Академический Документы

Профессиональный Документы

Культура Документы

Construction and Maintenance of Timber Structures - 2017 - : Section/Article Description

Загружено:

Mike2322Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Construction and Maintenance of Timber Structures - 2017 - : Section/Article Description

Загружено:

Mike2322Авторское право:

Доступные форматы

7

Part 4

Construction and Maintenance of

Timber Structures

— 2017 —

TABLE OF CONTENTS

Section/Article Description Page

4.1 Handling of Material (2016) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-2 1

4.2 Storage of Material (2017) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-2

4.3 Workmanship for Construction and Maintenance of Pile and Framed Trestles (2017) . . . . . . . . . . . . . . 7-4-3

4.4 Framing of Timber (2017) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-3

3

4.5 Substructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-4

4.5.1 Pile Posting, or Replacing Defective Portions of Piles (2014) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-4

4.5.2 Driving Timber Piles (2017) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-5

4.6 Superstructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-13

4.6.1 Open Deck Bridges (2017) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-13

4.6.2 Ballast Deck Bridges (2017) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-13

4.6.3 Stringers (2017) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-14

4.6.4 Walkways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-16

4.6.5 Backwalls & Wingwalls (2016) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-16

4.7 Support, Repair, Preserve, or Replace Damaged Portions of the Structure (2014) . . . . . . . . . . . . . . . . . . 7-4-16

4.7.1 Control Moisture (2014) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-19

4.7.2 Field Application of Preservative Chemicals (2014) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-19

4.8 Methods of Fireprotecting Timber Bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-19

4.8.1 Methods of Fireprotection (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-19

4.8.2 Fire Alarm Systems (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-19

4.8.3 Housekeeping (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-19

4.8.4 Fire Barriers (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-20

© 2017, American Railway Engineering and Maintenance-of-Way Association 7-4-1

Timber Structures

LIST OF FIGURES

Figure Description Page

7-4-1 Schematic Diagram of Pile Posting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-5

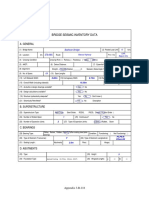

7-4-2 Sample Pile Record Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-12

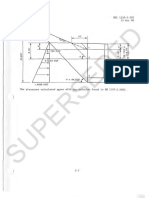

7-4-3 Staggered Chord Layout Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-15

7-4-4 Pile Restoration Using Cast in Place Reinforced Concrete Jacket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-17

7-4-5 Clamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-18

7-4-6 Stitching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-18

7-4-7 Earth Fill Break in a Long Trestle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-20

7-4-8 Reinforced Concrete Piers and Reinforced Concrete Bents as Fire Stops. . . . . . . . . . . . . . . . . . . . . . . . . . 7-4-21

SECTION 4.1 HANDLING OF MATERIAL (2016)

a. All material should be handled to avoid structural damage or unnecessary disfiguring.

b. Timber shall be preferably handled with web slings. Sharp-pointed bars, peavies, hooks, tongs or similar tools shall not

be used, except as approved by the Engineer.

c. Timber that has been treated with preservatives should be handled with extreme care in unloading and assembling to

avoid damage to the timber which would expose untreated wood.

d. Specialty material, such as engineered wood products, might require special handling procedures due to its unique

properties.

SECTION 4.2 STORAGE OF MATERIAL (2017)

a. Materials should be stored at the site in a neat manner at proper clearance to operated tracks.

b. Care should be exercised to prevent fires in material held in storage. The ground underneath and in the vicinity of

piling and timber should be scalped and cleared of all weeds, rubbish and combustible material.

c. Treated timber should be close-stacked off the ground in a manner that will prevent long timbers or preframed material

from sagging or becoming crooked.

d. Untreated timber should be open-stacked at least 1 foot above the ground and above possible high water; it should be

piled in a manner to shed water and to prevent warping. When required, it shall be protected from the weather by

suitable covering.

e. Piling should be stacked in a manner to prevent bending.

f. Uncoated hardware received at the job site should be protected from corrosion by storing under cover.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-2 AREMA Manual for Railway Engineering

Construction and Maintenance of Timber Structures

SECTION 4.3 WORKMANSHIP FOR CONSTRUCTION AND MAINTENANCE OF PILE

AND FRAMED TRESTLES1 (2017)

This section covers workmanship for the construction and maintenance of pile and framed trestles that carry railway traffic.

a. Work performed under this recommended practice should be built complete, in a workmanlike manner, and in strict

accordance with the plans and the intent of this recommended practice.

b. It is presumed that the design of structures to which this recommended practice attaches is in accordance with

prevailing practice, and, more specifically, in general accordance with, Part 2, Design of Wood Railway Bridges and

Trestles for Railway Loading.

c. Nothing contained herein shall be construed as superseding details or notations shown on design drawings. Where this

recommended practice conflicts with the drawings, the drawings will govern.

d. Workmanship should be of the best quality in each class of work. Competent bridge carpenters shall be employed and

all framing shall be true and exact. No blocking or shimming will be permitted, except as approved by the Engineer.

e. On completion of the work, all surplus material or material salvaged from an existing structure should be removed

from the premises as directed. Material not salvageable and other refuse should be properly disposed of in accordance

with applicable federal and local environmental regulations. Premises should be left in a clean, neat and orderly

condition.

