Академический Документы

Профессиональный Документы

Культура Документы

Installation Plan

Загружено:

ThirukkumaranBalasubramanianИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Installation Plan

Загружено:

ThirukkumaranBalasubramanianАвторское право:

Доступные форматы

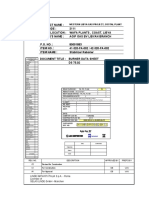

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

SUMMARY OF DOCUMENT REVISIONS

Rev. Date Section

No. Revised Revised Revision Description

0 26 Jun 08 New This is a new RTIP Specification

1 25 Jan 10 General Authorization for revision covered by A554-RFV-PRG-336. This

applies to EPC.

1 Added additional details to scope

1.1.1 Clarified responsibilities

1.1.3 Added purchaser/ buyer responsibilities

1.3 Added contractors/ purchasers plan

2.1 Added scope to cover shipping and transport

2.2.9 Added requirements for appropriate utilities to support protection

3.2 Added additional document

ATTACHMENT Added RTIP JMP Reliability & Maintenance Equipment and Material

1 Protection Plan Work Process (Documentum No: RT-6-1CS Rev. 1

Attachment 1)

ATTACHMENT Added Equipment and Material Protection Plan Work Process

2 spread sheet (Documentum No.: RT-6-1CS Rev. 1, Attachment 2)

2 26 July 10 General Authorization for revision covered by A554-RFV-PRG-567

Table of Deleted Attachment 1 and 2

Contents

Table 1 Added Note 2

2.14 Revise source for procedure

2.3.2 Deleted ref. to IPMS module

2.5.1 Deleted ref. to SMC1106

2.7.4.a/b Deleted ref. to IPMS module

3.1 Revised source for manual

3.2 Revised source for manual

Revised reference to Equipment and Material Protection Plan Work

Process

Added reference to spread sheet

This applies to EPC

3 22 Oct 10 1 Added note that this spec should be used in conjunction with

Schedules G and Q.

Table 1, 2.5 Added note to maintain vapour seals

Contains Confidential Information of both Dow and Saudi Aramco

Page 2 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

SUMMARY OF DOCUMENT REVISIONS

Rev. Date Section

No. Revised Revised Revision Description

Table 1, 2.12.4 Added note the HVAC equipment should be hooked – up and

operated in analyser shelters before the shelters are installed.

Table 1, 2.19.1 Added note that piping should be placed on cribs when stored in the

field.

Table 1,2.19.15 Added cautionary note about nuts and bolts

Appendix 1, 2 Changed meaning of IH to “HVAC Controlled”

Contains Confidential Information of both Dow and Saudi Aramco

Page 3 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

TABLE OF CONTENTS

Section Title Page No.

1. GENERAL..............................................................................................................4

1.1 Responsibilities ......................................................................................................4

1.2 Statutory Requirements .........................................................................................5

1.3 Industry Standards .................................................................................................5

2. EQUIPMENT PROTECTION DURING CONSTRUCTION AT JOBSITE ..............5

2.1 Scope .....................................................................................................................5

2.2 General Requirements ...........................................................................................5

2.3 Documentation .......................................................................................................6

2.4 Use and Application of Rust Preventives, Preservatives and Desiccants..............7

2.5 Examination of Equipment on Arrival at Jobsite.....................................................8

2.6 Machinery...............................................................................................................9

2.7 Motors and Generators ........................................................................................11

2.8 Transformers........................................................................................................12

2.9 Switchgear, Starters and Control Equipment .......................................................13

2.10 Cables ..................................................................................................................14

2.11 Storage Batteries .................................................................................................14

2.12 Instruments ..........................................................................................................14

2.13 Valves ..................................................................................................................15

2.14 Welding Consumables .........................................................................................16

2.15 Stainless Steel .....................................................................................................16

2.16 Flange Facings.....................................................................................................16

2.17 Vessels and Exchangers......................................................................................17

2.18 Computers, Telecommunications and Associated Equipment.............................18

2.19 Piping ...................................................................................................................18

3. QUALITY CONTROL PROCEDURES ................................................................22

3.1 General ................................................................................................................22

3.2 Relevant Documents............................................................................................22

4. MATERIAL CONTROL PROCEDURES .............................................................22

APPENDIX 1: ACTIVITY NUMBER CODES AND STORAGE LETTER CODES ..............23

APPENDIX 2: EQUIPMENT PRESERVATION AND MAINTENANCE LOG SUMMARY ..24

APPENDIX 3: CONSTRUCTION ENGINEERING MAINTENANCE LOG SHEETS (3

SHEETS)............................................................................................... 25-27

R2

R2

Contains Confidential Information of both Dow and Saudi Aramco

Page 4 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

1. GENERAL SCOPE

R3 The intent of this document is to outline the minimum requirement in developing the

specific RTIP material and equipment protection/preservation plan by the Contractor

and/or the Purchaser, and should be used in conjunction with Schedule G and Q requirements.

This includes the appropriate coordination with the principles such as the Owner’s team

and the supplier/vendor to support the applicable warranty and life expectancy.

The Plan (s) must cover Equipment and Material Protection from the time the item is

being prepared for shipping at the source (by the Manufacturer or at Vendor Shop),

through shipping, site delivery/storage, and installation and/or the warehousing. The

Contractor and/or the Purchaser shall remain responsible for the proper execution of the

Equipment and Material Protection and Preservation Plan (Plan) until the Owner’s formal

written acceptance of the installation and/or turnover of the facility. The Plan shall

conform to Engineering Design and manufacturer’s requirements for storage and

preservation.

1.1 Responsibilities

1.1.1 RTIP Site Material Control Manager may oversee implementation of the Material

and Equipment Protection and Preservation Plan, including the roles and responsibilities

as indicated in the Equipment and Materials Protection Plan Work Process, employing

the appropriate equipment, piping, and bulk materials maintenance and preservation

procedures defined in this Plan.

1.1.2 Procurement / buyers are responsible for conveying information to suppliers

relative to site climatic and other conditions affecting equipment storage and preservation

and ensuring that suppliers respond with appropriate preservation requirements.

1.1.3 Purchaser / buyer such as the contractor is responsible for the proper development

and execution of the Plan to support and provide the appropriate information for the Site

Material Handling/Storage as well as the Owner’s Maintenance and Warehousing

approach such as the data management software. The data management software shall

be able to deliver the data in a format for upload into the Owner’s Equipment

Maintenance System and Asset Management System.

1.1.4 Statutory Requirements: The Purchaser / Supplier shall mutually determine and

properly communicate the measures that must be taken to comply with all applicable

governmental codes, regulations, ordinances and rules which shall be applied as a first

precedence.

1.1.5 Purchaser’s equipment and/or material Work Group Leader (WGL) as the

Engineer of the record is responsible for requesting and reviewing equipment storage,

maintenance, and protection requirements provided by equipment suppliers. The

Equipment Preservation and Maintenance Log Summary (Appendix 2) or Supplier's

equivalent log shall be used by each WGL to document agreed requirements.

1.1.6 To avoid an unreasonable deferment of the requirements to the downstream

principles and shifting of the cost/responsibilities, the Purchaser must economically

Contains Confidential Information of both Dow and Saudi Aramco

Page 5 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

and/or technically justify the deferment of the engineering controls and shall obtain the

Owner’s concurrence. The Owner’s review and/or comment may also flag this upfront

design consideration and must be addressed appropriately.

1.1.7 Purchaser Site QA/QC Manager is responsible for reviewing the maintenance and

preservation procedures and performing the appropriate surveillances during the

implementation of this Material and Equipment Protection and Preservation Plan.

1.2 Statutory Requirements

The Purchaser and Supplier shall mutually determine the measures that must be taken to

comply with all applicable governmental codes, regulations, ordinances and rules which

shall be applied as the first precedence.

1.3 Industry Standards

The Contractor / Purchaser’s Plan must list the appropriate industry standards which may

apply to the equipment and material. As an example, the following document is

referenced herein and forms part of the standards. Current edition of the industry

standard shall apply unless otherwise indicated.

