Академический Документы

Профессиональный Документы

Культура Документы

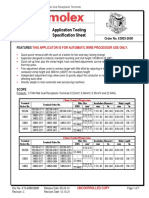

Hand Crimp Tool Specification Sheet: Order No. 63811-5200

Загружено:

AbhinavОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hand Crimp Tool Specification Sheet: Order No. 63811-5200

Загружено:

AbhinavАвторское право:

Доступные форматы

Hand Crimp Tool for SPOX™ Terminals

HAND CRIMP TOOL

SPECIFICATION SHEET

Order No. 63811-5200

TYPE 2C

FEATURES

A full cycle ratcheting hand tool ensures complete crimps

Ergonomic soft grip handles for comfortable crimping

A precision user-friendly terminal locator wire stop holds terminals in the proper crimping position

This tool is WHMA-IPCA620 Class 2 and RoHS compliant

SCOPE

SPOX™, 2.50mm (.098") Pitch Crimp Terminal, 22 - 28 AWG.

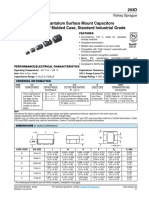

Wire Size ✴ Insulation Diameter Strip Length

Terminal Series No. Terminal Order No.

AWG mm² mm In. mm In.

08-70-0057 22-28 0.35-0.08 1.15-1.90 .045-.075 3.30-3.80 .130-.150

5103

08-70-0059 22-28 0.35-0.08 1.15-1.90 .045-.075 3.30-3.80 .130-.150

08-70-1040 22-28 0.35-0.08 1.15-1.90 .045-.075 3.30-3.80 .130-.150

5263 08-70-1046 22-28 0.35-0.08 1.15-1.90 .045-.075 3.30-3.80 .130-.150

39-00-0152 22-28 0.35-0.08 1.15-1.90 .045-.075 3.30-3.80 .130-.150

45627 45627-0002 22-24 0.35-0.20 1.15-1.90 .045-.075 3.30-3.80 .130-.150

✴ See Conditions on page 2.

DEFINITION OF TERMS

BEND UP

BRUSH CONDUCTOR

BELL MOUTH

CRIMP

INSULATION

ROLLING

CRIMP

TWISTING

STRIP

BEND

LENGTH

DOWN

CRIMP HEIGHT

The above terminal drawing is a generic terminal representation. It is not an image of a terminal listed in the scope.

Doc No. 63811-5200 Release Date: 04-03-06 UNCONTROLLED COPY Page 1 of 6

Revision: A Revision Date: 04-03-06

Hand Crimp Tool for SPOX™ Terminals

CONDITIONS:

After crimping, the conductor profiles should measure the following (see notes on page 5).

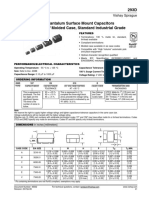

Hand Conductor Crimp Insulation Crimp

Terminal Wire Size Pull Force Min. ✴ Profile

Tool Height (Ref.) Width (Ref.) Height (Ref.) Width (Ref.)

