Академический Документы

Профессиональный Документы

Культура Документы

Injector SLV

Загружено:

InsannulАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Injector SLV

Загружено:

InsannulАвторское право:

Доступные форматы

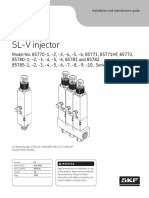

Model No.

85770-1, -2, -3, -4, -5, -6 85771, 85772

85780-1, -2, -3, -4, -5, -6 85781 and 85782

SL-V INJECTOR

Series “A”

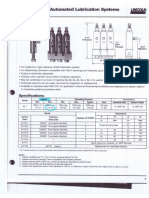

SINGLE AND MANIFOLD TYPE INJECTORS

for dispensing fluid lubricants and greases not

exceeding Lincoln ventmeter viscosity of 600 psi.

SPECIFICATIONS

Minimum operating pressure – 1850 psi [128 bar]

Maximum operating pressure – 6000 psi [413 bar]

Recommended operating pressure – 2500 psi [172 bar]

Maximum vent (recharge) pressure – 1000 psi [69 bar]

Temperature Range - -40°F to 180°F [-40°C - 80°C]

Lubricant output (adjustable):

SL-V - 0.015 to 0.080 cu. in. [0.25 to 1.31 ccm]

SL-V HO - 0.015 to 0.305 cu. in. [0.25 to 5.00 ccm]

Injectors can be mounted in any position and can be used

in circuits with SL-1, SL-11, SL-32 and/or SL33 injectors.

U.S Patent Number 6,705,432

Foreign Patents Pending

One Lincoln Way

St. Louis, MO 63120-1578

© Copyright 2003 Section - C8

Printed in USA

Phone +1.314.679.4200

Fax +1.800.424.5359

Web site:

www.lincolnindustrial.com

Page - 301

MARCH - 2004 Form 403353

Model No. 85770-1, -2, -3, -4, -5, -6

85771, 85772

85780-1, -2, -3, -4, -5, -6

85781, 85782

SL-V INJECTOR

MANIFOLD TYPE INJECTORS

Injector Model Type Dimension "A" Dimension "B" Dimension "C"

in. [mm.] in. [mm.] in. [mm.]

85770-1 Single injector manifold * * 2-1/2 [63.5]

85770-2 Tw o injector manifold * * 3 [76.2]

85770-3 Three injector manifold 1-1/4 [31.8] 4-1/4 [108]

SL-V 85770-4 Four injector manifold 2-1/2 [63.5] 5-1/2 [140] 8-3/4 [222]

85770-5 Five injector manifold 3-3/4 [95.3] 6-3/4 [171]

85770-6 Six injector manifold 5 [127] 8 [203]

85771 Replacement injector N/A N/A

85780-1 Single injector manifold * * 2-1/2 [63.5]

85780-2 Tw o injector manifold * * 3 [76.2]

85780-3 Three injector manifold 1-1/4 [31.8] 4-1/4 [108]

SL-V HO 85780-4 Four injector manifold 2-1/2 [63.5] 5-1/2 [140] 11-3/16 [284]

85780-5 Five injector manifold 3-3/4 [95.3] 6-3/4 [171]

85780-6 Six injector manifold 5 [127] 8 [203]

85781 Replacement injector N/A N/A

* Single mounting hole

SINGLE UNIT INJECTORS

Injector Model Type Dim ension "D"

in. [mm.]

SL-V 85772 Single unit injector 7-3/4 [191]

SL-V HO 85782 Single unit injector 10-3/16 [248]

Page Number - 2 Form 403353

Model No. 85770-1, -2, -3, -4, -5, -6

85771, 85772

85780-1, -2, -3, -4, -5, -6

85781, 85782

SL-V INJECTOR

1 12 13

3 14

4 15

14

5

16

6

7 17

8

9 18

10

19

11

20

Torque to

SERVICE PARTS

30-40 In. Lbs.

Item Description Qty. Part No.

