Академический Документы

Профессиональный Документы

Культура Документы

Replacements: AK 200 S / AK 200 ULTRA S Replacements 4:1

Загружено:

Wahyu Setyo PОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Replacements: AK 200 S / AK 200 ULTRA S Replacements 4:1

Загружено:

Wahyu Setyo PАвторское право:

Доступные форматы

Chapter 4

Replacements

Contents

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4:2

Replacement of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4:3

Change actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4:5

Replacement of Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4:7

List of batteries in AK 200 S and AK 200 ULTRA S . . . . . . . . . . . 4:7

Battery and electronic waste handling . . . . . . . . . . . . . . . . . . . . . . 4:7

HCEN9284 Revision 02.2010 AK 200 S / AK 200 ULTRA S Replacements 4:1

Program version 10.xx

General

The actions to carry out after a component replacement in AK 200 S /

AK 200 ULTRA S are brought together in two tables:

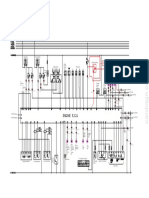

- a replacement matrix for the blood monitor (BM)

- a replacement matrix for the fluid monitor (FM)

The numbers in the matrix show which actions and in which order they

will be done. It is important that the actions are done and in correct

order.

This information is a guideline for service technicians, which actions

to perform when a component has been replaced.

A list of all actions and explanations how to execute them is found

further on in this chapter.

Note

• If the fluid path has been opened for troubleshooting, a heat

disinfection must be performed before the machine is ready

for next treatment.

Note

4:2 AK 200 S / AK 200 ULTRA S Replacements HCEN9284 Revision 02.2010

Program version 10.xx

Replacement of components

BM components

Replaced BM components

Blood Volume Sensor (BVS) E

Level detector (Air detector)

Venous / System air pump

AK 200 S / AK 200 ULTRA S

Blood pump motor unit

Replacement matrix

Clamp unit complete

Pressure Transducer

Blood pump rotor

Priming detector

Operator's panel

BM CPU board B

Heparin pump

I2c scan 1

C he c k /loa d progra m ( G X D ) 1

T ota l de fa ult 2

L oa d pre s e t file 4

J

2J

J

2J

J

2J

J J

2J

J

Fch 1 2 8 2 1 3 1

S e t time a nd da te 3

Calibrate Level detector

5 (BM 5) 1 (BM 5)

Actions to be done

(Air detector)

C a libra te P riming de te c tor ( B M 6 ) 6 (B M 6) 1 (B M 6) 1 (B M 6)

A A

Calibrate Pressure transducer 2

O c c lus ion 1

S imula te d tre a tme nt 3

BVS test with tool K22281001 4

Test clamp according to

3

the Maintenance manual

P E T -te s t 1 1

ELT-test

PLT-test

Remarks:

A

Not necassary to calibrate if new spare part is installed (factory calibrated)

B

Important to follow the order of the calibrations/actions for machine performance

C

Specify machine type, serial no and running time when ordering

D

Only AK 200 ULTRA S

E

BVS unit and BVS board must have the same serial number

F

Heating vessel: Level detector, stirrer, temp. Transducer

G

Heating vessel: Heating unit complete, inlet unit complete

H

FCH with BiCart

I

FCH in BiCart Select-mode

J

FCH without inlet water (ready when Priming-button is flashing)

HCEN9284 Revision 02.2010 AK 200 S / AK 200 ULTRA S Replacements 4:3

Program version 10.xx

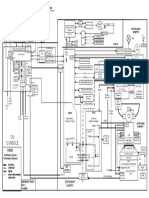

FM components

4:4 AK 200 S / AK 200 ULTRA S Replacements HCEN9284 Revision 02.2010

Program version 10.xx

Change actions

I2C scan Perform actions according to Service

Manual chapter Maintenance support

description, Diagnostic Flow diagram,

FM.

BVS test with tool Perform actions according to instructions

K22281001 in the Maintenance manual.

Calibrate BiCart Select Calibrate according to calibration

Control and Protective instructions in the Service Manual

Pump chapter Calibration manual.

Calibrate BiCart Select Calibrate according to calibration

Level detector instructions in the Service Manual

chapter Calibration manual.

Calibrate Bloodleak Calibrate according to calibration

instructions in the Service Manual

chapter Calibration manual.

Calibrate Conductivity Calibrate according to calibration

Cell A instructions in the Service Manual

chapter Calibration manual.

