Академический Документы

Профессиональный Документы

Культура Документы

48 Steam Heating Boiler Daily checks-JOB PROCEDURE

Загружено:

Saepul AnwarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

48 Steam Heating Boiler Daily checks-JOB PROCEDURE

Загружено:

Saepul AnwarАвторское право:

Доступные форматы

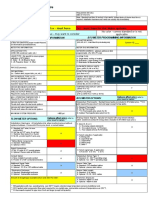

MAST

Safe Work Procedure

Division: Analysis By: Date:

Department: Supervisor: Frequency:

Job Title: Approved By: JSA Number: 48

Job Title: 48 Steam heating boiler daily Job Performed By:

checks

REQUIRED PERSONAL PROTECTIVE EQUIPMENT:

GENERAL NOTES: Although most heating boilers are now fully automatic, it is necessary that they are given regular attention to assure safe and

dependable operation. Whenever going on duty it is important to check the pressure of the steam boilers. It should be between the high and low limits of the

operating control. Do not carry a higher pressure than is necessary to satisfy the heat load. The maximum operating pressure should be kept 20 - 35 kPa (3 - 5

psi) lower than the operating pressure of the safety valves. Discharge pressure of the safety valves should not exceed 103 kPa (15 psi). This pressure

differential is required to allow the valve to close tightly if it has popped open under pressure.

JOB SAFETY ANALYSIS:

Step Description Hazard Controls

Take a 50 ml sample of boiler water from the gage glass spigot. This Possible scald by hot water Personal protective equipment (PPE) should

sample will be used for tests after it is allowed to cool. include the following; gloves, goggles

FLAME FAILURE

For Cleaver-Brooks boilers turn off the valve and watch to see if the

flame goes out. Press reset to start. On atmospheric burners press and

hold the flame failure button. Watch to see that the flame to the boiler

goes out. The flame should reignite after the test.

HIGH LIMIT test

Push and hold down the operator switch - let the boiler pressure increase

to high limit shut off point. At that point the boiler should shut down.

LOW WATER test

Blow down each control when the boiler is firing and steam pressure Hot water may splash Check drains to make sure they are not

shows on the gage. Boiler should shut down. causing scalding. clogged. Ensure there is some water in the

bucket prior to blow down to help prevent

splashing. IF THE BOILER DOES NOT SHUT

DOWN CONTACT THE MAINTENANCE SHOP

IMMEDIATELY.

Page 1 of 2 Print Date: Apr/12/2006

AIR FLOW SWITCH

Open air valve to atmosphere - boiler will shut down after approximately

10 minutes. Return valve to former position

SAFETY VALVE

Test by manually opening valve (use pull chain) Steam and water leaks Keep on the safe side

POP TEST

(once a year) Hold down operator and high limit together until boiler Steam and water leaks. Personal protective equipment (PPE) should

releases steam pressure for a full minute. Note and record the pressure --Explosion-Pressure include the following; hearing protection,

in the log book. Container--Hearing Loss goggles

MOLYBDENUM TEST

Measure 25 ml of sample in the sample flask

Add 1 ml of Molybdenum buffer. Swirl flask for 10 seconds

Add 1 scoop of Molybdenum Indicator and swirl in to mix. A blue colour

will develop.

While swirling the flask, add Molybdenum Titrant slowly, (one drop at a

time) until the blue colour has been eliminated. The endpoint is a very

light amber/straw colour. Record the number of drops required.

CALCULATION

1 drop of titrant x 10 = ppm Molybdate as MO.

