Академический Документы

Профессиональный Документы

Культура Документы

MattMill Student

Загружено:

benignoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MattMill Student

Загружено:

benignoАвторское право:

Доступные форматы

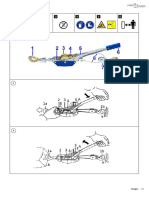

Grain opening

MattMill Student

Documentation Setscrew

1. Objective and exclusion of liability Mounting holes

2. Warning

3. Operation, maintenance, cleaning

and storage

4. Adjustment Mounting sample Housing screws

5. Actuation screw and hand crank

(optional) Actuation screw

6. Malfunction

1.1 Objective Hand crank

This present construction MattMill is a device for the manual crushing of dry barley and wheat (optional)

grains, respectively, with the purpose of preparing malts for mashing at a homebrewer scale

(non-commercial).

1.2 Exclusion of liability

This present construction was designed to the best of the constructor’s knowledge and belief. The distributor cannot be held liable for imper-

fections of the design and is hereby excluded. For the incorrect usage, i.e. differing from section 1.1, especially the non-stop operation and

the installation of a motor, only the operator of the construction can be held liable.

2. Warning

During the operation of the MattMill sources of danger are existent. Only adult persons are allowed to use the system! Do not remo-

ve safeguards! Only operate with the funnel attached. During usage any manual intervention is dangerous and can lead to major

injuries. Crushing of material not stated in section 1.1, especially the insertion of foreign matter must be excluded by the operator.

The device is not suitable for the long-term storage of goods and has to be filled directly before use. Any leftover has to be removed instanta-

neously.

3.1 Operation

Mount the MattMill Student tightly onto a wooden board, table etc using adequate screws . Make sure that the mounting will remain tight du-

ring usage. Tho outlet at the bottom must remain open.

To collect the crushed malt it is recommendet to place a sufficiently large container below the mill.

Mount a funnel (optional):

A large PET soda bottle (e.g. 1.5 or 2 l) can be used as funnel. For this cut off the bottom of the bottle. Place the bottle neck into the top

grain opening hole and carefully secure the bottle by gently tightening of the set screws (please use an Allan key SW3).

Prior to the first usage please crush and discard approximately 100 grams of grain in order to ensure that no montage residues will remain in

the housing.

Maximal rotation rate ~ 400 rpm.

3.2 Maintenance and cleaning

The MattMill Student is maintenance-free. In case of any irregularity please contact the distributor.

Do not use liquids for cleaning. Only tapping, brushing or blow-out with air should be used.

It is recommended to regularly check that all screws are tight. Furthermore regularly check the ease if movement of the rollers when the mill

is empty.

3.3 Storage

In order to avoid corrosion cool, dry storage is recommended.

4. Adjustment

The MattMill Student cannot be adjusted. The gap size is set to ~ 1.2 mm. For finly crushed malts 2 consecutive milling rounds are recom-

mended.

5. Actuation screw and hand crank (optional)

To mount the hand crank the actuation screw needs to be dismounted (if applicable). Block the rollers from the bottom side using a wooden

wedge. Do not use screw drivers etc. Place the wooden wedge from below between the rollers to avoid movements to the left. Using a

wrench size 13 losen the lock nut of the actuation screw by a left turn. Replace the actuation screw by the hand crank by screwing the crank

into the actuation roller (right turn). Fix the hand crank by tightly securing it with the lock nut. Remount the funnel and the hand-driven Matt-

Mill Student is set to go.

6. Malfunction

The MattMill Student can be opened easily e.g. in case one of the rollers only turns with difficulties. For this, unscrew the 4 housing screws

with an Allan wrench sice SW5. Make sure that everything sits in the correct positions when remounting the mill. When in doubt contact your

distributor.

