Академический Документы

Профессиональный Документы

Культура Документы

Commentary - 2017 - : Section/Article Description

Загружено:

Mike2322Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Commentary - 2017 - : Section/Article Description

Загружено:

Mike2322Авторское право:

Доступные форматы

7

Part 6

Commentary

— 2017 —

TABLE OF CONTENTS

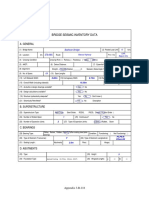

Section/Article Description Page

6.1 Materials Commentary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-2

6.1.1 Structural Grades of Lumber and Timber and Method of Their Derivation (2010) . . . . . . . . . . . . . . 7-6-2

6.1.3 Specifications for Engineered Wood Products (2017) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-2

6.1.4 Examples for Inquiry or Purchase Order (2010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-5

6.1.7 Specifications For Timber Bridge Ties (2017). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-5 1

6.2 Design Commentary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-6

6.2.2 General Features of Design (2016) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-6

6.2.3 Loads, Forces and Stresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-6

6.2.4 Designing for Engineered Wood Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-6

6.2.5 Notes on the Use of Stress-Graded Lumber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-8 3

6.3 Rating Commentary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-13

6.3.1 Rules for Rating Existing Wood Bridges and T restles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-13

6.4 Construction and Maintenance Commentary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-15

6.4.5 Driving Timber Piles (2017) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-15

6.4.6 Superstructure (2017). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-15

6.4.7 Support, Repair, Preserve, or Replace Damaged Portions of the Structure (2014) . . . . . . . . . . . . . . . 7-6-15

6.5 Inspection Commentary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-16

6.A1 Contemporary Designs and Design Aids Commentary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-16

6.A1.3 Pile Design Aids (2016) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-16

6.A1.6 Timber Trestle Details (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-16

LIST OF FIGURES

Figure Description Page

7-6-1 Chart Showing Relation of Design Stress to Duration of Load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-11

7-6-2 Typical Slope Cut Notches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6-13

© 2017, American Railway Engineering and Maintenance-of-Way Association 7-6-1

Timber Structures

LIST OF TABLES

Table Description Page

7-6-1 Derivation of listed values, using combination 16F-1.5E DF as an example . . . . . . . . . . . . . . . . . . . . . . . 7-6-12

SECTION 6.1 MATERIALS COMMENTARY

6.1.1 STRUCTURAL GRADES OF LUMBER AND TIMBER AND METHOD OF THEIR

DERIVATION (2010)

a. Lumber, including structural lumber, is the product of the saw and planing mill not further manufactured than by

sawing, resawing, passing lengthwise through a standard planing machine, cross cutting to length and working. After

the lumber is produced, it is necessary to inspect each piece individually to determine its grade. Lumber which is so

graded that working stresses can be assigned is called stress-graded or structural lumber.

b. Traditional design values for wood are based on testing of small clear samples; results summarized in ASTM D2555,

and are developed in accordance with ASTM D245 with reductions applied to account for various wood defects. For a

detailed explanation of the intial concepts see AREA Proceedings Vol. 30, 1929, pages 1206 to 1224. Starting in the

1980s, the coordinated Canadian and U.S. in-grade testing program started to develop properties based on full-sized

structural tests of members (Madsen) using proof loading concepts. At present there is a large database for dimension

lumber sizes in Douglas-fir-/Western Larch, Hem-Fir and Spruce-Pine-Fir. As in-grade testing is expanded to timber

sizes and other species, the values from this program will replace the results of tests done on small clear samples

adjusted for defects.

LUMBER INDUSTRY ABBREVIATIONS (2007)

a. The same as American Softwood Lumber Abbreviations, as approved by the American Lumber Standards Committee.

b. These standard lumber abbreviations are commonly used for softwood lumber, although all of them are not necessarily

applicable to all species. When used in the preparation or writing of contracts and other documents arising in

transactions of purchase and sale of American Softwood Standard Lumber, these abbreviations shall be construed as

provided therein.

NOMENCLATURE OF COMMERCIAL DOMESTIC HARDWOODS AND SOFTWOODS

(2007)

The standard commercial names for lumber cut from species or species groups of domestic hardwoods or softwoods are the

same as those used in the current standard grading rules for the species

6.1.3 SPECIFICATIONS FOR ENGINEERED WOOD PRODUCTS (2017)

6.1.3.1 Structural Glued Laminated Timber - Glulam

Glued laminated timbers (glulam) are manufactured by end jointing individual pieces of stress-graded lumber together with

rigid structural adhesives to create long lamination lengths. The laminations are then face bonded to create the desired

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-6-2 AREMA Manual for Railway Engineering

Commentary

member depth in accordance with layup specifications. The manufacturing standard for the glulam industry is America

National Standard - ANSI A190.1.

Chapter 7 Sections 1.3.1 and 2.4 are to be used in conjunction with railroad design practices and design methodology provided

in other sections of the chapter, and in conjunction with basic structural engineering equations. Glulam material properties to

be used for design are available primarily from industry technical trade associations. The values listed in Tables 7-2-7 and 7-2-

8 are traceable to association sources and the glulam section of the National Design Specification (NDS).

The glulam content in Chapter 7 has been heavily edited from building design and construction reference documents (such as

the NDS), to serve the needs of railroad bridge designers. Content in Sections 1.3.1 and 2.4 has been arranged to simplify use

of the material for design engineers that may not be familiar with glulam properties and recommended practices as they apply

to the use of glulam in railroad bridge applications. The primary need for editing glulam design reference tables and design

literature excerpts was to reduce the information by removing adjustment factors and design considerations commonly used in

building construction, but not applicable to railroad bridge design. Decisions on options for this simplification process were

guided primarily by committee members knowledgeable in railroad timber bridge design practices, input from glulam industry

members on Committee 7, and through contact with the glulam industry technical trade associations.

A number of modifications to basic glulam industry practice were included in this section to tailor the material for railroad

bridge structure applications. For this reason, direct comparisons with common glulam industry standards and specifications

will show differences.

6.1.3.1.1 General and Appearance

b. Appearance Classifications

1

Industry recommendations for finished appearance of glued laminated timber typically identify four classifications:

Premium, Architectural, Industrial and Framing. Framing and Industrial appearance classifications are shown.

Premium and Architectural appearance classifications are not applicable to railroad bridge applications.

It should be noted that appearance classifications are cosmetic in nature and do not affect the structural properties of

glulam members. 3

The glulam manufacturer should be contacted for details on Framing appearance classification.

Wane is not allowed for glued laminated timber members used in railway applications.

6.1.3.1.2 Layup Combinations

4

Layup combinations listed in the reference design property tables (Tables 7-2-7 and 7-2-8) have been limited to bending

"Stress Groups" that are most likely to be used for railroad bridge applications. Note that while both balanced and unbalanced

combinations are available in the respective stress groups, only balanced combinations are specified in Table 7-2-7 for the two

major species (Douglas-fir and Southern pine) used for railroad structures in North America. This is because only balanced

beams should be used in railroad applications where the top and bottom of the member are stressed in tension (see Article

6.1.3.1.3), or when the preservative treatments may make it difficult to distinguish the tension side.

