Академический Документы

Профессиональный Документы

Культура Документы

Barton LL Digital

Загружено:

Keny AmadorАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Barton LL Digital

Загружено:

Keny AmadorАвторское право:

Доступные форматы

v1.

1b (5/98)

©Copyright 1998, Barton Instrument Systems, LLC

Barton ®

®

MEASUREMENT INFORMATION SYSTEMS

TABLE OF CONTENTS

Introduction [4] Access™ Flow Computers, Totalizers, and

Batch Controllers

• Catalog Introduction Start Here!

• BA202i • BA405 (B/D/A/L)

• About ITT Barton • BA414 (/L) • BA415

• Barton Product Summary

[5] Single and Multi-Stream EFM/RTUs

• Barton DPE™ Sensor • Scanner™ 1130

• Scanner™ 1140/1140C

• Regional Offices/Reps.

• Scanner™ Firmware/Software

[1] Distributed Measurement Systems

• DataScan™

• CryoScan™

• Data/CryoScan PC Software We now have a new name:

Barton Instrument Systems, LLC

[2] Tank Gauging Systems

• 3500 Series ATG

• 3500 Series PC Software

[3] Electronic Transmitters

• FCX A-Series

Click here to Quit/Exit Catalog.

• FCX C-Series

MIS SF-CATALOG 1.1 ii

©1997, ITT Barton, a unit of ITT Industries, Inc.

Barton ®

®

MEASUREMENT INFORMATION SYSTEMS

About This Catalog... Printed Literature

Printed brochures are available for the products featured in

T his Measurement Information Systems short-form

Catalog features an overview of ITT Barton’s precision

products for measurement of fluids and gases in industrial

this electronic catalog. To request literature, contact your

local Barton representative (Barton locations/contact

and specialized applications. information is on page vii at the end of this section). You can

also download selected brochures in Acrobat PDF format

Printable Pages

from our Website (see page vii for our internet address).

If the “Print” menu selection is not grayed-out, the pages in this

catalog can be printed. A compatible color printer is required to

print pages in color.

Navigation

Movement through the catalog can be done using the standard

Acrobat Reader controls or by clicking on the buttons located on

the bottom of each screen.

Page Buttons

To go to table of contents,

click on Contents.

To go to next screen,

click on Next...

To go to previous screen,

click on single left arrowhead. About ITT Barton next page . . .

©Copyright 1997, ITT Barton, a unit of ITT Industries, Inc.. All rights reserved. If print

function is active, pages in this publication may be printed for non-commerical use as a

reference. Information subject to change without notification.

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... iii

Barton ®

®

MEASUREMENT INFORMATION SYSTEMS

About Barton ...

F or more than seven decades, ITT Barton has

set the standard for ruggedness, accuracy, and reliability in

the process measurement industry. Our products — from basic

sensors to highly sophisticated measurement systems — are in

widespread use in virtually every industry requiring precise and

reliable measurement.

It all started in 1925, when Barton Jones and two partners formed

a company to develop and sell forced air transformer coolers.

Over the years Barton has developed many products; however, Today, Barton is a unit of the new ITT Industries corporation, a

the one product line that emerged was the differential pressure worldwide leader in the development, design, and production of

measurement instruments. The heart of these instruments, the integrated products and systems in a wide range of residential,

liquid filled, dual-bellows differential pressure unit (DPU), was commercial, and industrial applications.

developed in 1943. This product was a completely new concept

With a worldwide network of service locations, Barton customers

in flow, liquid level, and differential pressure measurement.

can always get spare parts, accessories, new units, and service

In 1964, Barton was purchased by ITT Corporation, it self a pio- with a simple phone call.

neer in communications and engineering worldwide.

High quality and high accuracy products for today’s demanding

As ITT Barton’s business continued to grow, it moved to its present applications — Barton.

location in the City of Industry, California. This location is a quar-

ter-million square-foot facility that is constantly being updated to

streamline production and meet industry’s every changing require-

ments.

The ITT Barton family has grown over the years to include sub-

sidiaries around the world: ITT Barton Sales, City of Industry,

California; ITT Snyder, Houston Texas; ITT Barton UK, United

Kingdom; ITT Barton Industrial Sales, Illinois; and ITT Barton In-

struments, Canada.

Product Summary next page . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... iv

Barton ®

®

MEASUREMENT INFORMATION SYSTEMS

ITT Barton Products . . . Applications:

Barton products are used in a wide variety of industries and

Barton offers 100+ model configurations ranging from applications:

mechanical DP and Pressure indicators to highly sophisticated

electronic Measurement Information Systems that provide • Oil and Gas

highly accurate and reliable measurement in a wide variety of • Custody Transfer

industries and applications: • Bulk Fuel Storage/Inventory

• Chemical

• Cryogenics

DPU-based Products: • Pulp and Paper

• Power Generation/Nuclear

• Differential Pressure Units (DPU)

• P/DP Indicators

• P/DP Indicating Switches Barton 3500 ATG Network

• P/DP Transmitters

• P/DP/Temp./Flow Recorders

• Turbine Meters TCU TCU TCU TCU TCU

• Floco Meters

• Sealed Sensor Systems

Measurement Information Systems Products: Barton 3500

HOST

ATG Software

Coggins • PC/Fuels Manager

• Electronic Transmitters (P/DP/Level/Flow) • PLC

Modbus

• Single and Multi-stream EFM/RTUs Ethernet • DCS

• Automatic Tank Gauging Systems Local Fuels

Manager

• Flow Computers/Batch Controllers Series 8130 RTU

with Barton LON I/O Card

• Rate Totalizers

• Industrial/Cryogenic Distributed Measurement Systems Other LON Devices

(Level/Pressure/Mass/Volume/Flow)

ITT Barton Locations next page . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... v

Barton ®

®

MEASUREMENT INFORMATION SYSTEMS

Barton’s DPE™ Sensor . . . The DP/SP sensor outputs are amplified to 0-100 millivolt

(nominal) signals that are proportional to the sensed

pressures. Output signal conditioning is determined by end

device requirements with resulting signal accuracies from

0.1% to 0.5% of span. For specific accuracies, refer to end

device literature.

The DPE’s rugged pressure housings (available in Brass,

Carbon Steel, and Stainless Steel) can handle working

pressures up to 2500 psi.

General Specifications:

Service ..................................... Liquid, Gas, or Steam

DP Ranges ............................... 0-150" w.c. (5 psi)

At the heart of many of Barton’s Measurement Information 0-300" w.c. (11 psi)

System products is the Dual Pressure Electronics (DPE) 0-700" w.c. (25 psi)

Sensor. The DPE combines both pressure and differential Absolute Ranges ...................... 0-300 psi

pressure measurement into a single compact unit. With 0-500 psi

design and rigorous testing requirements that virtually eliminate 0-1000 psi

pressure and thermal hysteresis, drift, and sensor instability. 0-1500 psi

0-2500 psi

• High Accuracy and Repeatability

• Dual Micro-machined Silicon Sensors Normal Op. Temp. Limits ......... -40°F to +175°F

• Long-term Stability Safe working pressure ............. 0.5 PSIA to 2500 PSIG

• Low Hysteresis

Overpressure Limit ................... 0-2500 PSIG to either

The DPE is adaptable to the application requirements, thus side w/o damage

the accuracy specifications vary for each end-product (e.g.,

(See end device literature for detailed specifications.)

Scanner™, DataScan™, Series 3500 ATG, etc.) it is used in.

