Академический Документы

Профессиональный Документы

Культура Документы

Ronningen-Petter F-Series: Backwashing Pressure Filter System

Загружено:

ck19654840Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ronningen-Petter F-Series: Backwashing Pressure Filter System

Загружено:

ck19654840Авторское право:

Доступные форматы

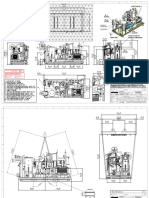

Ronningen-Petter® F-Series Backwashing Pressure

Filter System

For liquid filtering applications that require unattend-

ed operation, maximum uptime, and solids removal

from 1 to 1,700 microns, the F-Series family of filter

systems delivers unbeatable performance.

The key to the F-Series’ versatility is its modular design

that enables future capacity and configuration flexibili-

ty. F-Series systems can include 2 to 20 body tubes

on a single framed skid and can be ordered with

blank stations to allow low-cost expanded capacity.

Like many Eaton (Ronningen-Petter) filters, the F-Series

uses cleanable media. This further reduces life-cycle

costs and maximizes productivity in your plant by

eliminating the labor, replacement, disposal costs

and lost production of bags and cartridges. Key

benefits include:

• Single system flow rates up to 3,000 gpm

(681 m3/hr)

• Smooth pipe and nozzle connection transitions to

avoid dead spots in the fluid stream and

minimize pressure drop

• A broad selection of filter media materials and

retentions suitable for a wide range of applications

• Proprietary 3-way, full-ported valves allow fast,

frequent sequencing and maximum cleaning force

during backwashing

• Isolated top-to-bottom backwash flow ensures

complete and efficient media cleaning while

continuing to deliver filtered product downstream

• Numerous automated backwash options for

operator-free service and minimal backwash

effluent (<2% of system volume)

• Available ACCUFLUX® media dramatically

increases filter surface area in the same footprint

How the F-Series Works

When cleaning is required (triggered

by time or pressure differential), a

single valve removes the tube to

be backwashed from the incom-

ing flow stream. The resulting

pressure drop redirects a portion

Backwashing

of the clean process flow down-

Filtering

ward, flushing the contaminants

to the drain manifold. When

process liquids are very valuable,

or hazardous, an external back-

wash configuration, which uses a

small amount of secondary liquid

introduced through a separate

manifold, is recommended. External Backwashing

Industrial liquid filtration,

separation and mixing solutions

Ronningen-Petter F-Series Product Specifications

Backwashing Pressure Filter System

Connection Frame Materials Media

Inlet and Outlet: 3 in. ANSI or Standard: Painted carbon steel Table shows available media (with

80mm DIN to 12 in. ANSI or Optional: 304 stainless steel corresponding filter surface area)

300mm DIN Flanged and material (with corresponding

Drain: 3 in. ANSI or 80mm DIN Automation retention). Other configurations are

Flanged Standard: Choice of Programmable available on request.

Backwash (if external): 3 in. (80mm) Logic Controller (PLC), semi-automat-

weld stub ic, or manual Single element TRI-CLUSTER® ACCUFLUX® 7

364 in2 (.23 m2) 510 in2 (.33 m2) 791 in2 (.51 m2)

Optional: Wide range possible; ask

Process Parameters your representative for more infor- 316 SS Slotted wedge wire (1) 3-1/4” x 36” (3) 1-1/2” x 36” (7) 1” x 36”

Temperature: 350°F (177°C) system mation 23-1700 microns Filter Stick Filter Stick Filter Stick

maximum (determined by screen 316 SS Wire mesh (1) 3-1/4” x 36” (3) 1-1/2” x 36” (7) 1” x 36”

material and elastomer seals) Utilities 2-1700 microns Filter Stick Filter Stick Filter Stick

Operating pressure: up to 250 psig Electrical (automated models only): Fabric mesh (1) 3-1/4” x 36” (3) 1-1/2” x 36” N/A

(17 bar) 110 or 220 Volt, 50 or 60 Hz, 1-230 microns Sock over perforated Sock over perforated

single-phase 316 SS Perforated (1) 3-1/4” x 36” N/A N/A

Elastomer Seals Air (automated models only): 60- .024 to1 in.