A comprehensive list of all available layup combinations (for a variety of lumber species) is available from agencies, such as

APA - The Engineered Wood Association (http://www.apawood.org) or West Coast Lumber Inspection Bureau/American

Institute of Timber Construction (WCLIB/AITC, http://www.aitc-glulam.org) certifying glulam manufacturers.

Glulam members may also be supplied with all laminations of a single grade, from the desired species. Combinations for this

option are intended primarily for axial loading, such as columns. Combinations listed in Table 7-2-8 are for all one grade of

given species. All one-grade combinations are identified by number designations that identify specific lumber grade

categories within species groups.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-6-3

Timber Structures

Grade Requirements

Layup grade requirements may be achieved with the use of both visual and mechanically graded lumber sources in a variety of

species. Glulam manufacturers have the option to use alternate sources of lumber as long as species criteria are maintained in

layup grade requirements. Douglas-fir and Southern pine species are generally available in the United States, with Spruces

more common in Canada.

Manufacturing specifications for layup combinations are generally not needed by the designer. Glulam industry

manufacturing specifications are referenced in ANSI A190.1. Customized layup options are possible to meet specialized

design requirements within the scope of industry standards for glulam manufacture.

Bending Members

Bending members are typically specified on the basis of the maximum allowable bending stress and modulus of elasticity of

the member. For example, a 24F-1.8E designation indicates a member with an allowable bending stress of 2400 psi and a

MOE of 1,800,000 psi. This “stress class” may be produced in a variety of different species, each with the same properties

listed for the 24F-1.8E stress class. Table 7-2-7 is a simplified version of a stress class table listing only DF and SP balanced

combinations.

Glulam layup combinations are specified to provide the highest lumber grades in the zones of the member depth where

bending stresses are highest. Layup stress group combinations for members stressed primarily in bending are listed in Table 7-

2-7. Layup combinations may be provided based on selective grade zones through the member depth. However only

properties for balanced combinations are shown in Table 7-2-7.

6.1.3.1.3 Balanced Beams

Balanced beams should be used in railroad applications such as continuous stringers, where both the top and bottom of the

member are stressed in tension.

6.1.3.1.6 Finished Sizes

Finished sizes are provided for typical bridge stringers, deck panels and pile caps only. Other sizes are available.

Glulam can be manufactured in widths greater than 12-inch nominal widths through the use of laminations made up of

multiple-pieces of lumber. Specifications for special order members of this type should be negotiated directly with the glulam

manufacturer.

Multiple-piece laminations may be used to develop glulam members in widths greater than nominal lumber widths. Where

multiple-piece laminations are used, the allowable gap between laminations shall be limited to a maximum of 1/16 inch if a

gap-filling structural adhesive is specified. Otherwise, multiple-piece laminations to be used for pile cap applications shall be

edge-glued.

Typical Net Finished Glulam Deck Panels:

Depths (Thickness): 2-1/2 to 12-1/4-in. (hit & miss surfaces)

Widths: 45 to 52 in.

Lengths: 24 to 24 ft.

Other sizes may be supplied for specific applications as required.

Typical Net Finished Glulam Pile Caps:

Depth: 14 in., 16 in. or deeper as required

Width: 12 in. (hit & miss), 11-3/4 in. finished

Multiple-piece lams for 14 in., 16 in. or wider

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-6-4 AREMA Manual for Railway Engineering

Commentary

Length: Stock lengths up to 60 ft.

6.1.3.1.7 Preservative Treatments

In general, pressure preservative treatment processes commonly used for glulam do not affect the strength properties of glued

laminated timbers. Information on the possible effects of specific treatment is available through the AWPA or the treatment

provider.

Waterborne Treatments

Waterborne treatments are typically applied to lumber prior to the laminating process. Waterborne treatments applied to

glulam after the laminating process can cause dimensional changes such as warping, and twisting, in addition to excessive

checking as the result of the necessary re-drying process.

6.1.3.1.9 Certification, Wrapping and Shipping

Glulam members may be supplied in virtually any length, limited only by treating facilities, shipping routes and jobsite

handling capabilities. Glulam members to be pressure-treated with preservatives after manufacture may be supplied without

cover depending on conditions, or load wrapped as needed. If wrapping is to be specified for environmental protection or for

other reasons, members may be supplied either load wrapped, bundle wrapped or individually wrapped.

6.1.3.1.10 Storage and Handling

Seasoning checks in glulam members may be excessive if members are stored flat and placed unprotected in an environment

where changes in the relative moisture content of members is forced to change rapidly.

1

6.1.4 EXAMPLES FOR INQUIRY OR PURCHASE ORDER (2010)

Example 1: 30,000 fbm 2 x 8 x 12 feet, S4S, Select Structural joist and plank, Bald Cypress, Grading for structural Cypress,

Southern Pine Inspection Bureau (SPIB).

3

Example 2: 120 pieces 3 x 12 x 20 feet, S4S, selected structural joists and planks, Douglas-fir, coast region, in accordance

with Paragraph 123(a) Standard No. 17, Grading Rules for West Coast Lumber issued by West Coast Lumber Inspection

Bureau, except to have 90% heartwood.

Example 3: 48 pieces 2 x 12 x 12 feet, rough, dense select structural, Southern Yellow Pine, in accordance with Paragraph

401.1 of Southern Pine Inspection Bureau’s Grading Rules, except to be free of wane.

4

6.1.7 SPECIFICATIONS FOR TIMBER BRIDGE TIES (2017)

6.1.7.8 Bridge Tie Installation (2017)

6.1.7.8.1 Bridge Tie Spacing and Spacers

c. The end and edge distance for dowel type connections as per the National Design Specification for Wood Construction

(NDS) are based on the direction of load. The loaded edge distance perpendicular to grain is 4d, where d is the

diameter of the shank of the dowel type fastener. The loaded end distance parallel to grain is 7d for softwoods, and 5d

for hardwoods. The following lead holes sizes are specified in the NDS for bolts, drift pins and lag screws. Lead holes

for bolts shall be a minimum of 1/32” (1 mm) to a maximum of 1/16” (2 mm) greater than the bolt shank diameter. The

lead hole for the shank portion of lag screws shall equal the shank diameter. The lead hole for the threaded portion shall

have a diameter equal to 65% to 85% of the shank diameter in wood with G > 0.6, 60% to 75% in wood with 0.5 < G ≤

0.6, and 40% to 70% in wood with G ≤ 0.5 and a length equal to at least the length of the threaded portion of the lag

screw. This lead hole total length equals the sum of the shank lead hole length and the threaded portion lead hole

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-6-5

Timber Structures

length. The NDS goes on to say the larger diameter in each range shall apply to lag screws of greater diameters. Lead

holes for drift pins shall be 0” to 1/32” (1 mm) smaller than the actual pin diameter. The likelihood of wood splitting is

affected by specific gravity, moisture content, lead hole diameter and end distance. If there is no lead hole or too small

a diameter lead hole in the tie then there is a very strong possibility that the tie will split at the end due to shrinkage

stresses at the specified end and edge distances discussed above. See Table 7-2-5 for values of G (Specific Gravity).