Kirkel, 01.02.2016

MattMill, Matthias Hoßfeld Maschinenbau, Eibenweg 4, D-66459 Kirkel, hossfeld@CADin3D.de Further information: www.MattMill.de

Вам также может понравиться

- Atacama Roll Bag: Operating InstructionsДокумент18 страницAtacama Roll Bag: Operating InstructionsMajdy AlsobhiОценок пока нет

- Treadmill 81uu0NEHUzLДокумент11 страницTreadmill 81uu0NEHUzLSriRamCharanОценок пока нет

- Instruction Manual For Cleaver MAX CI-01: Usage and Safety RegulationДокумент2 страницыInstruction Manual For Cleaver MAX CI-01: Usage and Safety RegulationViren TrivediОценок пока нет

- IFU - PFM Rotary 3005 E - EN - Rev2016-12 - LowresДокумент28 страницIFU - PFM Rotary 3005 E - EN - Rev2016-12 - LowresDương HưngОценок пока нет

- Owner-s-Manual 70380 Chipper-Shredders 17839 19970101 X00195-105298 199900195-200105298Документ19 страницOwner-s-Manual 70380 Chipper-Shredders 17839 19970101 X00195-105298 199900195-200105298JoeОценок пока нет

- TM 1000 1 - S2 1eДокумент72 страницыTM 1000 1 - S2 1ekit101100% (1)

- Lathe Machine ManualДокумент80 страницLathe Machine Manualaeronkenneth.montanoОценок пока нет

- Klutch Angle Grinder Holder - 375354Документ5 страницKlutch Angle Grinder Holder - 375354boomissyОценок пока нет

- TM ZR860 1 - S1 1eДокумент134 страницыTM ZR860 1 - S1 1ekit10167% (3)

- 2. Инструкции Apple Ръчна лебедкаДокумент2 страницы2. Инструкции Apple Ръчна лебедкаeliaОценок пока нет

- High Capacity Stacker-C1: Option - Sta - USДокумент40 страницHigh Capacity Stacker-C1: Option - Sta - USAlejandro SotoОценок пока нет

- MattMill MasterДокумент1 страницаMattMill MasterbenignoОценок пока нет

- Truck Crane 1: GT-900XLДокумент270 страницTruck Crane 1: GT-900XLJulio Ramos100% (1)

- GR-700EXL-1 S2-2E Repair Manual PDFДокумент416 страницGR-700EXL-1 S2-2E Repair Manual PDFAhmed Trabelsi100% (1)

- Educational Injection Moulder Model 25 Instruction ManualДокумент17 страницEducational Injection Moulder Model 25 Instruction ManualDynamic SaravananОценок пока нет

- High Speed Lining Machine Operation ManualДокумент43 страницыHigh Speed Lining Machine Operation Manualfarhoy77Оценок пока нет

- EX1200-6 Maintenance PDFДокумент157 страницEX1200-6 Maintenance PDFaarizal80% (5)

- Manual Drillatt 7100 7200 Stihl Shop EskДокумент16 страницManual Drillatt 7100 7200 Stihl Shop Eskapi-238657580Оценок пока нет

- BLD M25Документ26 страницBLD M25sunwell.wilson6Оценок пока нет

- New Check ListДокумент24 страницыNew Check Listahmed agrodyОценок пока нет

- Operation Manual MTC CryostatДокумент21 страницаOperation Manual MTC CryostatNikolay PenevОценок пока нет

- Tiger Heated GripsДокумент9 страницTiger Heated Gripschampion11311Оценок пока нет

- WilTec Hydraulic 12 Ton Press With ManometerДокумент6 страницWilTec Hydraulic 12 Ton Press With ManometerWaleed MuradОценок пока нет

- GR 800XXL 1 - S2 (U) 1eДокумент402 страницыGR 800XXL 1 - S2 (U) 1eกิจรุ่งเรือง โพจัน100% (2)

- Microtomy Paraffin SectionДокумент36 страницMicrotomy Paraffin Sectiondante220Оценок пока нет

- Newlongind - Co.Ltd Model Cp4900 Operation ManualДокумент5 страницNewlongind - Co.Ltd Model Cp4900 Operation ManualkhaiphuongОценок пока нет

