Академический Документы

Профессиональный Документы

Культура Документы

Aluminium WPS

Загружено:

Anonymous yCpjZF1rFАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aluminium WPS

Загружено:

Anonymous yCpjZF1rFАвторское право:

Доступные форматы

WELDING PROCEDURE

SPECIFICATION

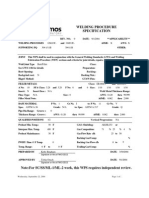

WPS - 3010-2X REV. NO.: 0 DATE: 10/6/2004 **APPLICABILITY**

WELDING PROCESS/ES: GMAW and GMAW ASME: X AWS: X

SUPPORTING PQR: P-WS-119-2 P-WS-119-1 Z-WS-7E OTHER: (4)**

Z-WS-7 Z-WS-7C Z-WS-7D Z-1-GMP-23

JOINT This WPS shall be used in conjunction with the General Welding Standards (GWS) and Welding

Fabrication Procedure (WFP) sections and criteria for joint details, repairs, NDE, inspection etc.

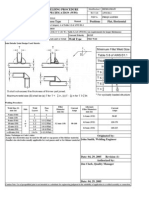

Weld Joint Type: Groove/fillet Class: Full/partial penetration

See GWS 1-06 for joint details Preparation: Mechanical/thermal-plasma

Root Opening: 1/16" - 1/8" Backing: Gas

Backgrind root: N/A Backing Mat.: Al when used

Bkgrd Method: N/A GTAW Flux: N/A Backing Retainer: N/A

FILLER METALS: Class: E-xxxx and ER-xxxx

A No: N/A SFA Class: 5.3 and 5.10 F No: 2x and 2x Size: .035 .045 .062

Insert: N/A Insert Desc.: N/A Weld Metal Thickness Range:

Flux: Type: N/A Size: N/A AWS: 0.030 thru 99.000

Filler Metal Note: SFA 5.3 electrodes limited to E1100, E3003 & E4043 ASME: 0.030 thru 2.000

BASE MATERIALS: P No. 2X Gr No. N/A to: P No. 2X Gr No. N/A

Spec. Aluminum Grade: All to: Spec. Aluminum Grade: All

Qualified Pipe Dia Range: = : 2.5

Qualified Thickness Range: AWS: 0.030 thru 99.000 ASME: 0.030 thru 2.000

QUALIFIED POSITIONS: All-pipe All-plate Vertical Progression: V-UP

Preheat Min. Temp.: *70 °F GAS: Shielding: Argon or ---------

Interpass Max. Temp.: 500 °F Gas Composition: 100 % 0 % 0 %

Preheat Maintinance: *70 °F Gas Flow Rate cfh: 25 to 50

Backing Gas/Comp: Argon 100 %

PWHT: Time @ °F Temp. N/A Backing Gas Flow cfh: 3 to 8

Temp. Range: N/A °F to N/A °F Trailing Gas/Comp: N/A %

PREPARED BY: KG Fellers DATE: 10/6/2004

Signature on file at FWO-DECS

APPROVED BY: Tobin oruch DATE: 10/6/2004

Signature on file at FWO-DECS

Note:For SC/SS/ML-1/ML-2 work, this WPS requires independent review.

Wednesday, October 13, 2004 Page 1 of 2

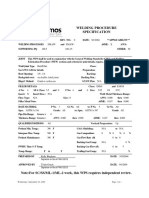

WPS NO: 3010-2X

WELDING CHARACTERISTICS:

Current: DCEP and ---- Tungsten type: N/A Transfer Mode: Spray

Ranges: Amps 80 to 250 Pulsing Cycle: N/A to N/A

Volts 17 to 34 Background Current: N/A

Fuel Gas: N/A Flame: N/A Braze temp. °F N/A to N/A

WELDING TECHNIQUE: For cleaning, grinding, and inspection criteria refer to Volume 2, Welding

Fabrication Procedures

Technique: Semi-auto Cleaning Method: Grind/wire brush/file

Single Pass or Multi Pass: M Stringer or Weave bead (S/W): S/W Oscillation: N/A

GMAW Gun Angle °: 0 to 15 Forehand or Backhand for GMAW (F/B): FH

GMAW/FCAW Tube to work distance: 3/8"-1/2"

Maximum K/J Heat Input: N/A Travel speed: As required Gas Cup Size: 1/2"-3/4"

No single pass shall deposit greater than 1/2" thickness of material.

