WITH THE ITEM "REINFORCING STEEL" SECTION ON EPOXY COATING; WITH A WELDED

24'-0" 24'-6" 25'-0"

SECTION B-B

SECTION B-B DOWEL ASSEMBLY SUPPORT, AS APPROVED. ENSURE THE CASING CONFORMS TO THE

R 12'-4" 12'-4" 12'-10" BAR REINFORCEMENT

BAR REINFORCEMENT REQUIREMENTS OF ONE OF THE GRADES OF ASTM AI67-70 OR AI76-71 AND IS NOT LESS

THAN 0.010 INCH THICK. PROVIDE A CASING AT LEAST 8 INCHES LONG AND THAT COVERS

S 11'-8" 12'-2" 12'-2"

LONGITUDINAL CONSTRUCTION JOINTS THE MIDDLE 8 INCHES OF THE DOWEL.

C EXPANSION JOINT C

L L EXPANSION JOINT

10. SECURE DOWELS PARALLEL TO THE PAVEMENT SURFACE AND PERPENDICULAR TO THE JOINT

…" …"

60'-6"

C WITH THE AID OF APPROVED WELDED WIRE BASKET ARRANGEMENTS. ENSURE WELDED WIRE

L SAWED JOINT C SAWED JOINT

L

BASKET ARRANGEMENTS DO NOT CROSS THE EXPANSION JOINT. UNIFORMLY COAT DOWELS

6"

3" NO.4 BARS AT 12" C-C 3"

LONGITUDINAL WITH A BITUMINOUS MASTIC ON THE END WITH THE DOWEL CAP.

6"

BARS CLASS 4, 5, OR 7 JOINT

CLASS 4, 5, OR 7 JOINT SEALING MATERIAL

D D SEALING MATERIAL

11. DO NOT BEND TIE BARS AND DOWEL BARS. TO PREVENT DISPLACEMENT OF WIRE FABRIC BY

CONCRETE PLACEMENT, TIE THE FABRIC PANEL TOGETHER AND TIE THE INITIAL FABRIC

D D D D

2"MIN - 4"MAX

8" FOR Z=12'-4"

7" FOR Z=12'-2"

7" FOR Z=11'-2"

PANELS OF EACH SLAB TO THE DOWEL BASKET OR AS DIRECTED.

T/2

T/2

2" MIN

LONGITUDINAL

12. TOOL PAVEMENT EDGES TO A RADIUS OF „ IN. WITH AN APPROVED EDGING TOOL.

SAWED JOINT

T

#10 WIRES

T

AT 6"

Z

TRANSVERSE BARS 12" LAP 13. DETAILS FOR PAVEMENT WIDTH, PAVEMENT THICKNESS, AND CROWN-SLOPE ARE ELSEWHERE

SHOWN ON THE PLANS.

C C

WELDED WIRE FABRIC

14. THE CONTRACTOR HAS THE OPTION OF USING WELDED WIRE FABRIC OR BAR

SECTION C-C

SECTION C-C REINFORCEMENT. LOCATE THE LONGITUDINAL STEEL AT THE CENTER OF THE SLAB.

WELDED WIRE FABRIC TAKE NECESSARY PRECAUTIONS TO INSURE THAT THE FINAL POSITION OF STEEL IS

BAR REINFORCEMENT

WITHIN • IN. OF THE SLAB CENTER. ENSURE THE LONGITUDINAL AND TRANSVERSE STEEL

C LONGITUDINAL SAWED JOINTS SPACING DOES NOT VARY MORE THAN ONE-TWELFTH OF SPACING SHOWN.

C

6" FOR Y=12'-0"

6" FOR Y=11'-0"

8" FOR Y=11'-4"

2"MIN - 4"MAX

15. LONGITUDINAL STEEL MAY BE SPLICED WITH 33 TIMES BAR DIAMETER LAPS.

NO.4 BARS #10 WIRES

AT 24" C-C

W

AT 12" 16. FOR LANE WIDTHS NOT SHOWN OR FOR VARIABLE PANEL LENGTHS AND WIDTHS, SPACE

C

L SAWED JOINT

C

L SAWED JOINT REINFORCING STEEL AND DOWELS AS DIRECTED.