Standard: Buna-N (180°F (82°C) 116 psig (4-8 bar) at 5 CFM (140

maximum) m3/m). Air must be clean, dry and

Optional: Food-grade Neoprene non-lubricated

(180°F (82°C) maximum); Backwash minimum flow: 90 gpm

Nordel (230°F (110°C) maximum); (340 l/min) for single and Tri-Cluster OUTLET

Viton® (300°F (149°C) maximum); media; 150 gpm (567 l/min) for

Teflon® (350°F (176°C) maximum); ACCUFLUX™ media

silicone (350°F (177°C) maximum)

Options EXTERNAL

Housing/Wetted Parts Internal or external backwashing BACKWASH

Materials Media-cleaning diffusers for more (optional)

Standard: 316 stainless steel effective cleaning at low operating

Optional: Wide range possible; ask pressures or volumes

your representative for more infor- Drain header trap

mation Quick-coupler valve connectors for

body tube removal INLET

DRAIN

Dimensions

Model Weight (dry) Height Footprint width x length Volume Configuration Footprint measurements on table at left

lbs (kg) in (mm) in (mm) gal (l) Number of Tubes

F202 450 (204) 62 (1575) 28.5 x 45 (725 x 1145) 18 (68) 2 Eaton

9151 Shaver Road

F203 600 (272) 62 (1575) 28.5 x 48 (725 x 1220) 23 (87) 3

Portage, Michigan 49024 USA

F204 750 (340) 62 (1575) 28.5 x 63 (725 x 1600) 30 (114) 4 Toll Free: 800-656-3344 (North America)

F205 900 (408) 62 (1575) 28.5 x 78 (725 x 1980) 37 (140) 5 Phone: +1 269-323-1313 Ronningen-Petter, TRI-CLUSTER

Fax: +1 269-323-0065 and ACCUFLUX are registered

F206 1200 (544) 62 (1575) 28.5 x 93 (725 x 2360) 65 (246) 6 trademarks of Eaton.

E-mail: info@eaton.com All other registered

F207 1350 (612) 62 (1575) 28.5 x 108 (725 x 2745) 75 (284) 7 Web: www.filtration.eaton.com trademarks and trademarks are

the property of their respective

F208 1500 (680) 62 (1575) 28.5 x 123 (725 x 3125) 85 (322) 8

owners.

F209 1800 (816) 62 (1575) 28.5 x 138 (725 x 3505) 124 (470) 9

Eaton SAS Eaton reserves

F210 1950 (885) 62 (1575) 28.5 x 153 (725 x 3885) 138 (522) 10 Immeuble Colisée Défense the right to change specifications

without prior notice.

F211 2100 (952) 62 (1575) 28.5 x 168 (725 x 4265) 151 (572) 11 50-64 avenue François Arago

F-92022 Nanterre Cedex France

F212 2400 (1089) 62 (1575) 28.5 x 183 (725 x 4650) 165 (625) 12 RPA-FSS

Phone: +33 (0)1 56 83 83 00 PWB RPF-140 04/02 4M

Weights and volumes are given for external backwash configured units. Internal backwash units weights and volumes will be lower. Fax: +33 (0)1 56 83 83 01 Litho in U.S.A.