AMERICAN PETROLEUM INSTITUTE (API)

API 686, Recommended Practices for Machinery Installation and Installation Design,

Chapter 3 – Jobsite Receiving and Protection

2. EQUIPMENT PROTECTION DURING CONSTRUCTION AT JOBSITE

2.1 Scope

This section outlines the technical requirements for protection of equipment and

associated materials at the jobsite during the construction phase of the project. Jobsite

is defined as the temporary warehouse facilities (heated and unheated), lay down yard or

outside sheltered storage as well as the permanent equipment installation location.

The Contractor / Purchaser must include the other elements of the equipment and

material protection requirements in the Plan such as the requirements during the

shipping/transport.

2.2 General Requirements

2.2.1 These procedures are generally aligned with API 686 recommended practices, if

applicable, for jobsite protection and preservation for equipment, piping, and bulk

materials.

2.2.2 All maintenance/preservation activities have been abbreviated by means of a code

number that is used with Equipment Maintenance Log Sheets and Equipment

Preservation and Maintenance Log Summary. These codes may be found in

Appendix 1.

Contains Confidential Information of both Dow and Saudi Aramco

Page 6 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

2.2.3 Additional or special protection procedures will be utilized on an individual item

basis as deemed necessary jointly by Purchaser and the Client. Purchaser’s Site

Material Control Manager will notify Purchaser Engineering and the Client when

packaged equipment or complex equipment arrives on site. Purchaser Engineering and

the Client will jointly agree in advance on any special preservation requirements to be

followed for the equipment.

2.2.4 Equipment manufacturers recommended storage and preservation procedures

shall be reviewed by Engineering WGL’s and incorporated into this plan as they are

received from Suppliers. In general, equipment manufacturer recommendations take

precedence over specific preservation requirements contained in this plan. Any

deviations from equipment manufacturer’s recommendations must be approved by

Purchaser Site Material Control Manager and agreed in writing with the Supplier to

ensure equipment warranties are not invalidated.

2.2.5 Storage and lay down areas shall be designed so that they are well drained. All

bulks stored outside shall be elevated above the ground and above the maximum water

run-off.

2.2.6 Protective covers and tarps are used to prevent contamination from blowing sand

and debris and shall be used in a manner that allows free air circulation around the bulks.

Covers or tarps shall not be sealed against the ground. Ventilation is needed to allow

moisture evaporation. Plastic tarps shall be used when appropriate with care to avoid

trapping moisture within the tarp and thus causing corrosion. This is especially sensitive

with rotating equipment. Woven or fabric moisture resistant tarps with impregnated vapor

corrosion inhibitors (VCI) are preferred.

2.2.7 Fibrous and other materials that can absorb moisture (e.g., pressed board,

cardboard, softwood, etc.) shall not be used as supports, spacers, separators, or covers.

Fibrous materials used in shipping crates and containers shall be removed and replaced

with suitable materials or the materials removed and suitably stored.

2.2.8 Materials shall not be stored outdoors in non-drainable positions. Components,

such as ells and bends, shall be stored in a horizontal position so that moisture and

condensation does not collect on the inside.

2.2.9 Arrangement for appropriate utilities must be in place for safe keeping of the

equipment such as the purge gas, heater power, etc.

2.2.10 Material identification markings shall be maintained.

2.2.11 All damaged and/or corroded materials shall be stored separately from

undamaged materials until corrective action is applied.

2.3 Documentation

2.3.1 Basic preservation and storage location requirements for individual equipment

items are outlined in the Equipment Preservation and Maintenance Log Summary

(Appendix 2). Preservation and storage location of auxiliary equipment and

Contains Confidential Information of both Dow and Saudi Aramco

Page 7 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

instrumentation that is shipped loose shall follow the requirements contained in this plan,

depending upon how the auxiliaries are categorized.

R2 2.3.2 Evidence of the implementation of the Equipment Protection Plan shall be

documented using the “Construction Engineering Maintenance Log Sheets"

(Appendix 3). A log sheet shall be completed for each equipment item or package

requiring preservation and used to record preservation activities as they occur.

2.3.3 For each equipment item, the type of preservation performed, the date each

activity was performed and the individual performing the preservation activity shall be

recorded. The original documentation will be maintained by the Purchaser Site Material

Control Manager and ultimately turned over to the Client with the project quality records.

2.3.4 Special storage and preventive maintenance activities as required for maintaining

extended warranties, if required, shall be included on the Construction Engineering

Maintenance Log Sheet (Appendix 3). The items for which this is required are identified

in the notes column of the Equipment Preservation and Maintenance Log Summary

(Appendix 2).

2.4 Use and Application of Rust Preventives, Preservatives, and Desiccants

2.4.1 All interior and exterior surfaces shall be cleaned and dried as required before any

rust preventive materials are applied.

2.4.2 For interior surfaces of bearing housings, the preservative of choice is provided by

Cortec, who provides a vapor phase inhibitor product (VPI) with characteristics that will

maintain a lubricated and protected surface during cold weather conditions and for

extended periods. Most suppliers will agree to furnish their equipment with the

appropriate VPI product prior to leaving the shop if specified in the Purchase Order.

2.4.3 Mineral spirits such as Varsol or any Stoddard solvent, as applicable, shall be used

for cleaning exterior surfaces prior to application of any rust preventive compounds.

Kerosene or gasoline shall not be used as cleaning agents.

2.4.4 API Type D asphaltic preservatives should be avoided, as most asphaltic films are

very difficult to remove. Non-asphaltic inhibitors such as Cortec 368 provide excellent

long term storage protection.

2.4.5 The rust preventives to be used are defined below, based upon required usage.

Equivalent rust preventatives may be used with prior approval.

Contains Confidential Information of both Dow and Saudi Aramco

Page 8 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

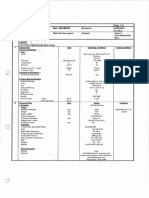

TABLE I: SAMPLE RUST PREVENTATIVES

Preservative Activity (2) Application Typical

Type Products (3)

Use as an additive to lubricants for protection of bearings

Lube Compatible #8 & #14 and internal surfaces. Compatible with mineral oil Cortec VCI-326

lubricants.

Use on exterior unpainted iron and carbon steel surfaces

Exterior #5 & #6 Cortec VCI-368

exposed to the weather.

Use on exterior unpainted iron and carbon steel surfaces Cortec VCI-368,

Storage #5 & #6 stored under a roof and sheltered from direct effects of VCI-369 and/or

the weather. Cor-Pak Film

Use as an additive to hydraulic systems for protecting

Hydraulic #Special ferrous and non-ferrous metals from corrosion due to Cortec VCI-326

moisture.

Use for filling seal chambers of double mechanical seals Consult machinery

Mechanical Seal #2

to prevent contamination of internal seal components. engineer

Consult machinery

Grease #12 Refer to the machinery lubrication schedule

engineer

Use in cast iron, carbon steel and aluminum equipment

casings were accumulation of moisture could cause

corrosion.

Desiccant #15 DRI-BOX (1)

• Not to be used with Vapor Phase Inhibitors.

• Not be used to protect stainless steel or components

with rubber parts.

Weldable #6 For use on ferrous weld bevels Deoxaluminite

Use on machined ferrous surfaces such as flange gasket

Petroleum Soluble #5 & #6 Cortec VCI-368

seating surfaces

Use to protect internal surfaces of equipment from

Vapor Phase

#15 corrosion. Cortec 307

Inhibitor

• Not to be used with desiccants.

Use to protect threaded ferrous and alloy surfaces, such

Anti-Seize #6 Jet-Lube 550

as valve stems, from corrosion.

Wax Cloth Tape #19 Use to protect exposed surfaces of shafts Denso Densyl Tape

Cortec VpCI 426

Rust Remover #20 Use to remove corrosion from carbon and stainless steel

and VpCI 426 Gel

Note 1 DRI-BOX is a transparent regeneratable dehydrating cartridge with color

indicating silica gel that turns from blue to pink when it can no longer pick-up

moisture

R2 Note 2 See Appendix 1

R2 Note 3 Products must be reviewed for process compatibility. Final product list to be

approved by Owner prior to shipment of equipment.