Y

A A WELDED WIRE

A A CLASS 4, 5, OR 7 JOINT

FABRIC 17. USE APPROVED BAR MAT CHAIRS. DO NOT EXCEED CHAIR SPACING OF 30 IN. C-C

SEALING MATERIAL

B (TRANSVERSE) AND 48 IN. C-C (LONGITUDINAL). GALVANIZING THE CHAIRS IS NOT

B REQUIRED.

T/2

18. OBTAIN BOARDS FOR EXPANSION JOINT FILLER FROM REDWOOD TIMBER.

T/2

19. PROVIDE AND CONSTRUCT THE JOINT PLATE AS APPROVED.

T

B 20. WHEN CURB IS PLACED SEPARATELY FROM THE CONCRETE PAVEMENT, PROVIDE THE

5" FOR X=12'-10"

B

8" FOR X=12'-4"

5" FOR X=11-10"

2"MIN - 4"MAX

REINFORCING STEEL AS SHOWN IN THE CURB DETAIL. THE CURB REINFORCING

TIE BARS STEEL MAY BE OMITTED WHEN THE CURB IS PLACED MONOLITHICALLY.

AT 24" C-C

TRANSVERSE BARS LONGITUDINAL BAR (GENERAL NOTES CONTINUED ON SHEET 2 OF 2)

X

SECTION D-D SECTION D-D

BAR REINFORCEMENT BAR REINFORCEMENT

Texas Department of Transportation

TRANSVERSE SAWED JOINTS

6"

Houston District

PROVIDE TOP & FACE OF CURB WITH

15'-3" 15'-0" 15'-0" 15'-3" ƒ" EXPANSION JOINT

FACE OF CURB

STEEL TROWEL FINISH

TO COINCIDE WITH EXPANSION JOINT JOINTED REINFORCED

C

L TRANSVERSE JOINT 6" IN PAVEMENT

EMBEDMENT

CONCRETE PAVEMENT

2"

WELDED WIRE FABRIC

1" MIN

‚"R 1"

2"R

BAR REINFORCEMENT

1„"X20" DOWELS AT 12" C-C 6" USUAL

1'-10"MIN

DETAILS

3"

(9" MAX.

AT INLETS)

THREE LANE PAVEMENT PLAN CONSTRUCTION JOINT (FOR PAVEMENT THICKNESS 10 INCHES OR LESS)

R

3" 3"

"

(PERMISSIBLE)

T-1"

3

WIDTH - W LONGITUDINAL NO.5 BARS LONGITUDINAL 6"

CURB DOWEL

TIE TO CURB DOWEL 3" (SEE DETAIL) #5 BARS TIE JRCP SHEET 1 OF 2

37'-0" 36'-0" 34-0" TO CURB DOWEL

CURB DOWEL CURB DOWEL FILE: STDB-2.dgn DN: CK: DW: CK:

(SEE DETAIL)

X 12'-4" 11'-10" NO.3 BARS AT 2'-6" C-C

12'-10"

C TxDOT MAR.2004 DIST FED REG PROJECT NO. SHEET

D = DIAMETER SECTION

Y 12'-0" 11'-4" 11'-0" 3" EDGE DISTANCE ALSO REVISIONS

R = RADIUS ELEVATION APPLIES TO TRANSVERSE HOU 6

5/05 2004 SPECS

Z 12'-2" 12'-4" 11'-2" GROOVED PLANE JOINT IN CURB

T = THICKNESS 7/10 ADDED NOTE

COUNTY CONTROL SECT JOB HIGHWAY

2/15 2014 SPECS

TYPICAL 6" CURB (DETAIL)

Вам также может понравиться

- BCM I - BUILDING COMPONENTS (Lecture 1)Документ48 страницBCM I - BUILDING COMPONENTS (Lecture 1)Divya Pardal100% (1)