Calibrate Conductivity Calibrate according to calibration

Cell B instructions in the Service Manual

chapter Calibration manual.

Calibrate FRN Calibrate according to calibration

instructions in the Service Manual

chapter Calibration manual.

Calibrate Internal Calibrate according to calibration

Pressure Regulator instructions in the Service Manual

chapter Calibration manual.

Calibrate Level detector Calibrate according to calibration

(Air detector) instructions in the Service Manual

chapter Calibration manual.

Calibrate pH Calibrate according to calibration

instructions in the Service Manual

chapter Calibration manual.

Calibrate Priming Calibrate according to calibration

Detector instructions in the Service Manual

chapter Calibration manual.

Adjust inlet pressure Adjust inlet pressure regulator according

regulator to Service Manual chapter Calibration

manual.

Calibrate Pressure Calibrate according to calibration

Transducer instructions in the Service Manual

chapter Calibration manual.

Check BPM Check according to BPM test instructions

in the Service Manual, chapter

Maintenance manual.

HCEN9284 Revision 02.2010 AK 200 S / AK 200 ULTRA S Replacements 4:5

Program version 10.xx

Check conductivity value Check conductivity value according to

hospital laboratory.

Check/Load program Perform actions according to instructions

(GXD) in Service Manual chapter Maintenance

support description.

Download new program version.

Clean the machine from Perform actions according to Operators

calcium and then from manual.

proteins and fats

ELT Perform the Earth Leakage Test (ELT)

according to instructions available in

chapter Electrical safety inspections for

AK-machines.

Fch Start the machine and let it perform a Fch.

Heat disinfection Perform a heating according to the

Operator's Manual.

Load preset file Perform actions according to instructions

in Service Manual chapter Maintenance

support description.

Occlusion Calibrate according to calibration

instructions in the Service Manual

chapter Calibration manual.

PET Perform the Protective Earth Test (PET)

according to instructions available in

chapter Electrical safety inspections for

AK-machines.

PLT Perform the Patient Earth Leakage Test

(PLT) according to instructions available

in chapter Electrical safety inspections

for AK-machines.

Set time and date Set time and date according to

instructions in the Service Manual,

chapter Maintenance support description.

Simulated Treatment Simulate a treatment according to

instructions in Service Manual chapter

Maintenance manual.

Test clamp according to Test the clamps according to instructions

the Maintenance manual in the Service Manual, chapter

Maintenance manual.

Total default Perform actions according to instructions

in Service Manual chapter Maintenance

support description.

4:6 AK 200 S / AK 200 ULTRA S Replacements HCEN9284 Revision 02.2010

Program version 10.xx

Replacement of Batteries

List of batteries in AK 200 S and AK 200 ULTRA S

The following batteries are present in AK 200 S and AK 200 ULTRA S:

Description Type Location

Battery to real time clock, CR2025 Below the buzzers at

3V Lithium the BM CPU board,

B1

Battery for power failure alarm, HR6F22 BM

9V NiMH

Battery backed memory, BR1632 BM CPU board.

SRAM IC 65, IC10.

Battery back-up during power LC-R127R2PG1 Below bottom tray on

failure, the monitor stand

12V, Rechargeable Lead battery

Battery and electronic waste handling

Separate collection for electrical and

electronic equipment

Waste handling

Batteries from AK 200 S and AK 200 ULTRA S shall not be discarded

in normal waste, instead separate and proper collection systems must

be used. If improperly disposed, batteries might contaminate the

environment and risk the health of people.

Note

• Follow local legislation applicable for Battery and electronic

waste handling.

Note

HCEN9284 Revision 02.2010 AK 200 S / AK 200 ULTRA S Replacements 4:7

Program version 10.xx

This page is intentionally left blank

4:8 AK 200 S / AK 200 ULTRA S Replacements HCEN9284 Revision 02.2010

Program version 10.xx

Вам также может понравиться

- Chery Tiggo Esquema PDFДокумент1 страницаChery Tiggo Esquema PDFtadeu67% (9)

- Maxxforce 13Документ3 страницыMaxxforce 13Pablo Cervantes100% (1)

- Bosch m7.9.7 PDFДокумент25 страницBosch m7.9.7 PDFRuben Dario Casique83% (24)

- 3126B Industrial Engine Electrical System: ECM AMP ConnectorsДокумент2 страницы3126B Industrial Engine Electrical System: ECM AMP Connectorsedcar100% (1)

