Академический Документы

Профессиональный Документы

Культура Документы

40 90 Mechanical Seal Kits SWI

Загружено:

Wong DaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

40 90 Mechanical Seal Kits SWI

Загружено:

Wong DaАвторское право:

Доступные форматы

S E R I E S 4 03 0, 4280, 4 36 0 D, 4 3 80, 4 3 82 File No: 40.

90

Date: nov. 15, 2013

& 4 3 92 | M EC H A N I C A L S E A L K I T S | Supersedes: 40.90

Date: jan. 06, 2011

SERVICE WORK INSTRUCTIONS

version française / versión en español / 中文版 - armstrongfluidtechnology.com

Refer to appropriate service work instructions (swi) file disc typically supplied with the seal. Contamination of the

for breakdown instructions for the pump being serviced. polished and lapped seat face could cause immediate leakage.

Mechanical seal replacement instructions are included 7 Replace the adapter, taking care that the seal seat is carefully

{

in the pump swi. The following instructions are included guided over the shaft.

for convenience.

spring holder

caution

spring

Always disconnect power supply from motor before seal head

beginning service work. assembly

rotating face,

seal hardware tab (typ)

seal kit installation instructions bellows, retainer

and drive band

1 Remove impeller and mechanical seal from pump or motor assembly

seat seat

shaft. The mechanical seal spring and spring holder usually

o-ring

comes free with the impeller. The mechanical seal rotating

element must be pried loose with pry bars or screwdrivers.

Once loosened, the seal may be pulled free of the shaft. l-cup

shaft key

shaft

2 When removing the impeller and seal from a motor shaft, spacer*(used on

4280, 4380, 4360d,

take care to retrieve the spacer from between the impeller 4382 & 4392

and shaft sleeve. Store for later use.

3 The o-ring or l-cup mounted mechanical seal seat must seal seat cavity

be pried loose from the recess in the adapter. To do this:

Separate the adapter from the bearing housing or motor.

A screwdriver may then be used to push the seal seat out

of the adapter from the rear. *important: Spacer may come off when old seal kit is removed.

Be sure it is on when installing new seal kit.

4 Clean the shaft sleeve surface, ensuring the entire former

seal elastomeric residue has been removed. Inspect for dam- caution

age and replace if necessary. (See separate instructions, File

No. 6042.25, for removal of the motor shaft sleeve). Inspect Do not use oil, Vaseline or other petroleum or

silicon based products for seal elastomer lubrication.

the water slinger and replace if damaged.

Otherwise elastomer swelling may occur, causing

5 Silicon carbide is a suitable replacement for ceramic, ni- seal failure. Recommended: International Products

resist, or tungsten carbide and is the seal seat of choice. Corp p-80 Rubber Lubricant Emulsion in usa & uk

Ceramic and silicon carbide are more brittle than ni-resist or www.ipcol.com

tungsten carbide and should be handled accordingly.

6 Install a new seal seat in the adapter cavity, being sure the 8 Lubricate the inside of the seal rotating assembly (The

lapped (polished) surface of the insert is facing up. Ensure ‘rubber’ bellows) with a small amount of temporary rubber lu-

that the cavity has been thoroughly cleaned. Lubricate the bricant emulsion and slide onto the shaft sleeve with a twisting

motion, carbon face first, until pressed to the carbon face. En-

outside of the seat elastomer o-ring or l-cup with a small

sure the seal is securely in place by pushing firmly with 2 screw

amount of temporary rubber lubricant emulsion and press

drivers simultaneously on opposite tabs of the seal hardware.

down, straight and even, into the cavity. Do not press the

Push the rotating seal retainer and seal hardware tabs simulta-

seat in with bare fingers; use a clean cloth or the cardboard neously to ensure the elastomer is not over-stretched.

servi ce wo r k Series 4030, 4280, 4360d, 4380, 4382 & 4392

i nstru cti o ns Mechanical seal kits

9 Remove the spring retainer from the seal spring and place the Slide the impeller into place on the shaft, taking care and ensur-

seal spring over the seal rotating assembly. Re-install the shaft ing the seal spring is kept in place on the seal rotating assembly

sleeve spacer, if appropriate, and impeller key on the shaft and and fits well into the retainer on the impeller hub. Secure impel-

place the seal spring retainer onto the impeller hub register. ler and finish reassembling pump.

