Академический Документы

Профессиональный Документы

Культура Документы

Detroit Diesel Pto

Загружено:

JESUS ARAIZAОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Detroit Diesel Pto

Загружено:

JESUS ARAIZAАвторское право:

Доступные форматы

DT12 PTO Installation Requirements

Beginning in late 2016, the DT12 will be available with a rear-facing Power Take-Off (PTO). This PTO is a

mechanical drive that attaches to the rear of the transmission and is used to transfer power produced by the

engine to an auxiliary component.

The interface is normally closed by a cover plate when not offered. However, when the DT12 PTO is ordered

by the OEM/Dealer, the DT12 Transmission will arrive with the PTO hardware preinstalled from DETROIT™.

Figure 1: Rear of DT12 without PTO (cover plate only).

CONFIGURATIONS AVAILABLE

The 6 different SpecPro DT12 PTO configurations available from DETROIT™ are shown below:

1. 362-2HB DT12 Hydrocar P89 Rear Mounted PTO for Hydraulic Pump (1:1.32 PTO Ratio)

In this configuration, the cover plate shown in Figure 1 above is replaced by a PTO drive assembly as shown

in Figures 2 & 3 below.

Page 1 of 12 DETROIT DDC-ENG-MAN-0001

Figure 2: Rear DT12 PTO drive assembly (option 362-2HB) with cover plate.

With the access cover removed, the PTO drive assembly mounting flange offers SAE-B mounting for 2 or 4

bolt configurations and an SAE B-B 15 tooth spline as shown below:

Figure 3: PTO drive assembly shown with SAE-B 2 or 4 bolt configuration.

The thread type for the 2 or 4 bolt pattern is M14 x 2.0 with a depth of 20mm. It is recommended to use a

bolt length that allows for thread engagement of 1-1.5 times the diameter of the bolt used to connect the

hydraulic pump. Unless otherwise specified by the pump manufacturer, use a bolt torque of 26-30 lb-ft (35-40

Nm) for the fasteners mounting the pump to the PTO drive assembly.

Page 2 of 12 DETROIT DDC-ENG-MAN-0001

With option 362-2HB:

- A transmission cooler will be added to DT12 configuration in SpecPro

- Some exhaust configurations are not compatible with DT12 PTO. Please consult with your local

vehicle representative to obtain specifics.

- Harnesses and controls are included for PTO operation

- The pneumatic line is installed

- The PTO is ready for operation via dashboard mounted switch

- Consult Section 8.28 of the DDEC13 A&I Manual (DDC-SVC-MAN-0127) for CPC parameterization

2. 362-318 DT12 Hydrocar P89 Rear Mounted PTO for Driveshaft (1:1.32 PTO Ratio).

This configuration is for applications utilizing a driveshaft in place of a direct mounted hydraulic pump. From

a transmission and PTO hardware perspective, it is identical to configuration #1 above. However, the

difference in the options is that the prep for driveshaft allows for more clearance on the chassis around the

PTO. Also with this option, the customer must order and install the correct flange kit part from the DTNA PDC

to adapt to their driveshaft. The two available Spicer flange kit part numbers are:

a. Spicer 1350/1410 Flange: A9472600317 (See Figure 6 for the dimensions)

b. Spicer 1310 Flange: A9472600417 (See Figure 7 for the dimensions)

Figure 4: Rear DT12 PTO driveshaft assembly with driveshaft mount.

An example of a successfully installed Spicer flange per option #2 can be seen in the following figure.

Page 3 of 12 DETROIT DDC-ENG-MAN-0001

Figure 5: Installation of configuration #2 as seen from the rear of the vehicle

With option 362-318:

- A transmission cooler will be added to DT12 configuration in SpecPro

- Some exhaust configurations are not compatible with DT12 PTO. Please consult with your local

vehicle representative to obtain specifics.