- Remarks:: Drainage Standard Details SHEET-01Документ1 страницаRemarks:: Drainage Standard Details SHEET-01Engineering WavesОценок пока нет

- The Star-Spangled Banner: C Am E7 Am D7 GДокумент2 страницыThe Star-Spangled Banner: C Am E7 Am D7 GarturoОценок пока нет

- An Energy Efficient Office Building in A Tropical ClimateДокумент6 страницAn Energy Efficient Office Building in A Tropical ClimaterjchpОценок пока нет

- Design of Pile FoundationДокумент12 страницDesign of Pile FoundationOrlando Carlos Ricaldi VictorioОценок пока нет

- Roof CoveringsДокумент25 страницRoof CoveringsBhanu Pratap SinghОценок пока нет

- Gulf Precast BrochureДокумент13 страницGulf Precast BrochureMohammad Abu-RadiОценок пока нет

- Schedule of Member Splice Connection Notes:: F H G E D C B AДокумент1 страницаSchedule of Member Splice Connection Notes:: F H G E D C B ARajveer SinghОценок пока нет

- Design of Reinforced Concrete Structures IДокумент5 страницDesign of Reinforced Concrete Structures IWissam NadirОценок пока нет

- Department of Defence Handbook-Mooring DesignДокумент264 страницыDepartment of Defence Handbook-Mooring DesigngarpheetОценок пока нет

- MTD Statement - GT Concrete Mattresses (302 401-Ms-0912)Документ2 страницыMTD Statement - GT Concrete Mattresses (302 401-Ms-0912)garpheetОценок пока нет

- Drawings 1 PDFДокумент20 страницDrawings 1 PDFjoegieОценок пока нет

- MTD Statement - GT Concrete Mattresses (302 401-Ms-0912)Документ2 страницыMTD Statement - GT Concrete Mattresses (302 401-Ms-0912)garpheetОценок пока нет

- Bus ShelterДокумент1 страницаBus ShelterCHVN NH173Оценок пока нет

- Waterfront Inspection Guidelines ManualДокумент126 страницWaterfront Inspection Guidelines Manualgarpheet100% (2)

- Methods For Effective Room Air DistributionДокумент56 страницMethods For Effective Room Air DistributiontfemilianОценок пока нет

- Ship Particular Ratu Zulaikha Update 28 April 2015Документ2 страницыShip Particular Ratu Zulaikha Update 28 April 2015garpheet0% (1)

- Design of Pile Caps FinalДокумент50 страницDesign of Pile Caps FinalImam Shakil100% (2)

- Ø Holes: GirderДокумент1 страницаØ Holes: GirderErika Faye GutierrezОценок пока нет

- Dma 28 MampangДокумент1 страницаDma 28 MampangIronhide EraacОценок пока нет

- Alternative 3 Bolted Connection: CaliforniaДокумент1 страницаAlternative 3 Bolted Connection: CaliforniaProfessor PuppiesОценок пока нет

- 010 Quarantine CabinДокумент1 страница010 Quarantine CabinYuzairry AmmryОценок пока нет

- Mott Macdonald: Tee To CancelДокумент1 страницаMott Macdonald: Tee To Cancelramanna kodandaОценок пока нет

- 2Nd Storey Plan - Lightning Protection: Construction DrawingДокумент1 страница2Nd Storey Plan - Lightning Protection: Construction DrawingrajavelОценок пока нет

- DHQC Cecb MB Ti Ar DW ML 02 80541Документ1 страницаDHQC Cecb MB Ti Ar DW ML 02 80541Kumudu PereraОценок пока нет

- Mulimbayan Residence - PL (For Construction)Документ7 страницMulimbayan Residence - PL (For Construction)Jhanchris CortezОценок пока нет

- Cabrillas STRUCДокумент1 страницаCabrillas STRUCJoeyBelle Almenanza RiveraОценок пока нет

- Fence Footing-Layout1 PDFДокумент1 страницаFence Footing-Layout1 PDFPraYush RajbhandariОценок пока нет