Series No 2

Locator AWG mm mm In. mm In. mm In. mm In. N Lb. A B C

5103 1 22 0.35 0.73-0.80 .029-.031 1.40 .055 1.68 .066 1.90 .075 44.48 10.0 X

5103 1 24 0.20 0.67-0.74 .026-.029 1.40 .055 1.57 .062 1.90 .075 28.91 6.5 X

5103 1 26 0.12 0.63-0.69 .025-.027 1.40 .055 1.42 .056 1.50 .059 17.79 4.0 X

5103 1 28 0.08 0.61-0.67 .024-.026 1.40 .055 1.42 .056 1.50 .059 11.12 2.5 X

5263 1 22 0.35 0.73-0.80 .029-.031 1.40 .055 1.68 .066 1.90 .075 44.48 10.0 X

5263 1 24 0.20 0.67-0.74 .026-.029 1.40 .055 1.57 .062 1.90 .075 28.91 6.5 X

5263 1 26 0.12 0.63-0.69 .025-.027 1.40 .055 1.42 .056 1.50 .059 17.79 4.0 X

5263 1 28 0.08 0.61-0.67 .024-.026 1.40 .055 1.42 .056 1.50 .059 11.12 2.5 X

45627 2 22 0.35 0.73-0.80 .029-.031 1.40 .055 1.68 .066 1.90 .075 44.48 10.0 X

45627 2 24 0.20 0.67-0.74 .026-.029 1.40 .055 1.57 .062 1.90 .075 28.91 6.5 X

✴ To Achieve IPC-A-620 Class 2 crimps. The following over-all wire insulation diameter ranges are recommended:

1. Profile A: 1.20-1.90mm (.047-.075 inch)

2. Profile B: 1.20-1.55mm (.047-.061 inch)

3. Profile C: 1.15-1.30mm (.045-.051 inch)

OPERATION

CAUTION: Install only Molex terminals listed above with this tool. Do not crimp hardened objects as damage can occur to

the tool or die.

Open the tool by squeezing the handles together, at the end of the closing stroke, the ratchet mechanism will release the handles, and

the hand tool will spring open.

Crimping Terminals

1. Select the desired terminal listed in the preceding charts. Make sure that the proper locator is mounted on the tool.

2. Swing the terminal locator away from the crimp tool shown in Figure 2. Some terminals JAWS OPEN

with large insulation grips may interfere with the crimp tooling when swinging the

locator into position. The terminal must then be loaded into the locator in the LOCATOR

closed/crimp position.

3. When using the locator, press down on the wire stop on the locator as shown in Figure

2. Insert the proper terminal into the proper nest opening. Make sure when choosing

the nest opening, it will correspond with the A, B, or C profile on the hand tool.

4. Return the locator to its original position.

5. Insert the proper wire over the terminal. Some large O.D. wires may need to be placed

into the terminal before closing the tool. Gently touch the wire stop with the end of the

wire. See Figure 3. Figure 1

6. Compress the terminal by squeezing the tool handles until the ratchet mechanism cycle

has been completed. Release handles to open the jaws.

Note: The tamper proof ratchet action will not release the tool until it has been fully closed.

Doc No. 63811-5200 Release Date: 04-03-06 UNCONTROLLED COPY Page 2 of 6

Revision: A Revision Date: 04-03-06

Hand Crimp Tool for SPOX™ Terminals

TERMINAL

SWING OPEN

LOCATOR

PUSH HERE TO LOCATOR TERMINAL IN PLACE WIRE STOP

OPEN WIRE STOP Figure 2

WIRE

7. Remove the crimped terminal from the terminal locator by pressing down on

the wire stop and gently pulling on the wire. The terminal locator can be in

either position.

8. Visually inspect the crimped terminal for proper crimp location.

LOCATOR TERMINAL

Note: IN PLACE

A crimp height chart is provided with this manual as Reference Only. Due to the

wide range of wires, strands, insulation diameters, and durometers, actual crimp

height measurements may very slightly. An occasional, destructive, pull force test

should be preformed to check hand tool crimp. Pull Force value Must exceed the WIRE STOP

Minimum pull force specifications listed on page 2.

WIRE AGAINST Figure 3

STOP

LIFT UP LOCATOR

Locator Change Over and Replacement

Multiple styles of locators maybe provided with the crimp hand tool. They

are different colors for easy identification. See the parts list on the last

JAWS OPEN page of the document. Make sure the desired style of locator is installed

for the proper terminal and wire. Follow the steps below to change the

PRESS DOWN ON

locators.

BRASS PIVOT SHAFT

1. Open the crimp hand tool.

2. Swing the existing locator open and away from the hand tool.

SWING

3. Firmly press down on the brass pivot shaft with your thumb, while

LOCATOR pulling the locator up. Slip the locator off the top of the brass

OPEN pivot shaft. See Figure 4.

4. Replace it with the desired locator by putting over the brass pivot

Figure 4

shaft and snapping it into place.