SECTION 4.4 FRAMING OF TIMBER (2017)

a. All cutting, framing, and boring of timbers to be treated, should be done before treatment unless otherwise shown on

the plans or specifically permitted by the Railroad Bridge Engineer.

3

b. All field cuts, bored holes, or other damage made in treated lumber should be carefully trimmed and then field treated

by the application of an approved topical wood treatment product and/or sealant as recommended by the American

Wood Protection Association in standard M4-15. All holes bored in treated material should be field treated, in such a

manner that the entire surface of the hole receives thorough penetration. All countersunk recesses for bolts which

would form pockets to retain water should be treated as for cuts and then filled with a suitable mastic after the bolt is

placed. All holes bored in treated material that will not be used for placement of hardware or for drainage should be 4

field plugged or filled with an approved sealant.

c. Sills should have a true and even bearing on foundation piles, timber grillages, mats or pedestals. Sills should be

installed either above ground to allow free air circulation, a minimum of four feet below ground level or as otherwise

determined by the Railroad Bridge Engineer.

d. Posts in framed bents shall be sawed to proper length (vertical or batter) and shall have an even bearing on caps, sills or

pile stubs. When posting batter piles directly onto a pile stub, the piles should be cut perpendicular to the pile axis.

e. Caps shall be sized to a uniform depth and placed to a uniform and even bearing on piles or posts.

f. Sash and sway bracing, tower bracing and girts shall bear firmly against the piles or timber to which secured. When

necessary, filler shall be placed to avoid bending the bracing more than 1 inch out of line when the bracing bolts or

1

References, Vol. 8, 1907, pp. 397, 442; Vol. 35, 1934, pp. 998, 1176; Vol. 36, 1935, pp. 781, 1009; Vol. 54, 1953, pp. 942, 1329; Vol. 61, 1960, pp. 587,

1095; Vol. 89, 1988, p. 106.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-4-3

Timber Structures

other fastenings are drawn up tight. Built-up fillers will not be permitted and each filler shall be a single piece of

creosoted lumber of like kind to that in the brace with a width of not less than 6 inches and a length of not less than 12

inches.

g. Stringers should be sized to provide a uniform depth and even bearing at supports.

h. All bridge components should be sized in accordance with the plans.

i. Bulkheads at the ends of trestles shall be of sufficient height and width to retain properly the shoulders of

embankments and to provide a berm sufficient to prevent loss of embankment from beneath the bulkhead. When

necessary, special anchorage, such as bulkhead piles or dead-men buried in the embankment, shall be provided to

support the bulkhead.

j. All fastenings, including machine bolts, dowels, drift pins, drift bolts, lag screws, threaded rods, timber connectors and

other type fastenings shall be placed in accordance with the plans, drawn up securely, and on completion of the

structure shall be retightened. Unless otherwise shown on the plans, holes for dowels, drift pins or drift bolts shall be

bored 1/16 inch smaller than the nominal diameter of the dowel, drift pin or drift bolt used; holes shall not be bored

deeper than the length of the dowel, drift pin or drift bolt. Holes for machine bolts and threaded rods other than

dowels, drift pins or drift bolts shall be bored a minimum of 1/32” larger to a maximum of 1/16 inch larger than the

nominal diameter of the machine bolt or threaded rod used. Holes for lag screws shall be bored 1/16 inch smaller than

the body of the screw at the base of the thread. All other fasteners shall be installed in accordance with manufacturer’s

recommendations.

k. Screw-type fastenings shall be screwed into place for the entire length of the fastening. Driving with a maul or other

tool will not be permitted.

l. Timber connectors shall be of the types specified on the plans. Split-ring and shear-plate connectors shall be installed

in pre-cut grooves of the dimensions shown on the plans or as recommended by the manufacturer. Toothed-ring and

spike-grid connectors, and clamping plates, shall be forced into the contact surfaces of the timbers joined by means of

proper pressure tools; all connectors of these types at any joint shall be embedded simultaneously and uniformly.

SECTION 4.5 SUBSTRUCTURE

4.5.1 PILE POSTING, OR REPLACING DEFECTIVE PORTIONS OF PILES (2014)

Pile Posting, or replacing defective portions of piles should be performed as follows:

a. Posting of timber piles may be accomplished per Figure 7-4-1 or other standard practice approved by the Bridge

Engineer.

b. With approval of the Railroad Bridge Engineer, multiple or adjacent piles may be posted provided adequate

longitudinal and lateral bracing is installed to ensure the stability of the posted piles and the bent as a whole.

c. Posting of piles utilizing multiple joints in the same bent is not recommended unless approved by the Railroad Bridge

Engineer and additional bracing is installed to ensure the stability of the pile.

d. When posting of piles is not practical, and with the approval of the Railroad Bridge Engineer, bents should be framed

or replaced along with suitable longitudinal and lateral bracing to ensure the stability of the bent.

e. Where piling are decayed at the top, they may be cut off and double capped or single pile corbels may be considered.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-4 AREMA Manual for Railway Engineering

Construction and Maintenance of Timber Structures

f. Cut offs on piles for posts or frames shall be done beyond the area of deterioration at a location of sound timber.

g. All field fresh cuts and bored holes should be treated with wood preservative as specified in Article 4.4, Paragraph b.