- Harnesses and controls are included for PTO operation

- The pneumatic line is installed

- The PTO is ready for operation via dashboard mounted switch

- Consult Section 8.28 of the DDEC13 A&I Manual (DDC-SVC-MAN-0127) for CPC parameterization

To correctly install a Spicer flange kit onto the DT12 PTO:

1. Remove cover plate on DT12 PTO housing

2. Insert the stud “1” into the center of the splined PTO drive on the DT12

3. Tighten stud to a torque of 11 + 1.5 lb-ft (15 + 2 Nm)

4. Install the spacer “3” on the back of the flange “4”

5. Apply grease “OKS 200” on the profile spline of the flange “4”

6. Install flange “4” into the PTO gear, then install nut “5” and torque to 26 + 3.5 lb-ft (35 + 5 Nm)

Figure 6: Installation of the 1350/1410 and 1310 series flange adaptor kits to the DT12 PTO.

Page 4 of 12 DETROIT DDC-ENG-MAN-0001

With this configuration the PTO drive shaft angle must be in the range of 1° to 6°.

Bolts and nuts for attaching the driveshaft to this adaptor flange are not included in either of the Spicer kits.

Use standard torque values to attach bolts to adaptor flange based on hardware material and grade.

3. 362-424 DT12 Hydrocar P89 Rear Mounted PTO with Prep for Hydraulic Pump (1:1 PTO Ratio).

This option is the same as option #1 (362-2HB), except that the PTO Drive ratio here is 1:1.

With Option #3 (362-424):

- The PTO drive assembly mounting flange offers SAE-B mounting for 2 or 4 bolt configurations and

an SAE B-B 15 tooth spline as shown in Figure 3 above.

- The thread type for the 2 or 4 bolt pattern is M14 x 2.0 with a depth of 20mm. It is recommended to

use a bolt length that allows for thread engagement of 1-1.5 times the diameter of the bolt used to

connect the hydraulic pump. Unless otherwise specified by the pump manufacturer, use a bolt torque

of 26-30 lb-ft (35-40 Nm) for the fasteners mounting the pump to the PTO drive assembly.

- A transmission cooler will be added to DT12 configuration in SpecPro.

- Some exhaust configurations are not compatible with DT12 PTO. Please consult with your local

vehicle representative to obtain specifics.

- Harnesses and controls are included for PTO operation.

- The pneumatic line is installed.

- The PTO is ready for operation via dashboard mounted switch.

- Consult Section 8.28 of the DDEC13 A&I Manual (DDC-SVC-MAN-0127) for CPC parameterization.

4. 362-425 DT12 Hydrocar P89 Rear Mounted PTO for Driveshaft (1:1 PTO Ratio).

This configuration is for applications utilizing a driveshaft in place of a direct mounted hydraulic pump. From

a hardware perspective, it is identical to configuration #2 above (362-318), except that the PTO Drive ratio

here is 1:1 instead of the 1:1.32 of option #2 (362-318) above.

With configuration #4 (362-425):

- The customer must order and install the correct flange kit part from the DTNA PDC to adapt to their

driveshaft. See Figure 4-5 above for installation pics of the driveshaft adaptor. The two available

Spicer flange kit part numbers are:

Spicer 1350/1410 Flange: A9472600317 (See Figure 6 for the dimensions)

Spicer 1310 Flange: A9472600417 (See Figure 7 for the dimensions)

- A transmission cooler will be added to DT12 configuration in SpecPro

- Some exhaust configurations are not compatible with DT12 PTO. Please consult with your local

vehicle representative to obtain specifics.

- Harnesses and controls are included for PTO operation

- The pneumatic line is installed

- The PTO is ready for operation via dashboard mounted switch

- Consult Section 8.28 of the DDEC13 A&I Manual (DDC-SVC-MAN-0127) for CPC parameterization

To correctly install a Spicer flange kit onto the DT12 PTO:

1. Remove cover plate on DT12 PTO housing

2. Insert the stud “1” into the center of the splined PTO drive on the DT12

3. Tighten stud to a torque of 11 + 1.5 lb-ft (15 + 2 Nm)

4. Install the spacer “3” on the back of the flange “4”

5. Apply grease “OKS 200” on the profile spline of the flange “4”

6. Install flange “4” into the PTO gear, then install nut “5” and torque to 26 + 3.5 lb-ft (35 + 5 Nm)

Page 5 of 12 DETROIT DDC-ENG-MAN-0001

With this configuration the PTO drive shaft angle must be in the range of 1° to 6°.

Bolts and nuts for attaching the driveshaft to this adaptor flange are not included in either of the Spicer kits.

Use standard torque values to attach bolts to adaptor flange based on hardware material and grade.