Вам также может понравиться

- Oxygen Generators Manual Ver - 20140507Документ63 страницыOxygen Generators Manual Ver - 20140507chrismo74Оценок пока нет

- Instrument Air Dryer Maintenance Plan - 1 YEARДокумент2 страницыInstrument Air Dryer Maintenance Plan - 1 YEARtskumarОценок пока нет

- 2749 - Carrier 30 GH 095Документ16 страниц2749 - Carrier 30 GH 095Mohammad Amer100% (2)

- ARCA Evolution160 240 enДокумент2 страницыARCA Evolution160 240 enadyturОценок пока нет

- Copeland Compresor 2019 ECT2014DS78 PDFДокумент166 страницCopeland Compresor 2019 ECT2014DS78 PDFFrancisco Sanchez RОценок пока нет

- Oil Free Scroll Compressors 2 30 KW Brochure NAДокумент8 страницOil Free Scroll Compressors 2 30 KW Brochure NAKervin CoronadoОценок пока нет

- A Range of Effective After-Coolers and Water Separators To Match Your CompressorДокумент2 страницыA Range of Effective After-Coolers and Water Separators To Match Your CompressorJohn TLОценок пока нет

- LMF-GP LX15-8 - 10 - 13Документ2 страницыLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- The Maisotsenko CycleДокумент10 страницThe Maisotsenko Cyclenishith_soni100% (1)

- HC-2380 - Air Dryer Instruction ManualДокумент122 страницыHC-2380 - Air Dryer Instruction ManualEduardo Pedraza100% (1)

- Catalog Foxboro Pneumatic Instruments 03-11Документ88 страницCatalog Foxboro Pneumatic Instruments 03-11Chu Tùng100% (1)

- 369 EN-BI 201601 Air-treatment-DRYERS PDFДокумент20 страниц369 EN-BI 201601 Air-treatment-DRYERS PDFMuhammad JahanzaibОценок пока нет

- Sullair Stationary Pocket GuideДокумент27 страницSullair Stationary Pocket GuideMiguel Angel Jiménez CarpioОценок пока нет

- Operating Instructions and PARTS LIST For: Rix Industries Gas CompressorДокумент65 страницOperating Instructions and PARTS LIST For: Rix Industries Gas CompressorDomingoscarlos RubbenОценок пока нет

- Maintenance/clearance Area: Dimensions Could Be Change +/-5 MMДокумент2 страницыMaintenance/clearance Area: Dimensions Could Be Change +/-5 MMZander MctrevorОценок пока нет

- 2.1 Operating Instructions - SparepartlistДокумент67 страниц2.1 Operating Instructions - SparepartlistneonmagnoОценок пока нет

- 360 CDE Atlas Copco Air Dryers ManualДокумент38 страниц360 CDE Atlas Copco Air Dryers Manualshamil130798100% (1)

- Zeks Compressed Air SolutionsДокумент39 страницZeks Compressed Air SolutionsChristian MabayaОценок пока нет

- LMV 2x/3x: E115X E140X E190XДокумент44 страницыLMV 2x/3x: E115X E140X E190Xhadzic zlataОценок пока нет

- Airmaster User ManualДокумент333 страницыAirmaster User ManualedgarОценок пока нет

- 2447 - Pneumatech Gas Generator Catalogue - LR PDFДокумент24 страницы2447 - Pneumatech Gas Generator Catalogue - LR PDFwgonzalesm100% (1)

- Pneumatic Control SystemfinalДокумент6 страницPneumatic Control SystemfinalneoОценок пока нет

- PSA Oxymat Servicio de MantenimientoДокумент28 страницPSA Oxymat Servicio de Mantenimientovictor hugo valqui lopezОценок пока нет

- Ficha Ig Compresoresdetornillo R37IE en 0Документ1 страницаFicha Ig Compresoresdetornillo R37IE en 0death666darkОценок пока нет

- Section VI DДокумент88 страницSection VI DAnonymous 7ZYHilDОценок пока нет

- N10DC2432-4 NitrogenGenerationPlant NB216Документ31 страницаN10DC2432-4 NitrogenGenerationPlant NB216ionut nicolaeОценок пока нет

- Aerzen Soffiatori LobiДокумент20 страницAerzen Soffiatori LobiBrayanОценок пока нет

- Manual EHDB1200-12000 - May 1996 PDFДокумент42 страницыManual EHDB1200-12000 - May 1996 PDFLAURA VANESA HERREROS QUISPE100% (1)