- HF62114 - Porta Power Super Heavy Duty Hydraulic JackДокумент12 страницHF62114 - Porta Power Super Heavy Duty Hydraulic JackBryanОценок пока нет

- CS510e03 060701Документ28 страницCS510e03 060701Bojan PenoОценок пока нет

- Giotto/Giotto Plus: Use and Maintenance Instructions ManualДокумент12 страницGiotto/Giotto Plus: Use and Maintenance Instructions Manualbrunolechat90Оценок пока нет

- SP661E Safety Ver 1.1 GBДокумент17 страницSP661E Safety Ver 1.1 GBDrow RangerОценок пока нет

- Belt ThresherДокумент3 страницыBelt ThresherDevish WakdeОценок пока нет

- Euroboor ECO.55 S TAДокумент37 страницEuroboor ECO.55 S TAahmedhamdi731Оценок пока нет

- EX3600-6 MaintenanceДокумент168 страницEX3600-6 MaintenancewillbuttoОценок пока нет

- Milling Machine ManualДокумент71 страницаMilling Machine Manualaeronkenneth.montanoОценок пока нет

- Chainsaw ManualДокумент17 страницChainsaw ManualflorinОценок пока нет

- Kenmore 385.19110 Sewing Machine ManualДокумент83 страницыKenmore 385.19110 Sewing Machine ManualWendy HawaОценок пока нет

- 3 Disassembly M5370 M4370 EngДокумент61 страница3 Disassembly M5370 M4370 Engpatricio godoyОценок пока нет

- Manual de Pieza de Mano NSKДокумент78 страницManual de Pieza de Mano NSKginalimartinezmu67% (3)

- HM0810TДокумент32 страницыHM0810TIVOR COSTAОценок пока нет

- IFU - PFM Rotary 3006 EM - EN - Rev.2017-04-07 - LowresДокумент32 страницыIFU - PFM Rotary 3006 EM - EN - Rev.2017-04-07 - LowresDương HưngОценок пока нет

- Rough Terrain Crane: GR-300EXДокумент335 страницRough Terrain Crane: GR-300EXIynsmla100% (1)

- Sewing Machine ManualДокумент70 страницSewing Machine Manualtonybogey100% (1)

- CF16RN Centrifuge User GuideДокумент45 страницCF16RN Centrifuge User GuideMd shoriful islamОценок пока нет

- Rough Terrain Crane 2: GR-600EXДокумент414 страницRough Terrain Crane 2: GR-600EXChathuranga senavirathna100% (1)

- Chain Saw Safety Manual: Warning!Документ29 страницChain Saw Safety Manual: Warning!wiiiОценок пока нет

- Ratchet Style Jack Stands: Operating Instructions & Parts ManualДокумент12 страницRatchet Style Jack Stands: Operating Instructions & Parts ManualxtusОценок пока нет

- Tadano - Manual de Sevicio 2-S1 (U) - 1EДокумент406 страницTadano - Manual de Sevicio 2-S1 (U) - 1EReinaldo Zorrilla100% (2)

- Technical Notice GRIGRI PLUS 1Документ29 страницTechnical Notice GRIGRI PLUS 1Sandra Milena Suarez CarreñoОценок пока нет

- Instructions Hydraulic Table PressДокумент26 страницInstructions Hydraulic Table PressHanna HorváthОценок пока нет

- User Manual 4089202Документ96 страницUser Manual 4089202sahebjanОценок пока нет

- Fume Hood: MRC LTDДокумент35 страницFume Hood: MRC LTDAndres GonzalesОценок пока нет

- STIHL 017 018: Warning!Документ54 страницыSTIHL 017 018: Warning!Krešimir IvanovićОценок пока нет

- Ricoh JP 5000Документ315 страницRicoh JP 5000Mihohoho100% (1)

- Installation Manual For Feed Head Liners: AddressДокумент3 страницыInstallation Manual For Feed Head Liners: AddresspredilettoОценок пока нет