2.5 Examination of Equipment on Arrival at Jobsite

R3 2.5.1 The following receiving inspection activities relate to preservation.

Contains Confidential Information of both Dow and Saudi Aramco

Page 9 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

2.5.2 All equipment shipped with protective covers or plugs over openings, and applied

rust preventive coatings on exterior machined and threaded surfaces, shall be examined

on arrival at the jobsite:

2.5.3 After Supplier approval, the covers with their full-face gaskets will be removed,

inspected, and reinstalled.

a. Protective covers, plugs, and coatings, shall be renewed if not intact (Appendix

1Activity #3, #4). Length of time that covers and plugs are removed shall be kept to

a minimum.

b. If water or dirt has entered the equipment through damaged or improperly secured

covers and plugs, the equipment shall be cleaned and preserved before covers,

plugs, and coatings are restored (Activity #10).

c. If vapor phase inhibitors or desiccants are used to protect the interiors of mechanical

equipment, the seals shall be examined when the equipment is received at the

jobsite. Any damaged vapor seals shall be repaired or replaced, and the inhibitor or

desiccant renewed if necessary (Activity #15).

d. Vapor seals shall be protected and maintained until the equipment is serviced for

startup. Any damage to seals prior to such time shall be immediately repaired

(Activity #15).

e. Equipment that is shipped in export crating and designated for outdoor covered (OC)

storage may remain in the original crating for a maximum period of 4 months unless

otherwise specified by the manufacturer. Following the 4 month period, preventive

maintenance shall commence.

2.6 Machinery

a. The shafts of all mechanical equipment shall be rotated as specified in the

Equipment Preservation and Maintenance Log Summary (Appendix 1) (Activity #1).

b. After installation at their final service location, rotating equipment such as turbines

and expanders, fans, gear unit cases, agitators, pumps, blowers, and centrifugal

compressors shall be protected as follows:

1. Continue to maintain all internal surfaces of bearing housings and gear unit

cases using the specified (Manufacturer/Brand) preservative. Vent and drain

connections shall be plugged, capped, or blinded, as applicable, using steel

fittings. Blinds shall be gasketed. The preservative oil level shall be checked at

bi-weekly intervals and topped up to manufacturer’s specification

(Activity #8, #11, #14).

2. Clean shaft couplings and exposed machined surfaces and coat them with

EXTERIOR preservative (Activity #5, #6).

Contains Confidential Information of both Dow and Saudi Aramco

Page 10 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

3. Cover the suction and discharge nozzles of centrifugal compressors, pumps, and

blowers with leak tight metal closures (or blinds), which shall remain in place until

hydrostatic testing, and flushing of connecting piping is completed. Blinds are to

have tabs, which clearly identify the blind's presence in the line (Activity #4).

4. If a pump is shipped with double mechanical seals installed, fill the entire seal

cavity with mechanical seal type lubricant (Activity #2).

5. Spare rotating elements shall be stored indoors and per the manufacturer's

recommendations.

6. Equipment seal pots, pressurization piston assemblies, and related

instrumentation that are shipped loose shall be preserved, wrapped, and stored

indoors.

7. After installation at their final service location, reciprocating pumps and

compressors shall be protected as follows:

i. For reciprocating compressors the following shall be performed; Metal flange

covers with gaskets shall be installed on all compressor openings. A

nitrogen blanket shall be kept inside the machine frame to prevent moisture

and contaminants from entering the equipment. The nitrogen blanket (kept

at 5 psig (35 kPa(g)) or as specified by supplier) shall be checked and

maintained if necessary on a bi-weekly basis. Exposed machined surfaces

shall be coated with EXTERIOR preservative. When applicable, reseal

enclosures if opened by Customs. Cover filters or remove (Activity #3, #4,

#9).

ii For proportioning and metering pumps the drive mechanism (gearbox) shall

be filled with LUBE COMPATIBLE preservative. The equipment shall be

checked at bi-weekly intervals to ensure the drive mechanism and hydraulic

mechanisms are filled with the preservative.

c. Other mechanical equipment not specifically covered herein shall be protected as

follows:

1. Fill the oil lubricated bearing housings and gear unit cases with specified

(Manufacturer/Brand) preservative (Activity #8, #11, #14).

2. Apply a coating of EXTERIOR preservative to all shafts, couplings, and exposed-

machined surfaces with (Manufacturer/Brand). Cover if required (Activity #5, #6).

3. Remove all exposed drive chains. Clean chains with solvent, coat with

STORAGE type preservative, and wrap them in Kraft paper. Label each

wrapped chain to provide the proper identification, and store with accessories.

2.7 Motors and Generators

Contains Confidential Information of both Dow and Saudi Aramco

Page 11 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

2.7.1 Indoor storage is required for all motors, except for motors designed for outdoor

use, which may be stored outdoors without protective covering if exposed shaft and

coupling are preserved.

2.7.2 For motors and electric motor operated valve actuators stored outdoors without

protective cover, the following shall be observed:

a. All enclosure openings not intended to be open during operation of the equipment,

such as conduit and cable entrance in terminal boxes, shall be closed with watertight

plugs. Temporary shipping plugs shall be replaced with permanent storage plugs

(Activity #3).

b. All motors and valve actuators shall be stored in their normal operating position, e.g.,

vertical motors in an upright position with their shaft extension downward. Inspect

and preserve seats.

c. If space heaters are furnished within the units, they shall be connected to a

continuous supply of power of the proper rating (Activity #17).

d. Insulation resistance values of each winding shall be measured and recorded on the

Construction Engineering Equipment Maintenance Log Sheet. This shall be done as

soon as possible after a unit arrives at the jobsite (Activity #18). If readings are low,

dry out the insulation using a method approved by supplier/manufacturer. Retest

periodically.

2.7.3 After installation at the final service location, motors with oil lubricated bearings

shall be protected as follows:

a. Maintain all internal surfaces of bearing housing with specified (Manufacturer/Brand)

preservative. Vent and drain connections shall be plugged, capped, or blinded, as

applicable, using steel fittings. Preservative oil level shall be checked at bi-weekly

intervals (Activity #3, #8, #11).

b. Every three months, measure and record insulation resistance values (Activity #18)

of each winding of units rated 2300 volts and higher on the Construction Engineering

Equipment Maintenance Log Sheet. Record temperature and weather conditions at

time of reading. If resistance is low and cables have been connected, disconnect the

cables and repeat the measurements. If resistance of winding insulation only is low,

dry out leads in unit's terminal box by removing the cover and exposing to dry, clear

weather, or by placing an electric lamp or heater in the terminal box. If this does not

result in acceptable insulation resistance values, dry out the windings by an

approved method until acceptable values are obtained.

c. Six weeks before commissioning, measure and record insulation resistance values of

each winding of all units on the Construction Engineering Equipment Maintenance

Log Sheet. Record temperature and weather conditions at time of reading. If

resistance is low, proceed per Paragraph 2.7.3.b.

Contains Confidential Information of both Dow and Saudi Aramco

Page 12 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

d. Immediately before commissioning measure and record insulation values of all units

with cables disconnected. If readings are low, dry out before starting.

2.7.4 After installation at the final service location, motors with grease lubricated

bearings shall be protected as follows:

R2 a. Every three months, measure and record insulation resistance values (Activity #18)

of each winding of units rated 2300 volts and higher on the Construction Engineering

Maintenance Log Sheet (Appendix 3). Record temperature and weather conditions

at time of reading. If resistance is low and cables have been connected, disconnect

the cables and repeat the measurements. If resistance of winding insulation only is

low, dry out leads in unit’s terminal box by removing cover and exposing to dry, clear

weather, or by placing an electric lamp or heater in the terminal box. If this does not

result in acceptable insulation resistance values, dry out the windings by an

approved method until acceptable values are obtained.