Figure 7-4-1. Schematic Diagram of Pile Posting

4.5.2 DRIVING TIMBER PILES1 (2017) 4

4.5.2.1 Scope (1990) R(2013)

This specification covers the driving of wood piles in trestles, foundations, and for protection work.2

4.5.2.2 T ests (1990) R(2013)

In the absence of other reliable information to determine pile lengths, a thorough exploration shall be made at the site by

borings, driving test piles, or by pile loading tests, prior to the selection of the length of piles for the work, and to determine

characteristics incident to pile resistance and penetration.

1

References, Vol. 12, 1911, part 1, pp. 279, 307; Vol. 16, 1915, pp. 894, 1181; Vol. 41, 1940, pp. 326, 864; Vol. 54, 1953, pp. 943, 1329; Vol. 62, 1961, pp.

513, 848; Vol. 89, 1988, p. 106; Vol. 91, 1990, p. 57.

2 For the driving of concrete piles and steel piles, and for information on loading tests, see Chapter 8, Concrete Structures and Foundations.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-4-5

Timber Structures

4.5.2.3 Materials (1990) R(2013)

The kinds of wood, physical requirements, dimensions, and manufacture are specified in Part 1, Material Specifications for

Lumber, Timber, Engineered Wood Products, Timber Piles, Fasteners, Timber Bridge Ties and Recommendations for Fire-

Retardant Coating for Creosoted Wood, under the subject title Specifications for Timber Piles.

4.5.2.4 Handling of Material (2013)

a. Treated piles shall be handled in accordance with requirements of Section 4.1, Handling of Material (2016).

b. The surface of treated piles below cut-off elevation shall not be disturbed by boring holes or driving nails or spikes into

them to support temporary material or staging. Staging may be supported in slings carried over the tops of piles or

attached to pile clamps of an approved design.

4.5.2.5 Selection and Preparation of Piles (1990) R(2013)

4.5.2.5.1 Size R(2013)

a. The piles in each bent of a pile trestle shall be selected for uniformity of size to facilitate placing of the brace timbers.

b. It is presumed that piles will be furnished in approximately the lengths required to secure the desired penetration and

bearing. In the event piles are found to be much in excess of the required lengths, they shall be shortened at the small

end before driving, as may be directed by the engineer, in order to preserve the desired diameter of pile at the cut-off.

4.5.2.5.2 Pointing R(2013)

Under ordinary conditions points of piles shall be cut perpendicular to the axis of the pile; where necessary or desirable, points

may be trimmed to form a truncated pyramid 4 inches to 6 inches square at the end and with length of trimming not to exceed

twice the tip diameter of the pile.

4.5.2.5.3 Pile Shoes R(2013)

a. Where the driving of a test pile or former experience at the site indicates that difficult driving will be encountered,

metal shoes of an approved design may be attached to the tips of the piles.

b. Each pile point shall be carefully trimmed to fit the shoe and obtain full and uniform bearing, and to avoid

displacement of the shoe or damage to the pile or shoe.

4.5.2.5.4 Collars R(2013)

Where the heads of piles tend to split when being driven, the heads shall be tightly wrapped with No. 12 gage annealed iron

wire to form a band not less than 2 inches in width, held in place with staples, or shall be protected with strap-iron bands

applied with a banding tool, or other effective means shall be used to prevent splitting.

4.5.2.5.5 Driving Cap R(2013)

The heads of piles shall be protected while being driven with a driving cap (bonnet) of approved design. The cap shall be

shaped to fit over the head of the pile to provide lateral support, and to uniformly distribute the hammer blow. Pile heads shall

be trimmed to fit snugly into the cap.

4.5.2.6 T ypes of Hammers (2013)

a. Pile driving shall not be started on any project until approval is secured from the engineer as to the type and weight of

the hammer to be used.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-6 AREMA Manual for Railway Engineering

Construction and Maintenance of Timber Structures

b. Piles shall be driven with the heaviest hammer that, in the judgement of the engineer, can be used to secure maximum

penetration without appreciable damage to the pile.1

c. Where a drop hammer is used, the striking ram shall weigh not less than 3000 lbs. The fall shall be so regulated as to

avoid damage to the pile.

d. Special care shall be used in choice of hammer where the shock to surrounding material may cause damage to an

adjacent structure.

4.5.2.7 Driving (2015)

4.5.2.7.1 Leads R(2013)

Pile driver leads shall be constructed in such a manner as to afford freedom of movement of the hammer, and they shall be held

in position to ensure support for the pile during driving. All piles shall be driven with leads and hammer in line with the neutral

axis of the driven pile.

4.5.2.7.2 Followers R(2013)

The use of followers shall be avoided if practicable and shall be used only with the written permission of the engineer.

4.5.2.7.3 Line R(2013)

Piles shall be driven as accurately as possible in the correct location, true to line both laterally and longitudinally, and to the

vertical or batter lines as indicated on the plans. On sloping ground or under difficult conditions of driving, the pile shall be

1

started in a hole or guiding template or other necessary means provided to insure driving in the proper location. In case a pile

works out of line in driving, it shall be properly aligned before it is cut off or braced, and the distance that it may be pulled

shall be determined by the engineer.

4.5.2.7.4 Jetting R(2013)

3

Jetting shall not be done unless specifically permitted by the engineer. When waterjets are used, the number of jets and the

volume and pressure of water shall be sufficient to freely erode the material adjacent to the pile. The plant shall have sufficient

capacity to deliver at least 100 psi pressure at two 3/4 inch nozzles. Before the desired penetration is reached, the jets shall be

removed and the pile finally set under normal driving by at least 50 blows from a gravity or single-acting hammer or 200

blows from a double acting hammer.