- SCM - 12-58-34Документ20 страницSCM - 12-58-34Wawan GuntoroОценок пока нет

- TM-ZT1000: SeriesДокумент146 страницTM-ZT1000: SeriesNur Muhammad Husen100% (1)

- Instruction Manual: Alfa Laval LKDC, LKD & COR CoversДокумент12 страницInstruction Manual: Alfa Laval LKDC, LKD & COR CoversDanielОценок пока нет

- Operator Manual TC1000Документ32 страницыOperator Manual TC1000Eduardo Cervera PerezОценок пока нет

- Manual Caminadora Comfort Track PrimeДокумент18 страницManual Caminadora Comfort Track PrimeCesar Raigoza Loaiza100% (2)

- ShopNotes Issue 43 PDFДокумент32 страницыShopNotes Issue 43 PDFbenigno0% (1)

- ShopNotes Issue 42 PDFДокумент32 страницыShopNotes Issue 42 PDFbenigno100% (1)

- ShopNotes Issue 44 PDFДокумент32 страницыShopNotes Issue 44 PDFbenignoОценок пока нет

- ShopNotes Issue 37 PDFДокумент32 страницыShopNotes Issue 37 PDFbenigno100% (1)

- ShopNotes Issue 41 PDFДокумент32 страницыShopNotes Issue 41 PDFbenignoОценок пока нет

- ShopNotes Issue 14Документ32 страницыShopNotes Issue 14benigno100% (2)

- ShopNotes Issue 38 PDFДокумент32 страницыShopNotes Issue 38 PDFbenignoОценок пока нет

- ShopNotes Issue 11Документ32 страницыShopNotes Issue 11benignoОценок пока нет

- ShopNotes Issue 12Документ32 страницыShopNotes Issue 12benignoОценок пока нет

- Compound Test Tapping: WorkingДокумент32 страницыCompound Test Tapping: Workingbenigno100% (1)

- MD Saw Blade Set-UD: StorageДокумент32 страницыMD Saw Blade Set-UD: Storagebenigno100% (1)

- ShopNotes Issue 10Документ32 страницыShopNotes Issue 10benignoОценок пока нет

- Briquette Manual by Mary N Jenga 2014Документ30 страницBriquette Manual by Mary N Jenga 2014benignoОценок пока нет

- Speidels Braumeister: Operating Manual/brewing InstructionsДокумент32 страницыSpeidels Braumeister: Operating Manual/brewing InstructionsbenignoОценок пока нет

- ShopNotes Issue 08Документ32 страницыShopNotes Issue 08benignoОценок пока нет

- ShopNotes Issue 05Документ32 страницыShopNotes Issue 05benignoОценок пока нет

- MattMill MasterДокумент1 страницаMattMill MasterbenignoОценок пока нет

- For Technical Questions or Replacement Parts, Please ContactДокумент4 страницыFor Technical Questions or Replacement Parts, Please ContactbenignoОценок пока нет

- ShopNotes 120 PDFДокумент52 страницыShopNotes 120 PDFbenigno100% (3)

- Screw Pressbriquettingmachinesandbriquette FiredstovesДокумент74 страницыScrew Pressbriquettingmachinesandbriquette FiredstovesbenignoОценок пока нет

- Helioscope User ManualДокумент38 страницHelioscope User ManualbenignoОценок пока нет

- Fabrication Procedure Steel Structure TSEДокумент21 страницаFabrication Procedure Steel Structure TSEspazzbgt67% (6)

- Grounding BusbarsДокумент6 страницGrounding Busbarsrogelio surcoОценок пока нет

- Manual RotorkДокумент0 страницManual RotorkMartin Alberto100% (1)

- Cleaning ScrewsДокумент6 страницCleaning ScrewsRodolfoAntonioLeónCárdenasОценок пока нет

- Kossel Mini Assembly Guide V1.0Документ205 страницKossel Mini Assembly Guide V1.0bomman69Оценок пока нет

