Академический Документы

Профессиональный Документы

Культура Документы

Impact Study On Ship Scrubbers

Загружено:

micaiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Impact Study On Ship Scrubbers

Загружено:

micaiАвторское право:

Доступные форматы

Exhaust gas scrubbers have high efficiency in limiting SOx

emissions

Exhaust Gas Scrubbers are becoming a topic of significant importance in the marine industry,

especially in the context of current and future regulations entering into force.

Developments in environmental research highlight the impact ships have on the quality of the air we

breathe. Vessels that don’t already operate on low-sulphur marine fuel are faced with two variants:

installation of new machinery or conversion of existing ones, in order to run on more expensive low-

sulphur fuel, such as LNG, or retrofitting of Exhaust Gas Cleaning Systems.

Marine exhaust gas scrubbers enable the ship operator to run on cost-efficient high-sulphur fuel and

still be compliant with the 0.1% SOx cap in ECA. In time, this means that the capital expenditure for

the scrubber installation will return in the form of fuel cost savings.

How to choose the right Scrubber?

Ship operators need to consider several facts regarding choosing the right exhaust gas scrubber for

their operations. Wet scrubbers have been widely accepted in the industry, for their increased

efficiency, compared to dry scrubbers. The challenge in determining the right type of wet scrubber is

choosing between the three available systems: open loop, closed loop and hybrid. The major factor

that needs to be taken into consideration is the operating route. Water scrubbing technology relies

on the natural alkalinity of the seawater. The liquid is sprayed on the exhaust gasses in order to

neutralize the sulphur oxides and remove some of the particulate matters.

In high alkaline waters, open loop system scrubbers use seawater as scrubbing liquid, due to its high

alkalinity. The waste stream is treated and discharged into the sea, leading to further removal of the

particulates and heavy metals from the exhaust gas. In closed loop scrubbers, the scrubbing is

generally performed with freshwater treated with additives that increase its alkalinity. The liquid is

recycled back into the scrubber after each passing through the tower and, occasionally, additives

and freshwater/ seawater are added to maintain efficiency levels and correct chemical composition.

For ships that operate along routes with variable alkalinity, the safe choice would be using a hybrid

type scrubber that can switch between the two operating modes.

Operating costs will vary according to the type of system used, as they each require different

resources. Factors such as seawater recirculation that increase the power consumption of the

pumps, the use of additives in the freshwater, additional equipments such as pumps, tanks, dosing

equipments, maintenance operations due to wear, make the case for one or the other.

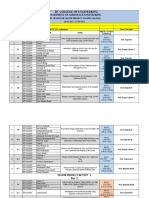

The infographic below aims to explain the context in which exhaust gas cleaning systems are

proving to be an increasingly popular option among ship operators.

Вам также может понравиться

- Marketing FinalДокумент15 страницMarketing FinalveronicaОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Mantel Colonized Nation Somalia 10 PDFДокумент5 страницThe Mantel Colonized Nation Somalia 10 PDFAhmad AbrahamОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Report Card Grade 1 2Документ3 страницыReport Card Grade 1 2Mely DelacruzОценок пока нет

- Wilcoxon Matched Pairs Signed Rank TestДокумент3 страницыWilcoxon Matched Pairs Signed Rank TestDawn Ilish Nicole DiezОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- 5c3f1a8b262ec7a Ek PDFДокумент5 страниц5c3f1a8b262ec7a Ek PDFIsmet HizyoluОценок пока нет

- Review1 ScheduleДокумент3 страницыReview1 Schedulejayasuryam.ae18Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Richardson Heidegger PDFДокумент18 страницRichardson Heidegger PDFweltfremdheitОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Agnes de MilleДокумент3 страницыAgnes de MilleMarie-Maxence De RouckОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Quantitative Methods For Economics and Business Lecture N. 5Документ20 страницQuantitative Methods For Economics and Business Lecture N. 5ghassen msakenОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Origami Oso HormigueroДокумент9 страницOrigami Oso HormigueroRogelio CerdaОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Post Appraisal InterviewДокумент3 страницыPost Appraisal InterviewNidhi D100% (1)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Week 7Документ24 страницыWeek 7Priyank PatelОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Analizador de Combustion Kigaz 310 Manual EngДокумент60 страницAnalizador de Combustion Kigaz 310 Manual EngJully Milagros Rodriguez LaicheОценок пока нет

- Chemistry Test 1Документ2 страницыChemistry Test 1shashankОценок пока нет

- Köppen Climate Classification - Wikipedia, The Free EncyclopediaДокумент15 страницKöppen Climate Classification - Wikipedia, The Free EncyclopediaAndreea Tataru StanciОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Test Your Knowledge - Study Session 1Документ4 страницыTest Your Knowledge - Study Session 1My KhanhОценок пока нет

- What Is TranslationДокумент3 страницыWhat Is TranslationSanskriti MehtaОценок пока нет

- Organization and Management Module 3: Quarter 1 - Week 3Документ15 страницOrganization and Management Module 3: Quarter 1 - Week 3juvelyn luegoОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- (123doc) - Toefl-Reading-Comprehension-Test-41Документ8 страниц(123doc) - Toefl-Reading-Comprehension-Test-41Steve XОценок пока нет

- Iec TR 61010-3-020-1999Документ76 страницIec TR 61010-3-020-1999Vasko MandilОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Vendor Information Sheet - LFPR-F-002b Rev. 04Документ6 страницVendor Information Sheet - LFPR-F-002b Rev. 04Chelsea EsparagozaОценок пока нет

- Hima OPC Server ManualДокумент36 страницHima OPC Server ManualAshkan Khajouie100% (3)

- Outdoor Air Pollution: Sources, Health Effects and SolutionsДокумент20 страницOutdoor Air Pollution: Sources, Health Effects and SolutionsCamelia RadulescuОценок пока нет

- Checklist & Guideline ISO 22000Документ14 страницChecklist & Guideline ISO 22000Documentos Tecnicos75% (4)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Assessment of Students' Oral Communication in English ClassДокумент10 страницAssessment of Students' Oral Communication in English ClassKeebeek S ArbasОценок пока нет

- Acute Coronary SyndromeДокумент30 страницAcute Coronary SyndromeEndar EszterОценок пока нет

- De Thi Hoc Ki 1 Mon Tieng Anh Lop 5 Co File NgheДокумент10 страницDe Thi Hoc Ki 1 Mon Tieng Anh Lop 5 Co File Nghetuyen truongОценок пока нет

- Functional DesignДокумент17 страницFunctional DesignRajivSharmaОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Radiation Safety Densitometer Baker PDFДокумент4 страницыRadiation Safety Densitometer Baker PDFLenis CeronОценок пока нет

- Product CatalogsДокумент12 страницProduct Catalogscab666Оценок пока нет