SECTION 6.2 DESIGN COMMENTARY

6.2.2 GENERAL FEATURES OF DESIGN (2016)

6.2.2.3 Stringers (2009)

An approximate analysis to determine the division of rail load to several stringers is given in the chart, Figure 7-A1-1, in

Appendix 1 - Contemporary Designs and Design Aids.

6.2.2.5.1 Tie Spacers, Guard Timbers and Guard Rails

In the past, spacer timbers and guard timbers were terms used interchangeably. With the use of metal strap timber spacers,

which do not function as guards, the need to differentiate between tie spacers and guard timbers became apparent (see Chapter

7 Glossary).

Metal fastenings between timber tie spacers and ties are more effective than dapping of spacer timbers, because of the

tendency of the wood to split off between daps.

Steel rail guard rails have been used in the past on the field side of the running rail but this is not considered recommended

practice in the industry.

6.2.3 LOADS, FORCES AND STRESSES

6.2.3.6 Longitudinal Force (2013)

d. Since longitudinal bracing in timber trestles is essentially there to provide L/d stability and geometrical constraint, the

longitudinal forces are transferred through the stringer and deck system with some help from the rails in proportion to

their axial stiffness. Where stringers are discontinuous, the load is likely transferred through the dowels to the cap and

back to the next set of stringers. This load path needs to be adequate to do this.

Traditionally this has been accomplished by the use of earth fill or similar fire barriers at 400-foot intervals but with the

addition of Articles 2.3.6.b, c and d it is necessary to include this limitation, as some of these fire details would not

transmit any appreciable force.

6.2.3.9 Deflection (2013)

The cases listed in the tables in Appendix 1 meet this criteria provided permanent set is not an issue.

6.2.4 DESIGNING FOR ENGINEERED WOOD PRODUCTS

6.2.4.1 Design Values for Glued Laminated Timber (Glulam) (2006)

Methods used to establish glulam design properties take into account basic lumber properties. Lumber properties published by

the grading agencies for Douglas-fir and Southern pine are derived from standard practices provided in ASTM D245 in

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-6-6 AREMA Manual for Railway Engineering

Commentary

conjunction with clear wood properties published in ASTM D2555. Basic lumber grade characteristics are adapted to a glulam

beam design modeling method described in ASTM D3737 to establish glulam beam properties for the various layup

"combinations" listed in Tables 7-2-7 and 7-2-8. Railroad bridge design applications require the use of basic structural

engineering principles and design equations in conjunction with published glulam allowable stresses.

6.2.4.1.1 Allowable Stresses

The National Design Specification (NDS) provides an "equation format" that may be used with the specialized equations and

loading requirements specified in the AREMA Manual for Railway Engineering for design of bridge structures. Design

methodology for connections is also included in the NDS. The allowable stresses included in Tables 7-2-7 and 7-2-8 may be

used directly for glulam bridge design. Appropriate stress adjustment factors for typical railroad bridge applications described

in the NDS and glulam industry design publications have been applied to these table values to simplify use of the values in

basic engineering equations.

Glulam beams are "engineered" to optimize grade characteristics of the lumber used to make the product. The highest

lamination grades are used in the outer zones of the beam depth. The X-X, Y-Y and Axial orientations are defined here to

explain the use of these terms as they are used in glulam product design.

Fasteners: The design methodology provided in Section 2.4 is applicable to glulam products. In addition, the information

provided in the NDS for fasteners in solid sawn members is applicable for glulam design. Fastener capacities for withdrawal,

single shear, double shear, and fastener group patterns in glulam members are controlled by wood species and the specific

gravity within species groups. Specific gravity values to be used with the stress groups listed in Tables 7-2-7 and 7-2-8 are

provided.

6.2.4.1.2 Tabular Design Values

1

See Appendix 1 - Contemporary Designs and Design Aids.

6.2.4.1.3 Adjustment Factors

Adjustment factors for wet-use, cyclic loading and the RR Use as defined in this section have been applied to the appropriate 3

values in Tables 7-2-7 and 7-2-8. Other factors that may be considered have been included in Table 7-2-3. In cases where

factors are not applicable, "none" is entered in the table. If adjustment for a given condition may be considered, but has been

judged to be not necessary for glulam applications, a value of 1.0 is noted in the table. For example the Beam Stability factor

CL is 1.0 when the compression side of a bending member is supported throughout its length, and the ends at points of bearing

have lateral support to prevent rotation.

Temperature effects (CT) are reversible for normal day/night cycles even in climates where daytime temperatures may be 4

extreme. The US Forest Service Handbook No. 72 indicates that potential temporary strength reductions due to temperatures

above 120oF will be offset by low member moisture content common to arid climates. The depth of heat penetration in given

members must also be recognized when considering the possible effect of temporary (daily) exposure to high temperatures on

beam properties. The Railroad Use Factor as defined for use in Chapter 7 is a duration of load adjustment not applicable to the

glulam shear stress values listed in Tables 7-2-7 and 7-2-8 since a compensating adjustment to account for cyclic loading has

already been applied by glulam industry standard recommendations. A factor of 0.72 has been applied to the listed values to

account for possible cyclic loading effects. The base value for glulam shear (prior to adjustment) is derived from full-scale

beam test results using static loading. Base shear values used in Tables 7-2-7 and 7-2-8, prior to application of the wet use

factor, are 265 psi for Douglas-fir and 300 psi for southern pine. This base value is higher than values originally derived from

small sample blocks shear tests and ASTM D245 adjustment factors.

Design shear stresses may also require adjustment to account for seasoning checks when they are expected to exceed 15% of

the member width in high shear zones --center half of the depth, in the end fourths of the member length, and mid depth over

intermediate supports. Technical Notes on the evaluation of checking in glued laminated timbers are available from industry

trade associations.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-6-7

Timber Structures

The KcE factor to be used in the column stability equation (shown as 0.418 for glulam), is related to stiffness COV (Coefficient

of Variation), and varies between products. The COV for glulam Modulus of Elasticity is assumed to be 10% for members

with 6 or more laminations.

Glued laminated timer members manufactured with wane lumber are not permitted for use in railway applications. Wane

lumber will affect the shear strength of structural glued laminated timber under repeated loading in railway structures and

voids may hold water, which could result in favorable conditions for decay.

6.2.4.2 Design Equations (2014)

In addition to basic structural design principles, the use of specialized design procedures and assumptions to account for

loading conditions unique to railroad bridge structures, as presented in Section 2.5, may be applied for glulam design in

conjunction with stresses listed in Tables 7-2-7 and 7-2-8.

Tables 7-2-7 and 7-2-8: To simplify use of these tables, basic adjustment factors that are to be applied generally for railroad

bridge applications have been applied to the respective values listed in the tables (see Article 6.2.4.1.3).

6.2.5 NOTES ON THE USE OF STRESS-GRADED LUMBER

6.2.5.1 Working Unit Stresses (1988)

Introduction

To make the most effective and efficient use of any material the designer should be familiar with the characteristics of that

material. In the following, the important characteristics which affect the strength of lumber are discussed briefly. Other

characteristics, such as durability, resistance to splitting, resistance to wear, hardness, holding power of nails, finishing

characteristics, etc., are not discussed, although they may be important and must not be overlooked.

