Академический Документы

Профессиональный Документы

Культура Документы

Ecc Cadd Centre

Загружено:

Jovana JovanovicАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ecc Cadd Centre

Загружено:

Jovana JovanovicАвторское право:

Доступные форматы

ISSN: 2277-9655

[Palya * et al., 7(2): February, 2018] Impact Factor: 5.164

IC™ Value: 3.00 CODEN: IJESS7

IJESRT

INTERNATIONAL JOURNAL OF ENGINEERING SCIENCES & RESEARCH

TECHNOLOGY

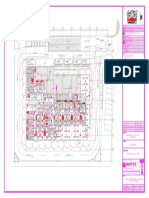

DESIGN OF A SEWAGE TREATMENT PLANT FOR A LOCALITY IN BHOPAL

TO RECYCLE THE LIQUID WASTE

Rajat Palya*1, Dr. V.K. Sethi2

P.G.D.E.M. scholar 1* Vice chancellor R.K.D.F.Univertsity Bhopal 2

EPCO institute of environmental studies, Bhopal M.P.

DOI: 10.5281/zenodo.1165918

ABSTRACT

Sewage treatment is the process of removing contaminants from wastewater and household sewage, both runoff

(effluents) and domestic. It includes physical, chemical, and biological processes to remove physical, chemical

and biological contaminants. Its objective is to produce a treated effluent and a solid waste or sludge suitable for

discharge or reuse back into the environment. This material is often inadvertently contaminated with many toxic

organic and inorganic compounds.

In this research work I will design a sewage treatment plant for a locality (Kohefiza) in Bhopal M.P. to settle down

the liquid waste generated from houses which is generally disposed to water bodies without any proper treatment

which is the cause of water pollution and effect our environment.

KEYWORDS: sewage plant, designing, population forecast, environment, water bodies.

I. INTRODUCTION

Sewage implies the collecting of wastewaters from occupied areas and conveying them to some point of disposal.

The liquid wastes will require treatment before they are discharged into the water body or otherwise disposed of

without endangering the public health or causing offensive conditions.

As the cities have grown, the more primitive method of excreta disposal have gain place to the water-carried

sewerage system. Even in the small cities the greater safety of sewerage, its convenience, and freedom from

nuisance have caused it to be adopted wherever finances permit.

II. OBJECTIVES

1. To design a sewage plant for a locality.

2. To provide sewage effeicient treatment plant to settle next 30 years waste.

3. To reduce environment impact due to sewage false disposal.

4. To settle waste hazarding water bodies near the locality.

Literature related to our research work

Caliberation the three subsystems. For testing of control strategies with model of Avedøre WWTP a benchmark

system with a normal dry weather influent file and various disturbance tests were prepared. The standard control

strategy used at the WWTP was simulated first for a validation. Variation for influent concentrations and flow

rates were created using a random number generator; thus, 90 days of variable influent concentration data was

created. In a successful phosphorous removal strategy also PHA (poly-hydroxy- alkanoate) content is taken into

account; moreover, that was noticed to reduce need of precipitation chemical considerably (Ingildsen et al., 2006).

http: // www.ijesrt.com© International Journal of Engineering Sciences & Research Technology

[193]

ISSN: 2277-9655

[Palya * et al., 7(2): February, 2018] Impact Factor: 5.164

IC™ Value: 3.00 CODEN: IJESS7

Three consulting teams conducted independent modelling projects at three different WWTPs in order to evaluate

and optimise the plant operation; two in USA (Denver, 1,800,000 p.e. andUpper Marlboro, 250,000 p.e.) and one

in Finland (Espoo, 250,000 p.e.) (Phillips et al., 2009).

III. METHODOLOGY

The main object of treatment units is to reduce the sewage contents (solids) from the sewage and remove all the

nuisance causing elements and change the character of the sewage in such a way that it can be safely discharged

in natural water course applied on the land. In other words, the objective of sewage treatment is to produce a

disposable effluent without causing harm or trouble to the communities and prevent pollution. Practically the

treatment of sewage is required in big cities only where the volume of the sewage is more as well as the quantity

of various types of solid, industrial sewage etc. is more and porous land or large quantity of water bodies is not

available for the proper disposal of sewage.

The following point should be kept in mind while giving layout of any sewage treatment plant:

All the plant should be located in the order of sequence, so that sewage from one process should directly

go to other process.

If possible all the plant should be located at such elevation that sewage can flow from one plant into next

under its force of gravity only.

All the treatment units should be arranged in such a way that minimum area is required it will also ensure

economy in its cost.

Sufficient area should be occupied for future extension.

Staff quarter and office also should be provided near the treatment plant, so that operators can watch the

plant easily.

The site of treatment plant should be very neat and give very good appearance.