Doc No. 63811-5200 Release Date: 04-03-06 UNCONTROLLED COPY Page 3 of 6

Revision: A Revision Date: 04-03-06

Hand Crimp Tool for SPOX™ Terminals

Maintenance

It is recommended that each operator of the tool be made aware of, and responsible for, the following maintenance steps:

1. Remove dust, moisture, and other contaminants with a clean brush, or

soft, lint free cloth. LUBRICATION POINTS

2. Do not use any abrasive materials that could damage the tool. (BOTH SIDES) LIGHT OIL

3. Make certain all pins; pivot points and bearing surfaces are protected (EVERY 3 MONTHS OR

with a thin coat of high quality machine oil. Do not oil excessively. 5,000 CRIMPS)

This tool was engineered for durability but like any fine piece of

equipment it needs cleaning and lubrication for a maximum service life

of trouble free crimping. Light oil such as 30 weight automotive oil

used at the oil points shown in Figure 6, every 5,000 crimps or 3

months, will significantly enhance the tool life.

4. Wipe excess oil from hand tool, particularly from crimping area. Oil

transferred from the crimping area onto certain terminations may

affect the electrical characteristics of an application. Figure 5

5. When tool is not in use, keep the handles closed to prevent objects

from becoming lodged in the crimping dies, and store the tool in a clean, dry area.

Miscrimps or Jams

Should this tool ever become stuck or jammed in a partially closed position, Do Not force the handles open or closed. The tool will

open easily by pressing the ratchet release lever. See Figure 6.

How To Adjust Tool Preload (See Figure 6) PRELOAD

CHECK POINT

This hand tool is factory preset to 25-45 LBS. preload. It 25.4MM

may be necessary over the life of the tool to adjust tool

handle preload force. Listed below are the steps required to SETTING WHEEL

adjust the crimping force of the hand tool to obtain proper ECCENTRIC AXLE

crimp conditions:

RATCHET

1. Remove or fold back the handle grip from the handle to HANDLE RELEASE LEVER

expose the eccentric axle and setting wheel. GRIP

2. Remove the locking screw with a 2mm hex wrench. The REMOVED

wrench set (63810-0101), is not supplied. It is sold WRENCH SET

Figure 6

separately from the hand tool. (SOLD LOCKING HANDLE

3. Turn the eccentric axle and setting wheel with the SEPERATELY) SCREW GRIP

wrench or pliers Counter-clockwise (CCW) will increase

handle force.

4. Replace the locking screw, aligning the nearest notch in the setting wheel to locking screw.

5. Replace the handle grip.

6. Check the crimp specifications or conduct a pull test after tool handle preload force is adjusted.

Doc No. 63811-5200 Release Date: 04-03-06 UNCONTROLLED COPY Page 4 of 6

Revision: A Revision Date: 04-03-06

Hand Crimp Tool for SPOX™ Terminals

Warranty

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality materials. All vital components are long

life tested. All tools are warranted to be free of manufacturing defects for a period of 30 days. Should such a defect occur, we will

repair or exchange the tool free of charge. This repair or exchange will not be applicable to altered, misused, or damaged tools. This

tool is designed for hand use only. Any clamping, fixturing, or use of handle extensions voids this warranty.

CAUTION: Molex crimp specifications are valid only when used with Molex terminals and tooling.

CAUTIONS

1. Manually powered hand tools are intended for low volume or field repair. This tool is NOT intended for production use. Repetitive

use of this tool should be avoided.

2. Insulated rubber handles are not protection against electrical shock.

3. Wear eye protection at all times.

4. Use only the Molex terminals specified for crimping with this tool.

Certification

Molex does not certify or re-certify commercial grade hand tools but rather supplies the following guidelines for customers to re-certify

hand tools.

% This tool is qualified to pull force only. To re-certify, crimp a terminal to a wire, which has been stripped 12.7mm (1/2”) long, so

there is no crimping of the insulation. Pull the terminal and wire at a rate no faster than 25mm (1.00”) per minute. See the

Molex web site for the Quality Crimp Handbook for more information on pull testing.