- A.Typical Roadway Section: Pavement Design ParametersДокумент1 страницаA.Typical Roadway Section: Pavement Design ParametersrickОценок пока нет

- Top View/ Vedere de Sus: Estimated Weight: 17000 KGДокумент1 страницаTop View/ Vedere de Sus: Estimated Weight: 17000 KGLavinia DamianОценок пока нет

- 560 000 ST S 004 - 0 - EscalerVerticalДокумент1 страница560 000 ST S 004 - 0 - EscalerVerticalRenzo Amiquero CrispinОценок пока нет

- Notes:: Water Line Gate Valve DetailДокумент1 страницаNotes:: Water Line Gate Valve DetailDJОценок пока нет

- 1.09 Chorus O Thou That TellestДокумент3 страницы1.09 Chorus O Thou That Tellest聪明聪明Оценок пока нет

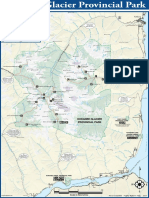

- Legend: Kokanee Glacier Provincial ParkДокумент1 страницаLegend: Kokanee Glacier Provincial ParkTganttОценок пока нет

- Detail of RCPC Ends: Embankment EmbankmentДокумент1 страницаDetail of RCPC Ends: Embankment EmbankmentJef Atillo RepuldaОценок пока нет

- Wet H2S Service Amine Service: 3D ViewДокумент1 страницаWet H2S Service Amine Service: 3D ViewMohamed SamirОценок пока нет

- Water Distribution Layout Sanitary Layout: Floor Drain Detail Detail of Water MeterДокумент1 страницаWater Distribution Layout Sanitary Layout: Floor Drain Detail Detail of Water MeterAllen Robert WaganОценок пока нет

- KAAR COW PW IC NTU FZS DWG STR 24633 Rev.01 PDFДокумент1 страницаKAAR COW PW IC NTU FZS DWG STR 24633 Rev.01 PDFSatyanarayana MukkuОценок пока нет

- r2 Revised Ceiling Layout 25.09.2023Документ1 страницаr2 Revised Ceiling Layout 25.09.2023blackshark0809Оценок пока нет

- The Santorini 424337Документ24 страницыThe Santorini 424337Ferdous SamirОценок пока нет

- Fadil 2013 Fix-A3 (Plot)Документ1 страницаFadil 2013 Fix-A3 (Plot)Dimas WiryaОценок пока нет

- MNB Drawing-595+717 (4x5.0mx3.58m)Документ3 страницыMNB Drawing-595+717 (4x5.0mx3.58m)Aditya JoshiОценок пока нет

- 033 Montenegro Toilets Elevations PDFДокумент1 страница033 Montenegro Toilets Elevations PDFOcokoljic SrdjanОценок пока нет

- Elevation of Tower - 1 (Facing West) Part 1 of 3: Section A-AДокумент1 страницаElevation of Tower - 1 (Facing West) Part 1 of 3: Section A-AHozien OnofreОценок пока нет

- Lokotrack ST4.8 GA Drawing 2022 R013Документ3 страницыLokotrack ST4.8 GA Drawing 2022 R013Guilherme AssisОценок пока нет

- 2 - Dipilomat Villa Hawassa-ModelДокумент1 страница2 - Dipilomat Villa Hawassa-ModelJaspergroup 15Оценок пока нет

- Jackson Street GateДокумент1 страницаJackson Street GatePaolo MadambaОценок пока нет

- Plant AC SLD - TN Sunrise - R2Документ1 страницаPlant AC SLD - TN Sunrise - R2newattelectricОценок пока нет

- LooooooooooooooouiДокумент1 страницаLooooooooooooooouirim deОценок пока нет

- 1St Sty Plan - Fire Services: Construction DrawingДокумент1 страница1St Sty Plan - Fire Services: Construction DrawingrajavelОценок пока нет

- For StairДокумент1 страницаFor StairManish AcharyaОценок пока нет

- External Deck Plate Internal: Section P-PДокумент1 страницаExternal Deck Plate Internal: Section P-PProfessor PuppiesОценок пока нет