- Engine Wiring Diagram Form: ECM 96-Pin E1 ConnectorДокумент2 страницыEngine Wiring Diagram Form: ECM 96-Pin E1 Connectorjuan carlos rojas cadena100% (3)

- Wiring Diagram S300WD2H21Документ34 страницыWiring Diagram S300WD2H21Albert Briceño100% (4)

- Esquema Da Injeção Tiggo 2.0 PDFДокумент1 страницаEsquema Da Injeção Tiggo 2.0 PDFtadeu100% (1)

- Circuit Diagram 2.4 AT - Chery Tiggo T11Документ1 страницаCircuit Diagram 2.4 AT - Chery Tiggo T11limadacarlos67% (3)

- EVC - C2 Installation Gas & D3Документ2 страницыEVC - C2 Installation Gas & D3Tiên Lê Trần MỹОценок пока нет

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- AK96 Error Code 350Документ132 страницыAK96 Error Code 350Tyo67% (6)

- GE Corometrix 250cx Monitor - User ManualДокумент250 страницGE Corometrix 250cx Monitor - User ManualmanualslibОценок пока нет

- Case Analysis SampleДокумент22 страницыCase Analysis SampleMicaela EncinasОценок пока нет

- Predicting Residual Stresses Due To Solidification in Cast Plastic Plates VladoTropsaPhDДокумент225 страницPredicting Residual Stresses Due To Solidification in Cast Plastic Plates VladoTropsaPhDAghajaniОценок пока нет

- Ansi Hi 9.1-9.5-2000 PDFДокумент78 страницAnsi Hi 9.1-9.5-2000 PDFandhucaos100% (1)

- TM Daikin 50Hz SingaporeДокумент86 страницTM Daikin 50Hz SingaporeericyuenОценок пока нет

- McQuay Mini-Chiller M4AC-M5AC Technical Manual EngДокумент180 страницMcQuay Mini-Chiller M4AC-M5AC Technical Manual EngFernando SilvaОценок пока нет

- Deutz BFM 1015 Gas Engine DATA PDFДокумент4 страницыDeutz BFM 1015 Gas Engine DATA PDFMuhammad rizkiОценок пока нет

- Fssabs We 0125msДокумент59 страницFssabs We 0125mshigui2013Оценок пока нет

- Replacements: Replacement Matrix...................................... 2Документ6 страницReplacements: Replacement Matrix...................................... 2Mounir AngadОценок пока нет

- 04 2 40 - UsДокумент4 страницы04 2 40 - UsAbdul MajidОценок пока нет

- Daikin 60 HZДокумент83 страницыDaikin 60 HZNavin RamnauthОценок пока нет

- CK 800-EU Pump StationДокумент30 страницCK 800-EU Pump Stationtiago calderОценок пока нет

- TIO Console: Stationary GantryДокумент1 страницаTIO Console: Stationary Gantryjairo castroОценок пока нет

- Eh1102-05 - Alternator MountingДокумент2 страницыEh1102-05 - Alternator MountingBoBoMilovanovicОценок пока нет

- ES-LDS-Wireless General Submittal - 2208Документ2 страницыES-LDS-Wireless General Submittal - 2208ryanОценок пока нет

- Ch06EN ReplacementsДокумент6 страницCh06EN ReplacementsHermeson SantiagoОценок пока нет

- Spare Parts Creation Form: Bourbon Peridot Curto CEДокумент9 страницSpare Parts Creation Form: Bourbon Peridot Curto CELungeanuОценок пока нет

- 8 Final Test - ACCU Sub F & Far F - MДокумент1 страница8 Final Test - ACCU Sub F & Far F - MLê Hồng SơnОценок пока нет

- Certified Test, Adjust and Balance Report: Balancing DevicesДокумент1 страницаCertified Test, Adjust and Balance Report: Balancing Devicesahmed younisОценок пока нет

- Arnan Review Ina1 - Jci HruДокумент1 страницаArnan Review Ina1 - Jci HruDidik HariantoОценок пока нет

- w0719 Poster EVC-C D9 D12 D16 PDFДокумент2 страницыw0719 Poster EVC-C D9 D12 D16 PDFabduallah muhammadОценок пока нет

- Ipf710 GCD CDДокумент12 страницIpf710 GCD CDMarko PanajotovОценок пока нет

- Sod IvarДокумент41 страницаSod IvarSacha's ChannelОценок пока нет

- Petrochemical Complex In South Of Vietnam Tổ hợp hóa dầu Miền Nam Việt NamДокумент1 страницаPetrochemical Complex In South Of Vietnam Tổ hợp hóa dầu Miền Nam Việt NamLê Hồng SơnОценок пока нет