% If the tool does not meet minimum pull force values, handle preload should be increased and the pull test rerun, (See How To

Adjust Preload).

% When the hand tool is no longer capable of achieving minimum pull force, it should be taken out of service and replaced.

Doc No. 63811-5200 Release Date: 04-03-06 UNCONTROLLED COPY Page 5 of 6

Revision: A Revision Date: 04-03-06

Hand Crimp Tool for SPOX™ Terminals

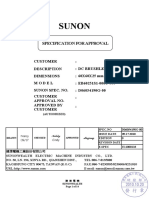

PARTS LIST

Item Number Order Number Description Quantity

1 63810-0101 Wrench Set (Not included) 0

2 63810-0102 Locator Base Assembly 1

3 63810-0103 Repair Kit (Not included) 0

4 63811-5275 Locator #1-Black 1

5 63811-5276 Locator #2-Gray 1

5

1

3

4

M4 X 5LG

RATCHET

BHCS

RELEASE LEVER

2

3

Figure 7

Molex Application Tooling Group

2200 Wellington Court

Lisle, IL 60532

Tel: 630-969-4550

Fax: 630-505-0049

Visit our Web site at http://www.molex.com

Doc No. 63811-5200 Release Date: 04-03-06 UNCONTROLLED COPY Page 6 of 6

Revision: A Revision Date: 04-03-06

Вам также может понравиться

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- 02-15 QCS 2014Документ17 страниц02-15 QCS 2014Raja Ahmed HassanОценок пока нет

- Quality Crimp HandbookДокумент24 страницыQuality Crimp HandbookFlavia DogojieОценок пока нет

- Manual Honda CivicДокумент469 страницManual Honda CivicshikinОценок пока нет

- 05 - SRX NatДокумент44 страницы05 - SRX NatLuc TranОценок пока нет

- HendrixACS - 2. Application & Design PDFДокумент40 страницHendrixACS - 2. Application & Design PDFJaime Orlando SantamariaОценок пока нет

- A Job InterviewДокумент8 страницA Job Interviewa.rodriguezmarcoОценок пока нет

- Parts Price ListДокумент5 325 страницParts Price ListAlva100% (1)

- d2l enДокумент982 страницыd2l enAbhinavОценок пока нет

- Trigger: Business Process Procedure OverviewДокумент11 страницTrigger: Business Process Procedure Overviewcalalitbajaj100% (1)

- 5556 Series Approval SpecificationДокумент8 страниц5556 Series Approval SpecificationEnzo AscañoОценок пока нет

- Fineadjust Applicator Specification Sheet Order No. 63900-0100Документ5 страницFineadjust Applicator Specification Sheet Order No. 63900-0100Amine MaaouiОценок пока нет

- Crimp Tool For King InstallsДокумент6 страницCrimp Tool For King InstallssafariОценок пока нет

- Ats 639023900 001Документ7 страницAts 639023900 001NombreuniversalОценок пока нет

- Application Tooling Specification Sheet: Fineadjust Applicator Order No. 63903-2600 FeaturesДокумент7 страницApplication Tooling Specification Sheet: Fineadjust Applicator Order No. 63903-2600 FeaturesAmine MaaouiОценок пока нет

- Molex Maquina Terminales 2002181900-000Документ8 страницMolex Maquina Terminales 2002181900-000FransoloОценок пока нет

- Features: Hand Crimp Tool Specification Sheet Order No. 63819-1300Документ9 страницFeatures: Hand Crimp Tool Specification Sheet Order No. 63819-1300Jose Antonio Huitron NuñezОценок пока нет

- App 2037023000Документ6 страницApp 2037023000danielОценок пока нет

- En Pulsor170assemblyДокумент2 страницыEn Pulsor170assemblysoorajssОценок пока нет