Basic Stress

The term “basic stress” is used to denote the allowable working stress for lumber which is unchecked, straight grained, and

clear, and which will be subject to maximum load for a long time and will be saturated all of the time. The basic stress is not a

working stress for any commercial grade. It must be modified for the grade of the lumber and for actual loading and moisture

conditions to obtain working unit stresses. For basic stresses and for the quantitative effect of lumber characteristics on

strength, see the Wood Handbook. The stresses given in Table 7-2-9 take into account the characteristics permitted in the

grading rules.

Knots and Holes

The distortion of the grain around a knot causes stresses across the grain which limit the allowable stress in tension and

compression parallel to grain for fully intergrown knots the same as for loose knots and knot holes. The effect of knots and

knot holes on compression perpendicular to the grain and on shear stress may ordinarily be disregarded. Holes from other

causes, such as bored holes, have approximately the same effect as knots. If there are many holes or large holes or grooves

made in the lumber during fabrication and erection, their effect on stress should not be disregarded.

Slope of Grain

Lumber is much stronger in both tension and compression along the grain than in any other direction, and since in a straight

beam or post there will be a component of stress across the grain whenever the grain is not parallel to the axis of the beam or

post, it is necessary to limit slope of grain. Ordinarily, grading rules limit the slope of grain throughout the length of posts, but

only in the middle half of beams and joists, on the assumption that the slope of grain near the ends will not be much greater

than the slope in the central part. If a beam or joist is to be used for continuous spans or a tension member, the slope of grain

should be further limited (see Note 8, Table 7-2-9). Since the allowable slope of grain for posts is somewhat greater than for

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-6-8 AREMA Manual for Railway Engineering

Commentary

beams and joists, it is not considered necessary to limit specifically the slope of grain near the ends of beams or joists which

are to be used as posts.

Pitch and Gum Pockets, Seams and Streaks

The effect of pitch or gum on the strength of wood may be disregarded, although it is sometimes associated with pockets or

seams where the absence of wood may affect the strength.

Wane

Wane is permitted in most structural grades. Its effect on the strength of the piece in bending or compression parallel to grain is

not great. Wane at a point of bearing perpendicular to grain has a proportional effect on bearing stress and, in addition, may

cause eccentricity of load or support. Where bearing stresses are high or eccentricity is objectionable, the structure can be

designed so that the wane will be removed in framing or the lumber can be ordered “to be free of wane.”

Density

Density has a large effect on the strength of lumber. For a few species a visual inspection method has been developed which

will separate the lumber into two density classifications, but there is considerable overlap of actual densities in the two

classifications. If a more accurate method of density segregation, economically applicable to commercial production, could be

devised, a large increase in allowable stress could be made for most lumber.

Warp, Cup, Bow

Warp, cup and bow may cause eccentricity of loading and torsional stresses and difficulties in framing. For ordinary

1

construction the stresses produced can be disregarded if the member is straight enough for easy framing.

Checks, Splits, Shakes

Some grading rules limit checks, splits and shakes throughout the length of structural lumber because of their effect on hazard

of decay, appearance, etc., and these considerations are the primary ones in post grades. In beams and joists the checks, splits 3

and shakes within the middle half of the height of the piece within a distance from each end equal to three times the height of

the piece are limited because of their effect on shear stresses. Outside of these limits checks, splits or shakes large enough to

cause a shear failure are unlikely.

Mismanufacture

Mismanufacture affects framing primarily. If the strength of the pieces is based on the smallest size permitted, mismanufacture 4

may be disregarded.

Moisture Content

a. The strength of lumber in tension, compression and shear is a function of the moisture content at the time and is

practically independent of its previous condition. However, changes in moisture content produce checks, and enlarge

checks and splits already present. The amount of checking will increase with an increase in the size of the piece and

will vary with the method of seasoning and exposure to weather. In Table 7-2-9, assume the lumber has not become

more severely checked, because of improper seasoning or severe exposure to weather, than contemplated by the

grading rules.

b. Under most conditions lumber which has been installed when green or saturated will dry out in service, and prolonged

exposure to moisture will be required to raise the moisture content very much. Lumber of joist and plank sizes and

larger which is not submerged or framed to retain moisture will not acquire much moisture content in exposure to usual

weather most places in the United States. Some contact surfaces, such as the bearing between stringers and caps of

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-6-9

Timber Structures

railway trestles, are conducive to the retention of moisture, and at such surfaces it is recommended that the stresses be

limited to those applicable to green or saturated lumber.

c. Good timber preservatives do not affect the strength-moisture content relations.

Decay

Decay weakens wood. The decrease in strength may be very marked when the decay is barely perceptible, and since decay

may spread rapidly, infected structural members should be inspected frequently until replaced. It is common practice to reduce

the allowable stresses for untreated lumber subject to decay hazard to offset loss of strength due to undetected decay. Such

reductions should not be relied on to compensate for loss of strength due to known decay. Good preservatives can protect

wood against decay for many years, and if applied by modern treating processes, properly conducted, the damage to the wood

by the treating process may be disregarded.

Duration of Load

The allowable load varies with the length of time the load is applied. Figure 7-6-1 shows graphically the approximate relation

of allowable stress to time. If the load is removed before failure is reached, there will be some recovery, but so little is known

about the amount of recovery that it should be disregarded, and the duration of load should be figured as the sum of all the

lengths of time that the load is applied. If lumber is subjected to several different loads with different durations, each

combination should be investigated, and if each alone is safe the lumber may be considered safe.

T emperature, Heat

The stresses recommended in Table 7-2-9, and the provisions in these notes on the use of stress-graded lumber assume the

lumber is to be used under ordinary conditions of temperature. If abnormal temperatures are anticipated, the designer should

refer to the U.S. Forest Laboratory Report No. R 471, Effect of Heat on the Properties and Serviceability of Wood.

6.2.5.6 Allowable Unit Stresses for Stress-Graded Lumber (2012)

6.2.5.6.1 Working Stresses

Table 7-6-1, Note 4: Inland Douglas-fir and Douglas-fir-/Western Larch are deemed to be refractory and hence very difficult to

treat. Douglas-fir South is not produced in sufficient quantities and is somewhat weaker; its suitability for Timber Railroad

Bridges is questionable.

The grades Dense Structural 86, 72 & 65 for Southern Yellow Pine are no longer included in Table 7-2-9 because the Southern

Pine Inspection Bureau (SPIB) has indicated that none of their members currently supply timbers meeting these grades as

published in the SPIB Special Product Rules. The last printing of the Special Product Rules was October 15, 1991.

The current Design tables in this Chapter for Sawn wood are in part based on tests on full-scale Douglas-fir and Southern

Yellow Pine timber stringers conducted at Texas A & M University (References 1, 16).

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-6-10 AREMA Manual for Railway Engineering

Commentary

Figure 7-6-1. Chart Showing Relation of Design Stress to Duration of Load

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-6-11

Timber Structures

Table 7-6-1. Derivation of listed values, using combination 16F-1.5E DF as an example

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-6-12 AREMA Manual for Railway Engineering

Commentary

6.2.5.10 Notched Beams (2016)

If notches are not slope cut there is a significant amount of tension perpendicular to grain stress development caused by

differential stiffness between the notched and the non-notched sections. Wood is anisotropic and its strength in the

perpendicular to grain direction, typically found in the notch zone in beams in bending, is very weak. The deeper the notch, the

higher the peeling stress that develops. The higher the stress in relation to the capacity of the element, the higher the peeling

stresses as well. Effectively, it is a deflection based stress caused by differential stiffness where the smaller the radius of

curvature of flexure in the element the greater the notch reentrant corner crack potential. Any slope for the notch is better than

a 90 degree angle with 1:6 being acceptable to reduce the stress in tension perpendicular to grain and reduce the potential for

reentrant corner cracking.