4.5.2.7.5 Drilling (2013) 4

a. When it has been satisfactorily demonstrated to the engineer that piling cannot be driven in the regular manner or by

jetting, holes may be predrilled to facilitate the driving.

b. Where drilling is permitted, the holes drilled shall have a diameter not more than 1 inch larger than the tip diameter of

the pile and the drilling will continue only through the strata of hard material obstructing the driving. Where the hard

material extends below the desired penetration, the drilling shall be stopped above that penetration level and the pile

finally set under normal driving in accordance to the bearing required. At least 50 blows from a gravity or single-acting

hammer or 200 blows from a double-acting hammer shall be used if possible to do so without damaging the pile.

1

For a discussion of the proper relationship of weight of ram to weight of pile, and net effective energy of blow, in selecting pile driving hammers, reference

is made to Vol. 37, 1936, AREMA Proceedings.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-4-7

Timber Structures

4.5.2.7.6 Penetration R(2013)

It is expected that piles shall be driven, jetted or drilled and driven to the full penetration shown on the plans or as otherwise

required. This shall not be construed to mean that driving may stop when such penetration as shown on the plans has been

secured, but on the contrary, driving shall continue in every case until the total penetration obtained is satisfactory to the

engineer, regardless of the fact that sufficient bearing capacity as determined by formula may be obtained at a lesser depth.

4.5.2.7.7 Bearing Capacity (2015)

a. Where possible, test piles shall be driven and loading tests made before construction is started, as referred to under

Article 4.5.2.2 Tests. In the absence of such data, the following “Engineering News” formulas may be used to estimate

the approximate safe bearing capacity of piles in most soils:

For drop hammers:

P = FWh

------------

S+1

For double-acting combustion hammers:

Replace with:

FE

P = -----------------

S + 0.1

For single-acting hammers:

FWh -

P = ----------------

S + 0.1

where:

P = safe load in pounds

W = weight of hammer or ram in pounds

h = fall of hammer or stroke of piston in feet

S = average penetration in inches per blow, for the last 5 blows of a drop hammer or 20 blows of a single or

double-acting hammer

F = 2 for piles driven to practical refusal in any material

E = energy per blow of hammer, in foot - pounds

b. These formulas are applicable only when the hammer has a free fall, the head of the pile is not broomed or crushed, the

penetration is reasonably uniform, and there is no appreciable bounce of the hammer. The character of the soil

penetrated; conditions of driving; spacing, size and length of piles; and experience under similar conditions; shall be

given due consideration in determining the value of piles by formula.

c. The formulas should not be applied to friction piles driving into such soils as silt, muck, peat, or plastic clays, nor to

piles which act as end-bearing piles.

d. For jetted piles the same formulas will apply and the test shall be made when driving is resumed after removal of the

jets. For piles driven in drilled holes, the tests shall be made after the tip of the pile has passed the bottom of the hole.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-8 AREMA Manual for Railway Engineering

Construction and Maintenance of Timber Structures

4.5.2.7.8 Delay (2013)

When driving is interrupted before final penetration is reached, record for bearing capacity shall not be taken until at least 12

inches penetration or refusal has been obtained after driving has been resumed.

4.5.2.7.9 Overdriving R(2013)

When the point of refusal is reached, care shall be taken to avoid damaging the pile by overdriving. This condition is indicated

when the hammer begins to bounce or when the energy of the blow is dissipated in the bending or kicking of the pile.

4.5.2.7.10 Replacing (2013)

Any pile driven too far out of line, driven below cut-off elevation, or so damaged in driving or straightening as to impair its

structural value as a pile under the conditions of use, shall be pulled and replaced by a new pile.

4.5.2.8 Framing (2017)

4.5.2.8.1 Cut-Off R(2013)

The tops of piles shall be pulled into line if necessary, fixed in position, cut off to a true plane as shown on the plans, and at the

elevation established by the engineer. Piles shall show a solid head at the plane of the cut off.

4.5.2.8.2 Treatment

After cut offs have been made, the tops of piles shall be treated in accordance with requirements of Section 4.4, Paragraph b.

1

4.5.2.8.3 Pile Covering

The treated pile cut-off should be covered with a coat of pitch, asphalt or similar material which should then be applied along

with a protective sheet material, such as metal, roofing felt or saturated fabric fitted over the pile cut-off.

3

4.5.2.8.4 Placing Caps

Caps shall be placed while the piles are held in correct position. Where drift pins or drift bolts are used for making the

connection, the caps and tops of piles shall be bored 1/16 inch smaller than the nominal diameter of the drift pin or drift bolt

and to a depth of 2 inches less than its driven length. Where the connection is made with straps and bolts, see Section 4.4,

Paragraph b for boring and treatment of holes.

4

4.5.2.8.5 Bracing1

a. Piling should not be trimmed or cut to facilitate the framing of sway or longitudinal bracing. Where necessary, filler

blocks should be used between the pile and brace to establish the bracing in a true plane. Filler blocks should be sized

in accordance with Section 4.4, Paragraph f.

b. Spike-grid or similar shear connectors may be installed between piles and bracing components to provide an enhanced

shear connection.

4.5.2.8.6 Holes for Bolts and Other Fasteners

a. Holes for bolts and fasteners shall be bored in accordance with Section 4.4, Paragraph j.