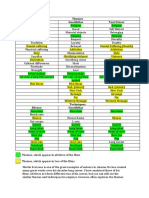

s - 1. 25" 9 975 0 01- 817 975 0 0 0 - 9 82 9 975 0 01- 813

seal kit

m - 1.625" 9 975 0 01- 8 37 975 0 0 0 - 9 8 4 9 975 0 01- 8 3 3

part number

l - 2 .125" 9 975 0 01- 877 975 0 0 0 - 9 8 5 9 975 0 01- 873

All glycols > 30% wt conc

Fluid type General non & potable water All other non-potable fluids

abrasives (tds) >2000ppm

Temperature To 250°f / 121°c =/< 200°f / 93°c > 200°f / 93°c

Seal type 2a

Rotating face Sintered silicon carbide Resin bonded carbon Antimony loaded carbon

Stationary face Sintered silicon carbide

Seat elastomer epdm (l-cup) epdm (O-ring)

Secondary seal epdm

Spring Stainless steel

Rotating hardware Stainless steel

Material code SCsc l epss 2a C-sc l epss 2a ACsc o epss 2a

Used on: 4030/4280 4380/4382/4392 vil & 4360d Notes:

Seal Type: 2a 1 Seal kit consists of rotating seal head, spring and holder,

Pump Construction: bf/ab/ai stationary seal seat with O-ring or l-cup.

Stationary face: Sintered silicon carbide Pump casing gasket and other minor hardware components

Secondary Seal: epdm possibly required to reassemble the pump are not included.

Consult service parts bulletins for more detail.

Spring: Stainless steel

Rotating Hardware: Stainless steel 2 O-ring and l-cup style seats are interchangeable between

centerline discharge pumps. Both styles are used as standard

for inside seals after October 2011.

3 O-ring and l-cup style seats are not interchangeable

between centerline and legacy tangential discharge pumps.

toronto

+1 416 755 2291

buffalo

+1 716 693 8813

birmingham

+44 (0) 8444 145 145

manchester

+44 (0) 8444 145 145

bangalore

+91 (0) 80 4906 3555

a r m s t r o n g f lu i d t e c h n o lo g y

shanghai established 1934 a r m s t r o n g f lu i d t e c h n o lo g y. c o m

+86 21 3756 6696

Вам также может понравиться

- P100 T16000 SM PDFДокумент136 страницP100 T16000 SM PDFVladimir100% (4)

- Rotating Equipment Codes and StandardsДокумент2 страницыRotating Equipment Codes and StandardsWong Da100% (6)

- Poseidon Pegasus Seals Deluxe (Forw) Installation and Maintenance Manual...Документ10 страницPoseidon Pegasus Seals Deluxe (Forw) Installation and Maintenance Manual...Marlon Alejandro Arboleda TapiaОценок пока нет

- T Rex PumpДокумент4 страницыT Rex PumpWong DaОценок пока нет

- High Performance Pumps: Rotary Lobe / Gear Pumps 120 450 92 3,400,000Документ24 страницыHigh Performance Pumps: Rotary Lobe / Gear Pumps 120 450 92 3,400,000Wong DaОценок пока нет

- OrthophotosДокумент33 страницыOrthophotosSaurabh SumanОценок пока нет

- Fagan Garrett PDFДокумент462 страницыFagan Garrett PDFJavier CuadraОценок пока нет

- Jung Red Book GuideДокумент21 страницаJung Red Book Guidesimonbuc95% (19)

- 42 84 - Seal and Impeller Replacement IandOДокумент2 страницы42 84 - Seal and Impeller Replacement IandOvimalmailbookОценок пока нет

- Armstrong Kit Sello MecanicoДокумент2 страницыArmstrong Kit Sello MecanicoGiorgio FerОценок пока нет