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... vi

Barton ®

®

MEASUREMENT INFORMATION SYSTEMS

ITT Barton, U.K.

ITT Barton Locations 3 Steyning Way

Headquarters/Factory: Southern Cross Trading Estate

900 South Turnbull Canyon Rd. Bognor Regis, West Sussex PO22 9TT

P.O. Box 1882 England

City of Industry, CA 91749-1882 Tel.: 44-1243-826741 • Email: buk@fluids.ittind.com

Tel.: (626) 961-2547• Email: ittbarton@fluids.ittind.com

Worldwide Sales Representative Offices:

Regional Sales Offices: For the location of the one nearest you, call us or check out ITT

Barton’s Internet website.

ITT Barton Sales

800 South Turnbull Canyon Rd. Other ITT Barton Locations

P.O. Box 90036

City of Industry, CA 91715-0036 ITT Barton Product Training Center

Tel.: (626) 336-4502 • Email: bsc@fluids.ittind.com 7707 Pinemont

Houston, Texas 77040

ITT Barton Industrial Sales

Tel.: (713) 682-3595

349 West 195th Street

P.O. Box 466

ITT Barton on the Internet

Glenwood, Illinois 60425-0466

Tel.: (708) 756-1472 • Email: bis@fluids.ittind.com Barton’s Home Page at: http://barton.ittind.com

New and Featured Products • PDF Literature

ITT Snyder

11413 Todd Street

P.O. Box 55629 Fax-on-Demand

Houston, Texas 77255

Tel.: (713) 682-1291 • Email: snyder@fluids.ittind.com Call our Fax-on-Demand system for more information, including

datasheets for our full-line of mechanical (DPU-based) products:

ITT Barton Instruments

3840 11A Street, N.E. (800) 408-2168 [US/Canada] or (714) 253-6821

Calgary, Alberta T2E 6M6 Request Index Document #100.

Canada

Tel.: (403) 291-4814 • Email: barton_can@fluids.ittind.com

Section 1 next page . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... vii

SECTION 1 — Distributed Measurement

Barton ®

®

Overview

DataScan ™/ CryoScan ™ Series. . .

DS30 General Applications

• DataScan™ DS10 — Datalogger/RTU w/Barton DPE™

• DataScan™ DS20 — Indicating/Transmitter w/DPE™

• DataScan™ DS30 — Blind P/DP Transducer w/DPE™

DS20 • DataScan™ DS40 — Datalogger/RTU (no DPE™)

[DS11/41 are CE versions]

DS10/40

(RTU)

• DataScan™ PC Software — Mgmt./DB/Reporting

Cryogenic Applications

CryoScan™ CS10/11/20/30/40/41 and CryoScan™ PC are equivalent

DataScan PC Software products for cryogenic applications.

Product Summary

The Barton DataScan products can be used almost anywhere differential pressure and pressure measurements are

needed. The CryoScan products are for cryogenic applications. Models for both lines range from a basic dual output

transducer to a full-featured electronic datalogger/remote transmitting unit (RTU) that can record process

measurements, provide local indication, and transmits measurements/alarm status to a remote PC (running DS/CS

PC), control system, or other process monitoring device.

With the Data/Cryo PC Software, multiple RTUs can be monitored from a central location. Polling schedules can be

established, RTUs can be configured, alarm status and measurement data can be viewed, graphed, and downloaded.

In addition, with this software, measurement data can be stored on the PC’s hardrive beyond the instrument’s 800

datapoints.

The DS/CS10/11/20/30 Models use ITT Barton’s unique Dual Pressure Electronics Sensor

(DPE™) that provides both static and differential pressure readings.

Continued . . .

ITT Barton Contents MIS SF-CATALOG 1.1

©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 1-1

SECTION 1 — Distributed Measurement

Barton ®

®

Overview

DataScan ™/ CryoScan ™ Series Instruments . . .

DataScan DS10/11/40/41 DataScan DS20 DataScan DS30

Industrial Measurement RTUs that Industrial Level and Pressure Indica- A blind Industrial Level and Pressure

measure both tank level and tor/Transmitter with an integral Transmitter, with an integral Barton

pressure. Measurements are Barton DPE™ Dual Pressure Sensor. DPE™ Dual Pressure Sensor. The

transmitted to a remote host via an The standard unit is battery powered unit’s electronics are housed in an

optional internal 2400 baud modem. with two LCD displays. NEMA 4/IP66 enclosure.

The CS10 features an integrated • Accuracy ±0.25% of F.S. • Accuracy ±0.25% of F.S.

Barton DPE™ Dual Pressure Sensor • Internal Config. Keypad • Ext. 24 VDC provided by CryoScan

(DP/SP), two LCD displays, six 4-20 • Ext. powered 4-20 mA/Contact RTU or equiv.

mA analog inputs, and two contact outputs option • Optional Explosionproof Class I,

closure inputs. • Optional backlight display Div. 1, Group B enclosure

• Accuracy ±0.1% of F.S. • Optional 110VAC operation • Multiple CS30s can be connected

• 800 Datalog points/input • Optional Rechargeable backup to a CS10/40.

DS40 — Non-DPE™ Version battery • CE Compliant

DS11/41 — CE Versions • CE Compliant CS30 — Cryogenic Model

CS10/11/40/41 — Cryogenic Models CS20 — Cryogenic Model

Continued . . .

ITT Barton Contents MIS SF-CATALOG 1.1

©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 1-2

SECTION 1 — Distributed Measurement

Barton ®

®

Overview

DataScan ™/ CryoScan ™ Series RTU/Tank Management Software . . .

• Configure automatic polling, call-in,

and multiple modem operation.

• Manually poll RTUs by RTU, Group,

or Characteristic

• Setup and maintain built-in pass-

word security system.

Analog I/O Inputs:

Measured variables can be setup for

DataScan™ PC Software

Current Only, Pressure, Temperature, CryoScan™ PC Software

An MS Windows™-based PC program

Level, Mass, Volume, or Flow. A cryogenic-industry version, with the

that provides relational database

DS10/11 Quick Start: same interface and capabilities as

management, reporting, and modem

DataScan PC.

communications capabilities for From software installation to receiving

DataScan RTUs. level/pressure data (in US units) is a Note:

matter of minutes. DataScan™ and CryoScan™ PC

With DataScan PC:

Software is designed for use with

• Remotely configure RTUs (alarms, Configuration: Models 10, 11, 40, and 41.

datalog intervals, security, I/O, and • Security Passwords

polling operations) • Display Units

• View and graph RTU data captured • Product Types

by the RTU stored on the PCs • Tank Configuration (dimensions,

hardrive. capacities, etc.)

• Remotely view/acknowledge • RTU Configuration (Customer,

alarms. Communications, Sensor, alarms, I/

• Maintain an RTU/Client database. O, Polling, and misc. parameters).

• View and print Summaries, RTU • Optional Flow Calculations

Status, Alarm History, and more. . . . End of Section 1

ITT Barton Contents MIS SF-CATALOG 1.1

©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 1-3

SECTION 2 — Tank Gauging Systems

Barton ®

®

Overview

Barton 3500 Series ATG Systems . . .

Tank Control Communications

Unit (TCU)

Each system can monitor up to four tanks utilizing the

Tank Top ATG communications network that not only links Tank

Junction Box Control Units (TCUs) together, but allows monitoring,

Laptop reporting, and setup from a central PC computer

Computer

station.