1

See Part 6 Commentary.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-4-9

Timber Structures

b. All field drilled holes shall be treated with preservative in accordance with requirements specified in Section 4.4,

Paragraph b. Bolts shall be cleaned of rust and scale, and dipped in approved sealing compound before placing. All

unused holes shall be plugged at each end with tight fitting treated wooden plugs.

4.5.2.8.7 General Field Treatment

Where it is necessary to disturb the surface of treated piles or timber, or where the surface has been damaged in handling, such

surfaces shall be treated in accordance with requirements of Section 4.4, Paragraph b.

4.5.2.9 Foundation Piles (1990)

a. For the design of pile foundations, exploration at the site, and test pile loading, see Chapter 8, Concrete Structures and

Foundations; Part 4, Pile Foundations.

b. The general specifications above should apply to the driving of wood foundation piles.

c. Pile driving should not be started until foundation excavation has been carried to plan depth.

d. After all of the piles are driven, tests should be made to determine if any of the piles have raised due to driving of

adjacent piles. Any piles that have raised should be driven down again.

e. After driving is completed, the piles should be cut off as shown on the plans and at the elevation established by the

engineer. All loose and displaced materials down to the level of original excavation should be removed from the

foundation pit, leaving a clean solid surface on the piles, and bottom and walls of the pit.

4.5.2.10 Protection Work (1990)

a. The general specifications above should apply to the driving of wood piles for protection work.

b. It is essential that protection work be constructed as securely as possible, accurately located as shown on the plans, and

the piles driven to a fixed penetration or to refusal as may be determined by the Railroad Bridge Engineer.

4.5.2.11 Pile Record (1988)1

a. An accurate record should be kept of all piles, as each is driven, to show the location in the structure, size of pile,

penetration, resistance to driving and other essential data. See suggested form for reporting this information,

Figure 7-4-2. Size can be 8-1/211 or 8 10-1/2.

b. The size and arrangement of pile driving record forms may be varied to adapt them to the convenience of user, method

of filing, and use to be made of the data. The form found in Figure 7-4-2 embodies the minimum of information for a

satisfactory record. Among additional items which may be desirable are:

• reference to piles other than wood;

• steam hammer blows per minute;

• data on batter;

• reference to jetting;

• computed bearing value; and

1

References, Vol. 12, 1911, part 1, pp. 278, 307; Vol. 52, 1951, pp. 426, 846; Vol. 62, 1961, pp. 514, 848; Vol. 89, 1988, p. 106.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-10 AREMA Manual for Railway Engineering

Construction and Maintenance of Timber Structures

• other arrangement of data on length between butt, cut-off, ground and point of pile.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-4-11

Timber Structures

North and South Railroad

Pile Record of Bridge:

Location:

Weight and Kind of Hammer: Date:

Avg. Last Blows

Size of Pile

Bent No. of (Note 3)

Kind of Base-rail Total Kind of

Date No. Pile Cutoff Drop Remarks

Wood to Ground Penetration Soil

(Note 1) (Note 2) Tip Butt Length of Penetration

End End

Hammer

Note 1: Bents numbered in direction in which mile posts increase.

Note 2: Piles numbered from left to right.

Note 3: Five blows for drop hammers and 20 blows for single or double-acting hammers.

Figure 7-4-2. Sample Pile Record Form

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-12 AREMA Manual for Railway Engineering

Construction and Maintenance of Timber Structures

SECTION 4.6 SUPERSTRUCTURE

4.6.1 OPEN DECK BRIDGES (2017)

4.6.1.1 Decks on Timber Bridges

a. New ties on open deck bridges should be spaced in accordance with Article 1.7.8.1 Bridge Tie Spacing and Spacers.

b. At a minimum, decks should be securely fastened to the superstructure every fourth tie, and every other tie on curved

track or as directed by the Engineer.

c. All ties should be installed square to the superstructure and all ties should be evenly spaced. It may be practical to

decrease the spacing at end of bridges to improve load distribution, decrease wear, and reduce the amount of ballast

from falling on bearing seats.

d. Guard timber, tie spacers and/or timber spacer blocks should be secured fastened directly to all ties.

e. For tie plates, tie pads and tie fastening, reference Article 1.7.8 Bridge Tie Installation (2017).

4.6.1.2 Lining and Gaging

a. Prior to deck installation, verify condition of the rail. If the rail shows significant signs of wear, it may be necessary to

replace the rail prior to deck installation.

1

b. Identify the running rail, and start by lining it. Gage the rail accordingly.

4.6.2 BALLAST DECK BRIDGES (2017)

4.6.2.1 Decks on Timber Bridges1

a. Decks and track should be centered on the bridge. Any deviation should be evaluated by the Railroad Bridge Engineer

3

for correction to avoid eccentric loading on the structure.

b. Deck assemblies should be securely fastened to the superstructure to prevent movement.

4.6.2.2 Ballast Depth2

4

a. Minimum depth of ballast for existing bridges under timber or composite ties should not be less than 6 inches.

b. Minimum depth of ballast under concrete ties should not be less than 12 inches.

c. Excessive ballast should be removed by resurfacing of the track, or by raising the deck to avoid overloading.

4.6.2.3 Retainers

a. Ballast retainers should be adequately secured to the deck and should comply with provisions of Part 2 Design of Wood

Railway Bridges and Trestles for Railway Loading.

1

See Part 6 Commentary.