It is recommended that the notch is slope cut at 1:6 minimum to reduce the potential for reentrant corner splits and to improve

longevity of the element. To improve longevity in the element, the length of the notch into the span should be kept to a

minimum and limited to 8” maximum as shown in Figure 7-6-2 (below).

4

Figure 7-6-2. Typical Slope Cut Notches

SECTION 6.3 RATING COMMENTARY

6.3.1 RULES FOR RATING EXISTING WOOD BRIDGES AND TRESTLES

6.3.1.3 Carrying Capacity (2013)

a. There are many factors affecting the strength of lumber for which no satisfactory, commercially applicable methods of

evaluating the effects have been found. These factors produce a variability among pieces which otherwise seem to be

alike. Since the allowable stresses of Table 7-2-9 are based on the strength of the weakest pieces that may occur in the

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-6-13

Timber Structures

grade and assume that each piece must carry its load, it follows that if a load is carried by several members, not

independent of each other, the designer could reasonably allow somewhat higher stresses. Conversely, if the failure of

a single member would cause unusually great damage, the allowable stress on that member should be reduced. An

overload of 50 percent will cause failure in only rare cases, but if the load is doubled, failures will be frequent.

b. To be considered stable the structure must be able to safely transfer all loads from point of application to the ground or

suitable substructure in a manner that ensures the integrity and geometry of the structure.

6.3.1.4 Inspection (2013)

h. With regards to stability of bents:

• Bents should not be out-of-plumb by more than 1 inch in 4 feet, in the direction of the track without evaluation.

• Out of plumb bents should be straightened as much as possible without damaging the bent, and/or additional bracing

or struts added, and bolts tightened. If this repair does not hold for any appreciable time (6 to 12 months), then the

bent should be considered for additional strengthening or re-construction.

• If the problem is known to be purely a ground condition, then ground stabilization measures should be considered.

6.3.1.14 Unit Stresses (2017)

a. The decision to use all or any of the stresses for rating that exceed the design allowable stresses should be made by the

Engineer considering the effect of the increased stresses on the desired longevity of the structure being rated.

c. This paragraph is meant for Railroad owners who have the personnel and control over operations to meet the

conditions listed in the paragraph. Applying this paragraph will reduce component life. It is not common practice to

apply Article 3.1.14.c unless the rating is done by a person very well versed in timber rating and inspection (at least 4+

years of experience in tactile timber inspection and rating). If the person doing the rating is relying on other inspectors

and has any doubt in how the inspection was performed or to the condition of the timber; not applying Article 3.1.14.c

is the appropriate engineering judgment.

h. If wane is found during a tactile inspection of glued laminated wood beams, the following reduction factors should be

applied to the unit shear stress of an element when calculating shear capacity; 0.83 for wane one side and 0.67 for wane

both sides.

Wane is allowed in glued laminated wood beams as per the ANSI A190.1 Standard for Wood Products-Structural

Glued Laminated Timber (ANSI A190.1 – 2012) and APA ICC- ES Evaluation Report ESR-1940 (January 2016)

Glued-Laminated Timber Combinations and The GAP2006 Computer Program. This allowance applies to glued

laminated wood beams used in dry conditions. Dry conditions are defined as ambient conditions that cause wood, a

hygroscopic material, to equilibrate at a moisture content of 16-19% or lower. The threshold for moisture content is

different depending on whether full beam members are being considered or connections respectively. Due to this factor

wane may be found in railway bridge glulam beams. Wane is allowed in the following combinations as per the two

standards cited above; 24F-V4 SP/SP as per the ANSI A117 standard and EWS 24F-V4M1 DF/DF, EWS 24F-V4M2

DF/DF, EWS 24F-V8M1 DF/DF (balanced layup), EWS 24F-V8M2 DF/DF (balanced layup), EWS 16F-V5M1 SP/SP

(balanced layup), EWS 24F-V3M1 SP/SP, EWS 24F-V3M2 SP/SP, EWS 24F-V5M2 SP/SP (balanced), EWS 24F-

V5M3 SP/SP (balanced), EWS 26F-V3M1 SP/SP, EWS 26F-V3M2 SP/SP, EWS 26F-V4M1 SP/SP (balanced), EWS

26F-V4M2 SP/SP (balanced). In the EWS 24F-V3M1 SP/SP, EWS 24F-V5M2 SP/SP (balanced), EWS 26F-V3M1

SP/SP, EWS 26F-V4M1 SP/SP (balanced) layups, there is no wane allowed in the center 40% of the depth during

manufacturing and therefore there is no reduction factor required. Since layup combinations contained within each

stress group shown in Tables 7-2-7 may contain combinations that do now allow wane the specific combination being

inspected must be established to ascertain whether the unit shear stresses contained in the table apply to the

combination and subsequent application of reduction factors is proper. Table 7-2-8 combinations do not allow wane.

The maximum wane allowed can be up to 1/6th the width of the interior laminations on each side.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-6-14 AREMA Manual for Railway Engineering

Commentary

Wane that is ¼” (6mm) across the wide face of the lamination is commonly called pencil wane, which is allowed

without any reduction in unit shear design values.

SECTION 6.4 CONSTRUCTION AND MAINTENANCE COMMENTARY

6.4.5 DRIVING TIMBER PILES (2017)

6.4.5.2.8.5 Bracing

Care should be taken so that spike-grids or other shear connectors do not penetrate beyond the depth of preservative treatment.

6.4.6 SUPERSTRUCTURE (2017)

6.4.6.1 Open Deck Bridges (2016)

6.4.6.1.2 Lining and Gauging

a. Prior to deck installation, verify condition of the rail. If the rail shows significant signs of wear, it may be necessary to

replace the rail prior to deck installation.

b. Identify the running rail, and start by lining it. Gauge the rail accordingly. 1

6.4.6.2 Ballast Deck Bridges (2017)

6.4.6.2.1 Decks on Timber Bridges

b. Deviations over 1-1/2 inches between centerline of bridge and track may result in the overstressing of the stringer load

carrying capacity for certain track speeds. Depending on the track speed and loading of bridge, it will be up to the

3

Railroad Bridge Engineer to determine the acceptable deviation between centerline of bridge and track for the

structure.

6.4.6.2.2 Ballast Depth

a. Recommendation of six (6) inch minimum is based on some former standards and practices. For new construction and 4

design, see Part 2, Design of Wood Railway Bridges and Trestles for Railway Loading.

6.4.6.4 Walkways

a. Single walkways can be installed on the downstream side of the bridge for access for drift removal or consistently on

the same side of the bridge(s) in-line to allow train crew to inspect train. Other factors may include location of

switches, derails, curves, wayside detectors, and general terrain.