N2

Easy Installation

In-Tank Probe

The combination of a drop-in probe and low-power

Other ATG Network

ModBus™ (Intrinsically Safe) microprocessor unit provides simple, low-cost installa-

Compatible tions — even on operating tanks. No tank modifications,

Systems

PC with no tank-site power requirements, and minimal mainte-

Barton 3500 PC Software

nance. The result . . . No tank down time and continued

ATG safe operation.

Gateway

Series 3500 ATG — Tank Inventory System for Today’s

Requirements . . .

An inventory management system for above- and below-

ground tank applications.

Accuracy • Reliability

Highly accurate measurement of volume, level, mass,

density, temperature, and water bottoms —level accuracy

to 1 mm (0.04") and API volume accuracy to 0.05% — Typical 3500 Installation

without the need for periodic calibration!

Continued . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 2-1

SECTION 2 — Tank Gauging Systems

Barton ®

®

Overview

Barton 3500 Series Inventory Management Software . . .

Logs can be downloaded to disk for

storage and analysis.

TCU Configuration

The following can be configured

remotely:

• TCU Clock

Groups Screen

• TCU Parameters

• Tank Types/Parameters

• Measurement Times/Interval

• Measurement Units

Series 3500 PC Software — Tank Security

Inventory Management for 3500 TCUs and tanks can be assigned

User passwords can be setup to labels and for easy reference.

ATG Systems . . . restrict access.

A Windows™ based program that In addition, a TCU’s configuration

Operation (including strapping tables) can be

allows tank monitoring from a central

PC computer station. From the 3500 PC program, a user saved to disk for storage and re-

can view tank measurements, alarm trieval.

The 3500 Series PC Software can be status, acknowledge alarms, start/

used to perform any function that can Reports

stop transfer operation monitoring,

be performed at a Tank Control Unit view transfer log, perform leak/theft A printed report can be manually or

(TCU) — plus, reporting capabilities testing, view leak/theft logs, and automatically generated. This report

not available on-site from a TCU. remotely configure any TCU con- provides detailed tank, product, and

nected to the network. measurement information.

Information can be displayed by TCU,

tank, or assigned groups of TCUs.

. . . End of Section 2

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 2-2

SECTION 3 — Electronic Transmitters

Barton ®

®

Overview

FCX A-/C-Series Electronic Transmitters (Traditional and “Smart” Digital) . . .

FCX Line Updated — All New Models! Features

Analog Type (4-20 mA):

• Accuracy ±0.1% of F.S.

FCX A-Series • Local Zero/Span Adjust-

ments without terminal.

• Easily upgraded to digital

FCX C-Series

Digital “Smart” Type:

FCX Line • Accuracy ±0.1% of F.S.

These high-tech transmitters employ a micro-capacitance silicon sensor for superior • Ext. 24 VDC provided by

accuracy and stability — in a compact design. DataScan™ or Scanner™

Each model in the series is available in either traditional 4-20 mA analog or “Smart” RTU or equivalent

digital configurations — with an easy analog to digital upgrade path — simply plug in • HHC Terminal

the optional communications module. Communications

Both analog and digital indicators are available.

FCX Series

The A-Series Transmitters are high performance units design for demanding appli-

cations. The C-Series Transmitters provide a lower-cost alternative for less demand-

ing applications. Both lines provide microprocessor control for high accuracy, reliabil-

ity, and digital communications capabilities.

All models are designed using ASIC technology, resulting in a compact feature-

packed unit.

Unlike its analog competitors, FCX provides digital accuracy regardless of whether Model Summary on next page...

or not it contains the “Smart” communications Module. Continued . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 3-1

SECTION 3 — Electronic Transmitters

Barton ®

®

Overview

FCX A-Series Model Summary . . .

GENERAL

SPECIFICATIONS

Differential Pressure Gage Pressure Absolute Pressure Liquid Level

FCX A-SERIES

[FHC/FHF/FKC] [FHG/FKG] [FHA/FKA] [FHE/FKE]

(see individual spec.

sheets for details)

Upper Range Limit mm

in. w.c. mbar kPa psi kPa bar in w.c. kPa mbar

w.c. psi bar

(psid) (bar) (MPa) abs abs abs (psid) d d

(kPa)

Range: [1] 4 100 10 9 64 0.64 2.32 16 0.16 125 3.2 320

[2] 24 610 60 72 500 5 19 130 1.3 250 6.4 640

[3] 125 3175 320 435 3000 30 72 500 5 520 13 1300

[4] 250 6350 640 1500 (10) 100 435 3000 30 (72) 50 5000

[5] 520 13200 1300 7000 (50) 500

[6] (72 (500) (5)

[7] (290) (2000) (20)

[8] (435) (3000) (30)

Elevation/Suppression -100% to +100% URL (zero plus span, not to exceed URL)

Analog: 10:1 (1/10th of URL)

Turn-down (min. span)

Smart: 100:1 (1/100th of URL)

Safe Working Pressure psi kPa Bar psi kPa Bar

Range: [1] 450 3200 32 [1-2] 72 500 5

1500 10000 100 300% of URL [3] 210 1500 15 Up to Flange Rating

[2]

[3-8] 2300 16000 160 [4] 1300 9000 90

[3-8] 6000 42000 420

Analog: ± 0.1% of calibrated span

Accuracy

Smart: ± 0.1% of calibrated span (± 0.075% available, digital mode only)

Sensor: -40°F to +250°F (-40°C to +120°C)

Temperature Limits

Electronics: -40°F to +185° F (-40°C to +85°C)

316(L) SST, Hastelloy C276, Monel 400, Tantalum

Wetted Parts Materials

(see specification sheet for details)

Power Supply 11-45 VDC

Output Signal 4-20 mA

via Fuji or HART Protocol

Communications

(applicable to all "FK" models; "FH" models when communications module is added)

Enclosure IEC IP67 and NEMA 4X

Hazardous Locations Intrinsically Safe and Flameproof (Explosionproof) CSA, FM, BASEEFA, CENELEC, RIIS

Digital or Analog Indicator; Lightening Arrestor; Stainless Steel Electrnoic Housing; NACE Specification; High Temperature/High

Options Vacuum Service; Chlorine Service; Hydroseal Diaphragm for H2 Service; Tropicalization; Material Certification; Process

Adapters Continued . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 3-2

SECTION 3 — Electronic Transmitters

Barton ®

®

Overview

FCX C-Series Model Summary . . .

Differential Pressure

GENERAL Gage Pressure Absolute Pressure

and Flow

SPECIFICATIONS [FHP/FKP] [FHH/FKH]

[FHK/FHN/FKH]

FCX C-SERIES

(see individual spec. mm

in. w.c. mbar psi kPa bar

sheets for details) w.c. psi kPa Bar

(psid) (bar) abs abs abs

(kPad)

*24 610 60 19 130 1.3 19 130 1.3

125 3175 320 72 500 5 72 500 5

Upper Range Limit 520 13200 1300 435 3000 30 435 3000 300

(72) (500) (5) 1500 10000 100

(290) (2000) (20)

Elevation/Suppression -100% to +100% URL (zero plus span, not to exceed URL)

Analog: 10:1 (1/10th of URL)

Turn-down (min. span)

Smart: 16:1 (1/116th of URL)

psi kPa bar psi kPa bar

Safe Working Pressure *450 3200 32 300% of URL 72 500 5

2000 14000 140 220 1500 15

1300 9000 90

Accuracy ± 0.1% of calibrated span

Sensor: -40°F to +250°F (-40°C to +120°C)

Temperature Limits

Electronics: -40°F to +185° F (-40°C to +85°C)

316 SST; 316(L) SST

Wetted Parts Materials

(see specification sheet for details)

Power Supply 11-45 VDC

Output Signal 4-20 mA

via Fuji or HART Protocol

Communications

(applicable to all "FK" models; "FH" models when communications module is added)

Enclosure IEC IP67 and NEMA 4X

Hazardous Locations Intrinsically Safe and Flameproof (Explosionproof) CSA, FM, BASEEFA, RIIS

Digital or Analog Indicator; Lightening Arrestor; Stainless Steel Electronic Housing; NACE

Options

Specification; Degreasing; Tropicalization; Material Certification; Process Adapters

*Note: 450 psi SWP only applies to 24 inch w.c. URL

. . . End of Section 3

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 3-3

SECTION 4 — Flow Computers/Batch Controllers

Barton ®

®

Overview

Access™ Series Totalizers, Flow Computers, and Batch Controllers . . .