2

See Part 6 Commentary.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-4-13

Timber Structures

4.6.2.4 Ballast Leaks

a. Ballast leaks should be repaired by replacing individual deck boards or section of deck.

b. When replacing boards is not practical, a short term solution may be as follows: ballast should be dug out enough to

expose solid deck boards on all edges of the leak. A steel plate or minimum one inch thick treated timber board may be

cut to fit over the deteriorated section of decking. This plate or timber board should overlap the existing opening a

minimum of 3 inches onto solid timber decking. The plate or timber board should be placed so it lays flat on the deck

boards and is secured in place to the deck.

c. When ballast leaks become a frequent maintenance occurrence, the entire deck or portion of it should be considered for

replacement.

4.6.3 STRINGERS (2017)

Stringers should be installed in a manner to provide uniform top surface for tie or deck board installation. All stringers in each

span should be made of the same size, material and wood species. Intermixing of engineered and solid sawn timbers should be

approved by the Railroad Bridge Engineer.

4.6.3.1 Stringer Chords

a. Stringer chords should be centered under the running rails.

b. Any deviation between the centerline of rail and chord should be evaluated by the Railroad Bridge Engineer for

correction to avoid eccentric loading.

c. Stringer chords should have an adequate number of chord bolts. There should be a minimum of 4 bolts at intermediate

bents and a minimum of 2 bolts at end bents. See Figure 7-A1-26.

d. Washers shall be used under the head and nut of each chord bolt as specified in Paragraph 1.6.2.c Types of Fasteners,

Washers.

e. Chord bolts should not be tightened to the point of causing damage to wood fibers.

f. Individual stringers in a chord should be staggered, as shown in Figure 7-4-3. The stringers should be tightly packed

and all stringer ends centered on intermediate bents. Separate measurements should be taken on both sides of the

centerline of track to account for any skew of bents.

g. On end bent caps, all stringers should bear on the entire width of the cap.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-14 AREMA Manual for Railway Engineering

Construction and Maintenance of Timber Structures

Figure 7-4-3. Staggered Chord Layout Examples

4.6.3.2 Stringer Replacement in Chords

a. Individual stringers may be replaced with stringers that are equal in length and have similar properties to the remaining

stringers in the chord.

4

b. When multiple stringers are found to be defective in a chord, it may be practical to replace the entire chord or portion

of the chord. When only a section of the chord is replaced, the new stringer plug should be placed into the existing

chord in a manner that would maintain the continuity of the chord and with similar properties to the remaining

stringers.

c. If it is not practical to maintain continuity, a temporary stringer plug acting as a simple span may be installed to

maintain rail service. Such repairs should be considered as temporary and frequent inspection should be made to

evaluate the need for permanent repair.

d. All timber cuts must be treated with wood preservatives as outlined in Paragraph 4.4(b) Framing of Timber.

e. Stringers should be handled in such a way to prevent damage to wood fibers.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-4-15

Timber Structures

4.6.4 WALKWAYS1

a. When new walkways are to be installed on only one side of a bridge the walkway should be placed on the side as

specified by the Engineer.

b. Walkways should be maintained to minimize tripping hazards, and properly secured to walkway support structure.

c. New walkway handrails should be installed to provide clearance in accordance with Article 2.2.2 Clearances (1988)

R(2017) or with applicable regulatory requirements, whichever is more restrictive.

4.6.5 BACKWALLS & WINGWALLS (2016)

a. Backwalls and wingwalls play an essential role in maintaining approaches to bridges. Proper maintenance of these

bridge components helps to maintain the integrity of track structure at the approaches, including embankment and

geometry. Low approaches should be corrected to extend the life of the structure.

SECTION 4.7 SUPPORT, REPAIR, PRESERVE, OR REPLACE DAMAGED PORTIONS OF

THE STRUCTURE (2014)

a. Deteriorated pile may be restored by using a cast in place reinforced concrete jacket. The jacket must extend above and

below the defective area to adequately support the loads. See Figure 7-4-4.

1

See Part 6 Commentary.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-16 AREMA Manual for Railway Engineering

Construction and Maintenance of Timber Structures

Figure 7-4-4. Pile Restoration Using Cast in Place Reinforced Concrete Jacket

3

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-4-17

Timber Structures

b. Splits or checks may be arrested by clamping, using steel assemblies to compress the member, or stitching, using

Figure 7-4-5. Clamping

Figure 7-4-6. Stitching

through bolts to hold the member together. Configuration, number and size of fasteners should be determined on a case

by case basis. Stitch bolt spacing should be determined by Part 2, Design of Wood Railway Bridges and Trestles for

Railway Loading; Section 2.6, Details of Design, Article 2.6.4. Holes for stitch bolts should be sized in accordance

with Article 4.4.j. Stitch bolts should only be tightened to the point where they begin to take tension. Splits or checks

should not be closed as this may extend the defect to the other side of the clamp or stitched area. See Figure 7-4-5 and

Figure 7-4-6.

c. When individual structural components have become weakened beyond their ability to perform their intended function,

replacing these members shall be in accordance with the requirements established by the Bridge Engineer.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-18 AREMA Manual for Railway Engineering

Construction and Maintenance of Timber Structures

d. Shimming of stringers to provide proper surface and cross level should be performed using a single hard wood shim

under each chord or stringer. Shimming with stacked or multiple shims is to be avoided.

e. All bolts should be retightened during normal servicing of the structure.