- SD-55340-P-L13-201-A - Public Health Services, Tower C, Level 13 - Water Services Layout-R01Документ1 страницаSD-55340-P-L13-201-A - Public Health Services, Tower C, Level 13 - Water Services Layout-R01Aamer Abdul MajeedОценок пока нет

- SD-55340-P-L13-201-A - Public Health Services, Tower C, Level 13 - Water Services Layout-R01Документ1 страницаSD-55340-P-L13-201-A - Public Health Services, Tower C, Level 13 - Water Services Layout-R01Aamer Abdul MajeedОценок пока нет

- CL-MB (3) - 260-CV-DWG-0010 - 01 DWG For Guard House Floor Plan & Section - ApprovedДокумент1 страницаCL-MB (3) - 260-CV-DWG-0010 - 01 DWG For Guard House Floor Plan & Section - ApprovedSetyaji Nur HidayatОценок пока нет

- A B C D E F G H: Ga of SwitchyardДокумент1 страницаA B C D E F G H: Ga of SwitchyardDarshit VyasОценок пока нет

- Lighting and Small Power Cable Routing Layout Drawing-Ss02Документ1 страницаLighting and Small Power Cable Routing Layout Drawing-Ss02RaeesОценок пока нет

- Project Name: 18RRETEPD12430 and Oil Movement Area Units at Rre Installation of Closed Process CondensateДокумент3 страницыProject Name: 18RRETEPD12430 and Oil Movement Area Units at Rre Installation of Closed Process CondensateYogesh MittalОценок пока нет

- Mark Up L2 Slab (Zone 2)Документ7 страницMark Up L2 Slab (Zone 2)Emon SahОценок пока нет

- Nas Equipment List 1 - 1Документ1 страницаNas Equipment List 1 - 1Hatem Al-KhleweeОценок пока нет

- Perimetrico: Rectificacion de AreaДокумент1 страницаPerimetrico: Rectificacion de AreaLeyli Acevedo ReyesОценок пока нет

- LayoutДокумент1 страницаLayoutBima Dwi PutraОценок пока нет

- 2Nd Sty Plan - Fire Services: Construction DrawingДокумент1 страница2Nd Sty Plan - Fire Services: Construction DrawingrajavelОценок пока нет

- 02 - AA - HH 28 DE JULIO-ModelДокумент1 страница02 - AA - HH 28 DE JULIO-ModelCarlos Augusto Navas ArmasОценок пока нет

- A B C D: Striking Period of FormworkДокумент1 страницаA B C D: Striking Period of FormworkPhotoshop tutorialsОценок пока нет

- Notes:: Highways and Airports B.SC Graduation Project 2016Документ1 страницаNotes:: Highways and Airports B.SC Graduation Project 2016Eslam BelalОценок пока нет

- Floor Plan Layout: HallwayДокумент1 страницаFloor Plan Layout: HallwayClynne Jay DespiОценок пока нет

- X0231 PDW Ecb DG 20004 AaДокумент1 страницаX0231 PDW Ecb DG 20004 AajianranrenОценок пока нет

- F122 76-10526-Detail Design: Fire Protection Services - Ground Level PlanДокумент1 страницаF122 76-10526-Detail Design: Fire Protection Services - Ground Level PlanMazen IsmailОценок пока нет

- C.H. - 0+465.5 Section No5Документ1 страницаC.H. - 0+465.5 Section No5Fran LuqueОценок пока нет

- 110kV Son Dong - DC PanelДокумент54 страницы110kV Son Dong - DC PanelPhan Văn TúОценок пока нет

- Base Hinged Masts Technical Data PDFДокумент1 страницаBase Hinged Masts Technical Data PDFgarpheetОценок пока нет

- W1 - EN - Anchor Selector Chart 2019 05 24Документ1 страницаW1 - EN - Anchor Selector Chart 2019 05 24garpheetОценок пока нет