Bypass and overflow weir should be provided to cut out of operation any unit when required.

All channels, conduits should be laid in such a way as to obtain flexibility, convenience and economy in

the operation

http: // www.ijesrt.com© International Journal of Engineering Sciences & Research Technology

[194]

ISSN: 2277-9655

[Palya * et al., 7(2): February, 2018] Impact Factor: 5.164

IC™ Value: 3.00 CODEN: IJESS7

IV. PROBLEM FORMULATION

Following points are considered during the design of sewage treatment unit:

The design period should be taken between 25 to 30 years.

The design should not be done on the hourly sewage flow basis, but the average domestic flow plus

the maximum industrial flow on the yearly record basis.

Instead of providing one big unit for each treatment more than two numbers small units should

provided, which will provide in operation as well as no stoppage during maintenance and repair of the

plant.

Overflow weirs and the bypasses should be provided to cut the particular operation if desired.

Self cleaning velocity should develop at every place and stage.

The design of the treatment units should be economical; easy in maintenance should offer flexibility

in operation.

V. RESULTS ANALYSIS

http: // www.ijesrt.com© International Journal of Engineering Sciences & Research Technology

[195]

ISSN: 2277-9655

[Palya * et al., 7(2): February, 2018] Impact Factor: 5.164

IC™ Value: 3.00 CODEN: IJESS7

Sr No. ATTIBUTE DATA

1 Project Sewage Treatment Plant for

Koh-E-Fiza & Lalghati

2 Sewage type Partially Separate Sewerage

System

3 Population census

1963 64607

1973 70225

1983 75510

1993 80920

2003 87210

4 Method of Geometric Increase Method

Forecasting

5 Design Populaton

http: // www.ijesrt.com© International Journal of Engineering Sciences & Research Technology

[196]

ISSN: 2277-9655

[Palya * et al., 7(2): February, 2018] Impact Factor: 5.164

IC™ Value: 3.00 CODEN: IJESS7

Base year-2013 91190

Intermediate-2033 103042

Ultimate year-2043 119142

6 Per Capita Water 140 lpcd

Supply

7 Existing Sewerage Nil

system

http: // www.ijesrt.com© International Journal of Engineering Sciences & Research Technology

[197]

ISSN: 2277-9655

[Palya * et al., 7(2): February, 2018] Impact Factor: 5.164

IC™ Value: 3.00 CODEN: IJESS7

http: // www.ijesrt.com© International Journal of Engineering Sciences & Research Technology

[198]

ISSN: 2277-9655

[Palya * et al., 7(2): February, 2018] Impact Factor: 5.164

IC™ Value: 3.00 CODEN: IJESS7

VI. CONCLUSION

A successful technical project involves integration of various fields. This is an attempt to combine several

aspects of environmental, biological and chemical and civil engineering.

Since, in Bhopal Municipal Corporation there is no proper treatment plant for sewage, it is necessary to construct

a Sewage Treatment Plant. The plant is designed perfectly to meet the future expansion for the next 30 years in

accordance with Indian Codal provisions. This project consists the design of the complete components of a Sewage

Treatment Plant from receiving chamber, screening chamber, grit chamber, skimming tank, sedimentation tank,

Oxidation tank and sludge drying beds for sewage

VII. REFERENCES

[1] European Environment Agency. Copenhagen, Denmark. "Indicator: Biochemical oxygen demand in

rivers (2001)." (http:/ / themes. eea. europa. eu/ Specific_media/ water/ indicators/ bod/

[2] Tannery Wastewater Treatment by the Oxygen Activated Sludge Process Mamoru Kashiwaya and

Kameo Yoshimoto Journal (Water Pollution Control Federation), Vol. 52, No. 5 (May, 1980), pp. 999-

1007 (article consists of 9 pages) Published by: Water Environment Federation.

[3] Tchobanoglous, G., Burton, F.L., and Stensel, H.D. (2003). Wastewater Engineering (Treatment

Disposal Reuse) / Metcalf & Eddy, Inc. (4th ed.). McGraw-Hill Book Company. ISBN 0-07-041878-0.

[4] Beychok, Milton R. (1967). Aqueous Wastes from Petroleum and Petrochemical Plants (1st ed.). John

Wiley & Sons. LCCN 67019834.

[5] Water and Wastewater News, May 2004 <http://wwn-online.com/articles/50898/>

[6] American Petroleum Institute (API) (February 1990). Management of Water Discharges: Design and

Operations of Oil-Water Separators (1st ed.). American Petroleum Institute.

[7] Beychok, Milton R. (December 1971). "Wastewater treatment". Hydrocarbon Processing: 109–112.

ISSN 0818-8190.