- Stands C ManualДокумент8 страницStands C ManualJURAMA33Оценок пока нет

- Warning: Installation Instructions - 14 Gauge C-Track SystemДокумент4 страницыWarning: Installation Instructions - 14 Gauge C-Track SystemjorafestОценок пока нет

- Manual Da Máquina Strecker Se1Документ13 страницManual Da Máquina Strecker Se1Lucas ChavesОценок пока нет

- Vishay 293D107X9016D2TE3 DatasheetДокумент9 страницVishay 293D107X9016D2TE3 DatasheetAlejandro ChavarríaОценок пока нет

- MAGPOWR Tension Sensors Manual 850A260Документ8 страницMAGPOWR Tension Sensors Manual 850A260Jose CeballosОценок пока нет

- Manual Isolation Ring 81 AshcroftДокумент12 страницManual Isolation Ring 81 AshcroftToño OrnelasОценок пока нет

- Vishay 293D475X9025C2TE3 DatasheetДокумент9 страницVishay 293D475X9025C2TE3 DatasheetMiguel VОценок пока нет

- Sunon: Specification For ApprovalДокумент14 страницSunon: Specification For ApprovalVictor Mihai Oglinda ElivicОценок пока нет

- PowerCutter Assembly and Arming ProceduresДокумент7 страницPowerCutter Assembly and Arming ProceduresmortizОценок пока нет

- 7" 17.0 35.0# STWB, Bridge Plug, Wireline Set, Cast Iron, Drillable, 300 Deg FДокумент3 страницы7" 17.0 35.0# STWB, Bridge Plug, Wireline Set, Cast Iron, Drillable, 300 Deg Fdiah andrianaОценок пока нет

- AppendicesДокумент69 страницAppendicesIvan CanoОценок пока нет

- Appendices V2Документ76 страницAppendices V2Nikola AngjelkovskiОценок пока нет

- Operating Instructions: Coring Stripping ToolДокумент2 страницыOperating Instructions: Coring Stripping ToolCarlos CastilloОценок пока нет

- Swosc-V Swosc-V: Oil Tempered Sicr-Alloyed Valve Spring Wire Only Manufactured in ChinaДокумент5 страницSwosc-V Swosc-V: Oil Tempered Sicr-Alloyed Valve Spring Wire Only Manufactured in ChinaAsad EjazОценок пока нет

- 6000-700E Installation Operation Maintenance InstructionsДокумент8 страниц6000-700E Installation Operation Maintenance InstructionsliengsamsonОценок пока нет

- SUNON MF40201V1-1000U-G99 pg8Документ15 страницSUNON MF40201V1-1000U-G99 pg8dkelicОценок пока нет

- Manual 80 81 Isolation RingsДокумент10 страницManual 80 81 Isolation RingsFelix UscangaОценок пока нет

- 2643 SBC782-ENG April20Документ8 страниц2643 SBC782-ENG April20Radhakrishnan PaulОценок пока нет

- Assembly and Torque Procedures For V-Band CouplingsДокумент3 страницыAssembly and Torque Procedures For V-Band CouplingsFranco BasualdoОценок пока нет

- Pinnacle Alloys E7018 E7018 1Документ2 страницыPinnacle Alloys E7018 E7018 1BerniIrleОценок пока нет

- KDF71Документ6 страницKDF71ADAОценок пока нет

- Fineadjust Applicator Applicator Tooling Specification Order No. 63901-7400Документ5 страницFineadjust Applicator Applicator Tooling Specification Order No. 63901-7400Ernesto VelásquezОценок пока нет

- Operating Manual: Models C200 & C300 Rotary Head Wire Strippers and TwistersДокумент8 страницOperating Manual: Models C200 & C300 Rotary Head Wire Strippers and TwisterssnsidhpuriОценок пока нет

- M22520 2 01 HarwinДокумент5 страницM22520 2 01 Harwin이용일Оценок пока нет

- Order Number 215786-0500: Application Tooling SpecificationДокумент7 страницOrder Number 215786-0500: Application Tooling SpecificationAmine MaaouiОценок пока нет