PROCEDURE QUALIFIED FOR:

Charpy "V" Notch: N/A Nil-Ductil Transition Temperature: N/A Dynamic Tear: N/A

Comments: (1) *200 °F min. for materials =.75" in thickness. (2) AWS pipe dia. Limited to = 4.0"OD and Sch. # = =

80. (3) ASME pipe dia. limited to = 2.5"OD and Sch. # = = 160. (4)**ANSI/AISC/AWWA

Weld Manual Filler Metals Nozzel

Layer Process Size Amp Range Volt Range Travel/ipm Angle Other

1 GMAW E-xxxx .035 80 to 100 17 to 24 10 to 15 0 - 15

2 GMAW ER-xxxx .045 150 to 250 26 to 34 12 to 24

3

GMAW ER-xxxx .062 0 to 0 0 to 0 12 to 24

4

5

6

7

8

REM. * Weld layers are representative only - actual number of passes and layer sequence may vary due to

variations in joint design, thickness and fitup.

Use of LANL Welding Procedures and Welder Qualifications for non-LANL work shall be at the sole risk and

responsibility of the Subcontractor, and the Subcontractor shall indemnify and save LANL and the Government

harmless from any and all claims, demands, actions or causes of action, and for any expense or loss by reason of

Subcontractor's and their employees posession and use of LANL procedures and qualifications.

Wednesday, October 13, 2004 Page 2 of 2

Вам также может понравиться

- Sample API 1104 WpsДокумент3 страницыSample API 1104 WpsMuhammadShabbir0% (1)

- Manual Joints (QW - 402) : Page 1 of 12Документ12 страницManual Joints (QW - 402) : Page 1 of 12miteshpatel191Оценок пока нет

- Ilcs-Smaw-D1.3-Deck (G) WPSДокумент3 страницыIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPS Format For ISO 9606-1 WelderДокумент2 страницыWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- Ami-001 WPSДокумент2 страницыAmi-001 WPSPramod Athiyarathu100% (1)

- Gta+sma PQRДокумент3 страницыGta+sma PQRRahul MoottolikandyОценок пока нет

- WPQ Process As Per ISO-9606-1 2013Документ4 страницыWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Aws 001Документ1 страницаAws 001akshay sarfareОценок пока нет

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Документ2 страницыWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialОценок пока нет

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Документ1 страницаQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuОценок пока нет

- WPS 136 FWДокумент1 страницаWPS 136 FWsocaugusto100% (1)

- Ami-003 WPSДокумент2 страницыAmi-003 WPSBenjamin BrownОценок пока нет

- Aws d1.5 PQRДокумент2 страницыAws d1.5 PQRjacquesmayolОценок пока нет

- Duties of The RWCДокумент3 страницыDuties of The RWCbluegalago100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Документ2 страницы(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFДокумент1 страницаPQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraОценок пока нет

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Документ3 страницыWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielОценок пока нет

- Format WPQДокумент2 страницыFormat WPQAkash Singh TomarОценок пока нет

- Aws B2.5 - B2.5M-2021Документ34 страницыAws B2.5 - B2.5M-2021Noe NuñezОценок пока нет

- WPS BhelДокумент2 страницыWPS BhelpradhankruhsnaОценок пока нет

- P-WPS 135 - MAG (GR 316)Документ9 страницP-WPS 135 - MAG (GR 316)Tarun PatelОценок пока нет

- Tacom Weld Code SteelДокумент165 страницTacom Weld Code SteelAles Kubat0% (1)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalДокумент1 страницаWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavОценок пока нет

- WPS 19Документ15 страницWPS 19Avishek Gupta100% (1)

- Specification For Fluxes For Brazing and Braze Welding: ANSI/AWS A5.31-92R An American National StandardДокумент23 страницыSpecification For Fluxes For Brazing and Braze Welding: ANSI/AWS A5.31-92R An American National StandardErol BurnsОценок пока нет

- 25 Tack Welder - ABSДокумент7 страниц25 Tack Welder - ABSvudinhnambrОценок пока нет

- Wps For Aluminium WeldingДокумент8 страницWps For Aluminium WeldingMohammed MusaОценок пока нет

- WPQR2Документ3 страницыWPQR2Thanasis KyrgiazoglouОценок пока нет

- Reports - QAQC - R0Документ10 страницReports - QAQC - R0talupurumОценок пока нет

