Академический Документы

Профессиональный Документы

Культура Документы

Komatsu PC200-8

Загружено:

Agung Ardhana0 оценок0% нашли этот документ полезным (0 голосов)

416 просмотров1 страницаTorque head bolt

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документTorque head bolt

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

416 просмотров1 страницаKomatsu PC200-8

Загружено:

Agung ArdhanaTorque head bolt

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

50 Disassembly and assembly

Installation

1. Cylinder head assembly

1) Measure under head length a of all the

cylinder head mounting bolts to check that

they are within the length limit.

© Bolt length limit: less than 132.1 mm

% Ifa bolt is longer than the using limit,

do not reuse it but replace it.

% Tool A7: gauge is adopted for the

‘measurement. (Refer to the too! list)

owe00275

2) Set head cylinder gasket (62) after check-

ing that there is no dust or foreign material

on the cylinder head mounting face and

inside the cylinders.

* Check that the gasket is properly

matched with the cylinder head holes.

3) Set cylinder head assembly (61) on the

cylinder block, screw in mounting bolts

(60) by hand a few tums, and tighten them

‘according to the following procedure

< : Coat the threads and seat surface

of the mounting bolts with engine

oll (EO15W-40),

941804376

C200, 220-8

SEN00660-00

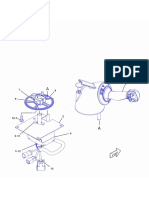

‘How to tighten mounting bolts (60)

%* Tighten the bolts in the order shown

below.

1] 90+3Nm {9.20.3 kgm)

2] Recheck the torque:

90 £3 Nm (9.2 + 0.3 kgm).

3] 90° & 5° (Tighten with an angle tight:

ening tool.)

Tool AG: wrench is adopted for

angle tightening, (Refer to the

tool list) (Refer to the too! list.)

Ung) C2) C8) 14) C1) 05) 9) (13) C171 (210 (281

{—J-—

(191 UN 13) U6) 1) 22h csero69s

‘© When an angle tightening too! is not used:

Put marks on the cylinder head and bolts with

a felt-tip pen, and then tighten the bolts an

additional 90° + 5°

cuer0696

23

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Testing & Adjusting: SAA6D140/125-CRIДокумент20 страницTesting & Adjusting: SAA6D140/125-CRIeko sunaryo100% (1)

- Fuel Injection Pump 320D2Документ1 страницаFuel Injection Pump 320D2Agung ArdhanaОценок пока нет

- Manual Technical Hitachi Zaxis zx110 120 130lcn Hydraulic Excavators Safety Operation Troubleshooting Systems PDFДокумент447 страницManual Technical Hitachi Zaxis zx110 120 130lcn Hydraulic Excavators Safety Operation Troubleshooting Systems PDFRoyen95% (44)

- Tencreng0001 PDFДокумент24 страницыTencreng0001 PDFAgung ArdhanaОценок пока нет

- Kenr2929 00Документ2 страницыKenr2929 00Ebied Yousif AlyОценок пока нет

- Ford 6600 Parts Catalogue PDFДокумент9 страницFord 6600 Parts Catalogue PDFDario JaimesОценок пока нет

- Kenr8665kenr8665-04 Sis PDFДокумент6 страницKenr8665kenr8665-04 Sis PDFAgung ArdhanaОценок пока нет

- Caterpillar SchematicДокумент18 страницCaterpillar SchematicAgung Ardhana75% (4)

- Uenr1369uenr1369 Sis PDFДокумент26 страницUenr1369uenr1369 Sis PDFAgung ArdhanaОценок пока нет

- Manual Oficina c4.2 c6.4 CaterpillaДокумент177 страницManual Oficina c4.2 c6.4 CaterpillaIvo Silva88% (52)

- Troubleshooting Cat 320DДокумент99 страницTroubleshooting Cat 320DAdhie Morello100% (17)

- Caterpillar 773EДокумент1 страницаCaterpillar 773EAgung ArdhanaОценок пока нет

- KENR2918KENR2918Документ2 страницыKENR2918KENR2918Agung ArdhanaОценок пока нет

- 4HK1 & 6HK1 ManualДокумент352 страницы4HK1 & 6HK1 Manuallionkinghd94% (104)

- Renr7872-01 PubДокумент2 страницыRenr7872-01 PubAgung ArdhanaОценок пока нет

- Caterpillar DozerДокумент1 страницаCaterpillar DozerAgung ArdhanaОценок пока нет

- D6R Schematic ElectricДокумент30 страницD6R Schematic ElectricAgung Ardhana71% (7)

- Caterpillar 320cДокумент1 страницаCaterpillar 320cAgung ArdhanaОценок пока нет

- Komatsu pc200-7Документ1 страницаKomatsu pc200-7Agung ArdhanaОценок пока нет

- 320D2 DFM Schematic ElectricДокумент22 страницы320D2 DFM Schematic ElectricAgung Ardhana100% (4)

- Komatsu pc200-7Документ1 страницаKomatsu pc200-7Agung Ardhana0% (1)

- Caterpillar D3K LGPДокумент1 страницаCaterpillar D3K LGPAgung Ardhana100% (1)

- Caterpillar D5R2 XLДокумент2 страницыCaterpillar D5R2 XLAgung ArdhanaОценок пока нет

- D6N Schematic Electric PDFДокумент29 страницD6N Schematic Electric PDFAgung ArdhanaОценок пока нет

- 3406E, C-10, C-12, C-15, C-16 AND C-18 TS ManualДокумент420 страниц3406E, C-10, C-12, C-15, C-16 AND C-18 TS ManualMarco Antonio Aduviri Fernandez86% (37)

- Sensor Position Rotary D5R2 XLДокумент1 страницаSensor Position Rotary D5R2 XLAgung ArdhanaОценок пока нет

- Volvo Ec 210bДокумент1 страницаVolvo Ec 210bAgung Ardhana100% (2)

- KomatsuДокумент1 страницаKomatsuAgung ArdhanaОценок пока нет

- Komatsu WA500-6Документ1 страницаKomatsu WA500-6Agung ArdhanaОценок пока нет

- Komatsu pc200-7Документ1 страницаKomatsu pc200-7Agung ArdhanaОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)