R2 b. Six weeks before commissioning, measure and record insulation resistance values of

each winding of all units on the Construction Engineering Maintenance Log Sheet

(Appendix 3). Record temperature and weather conditions at time of reading. If

resistance is low, proceed per Paragraph 2.7.4 a.

c. For periods over 4 months, bearings shall be re-lubricated, if required, in accordance

with Manufacturer’s Recommendations and Instructions. If grease lubricated units

are at Work Site more than one year from the date of shipment from the factory

without having been operated, inspect the bearing grease (this does not apply to

“Sealed Bearings”). If there has been any visible deterioration of the lubricating

properties of the grease, clean it out and repack the bearings per manufacturer’s

recommendations (Activity #12).

d. Immediately before commissioning, measure and record insulation values of all units

with cables disconnected. If readings are low, dry out before starting.

2.8 Transformers

2.8.1 Indoor storage is required for all transformers except the following:

a. Transformers intended for outdoor installation may be stored outdoors without

protective covering. See the Equipment Preservation and Maintenance Log

Summary (Appendix 2) for storage categories.

b. Large indoor units may be stored outdoors if raised above grade to prevent any

damage from surface water and if a shed roof and tarpaulin siding (or equivalent) is

provided. See the Equipment Preservation and Maintenance Log Summary

(Appendix 2) for storage categories.

c. Drums of insulating liquid stored outdoors shall be laid on their side with the large

bung at about a 45 degree angle from the bottom center position and above grade.

Contains Confidential Information of both Dow and Saudi Aramco

Page 13 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

d. Transformers filled with insulating liquid

If a transformer is shipped with its main tank filled with insulating liquid (except for

expansion space), measure and record the level of the liquid and the ambient

temperature when the unit arrives on Site, and every month thereafter. If the level

falls, repair leaks and add insulating liquid to keep the level within tolerances.

e. Gas under pressure

If a transformer is shipped with its main tank filled with insulating liquid and blanketed

with gas under pressure (or filled with gas under pressure), measure and record the

gas pressure and the ambient temperature when the unit arrives at site. Measure

and record the gas pressure and the ambient temperature every month thereafter. If

the pressure falls, repair leaks and add gas to keep the pressure within tolerances.

f. Primary disconnect switches

Primary disconnect switches shall be handled per the requirements for switchgear,

starters, and control equipment.

2.9 Switchgear, Starters and Control Equipment

2.9.1 Equipment shall be stored indoors in a dry, warm place where condensation of

water vapor cannot occur, and as follows:

a. There shall be good ventilation of the warehouse.

b. If high relative humidity or large, rapid changes in temperature are experienced,

heaters shall be used to maintain the temperature at a level approximately 10 oF

(6 oC) above minimum daily temperature.

c. If space heaters are furnished within the equipment, they shall be connected to a

continuous source of power of the proper rating upon arrival at Jobsite.

d. Free-standing metal enclosed equipment shall be stored in an upright position.

e. Oil immersed starters, circuit breakers, and similar items, which are shipped dry,

shall be stored indoors, or shall be filled with insulating liquid as soon as they are

received at site. Units filled with liquid may be stored outdoors if raised above grade

to prevent any damage from surface water and if a shed roof and tarpaulin, siding (or

equivalent) is provided.

f. Insulation resistance values of such parts as operating coils shall be spot checked

every (Select Time Frame). If any readings are low, the affected parts shall be dried

out before they are placed in operation.

2.10 Cables

Contains Confidential Information of both Dow and Saudi Aramco

Page 14 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

2.10.1 Reels of paper insulated lead sheathed cable shall be rotated 90o every (Select

Time Frame).

2.10.2 Low-pressure gas filled cable shall be handled as follows:

a. Gas pressure shall be measured and recorded when the cable is received at site,

and every month thereafter. The pressure should be between 5 and 13 psig (35 and

90 kPa). If falling pressure indicates a leak in the cable, connect a cylinder of dry

nitrogen to the cable to maintain pressure until the leak is located and sealed.

b. Nitrogen used to maintain pressure during storage, if required, shall be per ASTM

D1933, Type I, II or III (Type III is preferred, if available). Manufacturer's

recommendations shall be followed during installation and operation of any nitrogen

cylinders.

2.11 Storage Batteries

2.11.1 All batteries shall be stored indoors, in a dry place.

2.11.2 Batteries that have been shipped dry and sealed shall have the seals inspected

when they are received at site. Any seals that are damaged shall be renewed per the

manufacturer's instructions.

2.11.3 Lead-acid batteries that have been shipped wet shall be handled as follows:

a. Electrolyte level shall be inspected when batteries are received at site. Electrolyte

shall be added to the proper level, if any has been lost.

b. Three months after date of shipment from the factory, and every 3 months thereafter,

batteries shall be given a freshening charge to restore the voltage to 2.15 volts per

cell and the specific gravity to 1.21 at 77 oF (25 oC). The charging rate shall not

exceed the manufacturer's recommended value; batteries shall not be overcharged.

c. Other type batteries that have been shipped wet shall be handled per the

manufacturer's instructions.

2.12 Instruments

2.12.1 Satellite Buildings (Remote Instrument Enclosures) with DCS, SIS or other

sensitive or computer-based instrument hardware should not be shipped to jobsites

where high temperatures or humidity are encountered, until permanent or temporary

power can be connected and air conditioning units can be run.

2.12.2 DCS, SIS, or other sensitive or computer-based hardware shipped loose should

not be shipped to the jobsite until it can be installed or stored in its final building, i.e.,

control building, satellite building, rack room, etc., or other indoor air conditioned area.

Contains Confidential Information of both Dow and Saudi Aramco

Page 15 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

2.12.3 DCS hardware, such as field-bus racks, multiplexers, remote I/O modules, etc.

which will ultimately be installed in the field may be installed indoors, where heat and

humidity are limited, however they need not be stored in control room or satellite building

areas.

R3 2.12.4 Analyzer shelters and complex analyzers shall be stored per the

recommendations of the Suppliers. HVAC units shall be hooked up and operated to

maintain equipment inside the shelter.

2.12.5 All instruments requiring a temperature controlled environment shall be stored

indoors and as follows:

a. Temperature shall be controlled to prevent the condensation of humidity.

b. Prefabricated panel boards shall be left in their shipping cases until moved into the

control house or other location.

c. Potentiometers shall never be exposed to temperatures below 32 oF (0 oC) or above

125 oF (52 oC).

d. Instruments including control valve and motor actuators installed at outdoor locations

shall be protected from the weather and mechanical damage. Wood covers over

glass fronts may be used.

e. Control valves actuators shall be protected from severe shock and extreme

temperatures as they may contain electronic hardware. Conduit openings shall

remain with plastic plugs or other devices to inhibit rain, snow, and dust from entering

these enclosures until conduit or cable glands can be installed.

f. Motor actuators shall be protected in the same manner as motors.

2.13 Valves

2.13.1 Indoor storage shall be provided for all valves except the following:

a. Manually operated valves Size NPS 4 (100 mm) or larger may be stored outdoors on

a paved area (or pallets), with the valve stem upright. Valves stored outdoors must

be protected from blowing sand and salt spray.

b. Large automatic control valves such as slide valves and motor operated valves may

be stored outdoors on a paved area, or on pallets, if a shed roof and tarpaulin siding

(or equivalent) are provided. Actuators on control valves and motor operated valves

shall be protected against mechanical damage. All conduit connections shall be

covered to prevent water entry.

c. Valves shall be stored in the closed position, unless they have a spring actuator,

then the valve should be stored in the position such that the spring is in a relaxed

state.

Contains Confidential Information of both Dow and Saudi Aramco

Page 16 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

d. Flange protectors shall be left on until the valve is ready to be installed (See Section

2.16).

e. Control valves shall be stored in accordance with the manufacturer’s storage

procedures and requirements.

2.14 Welding Consumables

R2 All bulk covered electrodes, SAW flux, spooled or straight length solid bare and flux and

metal cored wire shall be stored in a clean, warm (70 °F/21 °C minimum) and dry location

(70% maximum relative humidity) and shall be placed on wooden pallets or suitable

cribbing to eliminate contact with the floor. Procurement and management of welding

consumables should be in accordance with Engineering Procurement Contractor’s(EPC)

procedure for Welding Filler Metal and Electrode Procurement and Management.