• Access™ BA202i — Rate-Totalizer

• Access™ BA400 Series:

_ BA405 B/D/A — Flow Computer

_ BA405L — Flow Computer w/Temp. Compensation

_ BA414 — Batch Controller

_ BA414L — Batch Controller w/Temp. Compensation

_ BA415 — Gas and Steam Flow Computer

New Products that will be included in future MIS

Catalog versions are:

• BA212 — Heat Calculator

• BA214i — Batch Controller (Intrinsically Safe)

• BA415C — Steam to Condensate Computer

• BA430D — Batch Controller (variable quantity)

Contact us for details on these products.

Product Summary

The Barton Access family of products provide accurate and flexible flow measurement and batch control solutions for

a wide range of applications.

The Model BA202i Rate-Totalizer is ideal for irrigation and pipeline applications, or as a replacement for mechanical

registers. It is designed to operate with turbine, positive displacement, and paddle wheel flowmeters.

The BA400 Series consists of three basic mode: BA405, BA414, and BA415. The BA405 has four configurations:

basic freq. input, freq. input with conditioning, analog with fully isolated input, and a temperature compensated version

for liquids. The BA414 Batch Controller comes in two configurations: standard and temperature compensated for

liquids. The BA415 features mass flow, corrected volume, and energy flow display, 4-20 mA and freq. inputs, both

temp. and pressure compensated, and data logging output. Continued . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 4-1

SECTION 4 — Flow Computers/Batch Controllers

Barton ®

®

Overview

Access™: BA202i Rate-Totalizer . . .

High-Tech Enclosure BA 202i Versions

The BA202i is housed in a • Internal Battery Powered

polycarbonate enclosure that is • 4-20 mA Output

completely watertight. It can be

mounted directly to a flowmeter, wall • External DC Power Input

mounted (w/universal bracket), or The battery powered (standard)

pipe mounted (optional 2-inch pipe version uses long life lithium

mount). batteries.

The enclosure, approx. 6” x 4” x 2” in The 4-20 mA Output version provides

size, has a large easy to read LCD a two-wire 4-20 mA scalable output

Model BA202i display and three control buttons on with a fast response to changes in

Designed to operate with turbine, its front face. flowrate — accuracy 0.5% of range.

positive displacement, and paddle Fully Programmable With this version, all power is drawn

wheel flowmeters, the BA202i is ideal from the 4-20 mA loop.

The unit is fully programmable with K-

for irrigation and pipeline The third version combines an

factor, decimal point positions, filter

applications, or as a replacement for external DC power input (12-28 VDC)

constants, and timebase values user

mechanical registers. with high- and low-flow alarms (two

entered.

Flexible Power Options open collector outputs for driving DC

Rate and totals can be displayed in solenoids or ext. relays). Switchable

Internal battery (std. model, no ext. different engineering units. power is 200 mA 30 VDC max.

power req.), optional loop powered

(4-20 mA output), or optional ext. DC

power input.

Continued . . .

ITT Barton Contents MIS SF-CATALOG 1.1

©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 4-2

SECTION 4 — Flow Computers/Batch Controllers

Barton ®

®

Overview

Access™: BA400 Series Flow Computers . . .

BA405B/D/A The unit operates on 12-28 VDC or Communications

Flow Computers 110/220 VAC power. Baudrate: 300-9600

The facia is fully watertight to NEMA Versions

3S or IP65 — resistant to most

chemicals. Wall mount (std.), field or • BA405B - basic freq. input

explosionproof enclosure available. • BA405D - freq. input w/conditioning

Setup • BA405A - analog w/fully isolated

The Model BA405 is designed for a The unit is initially setup with a input (4-20 mA, 0-20

wide range of flow applications, with calibration procedure that enables mA, and 0-10V) [linear,

high accuracy and flexibility built in. scaling factors, digital filtering, and square root, or

display formatting. This information is programmable].

BA405 provides rate, total,

accumulated total, and scaled pulse stored in nonvolatile memory without Accuracy: 0.075,

output (remote totalizers). the need for battery backup. w/span factor 0.1 to

Ticket Printing 50,000.

Options

Software drivers are included (w/ Case

4-20 mA output, RS232 or RS422/

485 bi-directional communications, communications option) that allow The BA405 has an aluminum case

and high/low flowrate alarms are ticket printing (sequential number, approximately 5.7” x 2.8” x 7” (6.3”

available resettable and accumulated totals, depth behind panel) and cutout of

date, and time). 5.5” x 2.6”, with a single rear terminal

Operation

High/Low Alarms block.

Either flowrate or a resettable total

can be continuously displayed on the Two Form-C Relays (5A, 250 VAC or

unit’s large six digit LCD display. A 30 VDC max.)

non-resettable accumulated total can

also be displayed. Continued . . .

ITT Barton Contents MIS SF-CATALOG 1.1

©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 4-3

SECTION 4 — Flow Computers/Batch Controllers

Barton ®

®

Overview

Access™: BA400 Series Flow Instruments (w/Temp. Compensation for Liquids) . . .

BA405L — Flow Computer BA414L displays batch total, preset Custody Transfer

BA414L — Batch Controller quantity, accumulated total, flowrate, With additional features, such as a 10-

gross total, and temperature. point linearity correction and

Both instruments operate on either quatrature pulse input, the BA405L is

12-28 VDC or 110/220 VAC power. ideal for precise flow measurements

The facias are fully watertight to required for custody transfer.

NEMA 3S or IP65 and resistant to Ticket Printing

most chemicals.

The Model BA405L is designed for A number of drivers are included.

general liquids, petroleums, LPG, Standard models are supplied as Printouts include time and date, a

custody transfer, and truck-mounted panel mount units, optional field sequential delivery/batch number, and

applications. mount and explosionproof enclosures the gross, net, and accumulated

are available. totals. An optional header can also be

BA405L displays flowrate, total,

accumulated total, gross total, and Mass Flow printed.

temperature. Low cost mass flow measure-ment Options

can be achieved by using a BA405L Backlight display, RS232/422

with an RTD temp-erature sensor and

volumetric flowmeter (e.g., turbine

meter or PD meter).

Volume Correction

The Model BA414L Batch Controller Correction to 15°C or 60°F for

incorporates two relays that can be petroleum products — API/ASTM

used to control a single or two-stage standards tables/equations are built

control valve. into the unit.

Continued . . .