- EteclowerДокумент4 страницыEteclowercapemarinesurveyОценок пока нет

- Series 4280: Motor Mounted Horizontal End Suction Pump Service Work InstructionsДокумент4 страницыSeries 4280: Motor Mounted Horizontal End Suction Pump Service Work InstructionsvimalmailbookОценок пока нет

- Suppl. Operating InstructionsДокумент4 страницыSuppl. Operating InstructionsIVANOV OSORIO ESTEBANОценок пока нет

- Trailer Buddy VaultДокумент10 страницTrailer Buddy VaultjeffОценок пока нет

- Fox Podium RC3 Service ManualДокумент22 страницыFox Podium RC3 Service ManualBrianCook100% (1)

- Interbrake AEBДокумент6 страницInterbrake AEBKarim BaddagОценок пока нет

- 6.38 10M EH Single Shear Seal BOPДокумент19 страниц6.38 10M EH Single Shear Seal BOPpramodptvpm_65797156Оценок пока нет

- Cummins Ism, QSMДокумент11 страницCummins Ism, QSMibnu67% (6)

- Cummins Ism QSM PDFДокумент11 страницCummins Ism QSM PDFEng-AhmedRashadОценок пока нет

- Repair Instructions: 3AV 30 To 3AV 430Документ11 страницRepair Instructions: 3AV 30 To 3AV 430KevinОценок пока нет

- Valvula DireccionДокумент8 страницValvula DireccionVictor Manuel Lozada ObessoОценок пока нет

- Clean and Inspect For ReuseДокумент8 страницClean and Inspect For ReuseBac NguyenОценок пока нет

- FIS113eng Hi Temp BellowsДокумент8 страницFIS113eng Hi Temp Bellowsandres castroОценок пока нет

- 2100103-Tilt CylindersДокумент17 страниц2100103-Tilt CylindersFrancisco DiazОценок пока нет

- Manual Terex # 55 (Iguana) - 2Документ26 страницManual Terex # 55 (Iguana) - 2Victor Manuel riveraОценок пока нет

- HPH Burgmann SealsДокумент4 страницыHPH Burgmann SealsNguyễn HưngОценок пока нет

- 2761 252 00Документ8 страниц2761 252 00joravicaОценок пока нет

- Fis116 en A5 PDFДокумент4 страницыFis116 en A5 PDFroyert8Оценок пока нет

- Tilt Cylinders PDFДокумент12 страницTilt Cylinders PDFamineОценок пока нет

- Operation Instructions Seal Replacement: Vil 4300 - 20×20×19 Installation and Operating InstructionsДокумент4 страницыOperation Instructions Seal Replacement: Vil 4300 - 20×20×19 Installation and Operating InstructionsDiego ArmandoОценок пока нет

- E-AK200-HDX Rev 03Документ82 страницыE-AK200-HDX Rev 03Douglas SilvaОценок пока нет

- 26850A005Документ12 страниц26850A005Luciano AlencastroОценок пока нет

- 2010-2015 DHX RC4 - RC2 Rebuild - Bike Help Center - FOXДокумент34 страницы2010-2015 DHX RC4 - RC2 Rebuild - Bike Help Center - FOXYadi RomaОценок пока нет

- Drive ShaftДокумент9 страницDrive ShaftSteven AmadorОценок пока нет

- Camshaft / Lifters / Lube Kit CATALOG # 3702 General InstructionsДокумент4 страницыCamshaft / Lifters / Lube Kit CATALOG # 3702 General InstructionsFREDDYJIMENEZОценок пока нет

- TRW Input Shaft Seal RemovalДокумент6 страницTRW Input Shaft Seal RemovalMichael ForrestОценок пока нет

- 2388 - Catalogo de PeçasДокумент5 страниц2388 - Catalogo de PeçascleversonОценок пока нет

- Magpower Clutch Model CДокумент4 страницыMagpower Clutch Model CJuan CaceresОценок пока нет

- 2531Документ5 страниц2531sangkil05Оценок пока нет

- 3.20 On-Off - 27000Документ13 страниц3.20 On-Off - 27000Cuong TranОценок пока нет