- Val Caraig WPQTДокумент1 страницаVal Caraig WPQTMark Jason M. BrualОценок пока нет

- BS en 439 94 PDFДокумент12 страницBS en 439 94 PDFDario RamljakОценок пока нет

- WPS - 024Документ4 страницыWPS - 024MAT-LIONОценок пока нет

- AWS CodesДокумент2 страницыAWS Codeshunkmopoo50% (2)

- WQT - 1 PDFДокумент2 страницыWQT - 1 PDFLuttpi100% (1)

- List of WPS (Jerp) PDFДокумент2 страницыList of WPS (Jerp) PDFAlam MD SazidОценок пока нет

- WPS SumДокумент61 страницаWPS SumA. ΒρατσισταОценок пока нет

- Filler Metal Selection ChartДокумент1 страницаFiller Metal Selection ChartMuhammed NoorulОценок пока нет

- Aws d1.1 WPS, PQR & WQTДокумент4 страницыAws d1.1 WPS, PQR & WQTWeld Bro SandeepОценок пока нет

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Документ3 страницыWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateДокумент3 страницыWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaОценок пока нет

- Fillet Weid Break and Macroetch Test PlateДокумент1 страницаFillet Weid Break and Macroetch Test PlatewijiestОценок пока нет

- KGP-Flamme Cutting Proce For BEI PDFДокумент4 страницыKGP-Flamme Cutting Proce For BEI PDFoomoomОценок пока нет

- 004 Gtaw P5aДокумент16 страниц004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Smaw Fillet Aws d1.1Документ1 страницаSmaw Fillet Aws d1.1fallalovaldes100% (1)

- B2.1 B2.1M 2021 Web - PVДокумент14 страницB2.1 B2.1M 2021 Web - PVIsabel BurnetteОценок пока нет

- Welding Procedure Qualification Record: Shipyard LogoДокумент4 страницыWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Gmaw Complete Aws d1.6Документ1 страницаGmaw Complete Aws d1.6Hamza Nouman100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateДокумент3 страницыWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaОценок пока нет

- En Iso 9606 1 GДокумент2 страницыEn Iso 9606 1 GAnonymous dziHEjc7Y100% (1)

- Udlp-Tacom Welding Code, Almn (Ansi-Aws d1.2)Документ120 страницUdlp-Tacom Welding Code, Almn (Ansi-Aws d1.2)mtcengineering100% (2)

- Template For "Review of Requirements"Документ1 страницаTemplate For "Review of Requirements"Satish KeskarОценок пока нет

- WPS Sa 517Документ2 страницыWPS Sa 517DHANANNJAI SINGH -Оценок пока нет

- GWAW Welding SpecificationДокумент2 страницыGWAW Welding SpecificationSaurabh GuptaОценок пока нет

- Welding Procedure SpecificationДокумент2 страницыWelding Procedure SpecificationFrancisco HoyosОценок пока нет

- Aluminim WPSДокумент2 страницыAluminim WPSmahmoud_allam3Оценок пока нет

- Welding Procedure SpecificationДокумент2 страницыWelding Procedure SpecificationWaranya Musika100% (1)

- 1000 XXXX HY80 HSLA100Документ2 страницы1000 XXXX HY80 HSLA100srb metallurgОценок пока нет

- WPS ExampleДокумент2 страницыWPS ExampleMarcio Jr.Оценок пока нет

- Welding Procedure Specification: Monday, April 27, 2009 Page 1 of 2Документ2 страницыWelding Procedure Specification: Monday, April 27, 2009 Page 1 of 2srb metallurgОценок пока нет

- Rivers and OceansДокумент6 страницRivers and OceansAnonymous yCpjZF1rFОценок пока нет

- Flying CodДокумент4 страницыFlying CodAnonymous yCpjZF1rFОценок пока нет

- The Bronze Age: Downloadable Resource 3Документ14 страницThe Bronze Age: Downloadable Resource 3Anonymous yCpjZF1rFОценок пока нет

- Gulbarga (Karnataka) : A Baseline Survey of Minority Concentration Districts of IndiaДокумент75 страницGulbarga (Karnataka) : A Baseline Survey of Minority Concentration Districts of IndiaAnonymous yCpjZF1rFОценок пока нет

- Traffic SignalДокумент6 страницTraffic SignalAnonymous yCpjZF1rFОценок пока нет