See Figure 6 above for the installation of the 1350/1410 and 1310 series flange adaptor kits to the DT12

PTO.

5. 362-822 PTO Prep Kit for DT12 Hydrocar P89 Rear Mounted PTO Prep for Driveshaft.

This is the same as option # 2 (262-318) and option #4 (362-425) above, except the PTO drive assembly is

NOT installed on the DT12 transmission as delivered. When this option is ordered, the customer must order

the following parts from the DTNA PDC:

- DT12 PTO drive assembly

- Shaft kit for attaching the rear-mount DT12 PTO drive assembly

- Spicer 1400 or 1300 flange kit

See DTNA PTO installation guideline document for installation instructions and torque specifications for

installing the DT12 PTO drive housing.

With option 362-822:

- A transmission cooler will be added to DT12 configuration in SpecPro

- Some exhaust configurations are not compatible with DT12 PTO. Please consult with your local

vehicle representative to obtain specifics.

- Harnesses and controls are included for PTO which is installed at a later time

- The pneumatic airline is NOT installed and would need to be added at the time of PTO install

- Consult Section 8.28 of the DDEC13 A&I Manual (DDC-SVC-MAN-0127) for CPC parameterization

6. 362-825 PTO Prep Kit for DT12 Hydrocar P89 Rear Mounted PTO Prep for Hydraulic Pump.

This is the same as option # 1 (362-2HB) and option #3 (362-424) above, except the PTO drive assembly is

NOT installed on the DT12 transmission as delivered. When this option is ordered, the customer must order

the following parts from the DTNA PDC:

- DT12 PTO drive assembly

- Shaft kit for attaching the rear-mount DT12 PTO drive

With option 362-825:

- A transmission cooler will be added to DT12 configuration in SpecPro

- Some exhaust configurations are not compatible with DT12 PTO. Please consult with your local

vehicle representative to obtain specifics.

- Harnesses and controls are included for PTO which is installed at a later time

- The pneumatic airline is NOT installed and would need to be added at the time of PTO install.

- Consult Section 8.28 of the DDEC13 A&I Manual (DDC-SVC-MAN-0127) for CPC parameterization

See DTNA PTO installation guideline document for installation instructions and torque specifications for

installing the DT12 PTO drive assembly as well as the pneumatic line referenced above.

Page 6 of 12 DETROIT DDC-ENG-MAN-0001

The dimensions for the Spicer 1350/1410 and 1310 series PTO flanges are listed in the figures below.

Figure 7: PTO mounting adaptor flange for Spicer 1350/1410 series, p/n A9472600317.

Figure 8: PTO mounting adaptor flange for Spicer 1310 flange, p/n A9472600417.

Page 7 of 12 DETROIT DDC-ENG-MAN-0001

TECHNICAL INFORMATION / INSTALLATION REQUIREMENTS

Engine speed: 850 - 2080 rpm

PTO output speed:

o 1 : 1.32 PTO Ratio:

Direct Drive Split Low 900 - 2250 rpm

Direct Drive Split High 1150 - 2850 rpm

Over Drive Split Low 1150 - 2850 rpm

Over Drive Split High 1500 - 3700 rpm

o 1 : 1 PTO Ratio:

Direct Drive Split Low 650 - 1600 rpm

Direct Drive Split High 850 - 2100 rpm

Over Drive Split Low 850 - 2100 rpm

Over Drive Split High 1100 - 2700 rpm

Max PTO output torque: 295 lb·ft (400 N·m)

384 lb ft (520 N·m) max. shock load

PTO drive shaft angle 1° to 6°

Interface (mount) 2 or 4 bolt SAE B pad mount

Interface (shaft) SAE BB 15 tooth spline drive

Interface (flange drive) Spicer 1350/1410 and Spicer 1310 flange drives

PTO rotation Counterclockwise (CCW) looking from rear of DT12

(Requires CW input pump)

Figure 9: PTO rotation direction

Transmission Oil temperature range: average 80°C (176°F)

max. 100°C (212°F)

Ambient operating conditions -40°C (-40°F) to 45°C (113°F)

Transmission PTO variant availability All DT12 variants (oil cooler is required)

The maximum bending moment 29.5 lb-ft (40 Nm)

Page 8 of 12 DETROIT DDC-ENG-MAN-0001

NOTE: Maximum bending moment of the transmission PTO on the mounting surface

must be calculated including the length of unsupported hydraulic hoses, and

the weight of the fittings and hydraulic fluid.

