Академический Документы

Профессиональный Документы

Культура Документы

R-103 Heater 2019.04.22

Загружено:

Venkatesan ManikandanИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

R-103 Heater 2019.04.22

Загружено:

Venkatesan ManikandanАвторское право:

Доступные форматы

Bid Summary

No. Description CONTRACTOR VRV ASIA PACIFIC Remarks Status Electricfor

For electric type vaporizer vessel, please confirm paint system equivalent The evaporator tank is insulated and cladded with SS

1.0 Painting and Rust Prevention to paint system D1 as per S-0000-13A0-001 sheet, so painting is not considered. CLOSED

ok

As per point 8, vessel material is stainless steel, Telecon 2019-04-2019

1.1 Painting and Rust Prevention If so, no painting is required. Yes pickling and passivation will be applied by CLOSED

Vendor All the weld joints will be done by Pickling & Passivation, entire ves

Please confirm to provide the necessary documents related to vaporizer

2.0 Vendor Documentation as per Requisition R-215A-103 Confirmed CLOSED

ok

3.0 Test and Inspection including PMI Please confirm test and inspection will be Applied for the electric type Confirmed CLOSED

vaporizer as per Requisition R-215A-103 including PMI where applicable

ok

4.0 Applicable documents Please confirm applicable documents will be considered for the electric Confirmed CLOSED

type vaporizer as per Requisition R-215A-103 ok

Please confirm same fenced area below can be used for complete system

5.0 Plot Area including tank, vaporizer, and outlet piping. Confirmed CLOSED

7000mm x 4000mm ok

6.0 Design Code - Vaporizer Please advise if vaporizer can be designed as per ASME VIII DIV 1 ASME VIII,Div-1 CLOSED

If not, what standard is used? Manufacturer standard? ok

7.0 Design Code - Heating coil Can the heating coil be designed as per ASME VIII or TEMA? TEMA CLOSED asme

Material of Construction - CLOSED

We understand carbon steel as water bath tank material. Please confirm

8.0 Water Bath Vessel SS 304 CLOSED

9.0 Heat Exchange Tube We understand SS304 as tube material. Please confirm Yes CLOSED

Design Parameters - CO2 Line - CLOSED

11.0 Evaporating Capacity Please confirm operating range 60 Kg/hr CLOSED

0 to 53 m3/hr liquid CO2

Please confirm below is considered as feed temperature of CO2

12.0 Temperature - Inlet - 20 degrees C(inlet) Yes CLOSED

Please confirm below is considered as outlet temperature of vaporized

13.0 Temperature - Outlet (min / max) CO2 Yes CLOSED

min +30 (outlet)

max +50 (outlet)

14.0 Water Bath Temperature Please advise bath temperature considering above outlet range Yes CLOSED

requirement. Our understanding it can be 50 degrees.

please advise design temperature of CO2 lines

15.0 Temperature - Design we expect at least - 45 / +75 -60/80 CLOSED

16.0 Pressure - Inlet Operating Please advise inlet pressure considered for vaporizer if available 22 Barg CLOSED

Please reconfirm the same outlet pressure range is guaranteed

17.0 Pressure - Outlet Operating 2.15 to 0.7 MPaG Outlet 21 Barg CLOSED

Please consider 2.15 MPaG (21.5 Barg) as regulator set pressure. It Telecon 2019-04-2019

17.1 Pressure - Outlet Operating means when this pressure is reached, regulator valve is closed. Noted Vendor confirmed CLOSED

Please confirm design pressure below for CO2 line

18.0 Pressure - Design 2.9 MPaG 27 Barg CLOSED

18.1 Pressure - Design Please consider 2.9 MPaG (29 barg) for design pressure Confirmed Telecon 2019-04-2019 CLOSED

Vendor confirmed

Please confirm plant clarified water can be used

19.0 Water Quality Quality is in Basic Engineering Data Confirmed CLOSED

S-0000-1222-001

20.0 Power Consumption If possible , Please advise the expected consumption of heater per kg of Will be provided at detailed engineering stage CLOSED

CO2 vaporized VRV WILL CONFIRM TO ELECTRICFOR

Noted. However please advise preliminary Kilowatt rating of power to be

20.1 Power Consumption supplied. Yes CLOSED

As per drawing , it is around 8 kilowatts.

Please inform the power supply requirement of heater

21.0 Power for Heater 1. 380V, 3 Phase, 3 wire, 50 Hz 380V, 3 pahse, 50 HZ CLOSED

or

2. 230V, 1 Phase, 2 Wire, 50 Hz

Please confirm power supply below can be used

22.0 Control Panel Power supply AC 230 V, +-10%, 50 Hz, Single Phase, Non-Earthed No OPEN

380V AC, 3.PHASE

Telecon 2019-04-2019

Following points were confirmed by

vendor:

1. Electrical tie-in between CONTACTOR

and VENDOR will be at the Vendor Local

Electrical Panel only.

2. VENDOR shall provide the cables and

supply power between the Local Panel and

each consumer in the package.