6.4.7 SUPPORT, REPAIR, PRESERVE, OR REPLACE DAMAGED PORTIONS OF THE

STRUCTURE (2014)

6.4.7.2 Field Application of Preservative Chemicals (2014)

a. Liquids are brushed, squirted or sprayed on the surface and may be injected into timber.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 7-6-15

Timber Structures

b. Semi-solids, greases or pastes are spread on the affected area. They are mostly used in ground line applications or

treating fresh cuts.

c. Fumigants are normally injected into the wood. They originally are liquid and volatilize, creating a gas which

permeates wood cells inhibiting decay.

d. Plugs or pastes containing salts, which, when combined with moisture release an active ingredient which permeates

wood cells inhibiting decay.

SECTION 6.5 INSPECTION COMMENTARY

6.5.2.1 Identification

b. The Global Position System (GPS) location point(s) used for identification may be taken at the location on the bridge

as designated by the Engineer such as either or both bridge ends, channel span, piers or other applicable locations.

SECTION 6.A1 CONTEMPORARY DESIGNS AND DESIGN AIDS COMMENTARY

6.A1.3 PILE DESIGN AIDS (2016)

The procedure to use the Method of Consistent Deformations to determine pile load distributions was first introduced into the

A.R.E.A. manual in 1942. In 1943, the procedure was augmented to include transverse deformation of the cap in contact with

the pile and also shear deformation of the cap. In doing so, a few additional assumptions and material properties were required.

For timber members, neither the behavioral assumptions nor the material properties required (G and Et) improve the estimate

of pile load distribution. In fact, the outcome is a slight increase in the load apparently taken up by remote pile and a decrease

in load taken by near-rail pile. In addition, use of the 1943 procedures creates a difficulty when considering concrete or steel

caps. Neglecting the 1943 additions simplifies the form of the required calculations, generalizes the procedure to be valid for

alternative-material caps, and slightly changes the load distribution outcomes by less than 2% and in conservative direction for

the piles receiving the highest loads.

6.A1.6 TIMBER TRESTLE DETAILS (2015)

Figure 7-A1-26. The positives and negatives of a number of details going back to the 1930s from various railroads were

reviewed. There are several other good options, but the two details shown were determined to be the most suitable for E80

loading and current timber quality. The main objectives are to reduce water ingress while ensuring a good connection. The

locations of the bolts with respect to the rail, guard timbers, piles, and ties must be considered in the use of these connection

details.

© 2017, American Railway Engineering and Maintenance-of-Way Association

7-6-16 AREMA Manual for Railway Engineering

Вам также может понравиться

- AREMA MRE 2013 TOC-Vol2 Ch7 PDFДокумент2 страницыAREMA MRE 2013 TOC-Vol2 Ch7 PDFalaajabbar0% (1)

- 2 07P02 PDFДокумент42 страницы2 07P02 PDFMike2322Оценок пока нет

- Basic Research and Technologies for Two-Stage-to-Orbit Vehicles: Final Report of the Collaborative Research Centres 253, 255 and 259От EverandBasic Research and Technologies for Two-Stage-to-Orbit Vehicles: Final Report of the Collaborative Research Centres 253, 255 and 259Оценок пока нет

- AREMA MRE 2011 TOC-Vol2 Ch7Документ2 страницыAREMA MRE 2011 TOC-Vol2 Ch7Timbo6808Оценок пока нет

- AREMA MRE 2013 Volume 2 PDFДокумент1 634 страницыAREMA MRE 2013 Volume 2 PDFCESAR DANIEL ALVARADO CALDERON0% (1)

- 01-Arema Mre 2012 Volume 2Документ1 596 страниц01-Arema Mre 2012 Volume 2roberto floresОценок пока нет

- Statistics and Probability for Engineering ApplicationsОт EverandStatistics and Probability for Engineering ApplicationsРейтинг: 5 из 5 звезд5/5 (1)

- 2 07P01 PDFДокумент28 страниц2 07P01 PDFMike2322Оценок пока нет

- Wood I JoistДокумент40 страницWood I Joistlchavez04Оценок пока нет

- Greening Your Home: Sustainable Options for Every System In Your HouseОт EverandGreening Your Home: Sustainable Options for Every System In Your HouseРейтинг: 4 из 5 звезд4/5 (1)

- AREMA MRE 2010 Volume 2 PDFДокумент1 542 страницыAREMA MRE 2010 Volume 2 PDFDianaslashОценок пока нет

- Misturas Betuminosas SatccДокумент157 страницMisturas Betuminosas SatccHelio PedroОценок пока нет

- FinFET Modeling for IC Simulation and Design: Using the BSIM-CMG StandardОт EverandFinFET Modeling for IC Simulation and Design: Using the BSIM-CMG StandardРейтинг: 5 из 5 звезд5/5 (1)

- Fdot Modifications To LRFD Specifications For Structural Supports For Highway Signs, Luminaires and Traffic Signals (Lrfdlts-1)Документ26 страницFdot Modifications To LRFD Specifications For Structural Supports For Highway Signs, Luminaires and Traffic Signals (Lrfdlts-1)kayshephОценок пока нет

- Fdot Modifications To LRFD Specifications For Structural Supports For Highway Signs, Luminaires and Traffic Signals (Lrfdlts-1)Документ28 страницFdot Modifications To LRFD Specifications For Structural Supports For Highway Signs, Luminaires and Traffic Signals (Lrfdlts-1)Luis S Alvarez JrОценок пока нет

- Aesthetic Guidelines For Bridge DesignДокумент89 страницAesthetic Guidelines For Bridge DesignMai Hà ThanhОценок пока нет

- Manual For The Design of Hollowcore SlabsДокумент45 страницManual For The Design of Hollowcore SlabsReaksmey Soeurt100% (1)

- ANSI 117-2020 Standard Specification For Structural Glued Laminated Timber of Softwood Species PDFДокумент75 страницANSI 117-2020 Standard Specification For Structural Glued Laminated Timber of Softwood Species PDFAbdurrahman CinarОценок пока нет

- 2 09P01 PDFДокумент54 страницы2 09P01 PDFMike2322Оценок пока нет

- Geotechnical Design Manual: Oregon Department of TransportationДокумент60 страницGeotechnical Design Manual: Oregon Department of Transportationradespino1Оценок пока нет

- Pre Stressed Concrete (PSC) Girder Superstructure Bridge-SiДокумент316 страницPre Stressed Concrete (PSC) Girder Superstructure Bridge-SiWilfredo Salgado0% (1)

- Design of Monosymmetric Plate and Box GirdersДокумент55 страницDesign of Monosymmetric Plate and Box GirdersLệnh BùiОценок пока нет

- Asme b169 2018pdf CompressДокумент41 страницаAsme b169 2018pdf Compressandrea8bianchettoОценок пока нет

- ASME B16.11-2021 Forged Fittings, Socket-Welding and ThreadedДокумент34 страницыASME B16.11-2021 Forged Fittings, Socket-Welding and ThreadedCristhian Portocarrero100% (4)

- Repair and Rehabilitation of Concrete Structures - 2017 - : Section/Article DescriptionДокумент34 страницыRepair and Rehabilitation of Concrete Structures - 2017 - : Section/Article DescriptionMike2322Оценок пока нет