- 100 Hadees - Arbaeen Shiddat Ber Bad MazhabДокумент65 страниц100 Hadees - Arbaeen Shiddat Ber Bad MazhabTariq Mehmood TariqОценок пока нет

- 8 Unqiue Characterstics of AnimalsДокумент17 страниц8 Unqiue Characterstics of AnimalsAnonymous yCpjZF1rFОценок пока нет

- HopscotchДокумент2 страницыHopscotchAnonymous yCpjZF1rFОценок пока нет

- Every Pebble Tells A Story: Page 1 of 11Документ11 страницEvery Pebble Tells A Story: Page 1 of 11Anonymous yCpjZF1rFОценок пока нет

- Distinguishing Characteristics: Key Takeaways: RibosomesДокумент9 страницDistinguishing Characteristics: Key Takeaways: RibosomesAnonymous yCpjZF1rFОценок пока нет

- Key Takeaways From CellsДокумент7 страницKey Takeaways From CellsAnonymous yCpjZF1rFОценок пока нет

- Fire Water TankДокумент1 страницаFire Water TankAnonymous yCpjZF1rFОценок пока нет

- Primary, Secondary, and Tertiary Sources in HistoryДокумент1 страницаPrimary, Secondary, and Tertiary Sources in Historyc-191786Оценок пока нет

- Translation NotesДокумент4 страницыTranslation NotesRishikesh BhintadeОценок пока нет

- AUS PR ProcessДокумент5 страницAUS PR ProcessAnonymous yCpjZF1rFОценок пока нет

- InterpretationДокумент1 страницаInterpretationAnonymous yCpjZF1rFОценок пока нет

- Functions: Key Takeaways: PeptidesДокумент4 страницыFunctions: Key Takeaways: PeptidesAnonymous yCpjZF1rFОценок пока нет

- Kadaknath ChickenДокумент2 страницыKadaknath ChickenAnonymous yCpjZF1rFОценок пока нет

- 1.0 Purpose:: G. I. NumberДокумент13 страниц1.0 Purpose:: G. I. NumberAnonymous yCpjZF1rFОценок пока нет

- Clad Plate WeldingДокумент1 страницаClad Plate WeldingAnonymous yCpjZF1rFОценок пока нет

- Pte (Tips & Tricks)Документ9 страницPte (Tips & Tricks)Anonymous yCpjZF1rF100% (3)

- PML G2 GS 0003 - 2 Thread StandardДокумент5 страницPML G2 GS 0003 - 2 Thread StandardAnonymous yCpjZF1rFОценок пока нет

- Porta Cabin Inspection ChecklistДокумент4 страницыPorta Cabin Inspection ChecklistAnonymous yCpjZF1rF75% (4)

- Arc Strike After HydroДокумент1 страницаArc Strike After HydroAnonymous yCpjZF1rFОценок пока нет

- Load CellДокумент2 страницыLoad CellAnonymous yCpjZF1rFОценок пока нет

- Smoke Detector InspectionДокумент2 страницыSmoke Detector InspectionAnonymous yCpjZF1rF100% (2)

- Smoke Detector InspectionДокумент2 страницыSmoke Detector InspectionAnonymous yCpjZF1rF100% (1)

- Total Productive Maintenance (TPM) Refers To A Management System For Optimizing TheДокумент5 страницTotal Productive Maintenance (TPM) Refers To A Management System For Optimizing TheAnonymous yCpjZF1rFОценок пока нет

- Building Fire Safety PlanДокумент31 страницаBuilding Fire Safety PlanAnonymous yCpjZF1rFОценок пока нет

- Incident Investigation ProcedureДокумент35 страницIncident Investigation ProcedureAnonymous yCpjZF1rF100% (3)

- M1-Safety StandardsДокумент9 страницM1-Safety StandardscarlОценок пока нет

- Phytoremediation Acuatic PlantsДокумент120 страницPhytoremediation Acuatic PlantsFranco Portocarrero Estrada100% (1)

- ELC609F12 Lec0 IntroductionДокумент16 страницELC609F12 Lec0 IntroductionMohammed El-AdawyОценок пока нет

- TC AdvisoryДокумент1 страницаTC AdvisoryJerome DelfinoОценок пока нет

- Rein RoundRobinModelling FSJ09Документ30 страницRein RoundRobinModelling FSJ09Noah RyderОценок пока нет