- Pumps and Cooling TowersДокумент51 страницаPumps and Cooling TowersMikho SaligueОценок пока нет

- APFF 1814 Release of New Roto-Z Oil PDFДокумент2 страницыAPFF 1814 Release of New Roto-Z Oil PDFJoelОценок пока нет

- Auto Drain ValveДокумент2 страницыAuto Drain ValveRoopa MahtoОценок пока нет

- Valvula Expansao Te5 PDFДокумент6 страницValvula Expansao Te5 PDFJosé Edgard Pereira BarrettoОценок пока нет

- Broad Xii Non-Electric Chiller: Model Selection & Design ManualДокумент50 страницBroad Xii Non-Electric Chiller: Model Selection & Design ManualUmar MajeedОценок пока нет

- Standard Operating Procedure - Liquid Nitrogen - Storage, Use & Transportation Guidance & Code of PracticeДокумент9 страницStandard Operating Procedure - Liquid Nitrogen - Storage, Use & Transportation Guidance & Code of PracticejrodОценок пока нет

- Manual Compressor CSD 102, EnglishДокумент108 страницManual Compressor CSD 102, EnglishАлександр ЩербаковОценок пока нет

- Microplasma OzonatorДокумент16 страницMicroplasma Ozonatoranurag jhaОценок пока нет

- Refrigerant Dryer CatalogДокумент4 страницыRefrigerant Dryer CatalogManny MendozaОценок пока нет

- N2-GEN® T Series Nitrogen Generator - South-Tek SystemsДокумент1 страницаN2-GEN® T Series Nitrogen Generator - South-Tek SystemsSouth-Tek SystemsОценок пока нет

- Parker Oil Cross ReferenceДокумент3 страницыParker Oil Cross ReferenceWarwick HolthamОценок пока нет

- Oil Injected Electric Skid Tank Mounted Screw CompressorsДокумент11 страницOil Injected Electric Skid Tank Mounted Screw CompressorsNicky BradОценок пока нет

- Ed 04 (EN)Документ32 страницыEd 04 (EN)King MaxОценок пока нет

- Atmospheric Relief Valve ManualДокумент12 страницAtmospheric Relief Valve ManualTarun ChandraОценок пока нет

- 070.450-IOM XJF 2013-11 Rev 2022-03Документ38 страниц070.450-IOM XJF 2013-11 Rev 2022-03Mohamed HeshamОценок пока нет

- Drying AgentsДокумент28 страницDrying AgentsccatrineОценок пока нет

- Twin Screw Compressor PLC Operation Manual (PDFDrive)Документ158 страницTwin Screw Compressor PLC Operation Manual (PDFDrive)sola sidoОценок пока нет

- Lupamat Oil Free 40 Bar CompressorДокумент8 страницLupamat Oil Free 40 Bar CompressorСергей Колесников100% (1)

- DXR75 1000 June 1996Документ2 страницыDXR75 1000 June 1996SergiSerranoОценок пока нет

- Screw Air Compressor manual60A-100AДокумент13 страницScrew Air Compressor manual60A-100AInge NecoОценок пока нет

- FE800 Bedienungsanleitung Standard 3297-80D1 1 ENGLДокумент44 страницыFE800 Bedienungsanleitung Standard 3297-80D1 1 ENGLMantencion ProverdeОценок пока нет

- Xebec Desiccant Air DryerДокумент41 страницаXebec Desiccant Air DryerGhazali NasirОценок пока нет

- General-Service Packaged Air Compressors and ReceiversДокумент11 страницGeneral-Service Packaged Air Compressors and ReceiversElie HajjОценок пока нет

- Operation, Installation & Maintenance Manual: Vertical Liquid Separator FPVS-SHДокумент12 страницOperation, Installation & Maintenance Manual: Vertical Liquid Separator FPVS-SHMehdi Hajd KacemОценок пока нет