No. SL-V SL-V HO 21

1 Protective Cap (polycarbonate) 1 273088 273089

2 O-ring (nitrile) 1 *

3 Adjusting Screw 1 272803 272819

4 Lock Nut 1 11624

5 Piston Stop Plug 1 273090 273091 25

6 O-ring 1 * Torque to

7 Backup Washer 1 * 40 - 45 Ft. Lbs.

22

8 U-cup (polyurethane) 1 *

9 O-ring (polyurethane) 1 * 23

10 Piston Assembly 1 273092 273093

11 O-ring (polyurethane) 1 *

12 Fitting Assembly 1 90471 24

13 Injector Body 1 273094 273095 Torque to

14 O-ring (fluorocarbon) 2 * 40-45 Ft. Lbs.

15 O-ring (fluorocarbon) 1 * MANIFOLD SINGLE UNIT

16 Spring 1 * INJECTORS INJECTOR

17 Spring 1 *

18 Spring Seat 1 272798

19 Body and Plunger Assy. 1 273096 SPECTRUM ADJUSTMENT SLEEVES

20 Socket Head Screw (8-32 x 1-1/2) 2 272796 Part # Output Ratio from Ratio from Sleeve

21 Gasket 1 * in3 (cc) Minim um Output Maxim um Output Color

Single Injector Manifold 1 12658 N/A 0.015 (0.25) 1 0.2 N/A

Tw o Injector Manifold 1 11962 85785-1 0.03 (0.50) 2 0.4 red

Three Injector Manifold 1 11963

22 85785-2 0.045 (0.75) 3 0.6 silver

Four Injector Manifold 1 11964

85785-3 0.06 (1.00) 4 0.8 gold

Five Injector Manifold 1 11965

85785-4 0.075 (1.25) 5 1.0 green

Six Injector Manifold 1 246965

23 Gasket 1 * NOTE: Remove and discard Lock Nut (Item 4) before installing Spectrum Adjustment

24 Adapter Bolt 1 273097 Sleeve onto Adjusting Screw (Item 3).

25 Adapter 1 273098

* Included in 272970 Repair Kit

Form 403353 Page Number - 3

Model No. 85770-1, -2, -3, -4, -5, -6

85771, 85772

85780-1, -2, -3, -4, -5, -6

85781, 85782

SL-V INJECTOR

SL-V Injector Operation

Indicator

Stem

Stage 1

The injector starts in its normal or rest position. In-

coming lubricant is directed through the slide valve

to both sides of the piston. The pressure of the in-

coming lubricant acting on both sides of the piston

causes the piston to move downward against the

Piston shoulder and fills the measuring chamber. The indi-

cator stem is fully retracted away from the stop of the Springs

adjusting screw.

Stage 2

Further increase in pressure causes the slide valve Passage 1

to move against the force of the springs. As the slide Outlet

valve moves, it closes passage 1 and opens pas- Port

sage 2 to the outlet port. The pressure of the incom-

Slide ing lubricant is now acting only upon the bottom of Passage 2

Valve the piston. The incoming lubricant displaces the pis-

ton which forces the lubricant in the measuring

chamber to be dispensed through passage 2, Slide

Lubricant

through the slide valve and through the outlet port to Valve

Supply

the lube point.

STAGE 1 STAGE 2

Stage 3

Adjusting The piston will dispense lubricant until the indicator

Screw stem hits the stop of the adjusting screw. The vol-

ume of lubricant dispensed can be adjusted by limit-

Indicator ing the travel of the piston. The piston and slide valve

Stem remain in this position until the lubricant pressure in

the supply line is vented.

Stage 4

As the pressure in the supply line vents to 1000 psig

Piston

[69 bar], the slide valve moves downward and closes

passage 2 and opens passage 1. The lubricant

pressure in the supply line is now acting upon both

sides of the piston causing it to move downward. As

the piston moves downward, a volume of lubricant

flows from the underside of the piston, past the slide

valve, through passage 1 and to the upper side of the

piston. Since the volume on top of the piston is great-

er than the volume under the piston, an additional Passage 1

volume of lubricant flows from the supply line to the

upper side of the piston. This volume of lubricant

leaving the supply line causes the pressure to drop

Slide Valve very quickly. The piston may or may not fully return to Passage 2

the shoulder, depending upon the volume of lubri-

cant in the supply line. The injector is now ready for Lubricant

the next cycle. Supply

STAGE 3 STAGE 4

Page Number - 4 Form 403353

Model No. 85770-1, -2, -3, -4, -5, -6

85771, 85772

85780-1, -2, -3, -4, -5, -6

85781, 85782

SL-V INJECTOR

Lincoln Industrial Standard Warranty

LIMITED WARRANTY

Lincoln warrants the equipment manufactured and supplied by Lincoln to be free from defects in material and workmanship

for a period of one (1) year following the date of purchase, excluding therefrom any special, extended, or limited warranty

published by Lincoln. If equipment is determined to be defective during this warranty period, it will be repaired or replaced,

within Lincoln’s sole discretion, without charge.