- Ship Particular-OB Oceanbay 23315 Update 18 Oktober 2016Документ2 страницыShip Particular-OB Oceanbay 23315 Update 18 Oktober 2016garpheetОценок пока нет

- Huesker Incomat Filterpoint Mattress Data Aug. 2010Документ2 страницыHuesker Incomat Filterpoint Mattress Data Aug. 2010garpheetОценок пока нет

- 05 Grating Info Interstate Grating Heavy DutyДокумент2 страницы05 Grating Info Interstate Grating Heavy DutygarpheetОценок пока нет

- STDB 2 BДокумент1 страницаSTDB 2 BgarpheetОценок пока нет

- ACEFormer™ Product Brochure PDFДокумент2 страницыACEFormer™ Product Brochure PDFgarpheetОценок пока нет

- Cim 16500 21aДокумент320 страницCim 16500 21agarpheetОценок пока нет

- Timber Structure Case StudiesДокумент15 страницTimber Structure Case StudiesarmyОценок пока нет

- Earthquake-Resistant Design of StructuresДокумент36 страницEarthquake-Resistant Design of Structures연민민Оценок пока нет

- Esperanza Health Center Plumbing FinalДокумент8 страницEsperanza Health Center Plumbing FinalArnold Donadillo0% (1)

- TempДокумент1 страницаTempFBFDNОценок пока нет

- Properties of Multi-Strength Grade EPS Concrete Containing Silica Fume and RiceДокумент9 страницProperties of Multi-Strength Grade EPS Concrete Containing Silica Fume and RiceManuel GutarraОценок пока нет

- ASHRAE 188 Standard The Impact On Domestic Hot Water System DesignДокумент24 страницыASHRAE 188 Standard The Impact On Domestic Hot Water System DesignSvetla NikolovaОценок пока нет

- 9 Types of Wood Framing To KnowДокумент19 страниц9 Types of Wood Framing To KnowMarion LauritoОценок пока нет

- 2810 29doorawindow 28w14 29Документ49 страниц2810 29doorawindow 28w14 29Nur MaishaОценок пока нет

- 71TMSS03R1Документ33 страницы71TMSS03R1Nabeel ZahidОценок пока нет

- 48h, t-5pd, 48TJ PDFДокумент300 страниц48h, t-5pd, 48TJ PDFlucasОценок пока нет

- CIVL2110 Tutorial 8 SolutionsДокумент5 страницCIVL2110 Tutorial 8 SolutionsShinobu KannaОценок пока нет

- Mass Housing Using GFRG Panels A Sustainable RapidДокумент7 страницMass Housing Using GFRG Panels A Sustainable RapidGanesh SuryawashiОценок пока нет

- DOE22Vol1 Basics PDFДокумент234 страницыDOE22Vol1 Basics PDFthermosol5416Оценок пока нет

- b+g+7 Palstine DesignДокумент82 страницыb+g+7 Palstine DesigngemedaОценок пока нет

- DEWA - List of Civil Standard DrawingsДокумент14 страницDEWA - List of Civil Standard Drawingsraviaggrawalla8727Оценок пока нет

- CRSI Manual To Design RC Diaphragms - Part9Документ4 страницыCRSI Manual To Design RC Diaphragms - Part9Adam Michael GreenОценок пока нет

- Technical Specification: A. Demolition, Clearing and Preparation of The SiteДокумент4 страницыTechnical Specification: A. Demolition, Clearing and Preparation of The SiteZen Marl Gaor0% (1)

- Basement InteriorДокумент1 страницаBasement Interiorshashank sharmaОценок пока нет

- Procedures For Hvac System Design and InstallationДокумент5 страницProcedures For Hvac System Design and Installationrawadsultan100% (1)

- Bce323l (1617) Ass2 VenusДокумент2 страницыBce323l (1617) Ass2 VenusDIOSAN DAVE VENUSОценок пока нет

- Detail at A: Steel Open Web Portal FrameДокумент1 страницаDetail at A: Steel Open Web Portal Frame32Siddhi ThakerОценок пока нет