ITT Barton Contents MIS SF-CATALOG 1.1

©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 4-4

SECTION 4 — Flow Computers/Batch Controllers

Barton ®

®

Overview

Access™: BA400 Series Gas & Steam Computer. . .

BA415 Inputs/Output Options

Gas & Steam Computer Inputs from a wide range of An isolated 4-20 mA re-transmission,

flowmeters, including: vortex, turbine, high- and low- flow alarms, and an

orifice plate, averaging pitot tubes, RS232/422 output.

wedges, and target flowmeters. The pulse output and alarms operate

A scaled output, suitable for driving as mass, corrected volume, or energy

remote totalizers, is a standard outputs.

feature. The RS232/422 option outputs all

Easy to Use displayed parameters — computer

The Model BA415 features: mass and printer protocols are provided.

A front panel keyboard and backlit

flow display, corrected volume and Flowrates and totals can be printed at

alphanumeric display simplify

energy flow, accepts 4-20 mA and programmed intervals for datalogging.

programming. And, the display is easy

frequency inputs, temperature and

to read. Versions

pressure compensated, dual ranged

DP transmitter inputs, simplified Flexible Power Two BA415 versions are available:

programming, and data logging The BA415 operates on 12-28 VDC BA415R with direct RTD input and

output. or AC mains (w/8-24 V available to BA415A with a 4-20 mA temperature

power sensors). input. Both accept 4-20 mA pressure

The BA415 incorporates

input.

compensation for gas and vapors to Enclosure

the ideal gas law, Redlich-Kwong (1)

state, The facial is watertight to IP65 or

NX-19, and equations for both NEMA 3S and resistant to most

saturated and superheated steam. chemicals.

Continued . . .

ITT Barton Contents MIS SF-CATALOG 1.1

©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 4-5

SECTION 4 — Flow Computers/Batch Controllers

Barton ®

®

Overview

Access™: BA400 Series Gas & Steam Computer. . .

BA414 Control Ticket Printing

Batch Controller 2-output relays for control of single or Software drivers included (w/

dual stage valve operation. First relay communications option) for ticket

energizes at start and de-energizes printing (seq. No., reset-table and

when batch is complete. The second accumulated totals, and date/time).

relay can be programmed to energize Versions

at a fixed time and de-energize at a

fixed quantity. • BA414B - basic freq. input

• BA414D - freq. input w/

The Model BA414 is designed for a Options conditioning

wide range of flow applications, An RS232 or RS422/485 • BA414A - analog with both linear

where precise measurement and bi-directional interface option is and square law input relationships.

control of batch quantities is required. available for communication with Temp. compensation, non-linearity

The BA414 will interface with most printers (for ticket printing) and correction, and quadrature input

flowmeters, with both pulse and computers (for full PC control over versions are available.

analog input versions available. The batch operations). Case

Batch Total, Flowrate, Accumulated Batch Features Aluminum case approx. 5.7” x 2.8” x

Total, and Preset Value can be

Automatic Overrun Compensation, 7” (144 mmx 72 mm x 178 mm) [6.3”

displayed in engineering units.

Batch Limit, Signal Timeout, Remote (160 mm) depth behind panel] and

The unit operates on 12-28 VDC or Start/Stop, Auto Restart, Count Up/ cutout of 5.5” x 2.6” (139 mm x 67

110/220 VAC power. Down, and End of Batch . mm).

Facia is watertight to NEMA 3S or

IP65 — resistant to most chemicals.

Wall mount (std.), field and

explosionproof enclosures available.

. . . End of Section 4

ITT Barton Contents MIS SF-CATALOG 1.1

©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 4-6

SECTION 5 — Single/Multi-Stream EFM/RTU

Barton ®

®

Overview

Scanner ™ 1100 Series Electronic Flow Measurement/Remote Telemetry Unit Systems...

• Scanner™ 1130 RTU — Dual-stream, intrinsically-safe

• Scanner™ 1140 RTU — Single-stream, intrinsically-safe

• Scanner™ 1140C RTU — w/Communications capability

• ScanPol™/ScanCom™ — Communications software

• ScanBase™ — Data management software

• OPSat™ —Production satellite measurement firmware

• ScanMod™ — Modbus™ application protocol

• ScanPC™ — DOS communications software

The Scanner Family

The Barton Scanner Family of products provide fast, accurate data at field, plant, and

central office locations. From stand-alone devices to fully-integrated measurement

automation systems, a Scanner solution can be configured to match the most

demanding application.

These low power instruments are ideal for single and multi-stream production, as well

as custody transfer measurement — configuration can be done on-site or remotely

with optional communications capability.

At the heart of the Scanner RTUs is ITT Barton’s unique Dual Pressure

Electronics Sensor (DPE™), which provides both static and differential

Scanner™ 1130 Installation

pressure readings for low power operation with higher accuracy.

Continued . . .

ITT Barton Contents MIS SF-CATALOG 1.1

©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 5-1

SECTION 5 — Single/Multi-Stream EFM/RTU

Barton ®

®

Overview

Scanner ™ 1130 Dual-stream RTU . . .

Display/Controls Up to 2 expansion boards can be

An LCD (4-line x 20-character) and added for additional I/O.

an 8-key keypad. Optional full function Flexible Configuration

keypad and graphical display are

Selectable sampling frequency

available.

(down to > 1X/sec.), user calibration

Communications points (linear or custom), number of

Configuration and measured data can points, hysteresis correction, and

be downloaded, using Barton’s hand- static pressure effect compensation

held terminal (HT88A) or PC via a on different pressure inputs.

front panel RS232 communications Custom Report Generation Custom

port. headers, descriptions, and intervals

Downloaded configurations can be (daily/weekly/monthly/etc.) can be

Scanner 1130 uploaded to other 1130s — reducing printed on any RS232 printer.

A solar (or 24 VDC) powered, EFM/ multiple-unit configuration time. Security System

RTU designed for single or dual- Inputs/Outputs Multi-level for four separate user

stream applications requiring AGA-3,

Up to (12) inputs from orifice and groups and one manager.

-7, -8, or other standard gas

calculations. turbine meters, RTDs, low-power Automatic Flow Estimation

transducers and transmitters, and the

• Intrinsically safe/Low Power Unit can be set to estimate flow

Barton DPE™ Sensor.

• SI Metric or US units during calibration, orifice plate

• Detailed audit trail Status outputs can be used to trigger changes, or power loss.

• IOSI Open Architecture external devices (e.g., counters,

• Barton DPE™ Sensor alarms, etc.).

• Selectable Sampling Freq.

• Automatic Flow Estimation Continued . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 5-2

SECTION 5 — Single/Multi-Stream EFM/RTU

Barton ®

®

Overview

Scanner ™ 1130 Dual-stream RTU (continued) . . .

Calculations data, the screen is blanked, Accessory Board: allows use of a

1130 solves complex gas calculations processor “goes to sleep,” (if set) end line-powered modem in conjunction

according to both North American devices can be cycled on and off, and w/RCU.

(Barton NGas) and International the calculation interval can be Digital Outputs: adds an additional

(Barton IGas) standards. The Barton increased (e.g., 1X/min. with RS232/RS485/RS422 port, the option

IGas program accommodates a compressibility every 5 min.). of adding (4) additional digital status

broader range of primary elements. Power Supply inputs/outputs, and a CCA sealing

NGas: AGA-3, -5, -7, and -8 for Remote or switch.

natural gas flow, including volume, hazardous locations: a solar panel Full Function Keypad: allows on-site

mass, and energy. Gas charges a sealed (gelled) lead-acid unit configuration and operation

compressibility: AGA-8, NX-19, battery. without a terminal

Redlich-Kwong, and Standing-Katz.