This warranty is conditioned upon the determination of a Lincoln authorized representative that the equipment is defective. To

obtain repair or replacement, you must ship the equipment, transportation charges prepaid, with proof of purchase to a

Lincoln Authorized Warranty and Service Center within the warranty period.

This warranty is extended to the original retail purchaser only. This warranty does not apply to equipment damaged from

accident, overload, abuse, misuse, negligence, faulty installation or abrasive or corrosive material, equipment that has been

altered, or equipment repaired by anyone not authorized by Lincoln. This warranty applies only to equipment installed,

operated and maintained in strict accordance with the written specifications and recommendations provided by Lincoln or its

authorized field personnel.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE WARRANTY OF MERCHANTIBILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

In no event shall Lincoln be liable for incidental or consequential damages. Lincoln’s liability for any claim for loss or

damages arising out of the sale, resale or use of any Lincoln equipment shall in no event exceed the purchase price. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, therefore the above limitation or

exclusion may not apply to you.

This warranty gives you specific legal rights. You may also have other rights that vary by jurisdiction.

Customers not located in the Western Hemisphere or East Asia: Please contact Lincoln GmbH & Co. KG, Walldorf, Germany,

for your warranty rights.

Lincoln Industrial Special Limited Warranty

SPECIAL LIMITED 2 YEAR WARRANTY

SL-V Series, Single Injectors-85772, 85782, and Replacement Injectors-85771, 85781

Lincoln warrants the SL-V Injector series to be free from defects in material and workmanship for two (2) years following the

date of purchase. If an injector model (single or replacement) is determined to be defective by Lincoln, in its sole discretion,

during this warranty period, it will be repaired or replaced, at Lincoln’s discretion, without charge.

Lincoln Industrial Contact Information

To find Lincoln Industrial’s Nearest Service Center

Call one of the following numbers, you may also use our wbsite

Customer Service - 314-679-4200

Website - www.lincolnindustrial.com

Form 403353 Page Number - 5

Model No. 85770-1, -2, -3, -4, -5, -6

85771, 85772

85780-1, -2, -3, -4, -5, -6

85781, 85782

SL-V INJECTOR

Declaration by the manufacturer as defined by

machinery directive 89/392/EEC Annex IIB

Herewith we declare that the supplied model of

SL-V

is intended to be incorporated into machinery covered by

this directive and must not be put into service until the

machinery into which it is to be incorporated has been

declared in conformity with the provisions of the directive.

Applied harmonized standards in particular:

EN292 T1/T2

prEN 809

Paul Conley,

Chief Engineer

Page Number - 6 Form 403353

Вам также может понравиться

- SLV XL PDFДокумент8 страницSLV XL PDFFaidh Maulana Aksyar Faidh100% (1)

- REHS2516-11 Procedure To Measure Bearing Movement in The Upper and The Lower Articulation HitchДокумент11 страницREHS2516-11 Procedure To Measure Bearing Movement in The Upper and The Lower Articulation HitchCarlosОценок пока нет

- 631D Trans Shift PointsДокумент20 страниц631D Trans Shift PointsDaveОценок пока нет

- 793D Off-Highway Truck FDB00001-UP MACHINE POWERED BY 3516B EngineSEBP3976 - 13Документ23 страницы793D Off-Highway Truck FDB00001-UP MACHINE POWERED BY 3516B EngineSEBP3976 - 13carlosОценок пока нет

- C 15 EngineДокумент2 страницыC 15 EngineAldo Cesar Mina SosaОценок пока нет

- 993k Wheel Loader Before Operation ManualДокумент6 страниц993k Wheel Loader Before Operation ManualGustavo VargasОценок пока нет

- 793D Off Higway Truck FDBДокумент28 страниц793D Off Higway Truck FDBMelissa TorresОценок пока нет

- FHS - 32-80 - 5 - Jan00 - EdE PumpaДокумент8 страницFHS - 32-80 - 5 - Jan00 - EdE PumpaDanicaОценок пока нет