[8] Choosing an Effluent Treatment Plant, M. Akhtaruzzaman, Alexandra Clemett, Jerry Knapp, Mahbubul

A. Mahmood, Samiya Ahmed.

[9] Biological Wastewater Treatment by Arun Mittal.

[10] http:// wikipedia.com

[11] http:// google.com

CITE AN ARTICLE

It will get done by IJESRT Team

http: // www.ijesrt.com© International Journal of Engineering Sciences & Research Technology

[199]

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Weld History Sheet-4Документ4 страницыWeld History Sheet-4MITHUNОценок пока нет

- Rainwater HarvestingДокумент3 страницыRainwater HarvestingShekh Muhsen Uddin AhmedОценок пока нет

- Rotating Equipment Chapter 3 PumpsДокумент125 страницRotating Equipment Chapter 3 PumpsMamdouhAlhanafy100% (3)

- FormatДокумент480 страницFormatPrabu RanganathanОценок пока нет

- Communal Sanitation SystemДокумент3 страницыCommunal Sanitation SystemkashemОценок пока нет

- Btce20 - Water and Waste Water EngineeringДокумент2 страницыBtce20 - Water and Waste Water EngineeringKarthiik88Оценок пока нет

- 15bch027 P&id MainДокумент1 страница15bch027 P&id MainMayur ParmarОценок пока нет

- PipingДокумент1 страницаPipingMustafa Mahmoud ElsayedОценок пока нет

- Pump DesignДокумент23 страницыPump DesignDidi Kurniadi100% (2)

- Savi General CatalogueДокумент8 страницSavi General CataloguecristyryeОценок пока нет

- Maintenance and Service Manual For Elevator Control Valve EV 100 BlainДокумент13 страницMaintenance and Service Manual For Elevator Control Valve EV 100 BlainCristian Liviu CiovicaОценок пока нет

- X FirefightingДокумент1 страницаX FirefightingArun UdayabhanuОценок пока нет

- Construction Procedure For HydrotestingДокумент7 страницConstruction Procedure For HydrotestingEddie Tai100% (1)

- Plumbing Experiment PDFДокумент9 страницPlumbing Experiment PDFjdpatel28Оценок пока нет

- Check List JnNURMДокумент36 страницCheck List JnNURMshahqazwsxОценок пока нет

- Important Hydraulic Structures Water Supply AND Distribution SystemДокумент15 страницImportant Hydraulic Structures Water Supply AND Distribution SystemMia ListaОценок пока нет

- Bikaner Amidst The Thar Desert - A Case Study On Water Management Systems and AlterlativesДокумент5 страницBikaner Amidst The Thar Desert - A Case Study On Water Management Systems and AlterlativesKNOWLEDGE CREATORS100% (1)

- SOP Rig Up Snubbing 225-340Документ5 страницSOP Rig Up Snubbing 225-340Deddy Bram100% (1)

- Installation, Operation and Maintenance Manual: 5-Stage Filtration Model S51-ICE4-2400-2Документ4 страницыInstallation, Operation and Maintenance Manual: 5-Stage Filtration Model S51-ICE4-2400-2WattsОценок пока нет

- Model 6115-74JM Installation InstructionsДокумент2 страницыModel 6115-74JM Installation InstructionsWattsОценок пока нет

- Dam FailureДокумент20 страницDam FailureSivaramakrishnaNalluriОценок пока нет

- PlumbingДокумент31 страницаPlumbingNicko Jay BajaoОценок пока нет

- Structures:: Potable Running WaterДокумент3 страницыStructures:: Potable Running WaterKevinNavidadОценок пока нет

- P101 FOR ISOMETRY Layout1Документ1 страницаP101 FOR ISOMETRY Layout1Cherish Taguinod AliguyonОценок пока нет

- TG 105ApplicationGuideДокумент12 страницTG 105ApplicationGuideJuan Pablo AriasОценок пока нет

- CompleteOnsiteManual PDFДокумент277 страницCompleteOnsiteManual PDFBambang Tutuko SudiroОценок пока нет

- Rate Consumption (CUBIC) Charge 0.180 2.110 0.66 00.770 0 2: Water Service FeesДокумент1 страницаRate Consumption (CUBIC) Charge 0.180 2.110 0.66 00.770 0 2: Water Service FeesRiyyaz HussainОценок пока нет

- Masterspec Copper SpecificationДокумент10 страницMasterspec Copper SpecificationNabil RamehОценок пока нет

- Midrange Pump Station Design RecommendationsДокумент8 страницMidrange Pump Station Design Recommendationsalan toomeyОценок пока нет

- Aquasafe Aquarium II Installation InstructionsДокумент24 страницыAquasafe Aquarium II Installation InstructionsAquasafeSystemsОценок пока нет