Unless specific information is available on the pump mounting hardware, please use the following formulas

and weights provided below.

Hydraulic hose fittings: 1.18 lbs each

Weight of hydraulic fluid:

= (# of hydraulic hoses) * (0.0361) * [(3.142)*((Hose ID/2)2) * (Length of hoses to first

clipping point)]

Weight of hydraulic hose

= (# of hydraulic hoses) * (Hose weight/ft) * (length in feet of hoses to 1st clipping point)

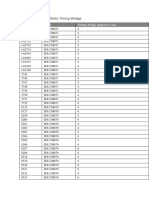

- Hydraulic hose weight estimation chart:

Hydraulic Hose

Chart Estimation

Hose I.D. lbs/ft

1/4 0.16

3/8 0.23

1/2 0.35

5/8 0.44

3/4 0.58

1 0.79

1 ‐1/4 1.5

Table 1: Typical hydraulic hose weight estimation chart.

Max Bending Moment = Mpump + Mftgs + Mfluid + Mhoses

where

Mpump = Bending Moment of the hydraulic pump (lb-ft)

= (weight of pump in lbs) * [(distance from pump center of gravity to PTO mounting surface in

inches)/12]

If center of gravity is not known, assume this is at ½ the total length of the pump

Mftgs = Bending moment of the hydraulic line fittings (lb-ft)

= (# of fittings) *(weight of fittings in lbs) * [(distance of fittings from pump mounting surface in

inches) / 12]

Mfluid = Bending moment due to the hydraulic fluid (lb-ft)

= (# of hydraulic hoses) * (weight of fluid) * [(1/2 * length of hoses until first clipping point) +

(distance of pump center of gravity to PTO mounting surface)]

Mhoses = Bending moment due to the hydraulic hoses (lb-ft)

= (# of hydraulic hoses) * (weight of hoses in lbs) * [(1/2 * length of hoses until first clipping

point) + (distance of pump center of gravity to PTO mounting surface)] / 12

If the calculated Bending Moment exceeds the 29.5 lb-ft limit, try shortening the length of the hydraulic hoses

to the first clipping/support point.

Page 9 of 12 DETROIT DDC-ENG-MAN-0001

PTO OUTPUT SPEED CALCULATION

Since the DT-12 PTO is driven by the countershaft inside the transmission, there are two effective gear ratios

possible, low neutral or high neutral. The low neutral and high neutral are referred to as “split low” and “split

high” respectively.

There is a data code module in SpecPro that allows for operation to be set to either “split low” or “split high”.

This functionality allows the operator to engage the PTO at the desired gear ratio for proper operation. The

PTO ratio, once chosen, will be active at the time of the PTO engagement, Split Low/High cannot be

changed by the driver in the cab.

The default data code for the DT12 PTO is “split low” upon PTO activation.

The available options in SpecPro are:

85P-001: PTO LOW NEUTRAL

85P-002: PTO HIGH NEUTRAL

85P-998: NO PTO NEUTRAL GEAR SELECTION

The default operation for the DT12 PTO is “split low” upon PTO activation. However, parameterization in the

CPC allows for operation to be set to either “split low” or “split high”. See the GHG17 DDEC13 Electronic

Controls Application and Installation Manual (DDC-SVC-MAN-0127) Section 8.28 Throttle Control/Governors

via DDCSN.com for specific parameter programming information.

PTO speed can be calculated by using the PTO output speed summary table below:

PTO Ratio (1 : 1.32) PTO Ratio (1 : 1)

DT-12 A & B Box "Split" Engine : PTO Percent Engine : PTO Percent

Split Low 1 : 1.07 107% 1 : 0.78 78%

DT12- Direct Drive

Split High 1 : 1.36 136% 1 :1 100%

Split Low 1 : 1.36 136% 1 :1 100%

DT12- Over Drive

Split High 1 : 1.76 176% 1 : 1.29 129%

NOTE: Ratios Greater than 1:1, or over 100% ---> PTO spins faster than engine

Table 1: PTO output speed summary table.