- Grease Audit Template HitachiДокумент28 страницGrease Audit Template HitachiInsannulОценок пока нет

- Media Search - REHS2210 - Assembly Procedure For The 793D Off-Highway Truck (7000, 7006, 7960)Документ383 страницыMedia Search - REHS2210 - Assembly Procedure For The 793D Off-Highway Truck (7000, 7006, 7960)Deyvi0% (1)

- Cat 992K Wheel Loader: Fuel BurnДокумент2 страницыCat 992K Wheel Loader: Fuel BurnDion BoedionoОценок пока нет

- 793 793b 793cДокумент8 страниц793 793b 793cJulio Elias Mayta RamosОценок пока нет

- Power Train: SERV1817 - 131 - Text Reference 04/06Документ105 страницPower Train: SERV1817 - 131 - Text Reference 04/06Wesley Gonzalo YupanquiОценок пока нет

- Hoist Output Pinion Assembly Featuring An Improved Grease Relief Passage Available On 7495, 7495HD, and 7495HF ERS - ServiceДокумент3 страницыHoist Output Pinion Assembly Featuring An Improved Grease Relief Passage Available On 7495, 7495HD, and 7495HF ERS - ServiceAnonymous ABPUPbKОценок пока нет

- D10R - AKT - Hose Management Guide PDFДокумент43 страницыD10R - AKT - Hose Management Guide PDFAla Eddine BarhoumiОценок пока нет

- 20190617-List PM Filter - Detail Interval - 2017 - 07Документ17 страниц20190617-List PM Filter - Detail Interval - 2017 - 07irsan pratama putraОценок пока нет

- 797B - JSM Mangueras PDFДокумент59 страниц797B - JSM Mangueras PDFJorge Aaron Veneros ApablazanОценок пока нет

- KomatsuДокумент8 страницKomatsuTuluss Kosonq Tiiga100% (1)

- Example PartsДокумент100 страницExample Partsmuhammad aliОценок пока нет

- Machine Profiles: D10R Track-Type TractorsДокумент5 страницMachine Profiles: D10R Track-Type TractorsJavier Pagan TorresОценок пока нет

- Machine Profiles: 992G Wheel LoadersДокумент7 страницMachine Profiles: 992G Wheel LoadersJavier Pagan TorresОценок пока нет

- Calenturitas Mining Equipment Population - February 2019Документ11 страницCalenturitas Mining Equipment Population - February 2019Jose luis ConsuegraОценок пока нет

- TA1 English - Compact Wheel LoadersДокумент16 страницTA1 English - Compact Wheel Loaderscarlos angelОценок пока нет

- BP Publication - Fluid Cooler D&a FixtureДокумент4 страницыBP Publication - Fluid Cooler D&a Fixtureleaw81Оценок пока нет

- Caterpillar Product Line 13Документ7 страницCaterpillar Product Line 13GenneraalОценок пока нет

- D8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsДокумент2 страницыD8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDarío Ache EmeОценок пока нет

- Fuel Burn To Overhaul ModelДокумент4 страницыFuel Burn To Overhaul ModelDwi NoviyantoОценок пока нет

- Handle-End Bottom Plate RemovalДокумент4 страницыHandle-End Bottom Plate Removalraul contrerasОценок пока нет

- C4.4 Acert PDFДокумент2 страницыC4.4 Acert PDFsandroyanezОценок пока нет

- Pruebas y Ajuste Tren de Potencia RENR2506!05!01-PTДокумент64 страницыPruebas y Ajuste Tren de Potencia RENR2506!05!01-PTtommy lanyonОценок пока нет

- 002 Cat-6040AC CAMP-SIL-BCS4 UndercarriageДокумент21 страница002 Cat-6040AC CAMP-SIL-BCS4 UndercarriageJorby CuadrosОценок пока нет

- Eaton RefrigeracionДокумент52 страницыEaton RefrigeracionPakoОценок пока нет

- 992K (ZMX) Component Hours Less Regulated Emissions: Wheel Loader Component CenterlinesДокумент1 страница992K (ZMX) Component Hours Less Regulated Emissions: Wheel Loader Component CenterlinesjogremaurОценок пока нет

- General Fuel InformationДокумент5 страницGeneral Fuel InformationElmer Tintaya MamaniОценок пока нет