- NG 5000Документ10 страницNG 5000Karthikeyan ParthasarathyОценок пока нет

- Specification ARX120HK EnglishДокумент5 страницSpecification ARX120HK Englishheruono sitorusОценок пока нет

- 12.07.20. O&M Manual 41013 - New PLCДокумент41 страница12.07.20. O&M Manual 41013 - New PLCFranco Sebastián GenreОценок пока нет

- Hydraulic and Lubrication Oil Filters: Filtration ProductsДокумент12 страницHydraulic and Lubrication Oil Filters: Filtration Productschristodoulos charalambousОценок пока нет

- Filtration Systems With Pile Cloth Filter MediaДокумент8 страницFiltration Systems With Pile Cloth Filter MediaSagnik DasОценок пока нет

- Extruder E105R E120R Update 05-2023Документ12 страницExtruder E105R E120R Update 05-2023Sheri MalikОценок пока нет

- Eaton Tubular Backwashing AFC AFR & F-Series FiltersДокумент14 страницEaton Tubular Backwashing AFC AFR & F-Series FiltersJuan CarvajalОценок пока нет

- Calculating Maximum Tube Metal TemperaturesДокумент12 страницCalculating Maximum Tube Metal Temperaturesck19654840Оценок пока нет

- Document PDFДокумент4 страницыDocument PDFck19654840Оценок пока нет

- API 579 Fitness For Service For Nozzles and Flanges (APIFFSB) Module OverviewДокумент49 страницAPI 579 Fitness For Service For Nozzles and Flanges (APIFFSB) Module Overviewck19654840Оценок пока нет

- G4051 S45C PDFДокумент1 страницаG4051 S45C PDFck19654840100% (1)

- Spherical Pressure Vessels PDFДокумент10 страницSpherical Pressure Vessels PDFck19654840Оценок пока нет

- Radiation Protection Program PDFДокумент49 страницRadiation Protection Program PDFck19654840Оценок пока нет

- Cooling Tower Components PDFДокумент4 страницыCooling Tower Components PDFck19654840Оценок пока нет

- Distillation Column Basics PDFДокумент4 страницыDistillation Column Basics PDFck19654840Оценок пока нет

- NDT RT PDFДокумент13 страницNDT RT PDFck19654840Оценок пока нет

- Gouging Procedure PDFДокумент11 страницGouging Procedure PDFck19654840100% (1)

- Thermo Scientific Niton XL3t: A History of InnovationДокумент2 страницыThermo Scientific Niton XL3t: A History of Innovationck19654840Оценок пока нет

- Felleslab: Distillation Columns: SeparationДокумент20 страницFelleslab: Distillation Columns: Separationck19654840Оценок пока нет

- Technical Bulletin: Hydrant Servicer Filter Monitor VesselsДокумент3 страницыTechnical Bulletin: Hydrant Servicer Filter Monitor Vesselsck19654840Оценок пока нет

- Product Quality: Jet Fuel ConductivityДокумент4 страницыProduct Quality: Jet Fuel Conductivityck19654840Оценок пока нет

- Medical Gas Pipeline Systems Ð: Part 1: Terminal Units For Compressed Medical Gases and VacuumДокумент18 страницMedical Gas Pipeline Systems Ð: Part 1: Terminal Units For Compressed Medical Gases and Vacuumck19654840100% (2)

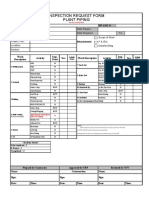

- Inspection Request For WeldingДокумент1 страницаInspection Request For Weldingck19654840Оценок пока нет

- Inspection Request Form Plant PipingДокумент1 страницаInspection Request Form Plant Pipingck19654840Оценок пока нет

- JIG Bulletin 60 PDFДокумент6 страницJIG Bulletin 60 PDFck19654840Оценок пока нет