For example, the PTO speed with a DT12 Direct Drive Split Low with the 1:1 PTO Ratio would be:

(Engine RPM) x (Engine:PTO Ratio) = 850rpm x 0.78 = 663rpm

Similarly, the PTO speed with a DT12 Overdrive Split High the 1:1.32 PTO Ratio would be

(Engine RPM) x (Engine:PTO Ratio) = 850rpm x 1.76 = 1496rpm

Page 10 of 12 DETROIT DDC-ENG-MAN-0001

Figure 10: Example of PTO Power Flow through a Direct Drive DT12

For a complete list of programming options for the DT12 PTO, please see the DETROIT™ Transmissions

Electronic Application and Installation Manual (DDC-SVC-MAN-0128) via DDCSN.com.

Page 11 of 12 DETROIT DDC-ENG-MAN-0001

Engineering Change Log

Technical Content /

Publisher Owner Rev. # Rev. Date Description of Revisions

C. Grissom R01 12OCT16 Initial release.

Added notes to PTO configurations 1 & 2.

Added Figure 5 showing option #2 installed in truck. Updated

C.Grissom R02 27OCT16 torque values on Spicer flange kit installation.

Modified torque values to show English units first.

Clarified verbiage for Table 1.

Updated footer, and added note regarding CPC

C.Grissom R03 07DEC16

parameterization for each configuration offered.

C.Grissom R04 19DEC16 Corrected PTO rotation direction on page 7.

Corrected PTO drive shaft angular requirement on page 6;

C.Grissom R05 23JAN17

clarified split low/high verbiage on page 9.

Modified document name, revised Technical Information on

C.Grissom R06 08APR17

page 7 including rotation direction, added Table 2 on page 9.

C.Grissom R07 03MAY17 Updated/inserted/labeled Figure 9 on page 7.

C.Grissom R08 19MAY17 Added note to page 7 regarding pump input direction

C.Grissom R09 25OCT17 Updated Figures 9 & 10.

Inserted 2 new PTO configurations (#3 & #4) and

corresponding configuration information, then renumbered

C.Grissom R10 16APR18 existing configurations to #5 & #6;

Removed previous Table 1, inserted new Table 1, inserted and

modified verbiage in PTO output speed calculation section.

Page 12 of 12 DETROIT DDC-ENG-MAN-0001

Вам также может понравиться

- Additions, Revisions, or Updates: Subject DateДокумент10 страницAdditions, Revisions, or Updates: Subject DateEduardo TorresОценок пока нет

- GHG17 Heavy Duty Troubleshooting Manual (DDC-SVC-MAN-0191)Документ37 страницGHG17 Heavy Duty Troubleshooting Manual (DDC-SVC-MAN-0191)Octavio Hernandez RodriguezОценок пока нет

- Step by Step Installation GuideДокумент10 страницStep by Step Installation Guidejeeva100% (1)

- Detroit DD15 Engine Demand DetroitДокумент1 страницаDetroit DD15 Engine Demand Detroitziad khalilОценок пока нет

- DTRANSRGДокумент20 страницDTRANSRGJose Martin Aquije HuayancaОценок пока нет

- Detroid SERIES 60 PDFДокумент10 страницDetroid SERIES 60 PDFO mecanico100% (1)

- 2009 Ddec ReferenceДокумент32 страницы2009 Ddec ReferenceCarlos RiffoОценок пока нет

- Dd15 FaultДокумент19 страницDd15 FaultSs100% (1)

- Fault Code 2274: EGR Valve Differential Pressure Sensor Circuit - Shorted LowДокумент3 страницыFault Code 2274: EGR Valve Differential Pressure Sensor Circuit - Shorted LowSuryadiОценок пока нет

- Gen 5 DD15 Platform Workshop Manual (DDC-SVC-MAN-0215)Документ7 страницGen 5 DD15 Platform Workshop Manual (DDC-SVC-MAN-0215)freddy100% (1)

- Identificacion de Modelos DD15 DD13Документ6 страницIdentificacion de Modelos DD15 DD13Ricardo LoredoОценок пока нет

- 505 10Документ28 страниц505 10carlos maradiagaОценок пока нет

- Engineering Installation Bulletin: Cooling SystemДокумент43 страницыEngineering Installation Bulletin: Cooling SystemmxnoxnОценок пока нет