- Geotechnical Design Manual: Oregon Department of TransportationДокумент60 страницGeotechnical Design Manual: Oregon Department of TransportationMYosef MTsegayeОценок пока нет

- ADAPT-Builder 2019 Tutorial - Single-Level Two-Way SlabДокумент188 страницADAPT-Builder 2019 Tutorial - Single-Level Two-Way Slabephrem100% (1)

- Bridge DesignДокумент153 страницыBridge DesignAbraham MukokandukuОценок пока нет

- Chapter 7 Substructure Design: WSDOT Bridge Design Manual M 23-50.13 Page 7-I February 2014Документ124 страницыChapter 7 Substructure Design: WSDOT Bridge Design Manual M 23-50.13 Page 7-I February 2014Alyana CalagosОценок пока нет

- ORSDM Chapter 7 Energy DissipatorsДокумент40 страницORSDM Chapter 7 Energy DissipatorsblОценок пока нет

- Code of Practice BridgeДокумент154 страницыCode of Practice BridgeNkosikhona GcabasheОценок пока нет

- PCI Hollow Core Manual 2nd EdДокумент142 страницыPCI Hollow Core Manual 2nd EdRosalio AcostaОценок пока нет

- Buettner, Becker - PCI Manual For The Design of Hollow Core Slabs (2000)Документ141 страницаBuettner, Becker - PCI Manual For The Design of Hollow Core Slabs (2000)DavorPijavicaОценок пока нет

- FDOT Structural DetailingДокумент329 страницFDOT Structural DetailingboyzesОценок пока нет

- Pavement Manual: Revised October 2019Документ480 страницPavement Manual: Revised October 2019emeterioОценок пока нет

- Seismic Design Guide: For Metal Building SystemsДокумент6 страницSeismic Design Guide: For Metal Building Systemsvictor50% (4)

- Transportation Design ManualДокумент19 страницTransportation Design ManualoppppsОценок пока нет

- Chapter 7 Substructure Design: WSDOT Bridge Design Manual M 23-50.16 Page 7-I June 2016Документ215 страницChapter 7 Substructure Design: WSDOT Bridge Design Manual M 23-50.16 Page 7-I June 2016Min Min IIОценок пока нет

- Bridge Design Manual (LRFD) : M 23-50.12 August 2012Документ1 332 страницыBridge Design Manual (LRFD) : M 23-50.12 August 2012Hector GuillenОценок пока нет

- AASHTO Bridge Design Manual (LFRD)Документ1 312 страницAASHTO Bridge Design Manual (LFRD)Ali Öztürk0% (1)

- Bridge Design Manual - LRFD: Revised October 2015Документ87 страницBridge Design Manual - LRFD: Revised October 2015KOLKIN HINOОценок пока нет

- Bridge Design Manual - LRFD: Revised October 2015Документ87 страницBridge Design Manual - LRFD: Revised October 2015KOLKIN HINOОценок пока нет

- NL Modeling and Analysis of RC Buildings Using ETABSДокумент129 страницNL Modeling and Analysis of RC Buildings Using ETABSabuzeinah100% (1)

- Chapter7 Substructure Design PDFДокумент132 страницыChapter7 Substructure Design PDFvsballaОценок пока нет

- Pav Man Texas 2018Документ480 страницPav Man Texas 2018Helio de AlmeidaОценок пока нет

- tm5 822 13Документ50 страницtm5 822 13Tin Aung KyiОценок пока нет

- 2018 KCI Traffic Planning ReportДокумент84 страницы2018 KCI Traffic Planning ReportThe Kansas City StarОценок пока нет

- Design of Steel Lighting System Support Pole StructuresДокумент81 страницаDesign of Steel Lighting System Support Pole StructuresyeeahinОценок пока нет

- Bridge Design Manual M 23-50.06 July 2011Документ1 316 страницBridge Design Manual M 23-50.06 July 2011monolith80Оценок пока нет

- Arema Mre Chapter 6 2019Документ3 страницыArema Mre Chapter 6 2019Septrum0% (1)

- AAPA IG6 Selection and Design of Flexible Pavements ReducedДокумент68 страницAAPA IG6 Selection and Design of Flexible Pavements Reducedrefika ivan0% (1)

- Camber Haunch Girder WSDOT A-Dimension RevisionsДокумент8 страницCamber Haunch Girder WSDOT A-Dimension RevisionsMike2322Оценок пока нет

- AASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Документ8 страницAASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Mike2322Оценок пока нет

- Guard Rail On-System Bridge (MASH) Set (4-13-23)Документ11 страницGuard Rail On-System Bridge (MASH) Set (4-13-23)Mike2322Оценок пока нет

- 2021-11-16 - ABCD NEOH - Cross-Frames - ChavelДокумент36 страниц2021-11-16 - ABCD NEOH - Cross-Frames - ChavelMike2322Оценок пока нет

- Guard Rail Special Details MASHДокумент11 страницGuard Rail Special Details MASHMike2322Оценок пока нет

- LARSA WJE Solving-For-StabilityДокумент39 страницLARSA WJE Solving-For-StabilityMike2322Оценок пока нет

- Design Spectra Philippines Seismic Part 4Документ144 страницыDesign Spectra Philippines Seismic Part 4Mike2322Оценок пока нет

- DPWH BSDS Bridge Seismic Design SpecificationsДокумент154 страницыDPWH BSDS Bridge Seismic Design SpecificationsChenthuran Vilvarajah100% (5)

- Public Roads Vol 23 Issue 7Документ32 страницыPublic Roads Vol 23 Issue 7Mike2322Оценок пока нет

- Design Example (New Bridge) Using DPWH-BSDSДокумент205 страницDesign Example (New Bridge) Using DPWH-BSDSAnn P100% (1)

- Philippines Spectral Map PDFДокумент204 страницыPhilippines Spectral Map PDFJoseph Cloyd LamberteОценок пока нет

- CompositeFloorSystems - ChienRitchie1984 Canada CISCДокумент171 страницаCompositeFloorSystems - ChienRitchie1984 Canada CISCMike2322Оценок пока нет

- Seismic Design Bridges For Rural Areas South East AsiaДокумент85 страницSeismic Design Bridges For Rural Areas South East AsiaMike2322Оценок пока нет

- Design Spectra Philippines Seismic Part 3Документ96 страницDesign Spectra Philippines Seismic Part 3Mike2322Оценок пока нет

- Seismic Design of Bridges South East Asia Part 1Документ173 страницыSeismic Design of Bridges South East Asia Part 1Mike2322Оценок пока нет

- Seismic Bridge Design Mitigation Outline Part 4Документ170 страницSeismic Bridge Design Mitigation Outline Part 4Mike2322Оценок пока нет

- Seismic Bridge Design Mitigation Outline Part 5Документ398 страницSeismic Bridge Design Mitigation Outline Part 5Mike2322Оценок пока нет

- Seismic Design of Bridges South East Asia Part 3Документ192 страницыSeismic Design of Bridges South East Asia Part 3Mike2322Оценок пока нет

- Mitigation of Seismic Disasters in Bridges Part 1Документ466 страницMitigation of Seismic Disasters in Bridges Part 1Mike2322Оценок пока нет

- Mitigation of Seismic Disasters in Bridges Part 1Документ291 страницаMitigation of Seismic Disasters in Bridges Part 1Mike2322Оценок пока нет