2.15 Stainless Steel

2.15.1 Stainless steel (alloys containing more than 10% chromium) equipment,

components, and materials shall be protected as follows:

a. Undercover. (Protective coatings are acceptable alternatives to covered storage.)

b. Not in contact with the soil or with porous supports such as raw wood. The

preservation procedures must reflect the potential for environmental conditions to

create contact between the stainless steel and a potential corrosive (e.g., blowing

sand).

c. In addition, austenitic stainless steels shall not be exposed to salt water or salt spray.

d. Shall be stored segregated from ferrous materials.

e. Where there are large extremes between day and nighttime temperatures, care must

be taken to avoid collection of dew point condensation on stainless steel equipment

and materials.

2.16 Flange Facings

2.16.1 Flange facings on all piping and equipment shall be protected at all times during

fabrication and construction. The use of mechanical flange protectors should be

maximized, in addition to coating with the appropriate preservative.

2.16.2 All high-pressure flanges (Class 1500 and higher) shall be fitted with robust metal

protective caps during shipment and storage onsite. RTIP QA/QC must witness and

document that every high pressure joint is clean, undamaged and properly assembled

when the final closure is made. Such documentation shall be included in the turnover

packages for that system.

Contains Confidential Information of both Dow and Saudi Aramco

Page 17 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

2.17 Vessels and Exchangers

2.17.1 Vessels and exchangers shall be stored and preserved in accordance with the

requirements set forth on the Equipment Preservation and Maintenance Log Summary

(Appendix 2) for storage categories.

2.17.2 Equipment maintenance and protection quality records shall be kept on the

Construction Engineering Maintenance Log Sheet (Appendix 3).

2.17.3 Special storage requirements as detailed in the Suppliers’ data books and

instruction manuals shall be adhered to.

2.17.4 Electric heaters shall have vapor phase inhibitor bags or desiccant bags on the

heater element side in order to prevent the absorption of moisture by the element

(Activity #15).

2.17.5 Air cooler fans should be prevented from rotating during storage, either by

restraining the fan blades, or by restraining the driven sprocket. Motors and belts should

be left in the shipping packaging as long as possible, and stored in a dry place at

moderate temperatures. Gear drives should be filled with lubricant. If storage lasts more

than three months, fan and motor shafts should be manually rotated at least 15

revolutions once a month, and should have grease added once every six months

according to the following table:

NEMA Frame Size (IEC) Vol. (mL)

182 – 215 (112 - 132) 8

254 – 286 (160 – 180) 16

324 – 365 (200 – 225) 24

404 – 449 (250 – 280) 40

Fan Bearings 75

After manual rotation of motor shafts, packaging should be returned to original state, and

desiccant should be added. Fans should be re-secured, and any covering replaced.

2.17.6 Louvers should be in the closed position. Carbon steel tubes with extruded fins

should have the exposed ends sprayed with oil every three months and the tube bundle

should be covered with plastic or canvas. If the exposed tube ends are painted with

epoxy paint, spraying with oil is unnecessary. For carbon steel tubes with embedded

fins, the entire length of the tubes should be sprayed with light oil every three months,

and the bundles covered. Machined surfaces of sprockets should be coated with grease.

For bundles with a nitrogen purge, pressure should be monitored, and nitrogen replaced

as necessary.

2.17.7 When air coolers are put in service, grease lines should be disconnected from

bearing housings, and lines should be purged with new grease. Lines should then be

reconnected, and bearing grease chambers should be purged with new grease, with

Contains Confidential Information of both Dow and Saudi Aramco

Page 18 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

bearing drain plugs removed. Motors should be started and run for 5 to 10 minutes

before drain plugs are re-tightened.

2.18 Computers, Telecommunications and Associated Equipment

(Also, see Paragraphs 2.12.1 and 2.12.2)

All computer, telecommunication and associated equipment will be stored and

maintained in accordance with the manufacturer’s specified requirements. All sensitive

electronic equipment items shall be stored in environmentally controlled, indoor storage

locations. Only qualified personnel shall perform preventive maintenance for such

equipment.

2.19 Piping

2.19.1 General

R3 Piping should be placed on cribs in the field. Pipe and piping materials arrive at the site in

various forms of fabrication including fabricated spools, assemblies, random lengths of

pipe, and bulks. All materials shall be suitably stored and protected from the site

conditions. Materials subject to sea spray, blowing dust and sand, freezing or elevated

temperatures may require special storage precautions. Piping and piping assemblies

intended for lube oil service shall be kept clean, dry and sealed to minimize the risk of oil

contamination and lengthy flushing time during commissioning.

2.19.2 Damage

Damaged materials shall be documented, photographed and reported. Report shall

indicate the reason for the condition of the materials. The receiving inspector shall

record condition of materials on the material receiving record so that the Materials

personnel can take necessary corrective measures. All damaged materials shall be

stored separately from undamaged materials.

2.19.3 Corrosion Protection

All materials shall be inspected for corrosion. Corrosion shall be removed by methods

that do not damage the machined surfaces (Activity #20) and the cleaned surfaces

coated with a suitable rust inhibitor (Activity #5, #6). Inhibitors shall be inspected

routinely and renewed if there are any breaks in the film or signs of corrosion.

a. Threaded surfaces shall be coated with an anti-seize rust inhibitor.

b. Machined surfaces shall be coated with a petroleum soluble rust inhibitor.

c. Ferrous weld bevels shall be coated with a weldable rust inhibitor.

2.19.4 Mechanical End Protection

Protective seals (e.g., covers, plugs, caps, etc.) shall be inspected and if found to be

ineffective shall be restored or replaced (Activity #3, #4).

Contains Confidential Information of both Dow and Saudi Aramco

Page 19 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

a. All openings shall be fully capped, plugged or covered to prevent damage and

ingress of moisture and foreign matter.

b. Wood covers may be used on flanges provided an impervious membrane is placed

between the wood and greased flange face.

c. Threaded ends shall be protected with high impact plastic wedge type protectors.

2.19.5 Internals

Internals shall be clear of debris and free of foreign matter. Internals protected with

desiccants, vapor corrosion inhibitors, or purges shall be tagged or marked to indicate

type of preservative used, when replaced, and when last inspected. Desiccants shall not

be used to protect stainless steel or high alloy materials, or components with rubber

internals. Silica gel used as desiccant shall be of the indicating type (blue-active) and

packaged to allow viewing of the material. The approximate volume to be used shall be

0.12 lb/ft3 (2 kg/m3). Purge items require internal inspection only when the purge is lost

(Activity #9, #15).

2.19.6 Shipping Containers

Materials may be stored in their original shipping container provided the container has

not been damaged and the container, and its internal dunnage, has been determined to

be suitable for the site storage conditions. Shipping containers determined to be suitable

for storage shall be resealed after receiving and inspection. Materials stored in shipping

containers shall be routinely inspected for corrosion.

2.19.7 Dunnage

All materials shall be stored on suitable dunnage to keep them clear of the ground and to

provide ventilation around materials to allow moisture evaporation. Fibrous dunnage

materials that can absorb moisture (e.g., pressed board, cardboard, softwood, etc.) shall

not be used to support or separate materials. Any fibrous dunnage materials located

shall be removed and replaced with suitable dunnage.

2.19.8 Traceability

Materials shall be inspected for proper markings in accordance with project standards

and the purchase order. Material traceability must be maintained at all times.

a. Alloy verified material should be segregated at all times from other materials.

b. Impacted tested carbon steel (ITCS) materials shall be color coded and segregated

from normal materials during storage.

2.19.9 Stainless Steel and High Alloy Materials

If site conditions dictate, uncoated SS and high alloy materials shall be stored under

cover or under tarps with adequate ventilation. The purpose of the cover is to prevent

contamination from airborne contaminants, blowing dust or sand, and iron-contamination

Contains Confidential Information of both Dow and Saudi Aramco

Page 20 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

from grinding, welding and fabrication operations. Stainless steel and high alloy

materials shall not be:

a. Stored with, or come into contact with any ferrous materials.

b. Stored in contact with porous or moisture retaining supports on the ground.

c. Exposed to salt water or sea spray.

d. Marked with any markers other than low chloride markers.

e. Sealed with any type of tape or adhesive.

f. Protected from moisture by the use of desiccants.