- Mercer 9100 ManualДокумент11 страницMercer 9100 Manualanara.aidОценок пока нет

- 56 143 5TC Coupler Brake Installation Service InstructionsДокумент4 страницы56 143 5TC Coupler Brake Installation Service InstructionsIvan PachecoОценок пока нет

- Eixo Dif Simples Vel ENGДокумент62 страницыEixo Dif Simples Vel ENGAhmedОценок пока нет

- Fuel Hose Reel Model 89010 & 102962 Series "A": SafetyДокумент3 страницыFuel Hose Reel Model 89010 & 102962 Series "A": SafetyLuis Carlos González LondoñoОценок пока нет

- BALEROSДокумент17 страницBALEROSjulio cesarОценок пока нет

- High Ambient 3GZV500002-6 9AKK104910 ML 06 - 2009 - WebДокумент32 страницыHigh Ambient 3GZV500002-6 9AKK104910 ML 06 - 2009 - WebLogist ChinaОценок пока нет

- Steering AxleДокумент14 страницSteering AxleSergioОценок пока нет

- Installation Instructions: BW Seals Q, QB SeriesДокумент8 страницInstallation Instructions: BW Seals Q, QB SeriesJoseGarciaRОценок пока нет

- 17 - Booster Pump Operational ManualДокумент6 страниц17 - Booster Pump Operational ManualDevaj NahkОценок пока нет

- Prensa Kurt D688Документ17 страницPrensa Kurt D688Arnulfo Larragoitia Martinez100% (1)

- 05-9040-070 Angmc-6028-UsДокумент2 страницы05-9040-070 Angmc-6028-Ustxlucky80Оценок пока нет

- Service Manual: Powershift Transmission T16000Документ138 страницService Manual: Powershift Transmission T16000Marcos Aldana VillaldaОценок пока нет

- Timing Belt Clinic Peugeot 206 14 Hdi 8hx8hz PDFДокумент1 страницаTiming Belt Clinic Peugeot 206 14 Hdi 8hx8hz PDFDОценок пока нет

- Rod Install PDFДокумент8 страницRod Install PDFVeterano del Camino100% (1)

- Centrifugal Pumps: DescriptionДокумент8 страницCentrifugal Pumps: Descriptionudrogono2Оценок пока нет

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureДокумент10 страницWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaОценок пока нет

- TimkenTT en Vol1 Iss3Документ2 страницыTimkenTT en Vol1 Iss3grupa2904Оценок пока нет

- B-02 Mechnical Seal For SBPO LubeДокумент8 страницB-02 Mechnical Seal For SBPO LubeMarvin DuarteОценок пока нет

- Installation Instructions: BW Seals Q, QB SeriesДокумент8 страницInstallation Instructions: BW Seals Q, QB Seriesaliihsan3461Оценок пока нет

- Valtek Spring Cylinder Rotary Actuators: General InformationДокумент8 страницValtek Spring Cylinder Rotary Actuators: General InformationJUAN ANTONIO HERNANDEZ SOSAОценок пока нет

- Tilt CylinderДокумент7 страницTilt Cylinderluis tocoraОценок пока нет

- DENSO Rastavljanje DizneДокумент22 страницыDENSO Rastavljanje Diznegalaxy63Оценок пока нет

- Caterpillar 988 Wheel Loader Service Manual SN 87a1 2384Документ6 страницCaterpillar 988 Wheel Loader Service Manual SN 87a1 2384gordkabirОценок пока нет

- Sample: Themanualmaster - TradebitДокумент3 страницыSample: Themanualmaster - Tradebitjorgewalbert0% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesОт EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesРейтинг: 5 из 5 звезд5/5 (1)

- MPU Brochure ZF TRWДокумент4 страницыMPU Brochure ZF TRWWong DaОценок пока нет

- Catalog Systems PDFДокумент36 страницCatalog Systems PDFWong DaОценок пока нет

- Anti Surge Control PDFДокумент4 страницыAnti Surge Control PDFWong DaОценок пока нет

- Overview of API 682 Second Edition PDFДокумент8 страницOverview of API 682 Second Edition PDFWong DaОценок пока нет

- Oil Mist Manual PDFДокумент34 страницыOil Mist Manual PDFWong DaОценок пока нет