AUTHORIZED EMPLOYEE INFORMATION:

ID NUMBER: LAST NAME: FIRST NAME: REMARKS:

JOB HISTORY INFORMATION:

DATE: REMARKS:

Approval Signature: Date:

Page 2 of 2 Print Date: Apr/12/2006

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Ge Triton XL Dishwasher ManualДокумент16 страницGe Triton XL Dishwasher ManuallksajdflkdsajfОценок пока нет

- 10 Gas Conditioning SystemДокумент24 страницы10 Gas Conditioning SystemRavi Sankar VenkatesanОценок пока нет

- Green Port GuidelinesДокумент60 страницGreen Port GuidelinesibadОценок пока нет

- Green Restaurant Certification StandardsДокумент19 страницGreen Restaurant Certification Standardskok20Оценок пока нет

- Central Chiller PlantДокумент2 страницыCentral Chiller PlantatiqulaОценок пока нет

- Grant Euroflame SE Models Installation Servicing Instructions 2003Документ48 страницGrant Euroflame SE Models Installation Servicing Instructions 2003Tom57Оценок пока нет

- Manual Exclusive-Mix - 35 PDFДокумент104 страницыManual Exclusive-Mix - 35 PDFAdrian Gologan100% (1)

- AO SMITH WH-Catalogue-2019Документ16 страницAO SMITH WH-Catalogue-2019siva chandraОценок пока нет

- Buderus EnglishДокумент64 страницыBuderus EnglishIvan AlandzakОценок пока нет

- Techical Submittal-Jubail Pharma - 07.06.2021Документ243 страницыTechical Submittal-Jubail Pharma - 07.06.2021Hameed UddinОценок пока нет

- ArticleIV ComprehensiveДокумент16 страницArticleIV ComprehensiveAshlyn RojasОценок пока нет

- 100 Ways To Save The EnvironmentДокумент3 страницы100 Ways To Save The EnvironmentSarvesh JaiswalОценок пока нет

- WG Instruction ManualДокумент84 страницыWG Instruction ManualsercopetrolОценок пока нет

- VELUX Project Daylight April 10Документ25 страницVELUX Project Daylight April 10cpg9294Оценок пока нет

- TH140-28 ThermostatДокумент4 страницыTH140-28 ThermostatAlkisgОценок пока нет

- En Catalogue Hydrospa 2010 PDFДокумент92 страницыEn Catalogue Hydrospa 2010 PDFMishealОценок пока нет

- Btu Meter FormДокумент2 страницыBtu Meter Formtkm2004Оценок пока нет

- CATALOG Camco-Manufacturing 07843Документ1 страницаCATALOG Camco-Manufacturing 07843Francisco RamirezОценок пока нет

- Data Sheet GeniousДокумент2 страницыData Sheet GeniousMarioОценок пока нет

- 000000009170Документ155 страниц000000009170Selena DelicОценок пока нет

- Calderas de Condensación COSMOGAS Mydens T - Ficha TécnicaДокумент24 страницыCalderas de Condensación COSMOGAS Mydens T - Ficha TécnicaFelipe Cáceres S.Оценок пока нет

- Solution Dynamics Boiler Efficiency ImprovementДокумент2 страницыSolution Dynamics Boiler Efficiency ImprovementtvsshindeОценок пока нет

- M&E EstimationДокумент17 страницM&E EstimationsofyanshahОценок пока нет

- Chapter 5-Electric HeatingДокумент31 страницаChapter 5-Electric HeatingAgonafirОценок пока нет

- Potterton Profile 30,40,50,60,80 eДокумент28 страницPotterton Profile 30,40,50,60,80 emadji100% (1)

- Rycroft Calorifier CatalogueДокумент20 страницRycroft Calorifier CataloguemasoodaeОценок пока нет

- Catalogue Solar LuckyIndiaДокумент43 страницыCatalogue Solar LuckyIndiaSharafat AliОценок пока нет

- Glow Worm Flexicom SX Boiler User GuideДокумент16 страницGlow Worm Flexicom SX Boiler User Guidehallgate1Оценок пока нет

- Casing Design ReferenciasДокумент7 страницCasing Design ReferenciasRichard More LeonОценок пока нет

- Air and Dirt SepratorДокумент12 страницAir and Dirt Sepratorkiran kumarОценок пока нет