2.19.10 Non-Metallics

Non-metallic materials shall be handled, stored, and protected in accordance with the

Suppliers recommended procedures and the following:

a. Exposed rubber parts shall be wrapped in opaque plastic covers secured with tape

or otherwise sealed.

b. Desiccants shall not be used to protect rubber or components with rubber parts.

c. Non-metallic materials shall be protection from UV exposure, high temperature and

mechanical abuse.

d. Openings shall be protected from mechanical damage by end caps.

e. Non-metallics shall be protected from impact against hard objects.

2.19.11 Special Protection Requirements

Manufacturer’s data shall be reviewed to determine if any special storage or preventative

maintenance procedures are required to maintain Suppliers' warranties.

2.19.12 Deficiency in Protection

Storage and protection methods shall be suitable for the site conditions. Some materials,

such as machined ferrous surfaces, are more sensitive to the environmental conditions

and require more frequent preventative maintenance. If the method of storage or level of

protection provided is not sufficient, then a deficiency exists and the materials shall be

marked for corrective action.

a. Storage and lay down areas shall be designed so that they are well drained.

b. All bulks stored outside shall be elevated above the ground and above the maximum

water run-off.

c. Bulks shall be stored in a manner that facilitates routine inspection and preventative

maintenance.

d. Storage methods shall protect materials from infiltration of water, dust, dirt, vermin,

insects, etc.

e. Materials shall not be stored in non-drainable positions, which will trap water.

f. Sensitive materials, such as stainless steel and non-metallics, are properly stored

and protected.

g. Materials subject to sea spray, blowing dust or sand, freezing or elevated

temperatures require additional protection.

Contains Confidential Information of both Dow and Saudi Aramco

Page 21 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

2.19.13 Valves

a. Plug and ball valves shall be stored in the opened position.

b. Valves with a spring actuator shall be stored in the position that the spring is in a

relaxed position.

c. All other valves shall be stored in the closed position.

d. Valves shall have the interior coated with light oil.

e. Valve stems shall be coated with an anti-seize corrosion inhibitor.

f. Hand wheels that have been removed shall be securely strapped to the valve.

g. Safety relief valves shall be stored upright with lifting levers strapped to the body of

the valve.

h. Actuators on motor operated valves shall be protected against mechanical damage.

2.19.14 Pre-Insulated pipe Supports

a. Pipe supports with insulation shall be stored in a covered location in original sealed

containers or bags.

b. Cold pipe supports shall be sleeved in polyethylene and heat-sealed in waterproof

packages.

c. Insulation shall be protected from UV degradation and moisture.

2.19.15 Nuts, Bolts, and Gaskets

a. Nuts, bolts and washers shall be kept in sealed watertight containers if stored

outside.

b. Gaskets shall be sleeved in polyethylene and heat-sealed or maintained in

waterproof vapor barrier packages if stored outside.

R3 c. Contractor shall take care as to not misplace nuts and bolts.

2.19.16 Pipe

a. Pipe stored in the storage yard shall be placed on level timbers or pallets providing

good ground clearance.

b. Pipe openings shall be protected from entry of rain and foreign matter until closure

welds are made.

c. Internal spiders shall be maintained on large diameter thin wall piping to prevent out-

of-roundness.

2.19.17 Fabricated Pipe and Assemblies

a. Fabricated pipe shall be placed on level timbers or pallets providing good ground

clearance.

b. Pipe openings shall be protected from entry of rain and foreign matter until closure

welds are made.

c. Fabricated assemblies shall be maintained in shipping packages to prevent

mechanical damage.

Contains Confidential Information of both Dow and Saudi Aramco

Page 22 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

d. Expansion joints shall be secured in a fixed position to prevent deflection during

handling, transport and storage.

e. Fabricated items and components shall not be stored outdoors in non-drainable

positions.

3. QUALITY CONTROL PROCEDURES

3.1 General

R2 This section references the Quality Control Procedures relevant to equipment protection

on the project. These procedures (and associated forms) may be found in the

Engineering Procurement Contractors (EPC) Construction Quality Control Procedures

Manual for the Program (Client), and/or the Project.

3.2 Relevant Document

R2 Construction Quality Manual: To be provided by Engineering Procurement Contractor

(EPC)

R2 RT-6-1-CSA Equipment and Material Protection Plan Work Process

R2 A554-K-PRG-CE-GEN-FRM-001 Equipment and Material Protection Plan work Process

Spreadsheet

4. MATERIAL CONTROL PROCEDURES

Refer to Engineering Procurement Contractor (EPC) Material Control Receiving

Procedures relevant to equipment receipt.

Contains Confidential Information of both Dow and Saudi Aramco

Page 23 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

APPENDIX 1

ACTIVITY NUMBER CODES AND STORAGE LETTER CODES

1. ACTIVITY NUMBER CODES

1 Rotate shaft 2 1/4 turns

2 Fill double and tandem mechanical oil seal with seal oil

3 Plug or cap any openings

4 Cover and protect all equipment nozzles

Spray shafts and hubs with preservative and protect exposed shafts with wax

5

cloth wrap as required

6 Inspect machined surfaces and coat with preservative

7 Protect oil and level gauges as required

8 Check preservation oil level

9 Check nitrogen blanket pressure and add nitrogen as required

10 Inspect for presence of moisture

11 Fill bearing housings with oil as required

12 Purge and grease bearings (once every four months)

13 Preserve internals of lube and seal oil system

14 Fill gear box with lubricant as required

15 Check and add desiccant or vapor phase inhibitor as required

16 Operate lube oil system as required

17 Verify space heaters are operational as required

18 Measure insulation resistance as required

19 Protect exposed shafts with wax cloth wrap as required

20 Remove rust prior to application of preservative

2. STORAGE LETTER CODES

I Indoor storage - Unheated

O Outdoor storage/Lay down - Unprotected

R3 IH Indoor storage – HVAC controlled.

OC Outdoor storage - Covered

Contains Confidential Information of both Dow and Saudi Aramco

Page 24 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

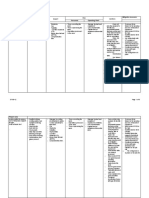

APPENDIX 2

(Client)(Site) Project - EQUIPMENT PRESERVATION AND MAINTENANCE LOG

SUMMARY (SAMPLE COPY)

Note. This form should be reviewed to ensure that sufficient room is provided on the form to allow pertinent information

and instructions to be recorded. As a minimum, the actual form should be size 11x17 (A3).

Contains Confidential Information of both Dow and Saudi Aramco

Page 25 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

APPENDIX 3

CONSTRUCTION ENGINEERING MAINTENANCE LOG SHEET (1 OF 3)

JOB NO.:

CLIENT: CONSTRUCTION ENGINEERING

CONT’D ON

LOCATION: EQUIPMENT MAINTENANCE LOG SHEET PAGE 1

PAGE 2

TYPE EQUIP.: ITEM NO.:

MFGR.: S/N:

MOTOR INSULATION RESISTANCE CHECK

TECHNICIAN

DATE T1 T2 T3 Q.C. Initials

INITIALS

ACTIVITY

ACTIVITY DESCRIPTION SCHEDULE

NUMBER B

W W

M SP

1 Rotate shaft 2 1/4 turns

2 Fill double and tandem mechanical oil seal with seal oil

3 Plug or cap any openings

4 Cover and Protect all equipment nozzles

5 Spray shafts and hubs with preservative and protect exposed shafts

with wax cloth wrap as required

6 Inspect machined surfaces and coat with preservative

7 Protect oil view ports and level gauges as required

8 Check preservation oil level

9 Check nitrogen blanket pressure and add nitrogen as required

10 Inspect for presence of moisture

11 Fill bearing housings with oil as required

12 Purge and grease bearings (once every four months)

13 Preserve internals of lube and seal oil system

14 Fill gear box with lubricant as required

15 Check and add desiccant or vapor phase inhibitor as required

16 Operate lube oil system as required

17 Verify space heaters are operational as required

18 Measure insulation resistance as required

19 Protect exposed shafts with wax cloth wrap as required

20 Remove rust prior to application of preservative

DATE Tech. QC

ACTIVITY NUMBER Init. Init.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

W = WEEKLY; BW = BIWEEKLY; M = MONTHLY; SP = SPECIAL PERIOD: ITEM NO.