- Seismic Design of Bridges in PhilippinesДокумент80 страницSeismic Design of Bridges in PhilippinesMike2322Оценок пока нет

- PL 05003Документ65 страницPL 05003Dave ThompsonОценок пока нет

- Construction Sequence Box Girder Concrete Bridge PDFДокумент15 страницConstruction Sequence Box Girder Concrete Bridge PDFMike2322Оценок пока нет

- Seismic Bridge Design Mitigation Outline Part 3Документ156 страницSeismic Bridge Design Mitigation Outline Part 3Mike2322Оценок пока нет

- Bridge Design PDFДокумент226 страницBridge Design PDFfredelino jumbas100% (1)

- Newdirectionsposttensioningvol10a PDFДокумент95 страницNewdirectionsposttensioningvol10a PDFNOEL RODRIGUEZОценок пока нет

- Xu - Jian Gong - DissertationДокумент341 страницаXu - Jian Gong - DissertationMike2322Оценок пока нет

- Curtis Carter Mass Concrete WorkshopДокумент38 страницCurtis Carter Mass Concrete WorkshopMike2322Оценок пока нет

- MATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Документ195 страницMATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Mike2322Оценок пока нет

- Standard Plans Timber Bridges IADOTfplgtr125 PDFДокумент56 страницStandard Plans Timber Bridges IADOTfplgtr125 PDFMike2322Оценок пока нет

- Analysis+of+Non Symmetrical+Flapping+AirfoilsДокумент18 страницAnalysis+of+Non Symmetrical+Flapping+AirfoilsAsif HameedОценок пока нет

- Find Serial Number of Computer in Windows 10Документ2 страницыFind Serial Number of Computer in Windows 10GabbarОценок пока нет

- 300-430-ENWLSI Implementing Cisco Enterprise Wireless Networks PDFДокумент3 страницы300-430-ENWLSI Implementing Cisco Enterprise Wireless Networks PDFEdu100% (1)

- DC Rectifier - OrionДокумент12 страницDC Rectifier - OrionLimbagaОценок пока нет

- Baseline Processing ReportДокумент17 страницBaseline Processing ReportMAMAN MAMANОценок пока нет

- Deep Drive - Customer Interface in AR - Oracle Apps EpicenterДокумент38 страницDeep Drive - Customer Interface in AR - Oracle Apps Epicenterjeetu_87Оценок пока нет

- Experiment 1Документ9 страницExperiment 1Shaun Loo50% (2)

- App Dev Guide 1062Документ770 страницApp Dev Guide 1062khiladi2100% (3)

- Ac Repair Doha QatarДокумент5 страницAc Repair Doha QatarperfectsolutionqaseoОценок пока нет

- SET-1: Answer To The Interview QuestionsДокумент9 страницSET-1: Answer To The Interview QuestionsÆshok IncreĐible KingОценок пока нет

- TS 34Документ2 страницыTS 34Sunil Maurya0% (1)

- Huawei Sun2000-60ktl-Hv-d1-001 Datasheet Draft A en - (20170217)Документ2 страницыHuawei Sun2000-60ktl-Hv-d1-001 Datasheet Draft A en - (20170217)Jose VicenteОценок пока нет

- StoichiotryДокумент57 страницStoichiotryJezriel Theana SisonОценок пока нет

- Guidance On Mooring System Management Plans (MSMP)Документ39 страницGuidance On Mooring System Management Plans (MSMP)PJ Apostol Alpacas100% (4)

- Gopez Wood Craft Spot Rep Feb 06, 2022Документ2 страницыGopez Wood Craft Spot Rep Feb 06, 2022Eller-Jed Manalac MendozaОценок пока нет

- Comparative Study of The Performances of Four Photovoltaic-Thermal Solar Air CollectorsДокумент21 страницаComparative Study of The Performances of Four Photovoltaic-Thermal Solar Air CollectorsMarco MGОценок пока нет

- Boiling MechanismДокумент16 страницBoiling MechanismherawanadifОценок пока нет

- Paver BlockДокумент16 страницPaver BlockRavinder Singh100% (1)

- Trouble Shooting Dewatering PumpДокумент136 страницTrouble Shooting Dewatering PumpMuhammad NoorОценок пока нет

- Course Catalog 2019Документ34 страницыCourse Catalog 2019Mehaboob BashaОценок пока нет

- 1Z0 053 PDFДокумент36 страниц1Z0 053 PDFOscarRamirezОценок пока нет

- The Punjab Factory RuleДокумент313 страницThe Punjab Factory Rulesafety_rliОценок пока нет

- Sukrosa PDFДокумент5 страницSukrosa PDFSilvi TatianОценок пока нет

- 6 - Reasoning PDFДокумент5 страниц6 - Reasoning PDFAgri CoachigОценок пока нет

- Superior Tuffy Valves: 290 Series LPD Globe Line ValvesДокумент1 страницаSuperior Tuffy Valves: 290 Series LPD Globe Line ValvesR M Abdullah WakeelОценок пока нет

- ABB Isomax Circuit BreakersДокумент53 страницыABB Isomax Circuit BreakersAshish GuptaОценок пока нет

- Chapter 10 ExamДокумент10 страницChapter 10 ExamOngHongTeckОценок пока нет

- D 2564 - 96 - Rdi1njqtotzb PDFДокумент5 страницD 2564 - 96 - Rdi1njqtotzb PDFAndre CasteloОценок пока нет

- (52621001078) DM - DM Half Inch Flex Jumper Spec SheetДокумент2 страницы(52621001078) DM - DM Half Inch Flex Jumper Spec SheetmicroqualОценок пока нет

- I J E C B S Issn (O) : 2230-8849: Cloud Computing: An AnalysisДокумент15 страницI J E C B S Issn (O) : 2230-8849: Cloud Computing: An AnalysisnoddynoddyОценок пока нет

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsОт EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsОценок пока нет

- To Engineer Is Human: The Role of Failure in Successful DesignОт EverandTo Engineer Is Human: The Role of Failure in Successful DesignРейтинг: 4 из 5 звезд4/5 (138)

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresОт EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresРейтинг: 1 из 5 звезд1/5 (2)

- Structural Cross Sections: Analysis and DesignОт EverandStructural Cross Sections: Analysis and DesignРейтинг: 4.5 из 5 звезд4.5/5 (19)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsОт EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsОценок пока нет

- Pile Design and Construction Rules of ThumbОт EverandPile Design and Construction Rules of ThumbРейтинг: 4.5 из 5 звезд4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingОт EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingОценок пока нет

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesОт EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsОт EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsРейтинг: 4 из 5 звезд4/5 (16)

- Engineering for Kids: Building and Construction Fun | Children's Engineering BooksОт EverandEngineering for Kids: Building and Construction Fun | Children's Engineering BooksРейтинг: 3 из 5 звезд3/5 (2)

- Transmission Pipeline Calculations and Simulations ManualОт EverandTransmission Pipeline Calculations and Simulations ManualРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Advanced Design Examples of Seismic Retrofit of StructuresОт EverandAdvanced Design Examples of Seismic Retrofit of StructuresРейтинг: 1 из 5 звезд1/5 (1)