- Cylinder Name Lift Cylinder Bucket Cylinder: Tube FosДокумент11 страницCylinder Name Lift Cylinder Bucket Cylinder: Tube FosSandipTakalikarОценок пока нет

- 15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFДокумент2 страницы15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFLuis MartinezОценок пока нет

- Sy LSZH Control Flexible CableДокумент3 страницыSy LSZH Control Flexible Cableandy175Оценок пока нет

- AD Drilling Manual 600 Series 2018pangeaДокумент20 страницAD Drilling Manual 600 Series 2018pangearoberto funezОценок пока нет

- (D04111400G 00) 1Документ14 страниц(D04111400G 00) 1Ronald Javier CuellarОценок пока нет

- Installation Acoplamiento Omega Rexnord Tipo E & ES Size 2M-140M - Eng.Документ4 страницыInstallation Acoplamiento Omega Rexnord Tipo E & ES Size 2M-140M - Eng.oscarОценок пока нет

- Bench Top Tube Bender: User's ManualДокумент14 страницBench Top Tube Bender: User's ManualOmar KhaledОценок пока нет

- Temperature Sensor TS-FM01-K Rev1 03.31.2017Документ2 страницыTemperature Sensor TS-FM01-K Rev1 03.31.2017spazzastura showОценок пока нет

- 593D Solid Tantalum Chip Capacitors T Commercial, Surface Mount For Switch Mode Power Supplies and ConvertersДокумент6 страниц593D Solid Tantalum Chip Capacitors T Commercial, Surface Mount For Switch Mode Power Supplies and ConvertersStelvio QuizolaОценок пока нет

- Sony Bdp-S490service ManualДокумент110 страницSony Bdp-S490service ManualInnocent Mutasa0% (1)

- AR SeriesДокумент8 страницAR SeriesphamОценок пока нет

- WW25W, WW20W, WW10W, WW12W, WW08W, WW06W 1%, 5%Документ8 страницWW25W, WW20W, WW10W, WW12W, WW08W, WW06W 1%, 5%Fazli WadoodОценок пока нет

- HVT Series Terminations 15-35kV Class High Voltage Termination For LC Shield CableДокумент6 страницHVT Series Terminations 15-35kV Class High Voltage Termination For LC Shield Cable20353124Оценок пока нет

- LS2SWUДокумент1 страницаLS2SWUManuel Stewar Tacuari ZeballosОценок пока нет

- SM 133Документ8 страницSM 133gabriel90ccОценок пока нет

- Cable Gland Types E1W, E2W, E1X, E2X, E1U & E2UДокумент2 страницыCable Gland Types E1W, E2W, E1X, E2X, E1U & E2UWidhi ImranovichОценок пока нет

- 13 Type C 2000 Control Standard I10Документ48 страниц13 Type C 2000 Control Standard I10nitsfre3Оценок пока нет

- Uniflow Copper Tubes TDSДокумент7 страницUniflow Copper Tubes TDSFilorОценок пока нет

- 31a10 PSV 001Документ3 страницы31a10 PSV 001JITHIN VIJAYANОценок пока нет

- TT-F60 / TT-F65: Vegetable Cutting MachineДокумент11 страницTT-F60 / TT-F65: Vegetable Cutting Machinenhan samОценок пока нет

- Installation Manual Global 4 - Telescopic 4 (En) Rev.0Документ53 страницыInstallation Manual Global 4 - Telescopic 4 (En) Rev.0Delwitt CampeloОценок пока нет

- Deutsch Racing CatalogueДокумент25 страницDeutsch Racing CatalogueIОценок пока нет

- British Commercial Computer Digest: Pergamon Computer Data SeriesОт EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesОценок пока нет

- Last Time TouchДокумент10 страницLast Time TouchAbhinavОценок пока нет

- Dbms program-WPS OfficeДокумент1 страницаDbms program-WPS OfficeAbhinavОценок пока нет