- PVsection PDFДокумент62 страницыPVsection PDFShihab MonОценок пока нет

- ZG1200 - Service Manual PDFДокумент276 страницZG1200 - Service Manual PDFR. Joseph BouvierОценок пока нет

- Manual Simulator TechSimДокумент246 страницManual Simulator TechSimAlefterix Anca100% (1)

- Engine Managment System TOO PDFДокумент9 страницEngine Managment System TOO PDFdane63Оценок пока нет

- 02 Sumitomo ExcavatorДокумент36 страниц02 Sumitomo Excavatorilonk antonie100% (1)

- FG - Multi-DENCO® Technical Data - Specification-Technical - UNДокумент44 страницыFG - Multi-DENCO® Technical Data - Specification-Technical - UNAbdullah.N FAAliОценок пока нет

- Air Cooled Mini Chiller AMAC-C-2009Документ180 страницAir Cooled Mini Chiller AMAC-C-2009ADV C&L Venture S/BОценок пока нет

- D85EX 15 EngineДокумент9 страницD85EX 15 EngineQuy Le Thanh100% (1)

- ATK-Tool Comunication and CablesДокумент12 страницATK-Tool Comunication and Cablesvitali_curteanuОценок пока нет

- Fmea Circulating Water PumpДокумент10 страницFmea Circulating Water PumpazisyuswandiОценок пока нет

- Abbreviations Used in Manual,: Downloaded From Manuals Search EngineДокумент11 страницAbbreviations Used in Manual,: Downloaded From Manuals Search EngineDavid QuispeОценок пока нет

- 2004 MY OBD System Operation Summary For 6.0L Diesel EngineДокумент46 страниц2004 MY OBD System Operation Summary For 6.0L Diesel EnginesergioОценок пока нет

- Engine Wiring Diagram (Side 1) : Maxxforce 11 and 13 2008 Model YearДокумент2 страницыEngine Wiring Diagram (Side 1) : Maxxforce 11 and 13 2008 Model YearIsaac Newton0% (1)

- EN EMR3-Training PDFДокумент60 страницEN EMR3-Training PDFvan long Bui100% (1)

- Dobdsm 304Документ39 страницDobdsm 304LuisangelDueñasОценок пока нет

- Russ Manual Suzuki SkyWave AN400 K3 40strДокумент387 страницRuss Manual Suzuki SkyWave AN400 K3 40strБорис Арлашин100% (1)

- Water Catalog 2021Документ132 страницыWater Catalog 2021Chris SalcidoОценок пока нет

- Sony hdr-sr5 sr7 sr8 Adjustment Ver1.0 PDFДокумент49 страницSony hdr-sr5 sr7 sr8 Adjustment Ver1.0 PDFsilictronicОценок пока нет

- Communicating With Auto-Adjust Turbo-Meter Gas Flowmeters: Last Updated: 19 June 2009Документ9 страницCommunicating With Auto-Adjust Turbo-Meter Gas Flowmeters: Last Updated: 19 June 2009syed jeelani ahmedОценок пока нет

- Case Cx200b Engine enДокумент5 страницCase Cx200b Engine enjacquiline100% (44)

- SMART Control Bujagali - DCS System Architecture Rev D PDFДокумент1 страницаSMART Control Bujagali - DCS System Architecture Rev D PDFBlažević JosipОценок пока нет

- Networking Touareg New Vehicle 2010Документ1 страницаNetworking Touareg New Vehicle 2010Krzysztof BydełekОценок пока нет

- Valve Schedule - 10.5.2021 (LATEST)Документ83 страницыValve Schedule - 10.5.2021 (LATEST)rvkheavenОценок пока нет

- EMR 3 Service - TrainingДокумент69 страницEMR 3 Service - TrainingJorge Gonzalez OsorioОценок пока нет

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- AK 95 / AK 95 S Service Manual: A Better Way To Better CareДокумент247 страницAK 95 / AK 95 S Service Manual: A Better Way To Better CareWahyu SetyoОценок пока нет

- Gambroak200operationmanualaubtewt 1219987298 PDFДокумент3 страницыGambroak200operationmanualaubtewt 1219987298 PDFWahyu Setyo PОценок пока нет