Non-hazardous locations: a 24 Graphics Display: (8-line X 28

An interpolation method is provided

VDC supply is available. character) for on-site viewing of

for fluids beyond the scope of

Options menus, data, and graphical charts of

standard algorithms.

flowrun variables.

IGas: international standards, Combiner accessory: multiple runs

including ISO-5167. can be summed for totalized flowrun

data.

Typical orifice calculations (including

AGA-8 primary method) in less than 8 Rackmount: 19” case

seconds. Analog Status Outputs: adds up to

Power Management (3) analog and (3) status/pulse

outputs.

Built-in power management system

controls power use for optimum Remote Serial Port: for (RCU)

performance. When not displaying Remote Communications Unit.

Continued . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 5-3

SECTION 5 — Single/Multi-Stream EFM/RTU

Barton ®

®

Overview

Scanner ™ 1140 Single-stream RTU . . .

Display/Controls Flexible Configuration

An LCD (4-line x 20-character) and Selectable sampling frequency

an 8-key keypad. Optional full function (down to > 1X/sec.), user calibration

keypad and graphical display are points (linear or custom), number of

available. points, hysteresis correction, and

Communications static pressure effect compensation.

Configuration and measured data can Custom Report Generation Custom

be downloaded via an RS232 headers, descriptions, and intervals

interface, using Barton’s hand-held (daily/weekly/monthly/etc.) can be

terminal (HT88A) or PC. printed on any RS232 printer.

Downloaded configurations can be Reports can also be saved as an

uploaded to other 1140s — reducing ASCII file.

Scanner 1140

multiple-unit configuration time. Security System

An economical solar (or 24 VDC)

Inputs/Outputs Multi-level (4 user groups and

powered, EFM/RTU designed for

single-stream applications, with flow 1-flowrun, (using Barton DPE™ and 1 manager).

and pressure control capabilities. 1-RTD input), 2-Analog channels for Automatic Flow Estimation

A powerful alternative to chart local signals, 4-digital inputs/outputs

Unit can be set to estimate flow

recorders. for control and status, 1-4 to 20 mA

during calibration, orifice plate

output, and 1-frequency input.

• Intrinsically safe/Low Power changes, or power loss.

• SI Metric or US units

• Detailed audit trail

• Barton DPE™ Sensor

• Power Management System

• Fast Configuration Continued . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 5-4

SECTION 5 — Single/Multi-Stream EFM/RTU

Barton ®

®

Overview

Scanner ™ 1140 Single-stream RTU (continued) . . .

Calculations When not displaying data, the screen

1130 solves complex gas calculations is blanked, processor “goes to sleep,”

according to both North American (if set) end devices can be cycled on

(Barton NGas) and International and off, and the calculation interval

(Barton IGas) standards. The Barton can be increased (e.g., 1X/min. with

IGas program accommodates a compressibility every 5 min.).

broader range of primary elements. Power Supply

NGas: AGA-3, -5, -7, and -8 for Remote or

natural gas flow, including volume, hazardous locations: a solar panel

mass, and energy. Gas charges a sealed (gelled) lead-acid

compressibility: AGA-8, NX-19, battery or an optional primary battery

Redlich-Kwong, and Standing-Katz. (6V Alkaline) configuration .

An interpolation method is provided Non-hazardous locations: a 24

for fluids beyond the scope of VDC supply is available.

standard algorithms.

IGas: international standards,

including ISO-5167.

Typical orifice calculations (including

AGA-8 primary method) in less than 8

seconds.

Power Management

Built-in power management system

controls power use for optimum

performance.

Continued . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 5-5

SECTION 5 — Single/Multi-Stream EFM/RTU

Barton ®

®

Overview

Scanner ™ 1140C Single-stream RTU with Communications Capabilities . . .

Advantages Turn-key Support

The 1140C’s single unit design offers Barton supplies complete

several advantages over other communications systems, including

instruments: base stations, radio tower

• Reduced space requirement installations, and radio license

• Faster Installation applications.

• Reduced wiring Base stations are designed with built-

in redundancy, diagnostics, and hot

Communications stand-by features to minimize

The 1140C radio options support communications delays and ensure

licensed VHF 450, UHF 900 MHz, continuous service.

and unlicensed spread spectrum

frequencies.

Scanner 1140C

Ultra-low power DC, dial-up modems

The Scanner 1140C combines the can be used with a solar powered

power/functionality of the Scanner 1140C in Div. 2 locations. These are

1140 with an integral capability that ideal for real-time monitoring at gas

can handle radio, phone, or cellular storage facilities, gas banks, main

communications. production batteries, and gas plants

• Built-in Communications where spare telephone capacity is

• Scanner 1140 features and ease of available.

operation The 1140C can also be used with Div.

• Single unit design 2 approved cellular phone modems.

• Class I, Div. 2 application enclosure

Continued . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 5-6

SECTION 5 — Single/Multi-Stream EFM/RTU

Barton ®

®

Overview

Scanner Related Products . . .

And, because of its multi-tasking

capabilities, a single ScanPol

installation can service a network of

100s of Scanner RTUs.

Automatic polling operations can be

once per day, by interval, or

continuous “real-time” polling to a

single RTU.

Comprehensive history records

collected from remote orifice and

turbine meter sites include hourly flow

ScanBase provides access to months

data, a complete audit trail of all

™

ScanPol PC Software of measurement data, user change/

alarms and user changes.

ScanPol for Windows™ automates event/alarm logs, and configuration

collection of historical data from ScanPol uses Barton’s ScanCom™ settings. Integrated data editing,

Barton’s Scanner EFM/RTU devices. protocol (based on OSI) for the recalculation, and graphing tools

ScanPol schedules which field transfer of complex electronic make data analysis easy.

devices to poll, the polling interval, measurement data.

All data/audit trail histories are stored

and what data to collect (which is ScanPol can also be used to remotely in a local database — making

stored in a specified database). update an RTU’s parameters — with regulatory compliance easy.

ScanPol is a fully-automated system a complete change audit trail.

that supports radio, telephone, and ScanBase™ PC Software

cellular communications. It can An MS Windows™-based program for

function as a stand-alone system or in managing flow measurement data

combination with Barton’s ScanBase collected from Scanner RTUs.

Software. Continued . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 5-7

SECTION 5 — Single/Multi-Stream EFM/RTU

Barton ®

®

Overview

Scanner Related Products (continued) . . .

OPSat™ Firmware Up to 40 different wells or production ScanMod™ Protocol

The optional OPSat firmware can be areas can be tracked with minimal An optional Modbus™ application

installed in a Scanner RTU for operator intervention. protocol is also available.

simultaneous measurement of gas In addition, to gas, oil, and waste

and liquids commonly encountered in ScanPC™ PC Software

measurements, OPSat can A DOS-based program used to

oil production (oil, water, emulsions, simultaneously measure other liquid

condensate). monitor/configure Scanner RTUs and

disposal, injection, and free water download stored data. Downloaded

OPSat features proportional and lines. Measurements can include data can be printed, saved, and

integral throttling, on/off control, temperature and pressure imported into ScanBase PC or a

alarm tracking, and direct report compensation, if needed. spreadsheet/DB program.

printing. OPSat allows a choice of methods for

A choice of supercompress-ibility switching wells on test, and for

calculations is offered for both orifice reconfiguring OPSat for each new

and turbine meter equations. test.