- Machine Profiles: 994, 994D Wheel LoadersДокумент9 страницMachine Profiles: 994, 994D Wheel LoadersAldo Cesar Mina SosaОценок пока нет

- 6040 Hydraulic Mining Shovel Swing SystemДокумент22 страницы6040 Hydraulic Mining Shovel Swing SystemFreedom MuchenjeОценок пока нет

- WD900 3Документ14 страницWD900 3Gustavo RathgebОценок пока нет

- EX 1200-5D Kit Part NumbersДокумент4 страницыEX 1200-5D Kit Part NumbersVinod GuptaОценок пока нет

- K2000Документ4 страницыK2000Cristian Mena Hidalgo100% (1)

- Cashman EM Solutions Brochure 3 16Документ2 страницыCashman EM Solutions Brochure 3 16jov100% (1)

- 2 WG-94 EC Betriebsanleitung ZF2WG94 ECДокумент55 страниц2 WG-94 EC Betriebsanleitung ZF2WG94 ECErnö Szabo100% (1)

- Mine Air Systems No Idle System BrochureДокумент2 страницыMine Air Systems No Idle System Brochureelia nugraha adiОценок пока нет

- Introduction of Service Tool List For The 107E-1 EngineДокумент2 страницыIntroduction of Service Tool List For The 107E-1 EnginejoseОценок пока нет

- MD6420 - Procedimiento de Cambio de Compresor - Manual de Servicio (EM005781)Документ16 страницMD6420 - Procedimiento de Cambio de Compresor - Manual de Servicio (EM005781)Victor ArceОценок пока нет

- Valv. Alivio de Direcc. 416eДокумент4 страницыValv. Alivio de Direcc. 416eJosé GonzalezОценок пока нет

- The Mining Truck T 282 BДокумент14 страницThe Mining Truck T 282 BVian MadridistaОценок пока нет

- c32 Cylinder HeadДокумент5 страницc32 Cylinder HeadHaidar SareeniОценок пока нет

- D11T - GebДокумент50 страницD11T - GebviniciusОценок пока нет

- KG 850,650 LB: Maximum GVWДокумент4 страницыKG 850,650 LB: Maximum GVWRohmanОценок пока нет

- Truck Body and Canopy - RemoveДокумент5 страницTruck Body and Canopy - RemoveBelimar CostaОценок пока нет

- M0101873-00 - The Frame Fore Aft Beam May Crack On Certain 793FДокумент2 страницыM0101873-00 - The Frame Fore Aft Beam May Crack On Certain 793FPercy Herrera Zeballos100% (1)

- AFA Guidelines For Analyzing Duo-Cone Seal FailuresДокумент4 страницыAFA Guidelines For Analyzing Duo-Cone Seal FailuresGracia SediОценок пока нет

- 793D MOM SafetyДокумент28 страниц793D MOM SafetyStanley Walford Brooks RomeroОценок пока нет

- Brochure Valvula Alivio 83948Документ4 страницыBrochure Valvula Alivio 83948Robert Karlo RodriguezОценок пока нет

- ZX140W-3 Full Service ManualДокумент1 774 страницыZX140W-3 Full Service ManualĐinh Công Văn100% (1)

- Hose Routing Management Guide: SN: Mb8 Lines Group - RipperДокумент31 страницаHose Routing Management Guide: SN: Mb8 Lines Group - RipperEderОценок пока нет

- Hydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionДокумент24 страницыHydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionMiguel Angel RodriguezОценок пока нет

- Ideal Air CatalogueДокумент60 страницIdeal Air CatalogueYAKOVОценок пока нет

- Evapco, Inc.: Plan ViewДокумент1 страницаEvapco, Inc.: Plan ViewTheVictor VSОценок пока нет

- Lincoln SL-V InjectorДокумент12 страницLincoln SL-V InjectorJuanОценок пока нет

- TTT00516#BDCT06013 1Документ2 страницыTTT00516#BDCT06013 1InsannulОценок пока нет

- Schedule Service CobaДокумент4 страницыSchedule Service CobaInsannulОценок пока нет

- TTT00318#BDCT06017 1Документ2 страницыTTT00318#BDCT06017 1InsannulОценок пока нет

- Parts Order Terex 100Документ44 страницыParts Order Terex 100InsannulОценок пока нет