- TR 94 13Документ25 страницTR 94 13Christian Norambuena VallejosОценок пока нет

- Lexium 23 Plus - BCH0802O12A1CДокумент4 страницыLexium 23 Plus - BCH0802O12A1Cagungch100% (1)

- UNIT 14 - On-Screen DigitizingДокумент6 страницUNIT 14 - On-Screen DigitizingResti KharismaОценок пока нет

- PLX7100A Digital Mobile C-Arm X-Ray Machine: 1. Technical SpecificationДокумент3 страницыPLX7100A Digital Mobile C-Arm X-Ray Machine: 1. Technical SpecificationAbdalhakeem AlturkyОценок пока нет

- Phrasal Verbs-Syntactic BehaviorДокумент4 страницыPhrasal Verbs-Syntactic BehaviorAntonija KnezovićОценок пока нет

- Module 1 Engineering ScienceДокумент38 страницModule 1 Engineering ScienceLogan JesseОценок пока нет

- Biomechanics of The KneeДокумент8 страницBiomechanics of The KneeJorge LopezОценок пока нет

- Hot and Cold ApplicДокумент33 страницыHot and Cold Appliccamille_12_15100% (1)

- Afroasiatic LanguagesДокумент13 страницAfroasiatic Languagesaskask2Оценок пока нет

- 144S... - PCB Series: Signal Conditioned Precision Pressure TransducersДокумент4 страницы144S... - PCB Series: Signal Conditioned Precision Pressure TransducersAnish KumarОценок пока нет

- Downloadble Science NotesДокумент55 страницDownloadble Science NotesJeb PampliegaОценок пока нет

- Elementary Surveying Problem Set 2 q1Документ2 страницыElementary Surveying Problem Set 2 q1soontobengineer50% (2)

- OODBMSДокумент19 страницOODBMSashimsarkar2006Оценок пока нет

- 23AE23 DS enДокумент4 страницы23AE23 DS enBhageerathi SahuОценок пока нет

- 106L Course ReaderДокумент408 страниц106L Course ReadercurufinorОценок пока нет

- Photo Luminescence of Surfaces and InterfacesДокумент25 страницPhoto Luminescence of Surfaces and InterfacesNick KellerОценок пока нет

- Industrial Engineering KTU M TechДокумент7 страницIndustrial Engineering KTU M Techsreejan1111Оценок пока нет

- 86-Article Text-596-1-10-20211030Документ7 страниц86-Article Text-596-1-10-20211030adel bbОценок пока нет

- Start Up and Commissioning of Chilled Water PumpsДокумент6 страницStart Up and Commissioning of Chilled Water PumpsAlaa AnwerОценок пока нет

- 30 - MACRS DepreciationДокумент4 страницы30 - MACRS Depreciationidriwal mayusdaОценок пока нет

- HPC168 Passenger CounterДокумент9 страницHPC168 Passenger CounterRommel GómezОценок пока нет

- Ee-502 Unit - IДокумент2 страницыEe-502 Unit - IVARAPRASADОценок пока нет

- EJ Mini Lesson #7Документ3 страницыEJ Mini Lesson #7ArmandoОценок пока нет

- AtomДокумент15 страницAtomdewi murtasimaОценок пока нет

- 1 s2.0 0304386X9190055Q MainДокумент32 страницы1 s2.0 0304386X9190055Q MainJordan Ulloa Bello100% (1)

- Script Track IP TermuxДокумент5 страницScript Track IP TermuxAsepОценок пока нет

- Good 1983Документ352 страницыGood 1983ASDA75% (4)

- Pearson Product-Moment Correlation Coefficient Table of Critical ValuesДокумент2 страницыPearson Product-Moment Correlation Coefficient Table of Critical ValuesOdy AjjaОценок пока нет

- Pelod Vs Sofa Scoring in PediatricДокумент6 страницPelod Vs Sofa Scoring in PediatricAdrian KhomanОценок пока нет

- Form in MusicДокумент8 страницForm in MusicAndri KurniawanОценок пока нет