The system can be field configured • Manually switch flowrun valves and

for: select new well ID from a list, pre-

• Complete LACT measurement w/ programmed flowrun parameters

control features are automatically updated.

• Test and group separator fluid • Use SCADA or a distributed control

measurement system to provide analog or status

• Trucked fluid measurement input to change configuration/well

• Custody transfer pipeline ID.

measurement OPSat™ is available for 1120, 1130, and

• Misc. fuel gas or reinjected fluids 1140/1140C.

measurement End of Section 5 . . .

MIS SF-CATALOG 1.1

ITT Barton Contents ©1997, ITT Barton, a unit of ITT Industries, Inc.

Next... 5-8

Вам также может понравиться

- Krff302ess01 Tech Sheet - w10787422 - Rev CДокумент10 страницKrff302ess01 Tech Sheet - w10787422 - Rev CJesikaGomezSaavedraОценок пока нет

- Manual MVEДокумент38 страницManual MVEKeny AmadorОценок пока нет

- 970803B Meter Fact. LinearДокумент4 страницы970803B Meter Fact. Linearsyed jeelani ahmedОценок пока нет

- TRG Module PPT - Flow MeasurementsДокумент30 страницTRG Module PPT - Flow Measurementspawan deepОценок пока нет

- Calculating The Sos in Natural Gas - Aga Report No. 10 To Aga Report No. 8Документ11 страницCalculating The Sos in Natural Gas - Aga Report No. 10 To Aga Report No. 8Malouk CheniouniОценок пока нет

- Chris Mills 2020Документ17 страницChris Mills 2020AminОценок пока нет

- Black-Scholes Excel Formulas and How To Create A Simple Option Pricing Spreadsheet - MacroptionДокумент8 страницBlack-Scholes Excel Formulas and How To Create A Simple Option Pricing Spreadsheet - MacroptionDickson phiriОценок пока нет

- Graham HoltДокумент4 страницыGraham HoltTung NguyenОценок пока нет

- BMath3 ProjectДокумент6 страницBMath3 ProjectRainbow VillanuevaОценок пока нет

- Dan Sof TG 0122Документ30 страницDan Sof TG 0122Erick Trujillo100% (1)

- HSQE Policy - English PDFДокумент1 страницаHSQE Policy - English PDFOws AnishОценок пока нет

- ISA SymbolsДокумент2 страницыISA SymbolsD_E_V_ZОценок пока нет

- FGM160 I Complete User ManualДокумент188 страницFGM160 I Complete User Manualjj ssОценок пока нет

- MI199 Training Flow MeasurementДокумент9 страницMI199 Training Flow MeasurementT S VirdiОценок пока нет

- Presentation 1-1 OverviewДокумент18 страницPresentation 1-1 OverviewfaisalardhyОценок пока нет

- Why 4-20 Ma Signal Is Used in Industrial Instrumentation?: Google ChromeДокумент2 страницыWhy 4-20 Ma Signal Is Used in Industrial Instrumentation?: Google Chromemunro_85Оценок пока нет

- FLOCALC Calculation DetailsДокумент21 страницаFLOCALC Calculation DetailsAhmed Hussein100% (1)

- Manual TP Prover Vessel PDFДокумент7 страницManual TP Prover Vessel PDFWilfredo MolinaОценок пока нет

- FS 3210 - FS-Gas Flow ComputerДокумент6 страницFS 3210 - FS-Gas Flow ComputerBinu ManiОценок пока нет

- FB 1200Документ52 страницыFB 1200Eduardo AlvarezОценок пока нет

- Smart Meter Verification & ProvingДокумент7 страницSmart Meter Verification & ProvingdianyvgnОценок пока нет

- Calibration Certificate: Device Under Calibration DetailsДокумент1 страницаCalibration Certificate: Device Under Calibration DetailsKyОценок пока нет

- High-Pressure Union Pressure Transducer Performance Verification Procedu...Документ11 страницHigh-Pressure Union Pressure Transducer Performance Verification Procedu...LudwinОценок пока нет

- Mexico Congress - FMD Not So Small Prover 2017 - Pemex Format Minus VideosДокумент43 страницыMexico Congress - FMD Not So Small Prover 2017 - Pemex Format Minus VideosMelina SbhОценок пока нет

- EGP Measurement ManualДокумент57 страницEGP Measurement ManualMohd HassanudinОценок пока нет

- Abb GCДокумент105 страницAbb GCMarthen TangkeОценок пока нет

- Model 2000 Flow ComputerДокумент8 страницModel 2000 Flow ComputerAdnan SalihbegovicОценок пока нет

- Flow Element Orifice SpecДокумент14 страницFlow Element Orifice Specvishal.nithamОценок пока нет

- Best Training For Flow 1Документ51 страницаBest Training For Flow 1Crispin HungОценок пока нет

- FloBoss™ S600+ Flow Computer Instruction Manual PDFДокумент152 страницыFloBoss™ S600+ Flow Computer Instruction Manual PDFSibabrata ChoudhuryОценок пока нет

- T14 Control Charts PDFДокумент9 страницT14 Control Charts PDFVictor Enrique Rosales ParadaОценок пока нет

- Emerson METCO Training Prog 3 Liquid MeteringДокумент4 страницыEmerson METCO Training Prog 3 Liquid Meteringsyed jeelani ahmedОценок пока нет

- Allocation Metering: Daniel Micro Motion Coriolis MetersДокумент8 страницAllocation Metering: Daniel Micro Motion Coriolis MetersNaser JahangiriОценок пока нет

- Operating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355Документ138 страницOperating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355farhan100% (1)

- Contour™ Flow Conditioner Data Pack PDFДокумент14 страницContour™ Flow Conditioner Data Pack PDFeduryuОценок пока нет

- Astm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your AdvertisementДокумент23 страницыAstm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your AdvertisementTUNG HOANGОценок пока нет

- E 180 000 2 11 13Документ408 страницE 180 000 2 11 13spaszko54Оценок пока нет

- Dse PN MetricДокумент29 страницDse PN MetricSuman DeyОценок пока нет

- Paper 39 Lawrence (Flow Measurement)Документ15 страницPaper 39 Lawrence (Flow Measurement)Philip A Lawrence C.Eng. F. Inst M.C.Оценок пока нет

- Flow Tutorial - PD Positive Displacement Flow MetersДокумент9 страницFlow Tutorial - PD Positive Displacement Flow MetersBrian McMorris100% (2)

- (SS0V002) Bi-Directional Sphere Type ProverДокумент2 страницы(SS0V002) Bi-Directional Sphere Type ProverRoberto Carlos TeixeiraОценок пока нет

- E-Plus 100 Flow ComputerДокумент290 страницE-Plus 100 Flow ComputerJimBoringОценок пока нет

- Gas Measurement Fundamentals & EFMДокумент4 страницыGas Measurement Fundamentals & EFMAtiqah OmarОценок пока нет

- Actuador Limitorque MX y QXДокумент6 страницActuador Limitorque MX y QXManuel FernizaОценок пока нет

- Improving Turbine Meter Measurement by Alternate Fluid Calibration PDFДокумент11 страницImproving Turbine Meter Measurement by Alternate Fluid Calibration PDFcsierracdtОценок пока нет

- 020501C Communicating With Daniel Ultrasonic Gas Flowmeter Model 3400 SeniorSonic PDFДокумент18 страниц020501C Communicating With Daniel Ultrasonic Gas Flowmeter Model 3400 SeniorSonic PDFSofyan HadiОценок пока нет