- 9286-2-Detroit Integrated Powertrain BrochureДокумент8 страниц9286-2-Detroit Integrated Powertrain BrochureCapacitaciones RutasОценок пока нет

- Hydrocarbon (HC) Doser Fuel Supply PressureДокумент14 страницHydrocarbon (HC) Doser Fuel Supply PressureJose AlanisОценок пока нет

- DDC SVC Man 0189 - 2018Документ194 страницыDDC SVC Man 0189 - 2018RuthAnayaОценок пока нет

- Detroit™ Transmissions Electronic Application and Installation ManualДокумент80 страницDetroit™ Transmissions Electronic Application and Installation ManualSonder B50% (2)

- Tabla Timing Isx CumminsДокумент3 страницыTabla Timing Isx CumminsRonald Gomez100% (3)

- Installation Instruction: Fuel Pump Short Block Service Kit Installation InstructionsДокумент4 страницыInstallation Instruction: Fuel Pump Short Block Service Kit Installation InstructionsSean DuncanОценок пока нет

- 13 - Engine Brake PDFДокумент14 страниц13 - Engine Brake PDFdinhvuОценок пока нет

- TRTS0950 En-Us August 2022 AДокумент673 страницыTRTS0950 En-Us August 2022 AMarcos MartinezОценок пока нет

- Air BrakeДокумент56 страницAir BrakeAlexanderОценок пока нет

- Newsletter Sam ChassisДокумент14 страницNewsletter Sam ChassisErik Shelber Calcina CalcinaОценок пока нет

- Ac t680 CompletoДокумент124 страницыAc t680 Completojamca100% (2)

- SPN 3482/FMI 5 DiagnosticДокумент2 страницыSPN 3482/FMI 5 DiagnosticHyo Won Lee100% (3)

- Engine Brake ControlsДокумент9 страницEngine Brake Controlsalejandro sanchezОценок пока нет

- DD15 MexicoДокумент36 страницDD15 MexicoElmer Tintaya Mamani50% (4)

- 3122 ISX CM570 CM870 CM871 Static Injection Timing MeasureДокумент7 страниц3122 ISX CM570 CM870 CM871 Static Injection Timing Measureralph aris100% (1)

- Ddec VДокумент30 страницDdec VeduardonemoОценок пока нет

- Rtoc 16909a 0711Документ36 страницRtoc 16909a 0711Олег КоваленкоОценок пока нет

- Meritor 9-10-13 Speed TransmissionsДокумент203 страницыMeritor 9-10-13 Speed TransmissionsJose Angel Melendez100% (8)

- PLV DD15Документ4 страницыPLV DD15ttrОценок пока нет

- 2014 Cascadia - 2Документ3 страницы2014 Cascadia - 2Kirk Easom100% (1)

- Ddec Vi (CPC) Vehicle Interface Harness: All Information Subject To Change Without Notice. (Rev. 3/06)Документ2 страницыDdec Vi (CPC) Vehicle Interface Harness: All Information Subject To Change Without Notice. (Rev. 3/06)ALEJO100% (1)

- DDC SVC Man 0189Документ195 страницDDC SVC Man 0189vo phuong100% (3)

- GHG17 Medium Duty Workshop (DDC-SVC-MAN-0194)Документ22 страницыGHG17 Medium Duty Workshop (DDC-SVC-MAN-0194)Namsa LABORATORIO100% (1)

- DD Unable Complete RegenДокумент6 страницDD Unable Complete RegenJOHN Wright100% (3)

- Fuller AutoshiftДокумент480 страницFuller AutoshiftAdal Vera67% (3)

- Engine Paccar Mx13 Diesel t800 Kenworth PDFДокумент2 страницыEngine Paccar Mx13 Diesel t800 Kenworth PDFThomas Parkinson67% (3)

- Manual DDC - DT-12 - InglesДокумент152 страницыManual DDC - DT-12 - InglesRonald Lopez100% (5)

- Engine Detroit S-60Документ76 страницEngine Detroit S-60josue100% (3)

- DDECVI AI Manual PDFДокумент538 страницDDECVI AI Manual PDFalejandro sanchez80% (5)

- 2010ddec10ai PDFДокумент440 страниц2010ddec10ai PDFalejandro sanchez100% (1)