Contains Confidential Information of both Dow and Saudi Aramco

Page 26 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

APPENDIX 3

CONSTRUCTION ENGINEERING MAINTENANCE LOG SHEET (2 OF 3)

JOB NO.:

CLIENT: CONSTRUCTION ENGINEERING

CONT’D ON

LOCATION: PAGE 2

EQUIPMENT MAINTENANCE PAGE 3

LOG SHEET

TYPE EQUIP.: ITEM NO.:

MFGR.: S/N:

DATE RECEIVED: DATE INSTALLED:

Tech. Q.C.

DATE

ACTIVITY NUMBER Initial Initial

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

W = WEEKLY, BW = BIWEEKLY, M = MONTHLY SP = SPECIAL PERIOD ITEM NO.:

Contains Confidential Information of both Dow and Saudi Aramco

Page 27 of 28

Ras Tanura Integrated Project (RTIP) Document No: RT-6-1CS

KBR Project No. A554 Revision: 3

MATERIAL AND EQUIPMENT PROTECTION

AND PRESERVATION PLAN Issue Purpose: IFD

APPENDIX 3

CONSTRUCTION ENGINEERING MAINTENANCE LOG SHEET (3 OF 3)

CLIENT: CONSTRUCTION ENGINEERING JOB NO.:

EQUIPMENT MAINTENANCE LOG

LOCATION: SHEET PAGE 3 LAST PAGE

TYPE EQUIP.: ITEM NO.:

MFGR.: S/N:

DATE NOTES (Record special precautions taken) Tech Q.C.

Initial Initial

W = WEEKLY, BW = BIWEEKLY, M = MONTHLY, SP = SPECIAL PERIOD ITEM NO.:

Contains Confidential Information of both Dow and Saudi Aramco

Page 28 of 28

Вам также может понравиться

- Norsok L-002 Piping System Layout, Design and StructuralДокумент36 страницNorsok L-002 Piping System Layout, Design and Structuralkhaireddin50% (2)

- Substantial Completion DocumentДокумент1 страницаSubstantial Completion Documentapi-324291104Оценок пока нет

- IONE-AA00-MS-MS-0004 WMS For Mechanical and Steel Structure Grouting - R6Документ44 страницыIONE-AA00-MS-MS-0004 WMS For Mechanical and Steel Structure Grouting - R6Yusuf100% (1)

- Logistic Case StudiesДокумент28 страницLogistic Case Studiessuhas_pr50% (2)

- Disposal-Siezed-Goods ManualДокумент110 страницDisposal-Siezed-Goods ManualRajesh Arora100% (1)

- Petrochemicals Plants From Commissioning To Normal Op. - Vol.1-March 2017-1Документ229 страницPetrochemicals Plants From Commissioning To Normal Op. - Vol.1-March 2017-1Mohamed S HelmyОценок пока нет

- 2013 09 Ebara PMI PresentationДокумент40 страниц2013 09 Ebara PMI Presentationcandra trisilawatiОценок пока нет

- MaSa-1-PC-F-07 - Attachment E - Safety & Fire Prevention Management PlanДокумент15 страницMaSa-1-PC-F-07 - Attachment E - Safety & Fire Prevention Management PlanSabheeh AliОценок пока нет

- Manual de Vaporizadores AmbientalesДокумент9 страницManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoОценок пока нет

- Piping Fabrication Installation Erection and Testing PDFДокумент33 страницыPiping Fabrication Installation Erection and Testing PDFDeepak0% (1)

- ROXUL Process Manual 082714 - Compliance To CINIДокумент191 страницаROXUL Process Manual 082714 - Compliance To CINIMichael TayactacОценок пока нет

- MFL Environmental Impact Assessment and Environmental Management PlanДокумент152 страницыMFL Environmental Impact Assessment and Environmental Management PlanKvvPrasadОценок пока нет

- Mechanical Project Engineer Job DescriptionДокумент2 страницыMechanical Project Engineer Job DescriptionBESTINОценок пока нет

- GEN-046 MOS-DR-01 - Sewer Water Pipe (Clay Pipe) Belowground InstallationДокумент15 страницGEN-046 MOS-DR-01 - Sewer Water Pipe (Clay Pipe) Belowground InstallationFrancisco M. RamosОценок пока нет

- Kingdom of Saudi Arabia: Epc of Package Sanitary Waste Water Treatment PlantДокумент26 страницKingdom of Saudi Arabia: Epc of Package Sanitary Waste Water Treatment PlantM Daud Aslam100% (2)

- EP FE CS STD 001 01 E Company Standard For Access RoadsДокумент157 страницEP FE CS STD 001 01 E Company Standard For Access RoadsagaricusОценок пока нет

- CV, TabrezДокумент3 страницыCV, TabrezShams TabrezОценок пока нет

- 076551C 000D Sow 9000 001 - R0Документ37 страниц076551C 000D Sow 9000 001 - R0ikenn100% (1)

- الخليجДокумент10 страницالخليجmohamedОценок пока нет

- EXHIBIT I - Project Execution Plan FДокумент56 страницEXHIBIT I - Project Execution Plan FMohamed SarfanОценок пока нет

- PETROFAC ScheduleДокумент14 страницPETROFAC Schedulegusyahri001Оценок пока нет

- Engineering, Procurement & Construction: Consolidated Contractors CompanyДокумент20 страницEngineering, Procurement & Construction: Consolidated Contractors Companymohammad kassarОценок пока нет

- Safety Check For Catalyst Loading Operation: SI. No. Description Observation Yes/No/NA RemarksДокумент1 страницаSafety Check For Catalyst Loading Operation: SI. No. Description Observation Yes/No/NA RemarksRísês ÃfrözОценок пока нет

- MP TenderДокумент216 страницMP TenderArchit JhunjhunwalaОценок пока нет

- Profile - Gayatri ElectДокумент51 страницаProfile - Gayatri ElectAlison LewisОценок пока нет

- PT 20200520 Sungrow ESS Business Introduction V10 enДокумент22 страницыPT 20200520 Sungrow ESS Business Introduction V10 enHoàng ChungОценок пока нет

- RFQ For Site Fabricated TanksДокумент10 страницRFQ For Site Fabricated TanksNil BorichaОценок пока нет

- KR Parco Ps6 Ms 0001 M.S For ConcreteДокумент11 страницKR Parco Ps6 Ms 0001 M.S For ConcretebulzaeОценок пока нет

- Compressor - Tech Spec - Signed & Stamped Dated 14.08.2017Документ13 страницCompressor - Tech Spec - Signed & Stamped Dated 14.08.2017ashish kumar pandeyОценок пока нет

- TR-CA-MS-001 - B Demolishing and Debris Removal-Sent To HibaДокумент17 страницTR-CA-MS-001 - B Demolishing and Debris Removal-Sent To Hibasamer8saifОценок пока нет

- Piping Progress Measurement (In Dia and in Meter)Документ6 страницPiping Progress Measurement (In Dia and in Meter)bumkj100% (1)

- JDs - Turnaround RolesДокумент9 страницJDs - Turnaround Rolesahmed sobhyОценок пока нет

- Attachment 5 - Valve Design Table PDFДокумент8 страницAttachment 5 - Valve Design Table PDFbisworupmОценок пока нет

- Supplier of Complete Piping PackagesДокумент13 страницSupplier of Complete Piping PackagesSlim KanounОценок пока нет

- NGL Extraction TechnologiesДокумент10 страницNGL Extraction Technologieswylie010% (1)

- RFQ Epc Final - 01112016Документ68 страницRFQ Epc Final - 01112016TAMILОценок пока нет

- Hyundai Electric ESS Project List-1Документ2 страницыHyundai Electric ESS Project List-1Rachmat HermawanОценок пока нет

- Guideline SW StorageДокумент57 страницGuideline SW StoragekeuromokОценок пока нет