22.1 Control Panel Power supply To be discussed power supply configuration. Confirmed 2. CONTRACTOR to provide cable and OPEN

power supply to the local panel. This

power is available as 380V, 3ph, 50 Hz,

3Wire only.

Vendor to confirm above and If necessary

to supply different power voltage rating to

package consumers , vendor shall confirm

that the related transformer shall be

included in their supply.

VRV WILL CONFIRM TO ELECTRICFOR ABOUT CABLE SUPPLY SCOPE

FLAME PROOF PANELS

23.0 Control Panel IP protection Please confirm IP protection of local panel is minimum IP54 Yes CLOSED PROVIDED BY SUPPLIER, IT IS

HIGHER CONFIGURATION

Please provide conventional pressure relief valve at the outlet of

24.0 Conventional Relief System vaporizer Yes CLOSED

EXTENT OF SHOP ASSEMBLY / SITE WORKS

Assembled at Vendor Shop with piping, valves, and panel completely

24.0 CO2 Evaporator wired in Single skid Yes CLOSED

25.0 Loose Item Pipe Spool between Tank and Vaporizer only Yes CLOSED

please reconfirm

26.0 Insulation for CO2 Evaporator By JGC at site. Please confirm common understanding The evaporator tank will be insulated and cladded CLOSED

with aluminium sheet at VRV.

Yes, we can remove insulation from our scope. Bare

26.1 Insulation for CO2 Evaporator Could VRV descope this insulation ? vessel without insulation will be assembled in the skid CLOSED

If not , can VRV follow JGC standard for insulation? and sent to JGC, the same shall be insulated from your

side.

VRV WILL CONFIRM TO SUPPLIER

Telecon 2019-04-2019

Following points were confirmed by vendor:

1. Local Electrical Panel is provided by vendor

2. Temperature Transmitter will be provided at the

outlet / CO2 gas line to monitor the temperature. JGC

27.0 Temperature Control and Monitoring To advise how to control will connect directly to this transmitter. (No need to CLOSED

connect to local panel)

3. For bath temperature control, temperature sensors

are provided to trip/stop the electric heater from

overheating the water bath and keep it at 50 degrees

Celsius.

VENDOR TO PROVIDE TRANSMITTER IN OUTLET OF VAPORIZER

Вам также может понравиться

- Cold Stretch Cal For 80KL-17bar On 28.05.2013Документ9 страницCold Stretch Cal For 80KL-17bar On 28.05.2013Venkatesan ManikandanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Codeware, Inc.: Sarasota, FL, USAДокумент20 страницCodeware, Inc.: Sarasota, FL, USAVenkatesan ManikandanОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Weld CalculationДокумент1 страницаWeld CalculationVenkatesan ManikandanОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Spec Eng MQ042Документ8 страницSpec Eng MQ042Venkatesan ManikandanОценок пока нет

- 80 - VRV Ancher BoltДокумент1 страница80 - VRV Ancher BoltVenkatesan ManikandanОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Anderson Greenwood Crosby Sanmar Limited 147, Karapakkam Village, Chennai - 600097, Tamil Nadu, INДокумент2 страницыAnderson Greenwood Crosby Sanmar Limited 147, Karapakkam Village, Chennai - 600097, Tamil Nadu, INVenkatesan ManikandanОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Cryogenic Composite InsulationДокумент1 страницаCryogenic Composite InsulationVenkatesan ManikandanОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- 2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Документ4 страницы2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Venkatesan ManikandanОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Bulk Tank WizardДокумент61 страницаBulk Tank WizardVenkatesan ManikandanОценок пока нет

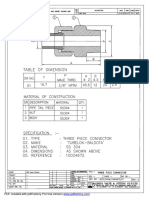

- (Three Piece Connector) PDFДокумент1 страница(Three Piece Connector) PDFVenkatesan ManikandanОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Rototel Float Level Gauge Dial Sticker For 230LДокумент1 страницаRototel Float Level Gauge Dial Sticker For 230LVenkatesan ManikandanОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Model Empty Weight KG Standard TankДокумент2 страницыModel Empty Weight KG Standard TankVenkatesan ManikandanОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Vaporizer Specification SR No. Description Unit Design ParametersДокумент1 страницаVaporizer Specification SR No. Description Unit Design ParametersVenkatesan ManikandanОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Status of Major Materials S.no Description Make StatusДокумент1 страницаStatus of Major Materials S.no Description Make StatusVenkatesan ManikandanОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Bellows PDFДокумент1 страницаBellows PDFVenkatesan ManikandanОценок пока нет

- TAG Description Make Size: V9, V10 Instrumentation ValveДокумент1 страницаTAG Description Make Size: V9, V10 Instrumentation ValveVenkatesan ManikandanОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Thermax Inc.: Climate Map and Freeze PeriodsДокумент1 страницаThermax Inc.: Climate Map and Freeze PeriodsVenkatesan ManikandanОценок пока нет

- Quotation : Terms & ConditionsДокумент1 страницаQuotation : Terms & ConditionsVenkatesan ManikandanОценок пока нет