- J16356#BDKM85006 1Документ2 страницыJ16356#BDKM85006 1InsannulОценок пока нет

- Spare Parts GUI SupplyДокумент4 страницыSpare Parts GUI SupplyInsannulОценок пока нет

- 1693 Mum#exhc12001 1Документ2 страницы1693 Mum#exhc12001 1InsannulОценок пока нет

- New Form OilДокумент1 страницаNew Form OilInsannulОценок пока нет

- 1693 Mum#exhc12001 1Документ2 страницы1693 Mum#exhc12001 1InsannulОценок пока нет

- Check List 16MДокумент4 страницыCheck List 16MInsannulОценок пока нет

- Sample CoolantДокумент4 страницыSample CoolantInsannulОценок пока нет

- U.S. Patent No. 6,102,676 U.S. Patent 6,102,676: Section Form 404383 JAN - 2012Документ41 страницаU.S. Patent No. 6,102,676 U.S. Patent 6,102,676: Section Form 404383 JAN - 2012InsannulОценок пока нет

- b19h22c032 New Coolant Petro 5 A 1Документ2 страницыb19h22c032 New Coolant Petro 5 A 1InsannulОценок пока нет

- PDS Delo ELC PDFДокумент6 страницPDS Delo ELC PDFInsannulОценок пока нет

- Grease Audit Template Liebherr R984Документ25 страницGrease Audit Template Liebherr R984InsannulОценок пока нет

- Form MaintenenceДокумент1 страницаForm MaintenenceInsannulОценок пока нет

- Sample CoolantДокумент4 страницыSample CoolantInsannulОценок пока нет

- Grease Audit Template HitachiДокумент28 страницGrease Audit Template HitachiInsannulОценок пока нет

- Grease Component Inspection Sheet: Component Description Brand / ModelДокумент27 страницGrease Component Inspection Sheet: Component Description Brand / ModelInsannulОценок пока нет

- Nitrate Nitrite 2 ND AddДокумент31 страницаNitrate Nitrite 2 ND AddAnne MarryОценок пока нет

- AnalyticalДокумент19 страницAnalyticalInsannulОценок пока нет

- The Reaction Between Aluminium Metal and Aqueous Solutions of The Nitrite IonДокумент3 страницыThe Reaction Between Aluminium Metal and Aqueous Solutions of The Nitrite IonInsannulОценок пока нет

- Grease Audit Template HitachiДокумент28 страницGrease Audit Template HitachiInsannulОценок пока нет

- Centro-Matic Automatic Lubrication Systems: Grease InjectorsДокумент7 страницCentro-Matic Automatic Lubrication Systems: Grease InjectorsInsannulОценок пока нет

- QRS R$$! " Rrts R! " RU! #$%&! VS W! RX! YS %& S Z! #$%&! " R S R (! /& S R! RX! YTS UДокумент3 страницыQRS R$$! " Rrts R! " RU! #$%&! VS W! RX! YS %& S Z! #$%&! " R S R (! /& S R! RX! YTS UInsannulОценок пока нет

- PC2000 Grease SysteДокумент4 страницыPC2000 Grease SysteInsannulОценок пока нет

- Injector SL-1Документ1 страницаInjector SL-1InsannulОценок пока нет

- Mines Safety Bulletin No. 123: SubjectДокумент4 страницыMines Safety Bulletin No. 123: SubjectInsannulОценок пока нет

- QRS R$$! " Rrts R! " RU! #$%&! VS W! RX! YS %& S Z! #$%&! " R S R (! /& S R! RX! YTS UДокумент3 страницыQRS R$$! " Rrts R! " RU! #$%&! VS W! RX! YS %& S Z! #$%&! " R S R (! /& S R! RX! YTS UInsannulОценок пока нет

- 122661-2006-Twin Ace Holdings Corp. v. Rufina Co.20180326-1159-RlgzhkДокумент7 страниц122661-2006-Twin Ace Holdings Corp. v. Rufina Co.20180326-1159-RlgzhkMarjorie BaquialОценок пока нет

- Quality Manual.4Документ53 страницыQuality Manual.4dcol13100% (1)

- CORPORATION An Artificial Being Created by Operation of Law Having The Right of SuccessionДокумент26 страницCORPORATION An Artificial Being Created by Operation of Law Having The Right of SuccessionZiad DnetОценок пока нет

- 14 Solid - Homes - Inc. - v. - Payawal PDFДокумент6 страниц14 Solid - Homes - Inc. - v. - Payawal PDFcelОценок пока нет