- Ep 08 030 37Документ18 страницEp 08 030 37Muhammad AwaluddinОценок пока нет

- Monitor The Construction Status of Piping InterfaceДокумент8 страницMonitor The Construction Status of Piping InterfaceAsraf Ali100% (1)

- SPRDДокумент49 страницSPRDnomurapreОценок пока нет

- 20-01-BRGA-MEC-RFQ-0001 - RevA RFQ For Pressure Vessels (Including Pig Launcher & Receiver, Diesel Filter)Документ17 страниц20-01-BRGA-MEC-RFQ-0001 - RevA RFQ For Pressure Vessels (Including Pig Launcher & Receiver, Diesel Filter)Bagus SigitОценок пока нет

- JPEP01231B0003 Control Procedure For Project DocumentДокумент7 страницJPEP01231B0003 Control Procedure For Project DocumentAmeya RevOsОценок пока нет

- ADNA SCHEDULE (Compatibility Mode)Документ2 страницыADNA SCHEDULE (Compatibility Mode)Enabulele OsakpamwanОценок пока нет

- What Is A Method Statement and Why Are They Used in Construction PDFДокумент8 страницWhat Is A Method Statement and Why Are They Used in Construction PDFKareemAdelОценок пока нет

- NG01023000 - Technical IttДокумент52 страницыNG01023000 - Technical IttendyОценок пока нет

- Demolishing WorkДокумент22 страницыDemolishing WorkArifian NugrohoОценок пока нет

- Flow Chart For Piping WorksДокумент1 страницаFlow Chart For Piping Worksspnx13Оценок пока нет

- Desalinationplant PDFДокумент10 страницDesalinationplant PDFYoungmin ParkОценок пока нет

- Pipeline Consultation PlanДокумент37 страницPipeline Consultation PlanhutuguoОценок пока нет

- 26 24 16.00 40-1 Submittal Review SheetДокумент6 страниц26 24 16.00 40-1 Submittal Review SheetLuisSalinasОценок пока нет

- Scope of Work Dismantling and Installation Wall and Roof Cladding at Compressor House Unit 1520Документ21 страницаScope of Work Dismantling and Installation Wall and Roof Cladding at Compressor House Unit 1520muhamadrafie1975Оценок пока нет

- PQ Structure PDFДокумент32 страницыPQ Structure PDFTompson StevenОценок пока нет

- Exhibit A-Scope of Work1 - 230315 - 122413Документ11 страницExhibit A-Scope of Work1 - 230315 - 122413Nada AmmarОценок пока нет

- Ramel Ornales Construction SuperintendentДокумент6 страницRamel Ornales Construction SuperintendentIndustrial WeldersОценок пока нет

- 025-Pro For Sewer & Drainage PDFДокумент25 страниц025-Pro For Sewer & Drainage PDFKöksal PatanОценок пока нет

- Commissioning of Industrial FacilitiesДокумент14 страницCommissioning of Industrial Facilitiesadalcayde2514100% (1)

- Bechtel EthicsДокумент21 страницаBechtel EthicsKhaled Abdelhamid100% (1)

- Cover LetterДокумент1 страницаCover LetterAbraham Immanuel AdamОценок пока нет

- DRP001-OUF-GMD-Q-000-500 Rev B1 PQPДокумент86 страницDRP001-OUF-GMD-Q-000-500 Rev B1 PQPDaniel Martinez100% (7)

- GS114-8 HVAC - Terminal Units For Offshore UseДокумент14 страницGS114-8 HVAC - Terminal Units For Offshore UseDH BОценок пока нет

- 02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Документ38 страниц02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Walid BdeirОценок пока нет

- CEIL Engineering FinHR Advt 202324 02Документ6 страницCEIL Engineering FinHR Advt 202324 02ThirukkumaranBalasubramanianОценок пока нет

- DS 7502Документ4 страницыDS 7502ThirukkumaranBalasubramanianОценок пока нет

- Job Description-Mechanical EngineerДокумент1 страницаJob Description-Mechanical EngineerThirukkumaranBalasubramanianОценок пока нет

- Job Description-Process EngineerДокумент1 страницаJob Description-Process EngineerThirukkumaranBalasubramanianОценок пока нет

- Job Description-Piping EngineerДокумент1 страницаJob Description-Piping EngineerThirukkumaranBalasubramanianОценок пока нет

- D2-001-AM Part 1Документ118 страницD2-001-AM Part 1ThirukkumaranBalasubramanianОценок пока нет

- Summarized Technical - Information Data'sДокумент1 страницаSummarized Technical - Information Data'sThirukkumaranBalasubramanianОценок пока нет

- A Guide To Failure Analysis For The Oil and Gas IndustryДокумент6 страницA Guide To Failure Analysis For The Oil and Gas IndustryThirukkumaranBalasubramanian100% (1)

- PALL FILTER - Process Data SheetДокумент2 страницыPALL FILTER - Process Data SheetThirukkumaranBalasubramanianОценок пока нет

- Final Report TOTAL EP MYANMARДокумент24 страницыFinal Report TOTAL EP MYANMARThirukkumaranBalasubramanianОценок пока нет

- Visual Inspection WeldДокумент53 страницыVisual Inspection Weldshifa100% (1)

- Mellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingДокумент9 страницMellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingThirukkumaranBalasubramanianОценок пока нет

- Corrosion Under InsulationДокумент21 страницаCorrosion Under InsulationRenan Soares KieferОценок пока нет

- Mellitah Oil & Gas BV: Field Bending OF LinepipeДокумент4 страницыMellitah Oil & Gas BV: Field Bending OF LinepipeThirukkumaranBalasubramanianОценок пока нет

- INITIAL RISK REVIEW - WAFA Cold CutДокумент6 страницINITIAL RISK REVIEW - WAFA Cold CutThirukkumaranBalasubramanianОценок пока нет

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFДокумент57 страницAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaОценок пока нет

- Cold CuttingДокумент2 страницыCold CuttingThirukkumaranBalasubramanianОценок пока нет

- Mellitah Oil & Gas BVДокумент12 страницMellitah Oil & Gas BVThirukkumaranBalasubramanianОценок пока нет

- Execution of Tie-Ins Without A Plant ShutdownДокумент3 страницыExecution of Tie-Ins Without A Plant ShutdownThirukkumaranBalasubramanianОценок пока нет

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureДокумент583 страницыMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanian0% (1)

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureДокумент19 страницMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianОценок пока нет

- Non Oily Wastewater To The SeaДокумент1 страницаNon Oily Wastewater To The SeaThirukkumaranBalasubramanianОценок пока нет

- JERES-D-001 Design Criteria For Pressure VesselsДокумент37 страницJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianОценок пока нет

- Aspee Hi-Tech: Knapsack SprayerДокумент2 страницыAspee Hi-Tech: Knapsack SprayerThirukkumaranBalasubramanianОценок пока нет

- PSG 15 Repairs or Modifications Dated 13th Nov 2013 PDFДокумент13 страницPSG 15 Repairs or Modifications Dated 13th Nov 2013 PDFThirukkumaranBalasubramanianОценок пока нет

- JERES-D-001 Design Criteria For Pressure VesselsДокумент37 страницJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianОценок пока нет

- DataSheet 105723Документ2 страницыDataSheet 105723ThirukkumaranBalasubramanianОценок пока нет

- Reference ListДокумент28 страницReference ListThirukkumaranBalasubramanianОценок пока нет

- DataSheet 105723Документ2 страницыDataSheet 105723ThirukkumaranBalasubramanianОценок пока нет

- CASE 1 Falcon-Logistics-A-Truck-Fleet-Is-Fleeting-PreviewДокумент5 страницCASE 1 Falcon-Logistics-A-Truck-Fleet-Is-Fleeting-PreviewShiela E. EladОценок пока нет

- giao dịch thuong mại quốc tếДокумент314 страницgiao dịch thuong mại quốc tếLinh TrangОценок пока нет

- Introduction To Warehousing:-: Types of Warehouses Private WarehousesДокумент6 страницIntroduction To Warehousing:-: Types of Warehouses Private Warehousessarfaraj123Оценок пока нет