- Experiment No:7 Date: 1.1 Aim:: Department of Computer Engineering, KBTCOEДокумент6 страницExperiment No:7 Date: 1.1 Aim:: Department of Computer Engineering, KBTCOEAbhinavОценок пока нет

- SummaryДокумент50 страницSummarygirjesh kumarОценок пока нет

- KR 10 Scara: The Compact Robot For Low PayloadsДокумент4 страницыKR 10 Scara: The Compact Robot For Low PayloadsBogdan123Оценок пока нет

- About FW TaylorДокумент9 страницAbout FW TaylorGayaz SkОценок пока нет

- 7a.simple InterestДокумент50 страниц7a.simple InterestJanani MaranОценок пока нет

- Microsoft Software License Terms Microsoft Windows Media Player Html5 Extension For ChromeДокумент2 страницыMicrosoft Software License Terms Microsoft Windows Media Player Html5 Extension For ChromeOmar PiñaОценок пока нет

- AMC Mining Brochure (A4 LR)Документ2 страницыAMC Mining Brochure (A4 LR)Bandung WestОценок пока нет

- 73-87 Chevy Truck 09 WebДокумент132 страницы73-87 Chevy Truck 09 WebBlaster Web Services100% (2)

- Title IX - Crimes Against Personal Liberty and SecurityДокумент49 страницTitle IX - Crimes Against Personal Liberty and SecuritymauiwawieОценок пока нет

- 450-11 Schmalensee RebuttalДокумент11 страниц450-11 Schmalensee RebuttalFlorian MuellerОценок пока нет

- The 8051 Microcontroller & Embedded Systems: Muhammad Ali Mazidi, Janice Mazidi & Rolin MckinlayДокумент15 страницThe 8051 Microcontroller & Embedded Systems: Muhammad Ali Mazidi, Janice Mazidi & Rolin MckinlayAkshwin KisoreОценок пока нет

- State of The Art Synthesis Literature ReviewДокумент7 страницState of The Art Synthesis Literature Reviewfvdddmxt100% (2)

- (English) 362L Stereoselective Wittig Reaction - Synthesis of Ethyl Trans-Cinnamate (#7) (DownSub - Com)Документ6 страниц(English) 362L Stereoselective Wittig Reaction - Synthesis of Ethyl Trans-Cinnamate (#7) (DownSub - Com)moОценок пока нет

- Book Shop InventoryДокумент21 страницаBook Shop InventoryAli AnsariОценок пока нет

- Frsky L9R ManualДокумент1 страницаFrsky L9R ManualAlicia GordonОценок пока нет

- Instructions For Comprehensive Exams NovemberДокумент2 страницыInstructions For Comprehensive Exams Novembermanoj reddyОценок пока нет

- TCO & TCU Series Container Lifting Lugs - Intercon EnterprisesДокумент4 страницыTCO & TCU Series Container Lifting Lugs - Intercon EnterprisesReda ElawadyОценок пока нет

- Product Management GemsДокумент14 страницProduct Management GemsVijendra GopaОценок пока нет

- Report - Summary - Group 3 - MKT201Документ4 страницыReport - Summary - Group 3 - MKT201Long Nguyễn HảiОценок пока нет

- Student ManualДокумент19 страницStudent ManualCarl Jay TenajerosОценок пока нет

- Course Outline ReviewerДокумент12 страницCourse Outline Reviewerjmd.besanaОценок пока нет

- MBA-CM - ME - Lecture 16 Market Structure AnalysisДокумент11 страницMBA-CM - ME - Lecture 16 Market Structure Analysisrohan_solomonОценок пока нет

- Goal of The Firm PDFДокумент4 страницыGoal of The Firm PDFSandyОценок пока нет

- Aaa0030imb02 FДокумент30 страницAaa0030imb02 FJvr Omar EspinozaОценок пока нет

- DOLE Vacancies As of 01 - 10 - 13Документ17 страницDOLE Vacancies As of 01 - 10 - 13sumaychengОценок пока нет