- Datasheet For Level TransmitterДокумент9 страницDatasheet For Level TransmitterVenkatesan ManikandanОценок пока нет

- Detail of Aluminium Channel - VRV SAP CODE - 10022319Документ1 страницаDetail of Aluminium Channel - VRV SAP CODE - 10022319Venkatesan ManikandanОценок пока нет

- Infino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateДокумент2 страницыInfino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateVenkatesan Manikandan0% (1)

- Datasheet For Pressure TransmitterДокумент8 страницDatasheet For Pressure TransmitterVenkatesan ManikandanОценок пока нет

- Continuous Beam Staad ReportДокумент14 страницContinuous Beam Staad ReportMuhammad Shukri Bin SaharinОценок пока нет

- Al CoatingДокумент17 страницAl Coatingjijith njОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Barrack and Store Building Detail EstimateДокумент178 страницBarrack and Store Building Detail EstimateShailendraОценок пока нет

- 02 Samss 005Документ13 страниц02 Samss 005eramioОценок пока нет

- Ciht Industrial Training FileДокумент48 страницCiht Industrial Training FileRishabОценок пока нет

- Design Standards-Newark SpecificsДокумент160 страницDesign Standards-Newark SpecificsibrahimtaherОценок пока нет

- Royal CordДокумент1 страницаRoyal CordWilfredoJrReyОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Plant - Room.Position - And.Size: DistributionДокумент26 страницPlant - Room.Position - And.Size: DistributionMhr IzadОценок пока нет

- Twin City Fan & Blower Guide Specification Plenum Fans: Model MPQS, Direct DriveДокумент7 страницTwin City Fan & Blower Guide Specification Plenum Fans: Model MPQS, Direct DriveMoriyasu NguyenОценок пока нет

- Ultra 145A 205A Installation ManualДокумент22 страницыUltra 145A 205A Installation ManualcharlesОценок пока нет

- HT Breaker Checklist - Fy22Документ1 страницаHT Breaker Checklist - Fy22chandanОценок пока нет

- Estey Library BrochureДокумент19 страницEstey Library BrochuremaxsmaxОценок пока нет

- Study On Working of Filler Materials in Bituminous ConcreteДокумент72 страницыStudy On Working of Filler Materials in Bituminous ConcreteChand Basha Shaik0% (1)

- Troldtekt Plus January 2013 UKДокумент8 страницTroldtekt Plus January 2013 UKStacey HayesОценок пока нет

- Content of Design Standard 4S-10.01: Manufacture and Installation Specification For FRP StructuresДокумент29 страницContent of Design Standard 4S-10.01: Manufacture and Installation Specification For FRP StructuresJuan Ayala ValdebenitoОценок пока нет

- Base Plate IPE200 Fe250Документ32 страницыBase Plate IPE200 Fe250Tejas SawantОценок пока нет

- Mechanics of Materials 7th Edition Beer Johnson Chapter 6Документ134 страницыMechanics of Materials 7th Edition Beer Johnson Chapter 6Riston Smith95% (96)

- Bionanocomposite: Vikram Singh Vikash Kumar Sunil Kumar Akshay PadghanДокумент14 страницBionanocomposite: Vikram Singh Vikash Kumar Sunil Kumar Akshay PadghanVikram KulriaОценок пока нет

- Recent Technology of Coke Oven Refractories: Technical ReportДокумент8 страницRecent Technology of Coke Oven Refractories: Technical ReportAmit Kumar DasОценок пока нет

- Installation Chapter OneДокумент16 страницInstallation Chapter Oneassefa0% (1)

- Mcode and Mname Commercial and Alternate Designations: Material - Cross - IndexДокумент33 страницыMcode and Mname Commercial and Alternate Designations: Material - Cross - IndexMohamedОценок пока нет

- Lecture Plate Girder Intro DSS 2Документ37 страницLecture Plate Girder Intro DSS 2Amarendra KojjaОценок пока нет

- Designers Guide To EN1994-2 Eurocode 4Документ19 страницDesigners Guide To EN1994-2 Eurocode 4Andrei Puscas0% (2)

- Asme B16.21Документ21 страницаAsme B16.21Anant RubadeОценок пока нет

- AWC NDS-2018-withCommentary 1805 DND PDFДокумент316 страницAWC NDS-2018-withCommentary 1805 DND PDFGlenn NewmarkОценок пока нет

- Odwadniacz Termostatyczny th13Документ1 страницаOdwadniacz Termostatyczny th13Fernando Moreno pereiraОценок пока нет

- 2015-5 - TechPresentation - Bentley ASME RTP 1Документ71 страница2015-5 - TechPresentation - Bentley ASME RTP 1Christian Cobo100% (4)

- Manual de Operacion MKДокумент8 страницManual de Operacion MKEmilioPerezBallesterosОценок пока нет

- CFF 2nd Series QP - Nov 2019Документ1 страницаCFF 2nd Series QP - Nov 2019Venkitaraj K PОценок пока нет

- BHUJKUTCHGUJARATДокумент16 страницBHUJKUTCHGUJARATsnehal kambleОценок пока нет