- SNMP OPC GettingStarted en PDFДокумент10 страницSNMP OPC GettingStarted en PDFalejocmedОценок пока нет

- ITTC - Recommended Procedures and Guidelines For Resistance Uncertainty AnalysisДокумент18 страницITTC - Recommended Procedures and Guidelines For Resistance Uncertainty AnalysisDaniel Vindex Kwabla DomehОценок пока нет

- Introduction To Metering & AllocationДокумент22 страницыIntroduction To Metering & AllocationSameer AhmadОценок пока нет

- 3095MV Calibration Procedure W QuickCal Merian 4010Документ8 страниц3095MV Calibration Procedure W QuickCal Merian 4010luisalbertopumaОценок пока нет

- 5 DanalyzerДокумент37 страниц5 Danalyzermalik shahzad AbdullahОценок пока нет

- Gas Metering TrainingДокумент276 страницGas Metering Trainingsushant shirsatОценок пока нет

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Документ8 страницTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmОценок пока нет

- OQDExpressUserGuide Gen 2 V1Документ22 страницыOQDExpressUserGuide Gen 2 V1Ernie Gomez ColquichaguaОценок пока нет

- Oil and Gas Metering 2Документ2 страницыOil and Gas Metering 2Prabu Kaaliannan100% (1)

- Flow Overview Brochure PDFДокумент64 страницыFlow Overview Brochure PDFRenzoОценок пока нет

- Flow MeasurementДокумент62 страницыFlow MeasurementLiji BrijeshОценок пока нет

- Rosemount 1495 Orifice PlateДокумент6 страницRosemount 1495 Orifice PlateRubénОценок пока нет

- Liquid Meter Proving TechniquesДокумент3 страницыLiquid Meter Proving TechniquesIkhsan ArifОценок пока нет

- GEK28126-Leak Detection For Fuel Gas PipingДокумент4 страницыGEK28126-Leak Detection For Fuel Gas Pipingkarim karimОценок пока нет

- Training - FlowДокумент32 страницыTraining - FlowTimothy LeonardОценок пока нет

- Barton Liquid Level (Mechanical)Документ36 страницBarton Liquid Level (Mechanical)Keny AmadorОценок пока нет

- ATI Industrial Automation - F - T Sensor Mini40Документ2 страницыATI Industrial Automation - F - T Sensor Mini40MUHAMMAD USMAN KhalidОценок пока нет

- Manual Plotter VP 500Документ15 страницManual Plotter VP 500Stefana TrifОценок пока нет

- Oerlikon Leybold Vacuum Catalog 2010 Sogevac Rotary Vane PumpsДокумент116 страницOerlikon Leybold Vacuum Catalog 2010 Sogevac Rotary Vane PumpsKeny AmadorОценок пока нет

- Barton Liquid Level (Mechanical)Документ36 страницBarton Liquid Level (Mechanical)Keny AmadorОценок пока нет

- Surplus Check Valves: Quantities Are Limited So Act Now!Документ1 страницаSurplus Check Valves: Quantities Are Limited So Act Now!Keny AmadorОценок пока нет

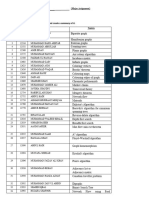

- Used Vessel ListДокумент2 страницыUsed Vessel ListKeny AmadorОценок пока нет

- Its ExtrasДокумент1 страницаIts ExtrasKeny AmadorОценок пока нет

- Verification ofДокумент14 страницVerification ofsamuel-kor-kee-hao-1919Оценок пока нет

- Norman Perrin-What Is Redaction CriticismДокумент96 страницNorman Perrin-What Is Redaction Criticismoasis115100% (1)

- Remaking The Indian Historians CraftДокумент9 страницRemaking The Indian Historians CraftChandan BasuОценок пока нет

- Nikolaenko Et Al 86287Документ7 страницNikolaenko Et Al 86287maytee19Оценок пока нет

- GVP CmdsДокумент3 страницыGVP CmdsShashank MistryОценок пока нет

- Sequential Circuit Description: Unit 5Документ76 страницSequential Circuit Description: Unit 5ramjidr100% (1)

- Effects of Temperature and Moisture On SMCДокумент20 страницEffects of Temperature and Moisture On SMCsenencostasОценок пока нет

- Third Periodical Assessment Test (Pat 3) Grade 8 - MathematicsДокумент10 страницThird Periodical Assessment Test (Pat 3) Grade 8 - Mathematicswerdubob100% (1)

- 240-2 - Review Test 2 - 2Документ4 страницы240-2 - Review Test 2 - 2Nathaniel McleodОценок пока нет

- Muhammad Adnan Sarwar: Work Experience SkillsДокумент1 страницаMuhammad Adnan Sarwar: Work Experience Skillsmuhammad umairОценок пока нет

- Guide Specification - SDP 200: GeneralДокумент10 страницGuide Specification - SDP 200: GeneralhbookОценок пока нет

- Graph Theory (B)Документ2 страницыGraph Theory (B)Waqar RoyОценок пока нет

- Decision Making Techniques: How To Make Good DecisionsДокумент10 страницDecision Making Techniques: How To Make Good DecisionsParanthaman RamanОценок пока нет

- Chap 4 - Shallow Ult PDFДокумент58 страницChap 4 - Shallow Ult PDFChiến Lê100% (2)

- Chapter Seventeen: Managing Conflict, Politics, and NegotiationДокумент32 страницыChapter Seventeen: Managing Conflict, Politics, and NegotiationFajar PranandaОценок пока нет

- Newton's Three Law of MotionДокумент6 страницNewton's Three Law of MotionRey Bello MalicayОценок пока нет

- The Peripatetic Observer 2003Документ10 страницThe Peripatetic Observer 2003SUNY Geneseo Department of EnglishОценок пока нет

- Doppler Weather RadarДокумент35 страницDoppler Weather RadarjosefalguerasОценок пока нет

- Talon Star Trek Mod v0.2Документ4 страницыTalon Star Trek Mod v0.2EdmundBlackadderIVОценок пока нет

- Fabrication of Mortar Mixer and CHB Filler PumpДокумент15 страницFabrication of Mortar Mixer and CHB Filler PumpRenjo Kim VenusОценок пока нет

- HP SMART ARRAY 641 USER GUIDEДокумент69 страницHP SMART ARRAY 641 USER GUIDEMichele BarbaОценок пока нет

- Filmmaking 101Документ4 страницыFilmmaking 101maheshОценок пока нет

- Kindergarten DLL MELC Q2 Week 5 AsfДокумент8 страницKindergarten DLL MELC Q2 Week 5 AsfDiana Rose AcupeadoОценок пока нет

- Sustainability Indicators and Indices: An OverviewДокумент22 страницыSustainability Indicators and Indices: An OverviewRigoberto ToprresОценок пока нет

- Mock Test: Advanced English Material For The Gifted 2020Документ13 страницMock Test: Advanced English Material For The Gifted 2020Mai Linh ThânОценок пока нет

- The Scientific Method Is An Organized Way of Figuring Something OutДокумент1 страницаThe Scientific Method Is An Organized Way of Figuring Something OutRick A Middleton JrОценок пока нет

- A Comprehensive Guide To Oracle Partitioning With SamplesДокумент36 страницA Comprehensive Guide To Oracle Partitioning With SamplesSreenivasa Reddy GopireddyОценок пока нет