- DIY Book ScannerДокумент101 страницаDIY Book Scannerjahanavi pethani100% (1)

- Wimax Antenna Installation GuideДокумент2 страницыWimax Antenna Installation GuideNoel de LeonОценок пока нет

- 6 - Nyt-909-C - Code of Test For Testing Ab Test Rack - Test SpecificationДокумент16 страниц6 - Nyt-909-C - Code of Test For Testing Ab Test Rack - Test SpecificationMauro Antonio BergantiniОценок пока нет

- Lista Częśco Neptun MH 4MДокумент45 страницLista Częśco Neptun MH 4MMirosław MroczkowskiОценок пока нет

- Stainless Steel Socket, Square Head, and Slotted Headless-Set ScrewsДокумент6 страницStainless Steel Socket, Square Head, and Slotted Headless-Set ScrewsDanZel Dan100% (1)

- QSB3.3 Parts Catalog 68331277Документ91 страницаQSB3.3 Parts Catalog 68331277Галина КарташоваОценок пока нет

- Ultimate RobotДокумент16 страницUltimate RobotIPAQVNОценок пока нет

- Printbar Replacement GuideДокумент16 страницPrintbar Replacement GuideAlberto Fernández VázquezОценок пока нет

- 1 Electrodes+HolderДокумент5 страниц1 Electrodes+HolderLLОценок пока нет

- Noctua NH U12s ManualДокумент6 страницNoctua NH U12s ManualJavier Torres MaldonadoОценок пока нет

- BTC B12C Ec 2013 0341381380054218Документ7 страницBTC B12C Ec 2013 0341381380054218MekhmanОценок пока нет

- ST-030 Correct Installation and Handling of Connecting Rods PDFДокумент7 страницST-030 Correct Installation and Handling of Connecting Rods PDFPopa MihaiОценок пока нет

- Web043 Safe Reliable Die ClampingДокумент40 страницWeb043 Safe Reliable Die Clampingsinr100% (1)

- Design Calculations For Light MastДокумент23 страницыDesign Calculations For Light Mastjobees7850Оценок пока нет

- Ancon Tension Systems March 2008Документ16 страницAncon Tension Systems March 2008Slinky BillОценок пока нет

- CH440 (H4800) PDFДокумент36 страницCH440 (H4800) PDFAndrey L'vovОценок пока нет

- Criterios para Diseño de Chutes - 1 Rev. 0Документ15 страницCriterios para Diseño de Chutes - 1 Rev. 0Lizbeth AtamariОценок пока нет

- Kopilya 8x80mmДокумент2 страницыKopilya 8x80mmmohamed bakryОценок пока нет

- XE03525 300 - ICARUS 50.18 - Kubota - Stage Tier IVF (2019 - )Документ455 страницXE03525 300 - ICARUS 50.18 - Kubota - Stage Tier IVF (2019 - )Best Impeks DooОценок пока нет

- MFS125PFVS Parts ManualДокумент36 страницMFS125PFVS Parts ManualglaucoОценок пока нет

- CH 11 - Column Bases and Anchorage Into Concrete Aug 2011Документ33 страницыCH 11 - Column Bases and Anchorage Into Concrete Aug 2011Stephanie DavisОценок пока нет

- 0302 Corp Standard, Furnishing of Steel Structures Rev 5 - (44557493) PDFДокумент31 страница0302 Corp Standard, Furnishing of Steel Structures Rev 5 - (44557493) PDFrpazbОценок пока нет

- Tiny Shipping Container Home PDFДокумент21 страницаTiny Shipping Container Home PDFDaniel GarzonОценок пока нет

- ASME B1.20.7 (2008) Hose Coupling Screw ThreadsДокумент28 страницASME B1.20.7 (2008) Hose Coupling Screw Threadsbobuncle03Оценок пока нет

- D - SC Sander: Owner'S ManuawДокумент10 страницD - SC Sander: Owner'S ManuawJT AlexanderОценок пока нет