- RIBA WorkstagesДокумент1 страницаRIBA WorkstagesCong TranОценок пока нет

- Shay Eshel - The Concept of The Elect Nation in Byzantium (2018, Brill) PDFДокумент234 страницыShay Eshel - The Concept of The Elect Nation in Byzantium (2018, Brill) PDFMarko DabicОценок пока нет

- Waf Rosary Group Leaflet - June 2018Документ2 страницыWaf Rosary Group Leaflet - June 2018Johnarie CardinalОценок пока нет

- CM Shopstar ManДокумент24 страницыCM Shopstar Mancj7man80100% (1)

- Trellick Tower PresentationДокумент2 страницыTrellick Tower PresentationCheryl Ng100% (1)

- PACIFIC ACE FINANCE LTD. (PAFIN) v. EIJI YANAGISAWAДокумент17 страницPACIFIC ACE FINANCE LTD. (PAFIN) v. EIJI YANAGISAWAAnne ObnamiaОценок пока нет

- Friday Foreclosure List For Pierce County, Washington Including Tacoma, Gig Harbor, Puyallup, Bank Owned Homes For SaleДокумент11 страницFriday Foreclosure List For Pierce County, Washington Including Tacoma, Gig Harbor, Puyallup, Bank Owned Homes For SaleTom TuttleОценок пока нет

- Compiled Case Digest For Criminal LawДокумент54 страницыCompiled Case Digest For Criminal LawMicah Clark-Malinao100% (7)

- PO-12 - F - 06 1 PA GE 2/ NU MPA GES 2: Învăţământ UniversitarДокумент3 страницыPO-12 - F - 06 1 PA GE 2/ NU MPA GES 2: Învăţământ UniversitarElena FilipОценок пока нет

- Aetna V WolfДокумент2 страницыAetna V WolfJakob EmersonОценок пока нет

- The Contemporary Global GovernanceДокумент12 страницThe Contemporary Global GovernanceSherilyn Picarra100% (1)

- IT Security Threats Vulnerabilities and CountermeasuresДокумент35 страницIT Security Threats Vulnerabilities and Countermeasureschristian may noqueraОценок пока нет

- April, 2020 DOM: Customer Number: Billing Month: Tariff/Customer Class: Bill ID: 712282339453Документ1 страницаApril, 2020 DOM: Customer Number: Billing Month: Tariff/Customer Class: Bill ID: 712282339453maazraza123Оценок пока нет

- Department of Education: Attendance SheetДокумент2 страницыDepartment of Education: Attendance SheetLiam Sean Han100% (1)

- Two Nation Theory - Docx NarrativeДокумент14 страницTwo Nation Theory - Docx NarrativeSidra Jamshaid ChОценок пока нет

- Talend Data Quality DatasheetДокумент2 страницыTalend Data Quality DatasheetAswinJamesОценок пока нет

- Spiritual Advisors Bhagavata Assembly: SabhaДокумент11 страницSpiritual Advisors Bhagavata Assembly: SabhaABHISHEKОценок пока нет

- Board of Commissioners V Dela RosaДокумент4 страницыBoard of Commissioners V Dela RosaAnonymous AUdGvY100% (2)

- People V Oloverio - CrimДокумент3 страницыPeople V Oloverio - CrimNiajhan PalattaoОценок пока нет

- Why I Love This ChurchДокумент3 страницыWhy I Love This ChurchJemicah DonaОценок пока нет

- Sinif Matemati̇k Eşli̇k Ve Benzerli̇k Test PDF 2Документ1 страницаSinif Matemati̇k Eşli̇k Ve Benzerli̇k Test PDF 2zboroglu07Оценок пока нет

- Deed of Real Estate MortgageДокумент6 страницDeed of Real Estate MortgageCristopher ReyesОценок пока нет

- Export-Import Documentation Aditya Kapoor PDFДокумент8 страницExport-Import Documentation Aditya Kapoor PDFPradeepОценок пока нет

- Od126200744691887000 4Документ1 страницаOd126200744691887000 4Swyam SaxenaОценок пока нет

- Processes To Compel AppearanceДокумент34 страницыProcesses To Compel AppearanceNayem Miazi100% (2)

- Notice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsДокумент1 страницаNotice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsJustia.comОценок пока нет