- Tmo 1043Документ43 страницыTmo 1043Jose Renny PenaОценок пока нет

- S60-ch3 Ddeciv PDFДокумент184 страницыS60-ch3 Ddeciv PDFAlex BravoОценок пока нет

- DDC-SVC-BRO-0118 - Jun2020 DETROIT DIESEL TRANSMISIONESДокумент22 страницыDDC-SVC-BRO-0118 - Jun2020 DETROIT DIESEL TRANSMISIONESangel017100% (1)

- Internal or External Leakage of The High Pressure Fuel System 2Документ11 страницInternal or External Leakage of The High Pressure Fuel System 2SatooAtheiОценок пока нет

- Eaton Fuller 15webДокумент4 страницыEaton Fuller 15webmancorabechОценок пока нет

- DDEC VI - Reference Guide PDFДокумент98 страницDDEC VI - Reference Guide PDFMike BОценок пока нет

- 1218 10Документ19 страниц1218 10Hamilton mirandaОценок пока нет

- Turbina DDC 15Документ7 страницTurbina DDC 15Raul Gerardo Delatour CarreroОценок пока нет

- EPA07 Maxxforce 11, 13 Diagnostic Manual-2Документ248 страницEPA07 Maxxforce 11, 13 Diagnostic Manual-2Manuel Alejandro Velez NavaОценок пока нет

- Eaton Ultrashift DM Heavy Duty Clutch Installation Guide Installation Instructions enДокумент2 страницыEaton Ultrashift DM Heavy Duty Clutch Installation Guide Installation Instructions enSatooAtheiОценок пока нет

- 03-Datalink, Cabin CANДокумент20 страниц03-Datalink, Cabin CANEbied Yousif AlyОценок пока нет

- SPN 84/FMI 0 and SPN 84/FMI 11 Have Been AddedДокумент4 страницыSPN 84/FMI 0 and SPN 84/FMI 11 Have Been AddedHamilton mirandaОценок пока нет

- Light Control Module (1776 VN)Документ21 страницаLight Control Module (1776 VN)gustavo100% (1)

- Jake Brake 1998 PDFДокумент10 страницJake Brake 1998 PDFvictoverОценок пока нет

- Inyector n3 TorquesДокумент2 страницыInyector n3 TorquesDiego MonroyОценок пока нет

- Injector s60Документ15 страницInjector s60Alex Forero100% (7)

- 378 200 Falk Quadrive Model A, Sizes 5107 5315 Shaft Mounted Gears Owners ManualДокумент52 страницы378 200 Falk Quadrive Model A, Sizes 5107 5315 Shaft Mounted Gears Owners ManualRemmaq MoreliaОценок пока нет

- 90203-1104DEC E Cont Operations PDFДокумент414 страниц90203-1104DEC E Cont Operations PDFelmacuarro5Оценок пока нет

- FRAMECAD F300i Operating Manual (FCF2) - Release 10102013Документ221 страницаFRAMECAD F300i Operating Manual (FCF2) - Release 10102013assssaaassd100% (4)

- Knowledge Based SystemsДокумент57 страницKnowledge Based SystemsRodel MoralesОценок пока нет

- ProxTransSysOpДокумент41 страницаProxTransSysOpNorman MoralesОценок пока нет

- Distance Measuring EquipmentДокумент12 страницDistance Measuring Equipmentमेनसन लाखेमरूОценок пока нет

- The Flow Chart of Tires Pyrolysis EquipmentДокумент4 страницыThe Flow Chart of Tires Pyrolysis EquipmentpyrolysisoilОценок пока нет

- Gear Mechanism Used in Wrist WatchesДокумент5 страницGear Mechanism Used in Wrist WatchesRaja Rv0% (1)

- Overview of Ultrasound Detection Technologies For Photoacoustic ImagingДокумент24 страницыOverview of Ultrasound Detection Technologies For Photoacoustic ImagingShuvam5 GuptaОценок пока нет

- 08 Sep-603b Thol Ret 670Документ9 страниц08 Sep-603b Thol Ret 670m khОценок пока нет

- T620 Plus DisassemblyДокумент25 страницT620 Plus DisassemblycdgmatОценок пока нет

- Guide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1Документ51 страницаGuide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1António FerreiraОценок пока нет