- Website Catalog PUMPS v2Документ14 страницWebsite Catalog PUMPS v2Wong DaОценок пока нет

- Trico Catalog May 09Документ120 страницTrico Catalog May 09Wong DaОценок пока нет

- Installing The Oil Return Line With Ballast Control On The Edwards RV5 Vacuum PumpДокумент8 страницInstalling The Oil Return Line With Ballast Control On The Edwards RV5 Vacuum PumpWong DaОценок пока нет

- Antifriction Bearings, Linear Systems: The Special Solution For Every IndustryДокумент16 страницAntifriction Bearings, Linear Systems: The Special Solution For Every IndustryWong DaОценок пока нет

- ReferenceДокумент2 страницыReferenceWong DaОценок пока нет

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyДокумент16 страницClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyWong DaОценок пока нет

- Wolfgang Amadeus Mozart: Series IIДокумент38 страницWolfgang Amadeus Mozart: Series IIKate WoodОценок пока нет

- Auteur Martin ScorseseДокумент3 страницыAuteur Martin ScorseseGeorge WestОценок пока нет

- Creating A Heraldic Device: Some General TermsДокумент6 страницCreating A Heraldic Device: Some General TermsjkadoshОценок пока нет

- Lego HouseДокумент2 страницыLego HouseRica Marie PadronesОценок пока нет

- Warm Up Exercises For Piano #1 (Beginner) : Tunneltypevision 60Документ3 страницыWarm Up Exercises For Piano #1 (Beginner) : Tunneltypevision 60Alin MariţaОценок пока нет

- A Valediction of WeepingДокумент12 страницA Valediction of WeepingJeffrey Fernández SalazarОценок пока нет

- Ifl 08Документ24 страницыIfl 08satyabashaОценок пока нет

- American Literature Paper 1Документ4 страницыAmerican Literature Paper 1api-266304976Оценок пока нет

- Anton Tchekov - The Three SistersДокумент40 страницAnton Tchekov - The Three SistersLucas Alves100% (3)

- Phrasal VerbsДокумент25 страницPhrasal VerbsEdina TyarОценок пока нет

- CovenantДокумент14 страницCovenantrobelinОценок пока нет

- PerfettiДокумент21 страницаPerfettiAshutosh SinghОценок пока нет

- Philippine National Artists in LiteratureДокумент13 страницPhilippine National Artists in LiteratureKawaii GlamourОценок пока нет

- Standard Hooks Card-ASTM PDFДокумент2 страницыStandard Hooks Card-ASTM PDFRhio CruzОценок пока нет

- Interview With Maria WastiДокумент2 страницыInterview With Maria WastiNabeel Aejaz100% (1)

- Pattern Making AssignmentДокумент5 страницPattern Making Assignmentsuneel kumar rathoreОценок пока нет

- Basic Characteristics of Islamic CivilizationДокумент7 страницBasic Characteristics of Islamic CivilizationSaad Ahmad100% (1)

- LotrДокумент35 страницLotrMaja MajaОценок пока нет

- Comparative and SuperlativeДокумент11 страницComparative and SuperlativesantisОценок пока нет

- Attukal Amma and Kannaki of Chilappathikaram Are Two Different Entities.Документ44 страницыAttukal Amma and Kannaki of Chilappathikaram Are Two Different Entities.Lekshmy RajeevОценок пока нет

- ChordsДокумент31 страницаChordsEngr Minna Minerva AclanОценок пока нет

- ORIGAMI - The History of Origami in JapanДокумент1 страницаORIGAMI - The History of Origami in JapanLenny LyRaОценок пока нет

- Samuel JohnsonДокумент11 страницSamuel JohnsonDimas SetiawanОценок пока нет

- Holy RosaryДокумент16 страницHoly RosaryerlynregОценок пока нет

- Properly Summarizing SourcesДокумент7 страницProperly Summarizing SourcesKking ChungОценок пока нет

- Alucobond LidlДокумент107 страницAlucobond LidlCatalin BunescuОценок пока нет

- Renderoc BF2Документ2 страницыRenderoc BF2MOHAMED.NOUSAR100% (1)