- 1 28701-FGC+101+3441+Router+6471+Datasheet+Rev+FДокумент2 страницы1 28701-FGC+101+3441+Router+6471+Datasheet+Rev+FВладимир ЕгоровОценок пока нет

- Wilson FR & Power Cable CatalogДокумент56 страницWilson FR & Power Cable CatalogRohim SuhadiОценок пока нет

- Web+Presentation+12+July+2016 EA+-+Eric+LumeДокумент57 страницWeb+Presentation+12+July+2016 EA+-+Eric+LumetranthabinОценок пока нет

- 2014 An125hkl4Документ69 страниц2014 An125hkl4El Turco ChalabeОценок пока нет

- 2.4 Assembly ManualДокумент139 страниц2.4 Assembly Manualgustavo dlsОценок пока нет

- Disa Match: A Match You Can Count OnДокумент8 страницDisa Match: A Match You Can Count OngОценок пока нет

- The Association Between Eating Disorders and Stress Among Medical Student: A Cross-Sectional StudyДокумент11 страницThe Association Between Eating Disorders and Stress Among Medical Student: A Cross-Sectional StudyIJAR JOURNALОценок пока нет

- Advanced Steel Structure Concepts: 2 MonthsДокумент4 страницыAdvanced Steel Structure Concepts: 2 MonthsAnkit SoniОценок пока нет

- NURS1108 Lecture 10 - Nervous System ENHANCEDДокумент40 страницNURS1108 Lecture 10 - Nervous System ENHANCEDJacia’s SpaceshipОценок пока нет

- Certified: Steelfab of VirginiaДокумент1 страницаCertified: Steelfab of VirginiaRamume188Оценок пока нет

- FENA-01 - 11 - 21 - Ethernet Adapter - User's Manual - Rev BДокумент388 страницFENA-01 - 11 - 21 - Ethernet Adapter - User's Manual - Rev BQUOC LEОценок пока нет

- Introduction To Reproduction PDFДокумент8 страницIntroduction To Reproduction PDFLmssvОценок пока нет

- Noxim MANUALДокумент5 страницNoxim MANUALSAI NRUSIMHA DEEPAK BURRA SAI NRUSIMHA DEEPAK BURRAОценок пока нет

- Indigo Airlines - Final ReportДокумент22 страницыIndigo Airlines - Final Reportanand_lihinarОценок пока нет

- Estimation of Fire Loads For An Educational Building - A Case StudyДокумент4 страницыEstimation of Fire Loads For An Educational Building - A Case StudyEditor IJSETОценок пока нет

- AdPoe The Hunting of The HareДокумент2 страницыAdPoe The Hunting of The HarePI CubingОценок пока нет

- Magneto-Convective Non-Newtonian Nanofluid With Momentum and Temperature Dependent Slip Flow From A Permeable Stretching Sheet With Porous Medium and Chemical ReactionДокумент18 страницMagneto-Convective Non-Newtonian Nanofluid With Momentum and Temperature Dependent Slip Flow From A Permeable Stretching Sheet With Porous Medium and Chemical ReactionIOSRjournalОценок пока нет

- Present Arlypon VPCДокумент1 страницаPresent Arlypon VPCErcan Ateş100% (1)

- Zetor Crystal 150 170 Tractor Operator Manual PDFДокумент234 страницыZetor Crystal 150 170 Tractor Operator Manual PDFAntonОценок пока нет

- Homophones WorksheetДокумент3 страницыHomophones WorksheetAmes100% (1)

- TA308 616configurationДокумент1 страницаTA308 616configurationJesus AvilaОценок пока нет

- Aplikasi Sistem Penuaian Air Hujan (Spah) Di Kawasan PerumahanДокумент18 страницAplikasi Sistem Penuaian Air Hujan (Spah) Di Kawasan PerumahanFarid Che DeramanОценок пока нет

- Coastal Management NotesДокумент2 страницыCoastal Management Notesapi-330338837Оценок пока нет

- With EU Stage V Engine Installed: 200 HP (149 KW) / 2,200 RPMДокумент4 страницыWith EU Stage V Engine Installed: 200 HP (149 KW) / 2,200 RPMSara Sarmiento EcheverryОценок пока нет

- Daphne Alpha Cleaner Series: Lubricant Product InformationДокумент2 страницыDaphne Alpha Cleaner Series: Lubricant Product InformationChart ChОценок пока нет