- Gambroak200operationmanualaubtewt 1219987298 PDFДокумент3 страницыGambroak200operationmanualaubtewt 1219987298 PDFWahyu Setyo PОценок пока нет

- AK 200 S AK 200 ULTRA S Dialysis Machine PDFДокумент356 страницAK 200 S AK 200 ULTRA S Dialysis Machine PDFMurat AytulunОценок пока нет

- Pickering PDFДокумент32 страницыPickering PDFWahyu Setyo PОценок пока нет

- AK 200 S Ak 200 Ultra S: Dialysis MachinesДокумент12 страницAK 200 S Ak 200 Ultra S: Dialysis Machinesbme_najiОценок пока нет

- Pickering PDFДокумент32 страницыPickering PDFWahyu Setyo PОценок пока нет

- AK 200 S AK 200 ULTRA S Dialysis Machine PDFДокумент356 страницAK 200 S AK 200 ULTRA S Dialysis Machine PDFMurat AytulunОценок пока нет

- Dok Baru 2019-03-30 09.31.09 PDFДокумент17 страницDok Baru 2019-03-30 09.31.09 PDFWahyu Setyo PОценок пока нет

- Gambroak200operationmanualaubtewt 1219987298 PDFДокумент3 страницыGambroak200operationmanualaubtewt 1219987298 PDFWahyu Setyo PОценок пока нет

- Trouble ShootingДокумент3 страницыTrouble ShootingWahyu Setyo PОценок пока нет

- Ak 200 Gambro Service Manual PDFДокумент1 страницаAk 200 Gambro Service Manual PDFWahyu Setyo PОценок пока нет

- Contoh CV ProfesionalДокумент2 страницыContoh CV ProfesionalElyani AdityaОценок пока нет

- 金宝ak200sfch701自检步骤详解Документ50 страниц金宝ak200sfch701自检步骤详解Oqba Alshek Ali100% (1)

- PH-11012 Phoenix Deaeration Issues PDFДокумент3 страницыPH-11012 Phoenix Deaeration Issues PDFWahyu Setyo PОценок пока нет

- Replacements: AK 200 S / AK 200 ULTRA S Replacements 4:1Документ8 страницReplacements: AK 200 S / AK 200 ULTRA S Replacements 4:1Wahyu Setyo PОценок пока нет

- Pickering PDFДокумент32 страницыPickering PDFWahyu Setyo PОценок пока нет

- Pickering PDFДокумент32 страницыPickering PDFWahyu Setyo PОценок пока нет

- AK 95 / AK 95 S Service Manual: A Better Way To Better CareДокумент247 страницAK 95 / AK 95 S Service Manual: A Better Way To Better CareWahyu SetyoОценок пока нет

- Contoh CV PDF Doc Untuk Lamaran Kerja EnglishДокумент1 страницаContoh CV PDF Doc Untuk Lamaran Kerja Englishriandikaa68Оценок пока нет

- Gambro Ak 200 Ultra S Operator Manual PDFДокумент1 страницаGambro Ak 200 Ultra S Operator Manual PDFWahyu Setyo PОценок пока нет

- Ch07 HCEN9287 02 2010 10 PDFДокумент24 страницыCh07 HCEN9287 02 2010 10 PDFWahyu Setyo PОценок пока нет

- Ch08 HCEN9297 02 2010 10 PDFДокумент26 страницCh08 HCEN9297 02 2010 10 PDFWahyu Setyo PОценок пока нет

- AK 200 S Ak 200 Ultra S: Dialysis MachinesДокумент12 страницAK 200 S Ak 200 Ultra S: Dialysis Machinesbme_najiОценок пока нет

- Gambroak200operationmanualaubtewt 1219987298Документ3 страницыGambroak200operationmanualaubtewt 1219987298Wahyu Setyo PОценок пока нет

- Manual Book Gambro cp12Документ104 страницыManual Book Gambro cp12Wahyu Setyo PОценок пока нет

- General Information 1:1Документ10 страницGeneral Information 1:1Wahyu Setyo PОценок пока нет

- Replacements: AK 200 S / AK 200 ULTRA S Replacements 4:1Документ8 страницReplacements: AK 200 S / AK 200 ULTRA S Replacements 4:1Wahyu Setyo PОценок пока нет

- Management - Ch06 - Forecasting and PremisingДокумент9 страницManagement - Ch06 - Forecasting and PremisingRameshKumarMurali0% (1)