4.7.1 CONTROL MOISTURE (2014)

Timber decay is reduced by controlling the amount of moisture present in timber bridges. To minimize moisture entry, the

following actions are recommended:

a. Remove dirt and debris.

b. Provide adequate drainage from deck.

c. Ensure adequate support surface for tie plates.

d. Provide water proofing systems for ballast decks.

e. Ensure hardware is tight, sealing holes preventing moisture entrance.

f. Plug any unused holes with treated wood plugs.

4.7.2 FIELD APPLICATION OF PRESERVATIVE CHEMICALS (2014)1

1

Timber decay can be prevented or arrested by field application of preservative chemicals. It is recommended they be used by

qualified personnel with experience in treating structural timber. Chemical treatments should be applied to all abrasions as

specified in Paragraph 4.4.b.

3

SECTION 4.8 METHODS OF FIREPROTECTING TIMBER BRIDGES2

4.8.1 METHODS OF FIREPROTECTION (2015)

The following methods may be used in providing fire protection to timber bridges. Fire protection can be accomplished via

other materials and their methods of application to timber may be acceptable. 4

4.8.2 FIRE ALARM SYSTEMS (2015)

a. Under this method detector systems are connected with the signal and communication systems that, in case of fire, the

block signals will show warning indications and the train dispatcher/control operator will receive notification to initiate

proper fire response.

b. Special fire-fighting apparatus and watchmen may be employed in unusual cases where conditions warrant.

4.8.3 HOUSEKEEPING (2015)

a. Decks should be kept clear of all combustible material.

1

See Part 6 Commentary.

2

References, Vol. 42, 1941, pp. 291, 868; Vol. 54, 1953, pp. 962, 1331; Vol. 62, 1961, pp. 514, 848; Vol. 63, 1962, pp. 453, 684; Vol. 89, 1988, p. 106.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-4-19

Timber Structures

b. Brush and weeds should be kept down within a distance of at least 25 feet from the outer most edges of the bridge.

4.8.4 FIRE BARRIERS (2015)

Under this method long bridges and trestles are protected by introducing fire barriers at intervals of about 400 feet. This

reduces the hazard by preventing loss of the entire structure in case of fire. Such barriers may be grouped by types of

construction, as follows:

a. Earth fill (see Figure 7-4-7).

b. Reinforced concrete piers or concrete pile bents with steel or concrete spans (see Figure 7-4-8).

c. Facing bents with fire-resisting materials (see Figure 7-A3-31).

Figure 7-4-7. Earth Fill Break in a Long Trestle

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-20 AREMA Manual for Railway Engineering

Construction and Maintenance of Timber Structures

Figure 7-4-8. Reinforced Concrete Piers and Reinforced Concrete Bents as Fire Stops

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-4-21

Timber Structures

THIS PAGE INTENTIONALLY LEFT BLANK.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-4-22 AREMA Manual for Railway Engineering

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Seismic Design of Bridges Example 7Документ62 страницыSeismic Design of Bridges Example 7Mike2322Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- BS 114 Rail Structure InteractionДокумент59 страницBS 114 Rail Structure Interactionpandeydb100% (2)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- RDSO Guide Lines of Earthwork 2003Документ90 страницRDSO Guide Lines of Earthwork 2003Abishek Kumar100% (1)

- Seismic Design of Bridges in PhilippinesДокумент80 страницSeismic Design of Bridges in PhilippinesMike2322Оценок пока нет

- TRANSNET - Manual de Via de Jun 2012Документ217 страницTRANSNET - Manual de Via de Jun 2012JorgeMourão100% (3)

- Jsa For Complete Erection of Tank-001Документ52 страницыJsa For Complete Erection of Tank-001Ashutosh80% (10)

- D0246 Concept of Earthing Bonding PS-PRD-ALL-EnB-GEN-03001-D - Annex 1Документ27 страницD0246 Concept of Earthing Bonding PS-PRD-ALL-EnB-GEN-03001-D - Annex 1Satish Kumar100% (2)

- Installation Manual MSDAC DACF-730P V2.6Документ128 страницInstallation Manual MSDAC DACF-730P V2.6Jeet DattaОценок пока нет

- LDCE Notes/Solution of LGS/Solution of LGS 1998Документ50 страницLDCE Notes/Solution of LGS/Solution of LGS 1998R Sathish KumarОценок пока нет

- Roof Systems: Eaves BeamsДокумент75 страницRoof Systems: Eaves BeamsatiattiОценок пока нет

- A Protocol For Railway Systems Integration-The Hudson-Bergen Experience PDFДокумент45 страницA Protocol For Railway Systems Integration-The Hudson-Bergen Experience PDFpoketupiОценок пока нет

- Railway Engineering-10 - Signalling and InterlockingДокумент81 страницаRailway Engineering-10 - Signalling and InterlockingLucifer DanteОценок пока нет

- Steel Ties and Turnout SetsДокумент30 страницSteel Ties and Turnout SetsIng Jose Antonio Guerrero Fernandez0% (1)

- FarmBot - Humanity's Open-Source Automated Precision Farming MachineДокумент53 страницыFarmBot - Humanity's Open-Source Automated Precision Farming MachineRory Landon Aronson80% (10)

- UIC E717Документ20 страницUIC E717umutakinОценок пока нет

- Finally Revised Paper On 'Modern Turnout For High Speed' For IPWE SeminarДокумент12 страницFinally Revised Paper On 'Modern Turnout For High Speed' For IPWE SeminarShipra MishraОценок пока нет