- M60 Main Battle TankДокумент7 страницM60 Main Battle Tankbcline50% (2)

- B200S-LF Low Freq Sounder Base Install 56-4151-003R-06-10Документ4 страницыB200S-LF Low Freq Sounder Base Install 56-4151-003R-06-10George P ReynoldsОценок пока нет

- Shell Spirax S6 Txme: Performance, Features & BenefitsДокумент2 страницыShell Spirax S6 Txme: Performance, Features & BenefitsAbdelhadi HoussinОценок пока нет

- SVT-RM10: Remote Control UnitДокумент2 страницыSVT-RM10: Remote Control UnitJOGITELEОценок пока нет

- Sagana Kutus 132kv Transmission Line and SubstationДокумент324 страницыSagana Kutus 132kv Transmission Line and Substationshivvaram-1100% (1)

- Asymmetric Cycler Time Relay: Instruction ManualДокумент2 страницыAsymmetric Cycler Time Relay: Instruction ManualRamius HamdaniОценок пока нет

- 24 - Article - $mbps Vs $MHZ Why Is This ImportantДокумент2 страницы24 - Article - $mbps Vs $MHZ Why Is This ImportantShiraz SiddiqОценок пока нет

- Firestop HILTIДокумент44 страницыFirestop HILTIronaldo aguirreОценок пока нет

- DMPCДокумент49 страницDMPCiprassandyОценок пока нет

- Inspection & Maintenance of Dams: Dam Safety GuidelinesДокумент79 страницInspection & Maintenance of Dams: Dam Safety Guidelinesvishu1909100% (1)

- WBNR La Auto BCM SpanishДокумент41 страницаWBNR La Auto BCM SpanishHaragopal KrishnaОценок пока нет

- Assignment 1 Low Temperature and SuperconductivityДокумент3 страницыAssignment 1 Low Temperature and SuperconductivityNadhrah MuradОценок пока нет

- 2014 03 Istanbul PDFДокумент3 страницы2014 03 Istanbul PDFFaraj DividОценок пока нет

- Resistance WeldingДокумент22 страницыResistance WeldingLOKENDRA91100% (2)

- Catalogo GIACOMINIДокумент45 страницCatalogo GIACOMINIIsrael Silva Hgo.Оценок пока нет

- Wolf Range TopДокумент2 страницыWolf Range TopArt BowlingОценок пока нет

- Cables TheoryДокумент15 страницCables TheorytceterexОценок пока нет

- Cat Reforming Part 2 3 PDF FreeДокумент68 страницCat Reforming Part 2 3 PDF FreeLê Trường AnОценок пока нет

- New Premium ListДокумент10 страницNew Premium ListAshwani SainiОценок пока нет

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsОт EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsОценок пока нет

- To Engineer Is Human: The Role of Failure in Successful DesignОт EverandTo Engineer Is Human: The Role of Failure in Successful DesignРейтинг: 4 из 5 звезд4/5 (138)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresОт EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresРейтинг: 1 из 5 звезд1/5 (2)

- Structural Cross Sections: Analysis and DesignОт EverandStructural Cross Sections: Analysis and DesignРейтинг: 4.5 из 5 звезд4.5/5 (19)

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsОт EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsРейтинг: 5 из 5 звезд5/5 (3)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsОт EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsРейтинг: 4 из 5 звезд4/5 (16)

- Net Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and ImplementationОт EverandNet Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and ImplementationРейтинг: 5 из 5 звезд5/5 (1)

- Non-destructive Testing and Evaluation of Civil Engineering StructuresОт EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacОценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОценок пока нет

- Earthquake-Resistant Structures: Design, Build, and RetrofitОт EverandEarthquake-Resistant Structures: Design, Build, and RetrofitРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Piping Engineering Leadership for Process Plant ProjectsОт EverandPiping Engineering Leadership for Process Plant ProjectsРейтинг: 5 из 5 звезд5/5 (1)

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesОт EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesРейтинг: 4.5 из 5 звезд4.5/5 (13)

- Pipeline Planning and Construction Field ManualОт EverandPipeline Planning and Construction Field ManualРейтинг: 5 из 5 звезд5/5 (3)

- Piezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringОт EverandPiezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringОценок пока нет

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsОт EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsОценок пока нет