- Book - Lattice Boltzmann Methods For Shallow Water FlowsДокумент117 страницBook - Lattice Boltzmann Methods For Shallow Water FlowsMauricio Fabian Duque DazaОценок пока нет

- Product Position and Overview: Infoplus.21 Foundation CourseДокумент22 страницыProduct Position and Overview: Infoplus.21 Foundation Courseursimmi100% (1)

- Unit - I Dynamics of Electric Drives: Electrical Power Transmission SystemsДокумент4 страницыUnit - I Dynamics of Electric Drives: Electrical Power Transmission Systemsyemane gebremichalОценок пока нет

- Research On RosesДокумент6 страницResearch On RoseskirilkatzОценок пока нет

- RoboticsДокумент41 страницаRoboticsMark Jason100% (3)

- Discovery of A New Energy VortexДокумент4 страницыDiscovery of A New Energy Vortexnblack3335140Оценок пока нет

- TERZ 94OMManualRev0107 PDFДокумент66 страницTERZ 94OMManualRev0107 PDFRoberto Andres Vasquez Campusano75% (4)

- Brugg Cables Presentation ECMC PDFДокумент47 страницBrugg Cables Presentation ECMC PDFlilcristiОценок пока нет

- Read and Write Action of RAM Using IC 7489Документ5 страницRead and Write Action of RAM Using IC 7489Deepak Kumbhar100% (1)

- Kathrein 80010430 PDFДокумент1 страницаKathrein 80010430 PDFRaúl Fernández SánchezОценок пока нет

- Stress Gradients in AlbertaДокумент22 страницыStress Gradients in AlbertaBehzadDastjerdyОценок пока нет

- Manual de Programacao r6 N 1.3Документ160 страницManual de Programacao r6 N 1.3Ian MechuraОценок пока нет

- In The Next Three Chapters, We Will Examine Different Aspects of Capital Market Theory, IncludingДокумент62 страницыIn The Next Three Chapters, We Will Examine Different Aspects of Capital Market Theory, IncludingRahmat M JayaatmadjaОценок пока нет

- 2206 SUBMISSION ManuscriptFile - PDF - .Docx 9327 1 10 20230711Документ13 страниц2206 SUBMISSION ManuscriptFile - PDF - .Docx 9327 1 10 20230711Meryouma LarbОценок пока нет

- An Adaptive Hello Messaging Scheme For Neighbor Discovery in On-Demand MANET Routing ProtocolsДокумент4 страницыAn Adaptive Hello Messaging Scheme For Neighbor Discovery in On-Demand MANET Routing ProtocolsJayraj SinghОценок пока нет

- Spring State Machine TransitionsДокумент6 страницSpring State Machine TransitionsGroza CristiОценок пока нет

- CNS TechnicianДокумент2 страницыCNS TechnicianSohailОценок пока нет

- Solar Radiation, Heat Balance and Temperature Chapter 8 - Class 11 Geography NCERT - Class Notes - Samagra Book Series Batch (Hinglish)Документ30 страницSolar Radiation, Heat Balance and Temperature Chapter 8 - Class 11 Geography NCERT - Class Notes - Samagra Book Series Batch (Hinglish)avnish.k.verma.2014Оценок пока нет

- A Handheld Gun Detection Using Faster R-CNN Deep LearningДокумент5 страницA Handheld Gun Detection Using Faster R-CNN Deep LearningJanderson LiraОценок пока нет

- Solar and Wind Hybrid Power GenerationДокумент35 страницSolar and Wind Hybrid Power Generationlatest advance guruji 2018Оценок пока нет

- 7 Maths em 2020-21Документ326 страниц7 Maths em 2020-21ThОценок пока нет

- Partially Miscible LiquidsДокумент4 страницыPartially Miscible LiquidsCatriona BlackОценок пока нет

- Holiday Homework Class 12 MathematicsДокумент2 страницыHoliday Homework Class 12 MathematicsKartik SharmaОценок пока нет

- Isoquants and Returns To ScaleДокумент14 страницIsoquants and Returns To ScaleAniket ChatterjeeОценок пока нет

- Cad Module 2Документ3 страницыCad Module 2JithumonОценок пока нет

- 31-12-2022 - SR - Super60 - NUCLEUS & STERLING - BT - Jee-Main-PTM-16 - KEY & Sol'SДокумент12 страниц31-12-2022 - SR - Super60 - NUCLEUS & STERLING - BT - Jee-Main-PTM-16 - KEY & Sol'SSameena LoniОценок пока нет