- LARSA WJE Solving-For-StabilityДокумент39 страницLARSA WJE Solving-For-StabilityMike2322Оценок пока нет

- Guard Rail On-System Bridge (MASH) Set (4-13-23)Документ11 страницGuard Rail On-System Bridge (MASH) Set (4-13-23)Mike2322Оценок пока нет

- Guard Rail Special Details MASHДокумент11 страницGuard Rail Special Details MASHMike2322Оценок пока нет

- AASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Документ8 страницAASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Mike2322Оценок пока нет

- 2021-11-16 - ABCD NEOH - Cross-Frames - ChavelДокумент36 страниц2021-11-16 - ABCD NEOH - Cross-Frames - ChavelMike2322Оценок пока нет

- Camber Haunch Girder WSDOT A-Dimension RevisionsДокумент8 страницCamber Haunch Girder WSDOT A-Dimension RevisionsMike2322Оценок пока нет

- Seismic Design Bridges For Rural Areas South East AsiaДокумент85 страницSeismic Design Bridges For Rural Areas South East AsiaMike2322Оценок пока нет

- Seismic Bridge Design Mitigation Outline Part 3Документ156 страницSeismic Bridge Design Mitigation Outline Part 3Mike2322Оценок пока нет

- Seismic Bridge Design Mitigation Outline Part 4Документ170 страницSeismic Bridge Design Mitigation Outline Part 4Mike2322Оценок пока нет

- Design Spectra Philippines Seismic Part 4Документ144 страницыDesign Spectra Philippines Seismic Part 4Mike2322Оценок пока нет

- MATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Документ195 страницMATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Mike2322Оценок пока нет

- Public Roads Vol 23 Issue 7Документ32 страницыPublic Roads Vol 23 Issue 7Mike2322Оценок пока нет

- Seismic Bridge Design Mitigation Outline Part 5Документ398 страницSeismic Bridge Design Mitigation Outline Part 5Mike2322Оценок пока нет

- Seismic Design of Bridges South East Asia Part 3Документ192 страницыSeismic Design of Bridges South East Asia Part 3Mike2322Оценок пока нет

- Mitigation of Seismic Disasters in Bridges Part 1Документ291 страницаMitigation of Seismic Disasters in Bridges Part 1Mike2322Оценок пока нет

- CompositeFloorSystems - ChienRitchie1984 Canada CISCДокумент171 страницаCompositeFloorSystems - ChienRitchie1984 Canada CISCMike2322Оценок пока нет

- Mitigation of Seismic Disasters in Bridges Part 1Документ466 страницMitigation of Seismic Disasters in Bridges Part 1Mike2322Оценок пока нет

- Seismic Design of Bridges South East Asia Part 1Документ173 страницыSeismic Design of Bridges South East Asia Part 1Mike2322Оценок пока нет

- ETL 1110-2-322 (1990) Retaining and Flood Walls (1 of 3) WMДокумент18 страницETL 1110-2-322 (1990) Retaining and Flood Walls (1 of 3) WMMike2322Оценок пока нет

- ETL 1110-2-322 (1990) Retaining and Flood Walls (2 of 3) WMДокумент18 страницETL 1110-2-322 (1990) Retaining and Flood Walls (2 of 3) WMMike2322Оценок пока нет

- Xu - Jian Gong - DissertationДокумент341 страницаXu - Jian Gong - DissertationMike2322Оценок пока нет

- AZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFДокумент76 страницAZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFMike2322Оценок пока нет

- Handbook PDFДокумент168 страницHandbook PDFrajan_2002eeeОценок пока нет

- JRC 2014 Crossing Paper 1Документ15 страницJRC 2014 Crossing Paper 1Pedro Henrry Marza ColqueОценок пока нет

- Infrarail 2018 BrochureДокумент4 страницыInfrarail 2018 BrochuresimsekekОценок пока нет

- Chainsaw Milling Summary ReportДокумент72 страницыChainsaw Milling Summary ReportJohn JohnsОценок пока нет

- 10 Ch7 DepotДокумент17 страниц10 Ch7 DepotSOMU_61Оценок пока нет

- Transportation and Planning Assignment#2: Department of Civil EngineeringДокумент11 страницTransportation and Planning Assignment#2: Department of Civil EngineeringALi niaziОценок пока нет

- Lucknow MetroДокумент581 страницаLucknow MetroAkash SahuОценок пока нет

- My It ReportДокумент64 страницыMy It ReportFrancis Victor100% (2)

- Axle Load KawasakiДокумент24 страницыAxle Load KawasakiSamir SharmaОценок пока нет

- Box PushingДокумент4 страницыBox PushingNArendra REddy100% (3)

- NDT of Rail Welds During The Construction of The Rapid Transportation System in KaohsiungДокумент7 страницNDT of Rail Welds During The Construction of The Rapid Transportation System in KaohsiungBenzhar TubieraОценок пока нет

- Permanent WayДокумент7 страницPermanent Wayaishwarya mundraОценок пока нет

- Skybus Tecnology: Bachelor of TechnologyДокумент21 страницаSkybus Tecnology: Bachelor of TechnologyAbhimanyu Singh Bhati100% (3)

- WeldComm Stair SpecДокумент16 страницWeldComm Stair Specsks_242Оценок пока нет

- CRN UnderbridgesДокумент49 страницCRN Underbridgestidus00_3Оценок пока нет