Академический Документы

Профессиональный Документы

Культура Документы

TS01-OP1703304 Operating Maintenance Assembly Manual-RevA

Загружено:

cbОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TS01-OP1703304 Operating Maintenance Assembly Manual-RevA

Загружено:

cbАвторское право:

Доступные форматы

ÚČEL VYDÁNÍ / ISSUE STATUS

☒ PRO SCHVÁLENÍ ZÁKAZNÍKEM / FOR APPROVAL BY CLIENT

☐ UVOLNĚNO PRO REALIZACI / RELEASE FOR CONSTRUCTION

☐ OSTATNÍ / OTHERS

First issue A

JulMa KriMi NohPe

Popis změny yyyy.mm.dd Vypracoval Kontroloval Schválil HIP Rev.

Nature of Revision Datum/Date Elaborated by Checked by Approved by Chief Engineer

Projekt/ Project

BIO 4

Název dokumentu/ Document title

Filter DN800 / PN40

AMV04 NDB11 AT001, AMV04 NDB12 AT001, AMV04 NDB13 AT001

Technical Manual for

Transport, Storage, Assembly, Operation and Maintenance

P100209

JulMa KriMi NohPe

Číslo projektu Stupeň projektu skupina.dok Vypracoval Kontroloval Schválil HIP

Project No. Project Stage Doc.Group Elaborated by Checked by Approved by Chief Engineer

Elektronický soubor / Electronic file:

Č. dokumentu projektu / Project - Doc. No.: Pr6012186 A

Č. dokumentu autora / Originator Doc. No.: AM TS01-OP1703304 A

Č. balíku SPWR-Archivní / Archive package. No.: Rev.

© Doosan Škoda Power s.r.o

Důvěrná informace/ Confidential Informarion of Doosan Škoda Power s.r.o.

DOCUMENT REVISION CONTROL

Rev. Page Description Name Date

Content:

1. INTRODUCTION ....................................................................................................................................................... 3

2. TECHNICAL DATA .................................................................................................................................................... 3

3. TECHNICAL DESCRIPTION ..................................................................................................................................... 3

4. STORAGE RULES .................................................................................................................................................... 4

6. ASSEMBLY RULES .................................................................................................................................................. 4

7. OPERATION INSTRUCTIONS.................................................................................................................................. 4

8. SPARE PARTS ......................................................................................................................................................... 4

Filter DN800 PN40 – BIO 4

Doc. No.: TS01-OP1703304 Project: Index: 0 Page: 2/4

Doosan Škoda Power

1. INTRODUCTION

The terminology and data used in this document apply to all documents and related attachments

and are superior to them. In case there is a conflict between this document and any related project

document, this document shall prevail.

2. TECHNICAL DATA

KKS marking AMV04 NDB11 AT001

AMV04 NDB12 AT001

AMV04 NDB13 AT001

Designation Filter DN800 PN40

Quantity 3 pieces

Inlet DN800

Outlet DN800

Maximum Allowable Pressure PS 26 bar (g)

Maximum allowable temperature TS 120 °C

Minimum design metal temperature 5 °C

Corrosion allowance 1 mm

Test Pressure 38 bar (g)

Design Code EN 13480-3

Fabrication Code EN 13480-4

Testing Requirements EN 13480-5

Scope of NDE EN 13480-5 Table 8.2-1

Fabrication tolerances EN 13920 BF

Dimensions

Inlet weld Ø813x18 mm, Material P355GH

Outlet weld Ø813x18 mm, Material P355GH

Drain flange DN25 PN40 EN1092-1 / P245GH

Total length 1300 mm

Total height 1991 mm

Total Weight empty 1319 kg

3. TECHNICAL DESCRIPTION

The filter D73 is designed to strain solid particles contained in liquids. It is installed in horizontal

piping. The mesh screen is made from a perforated metal sheet with a surface area equal to twice

the area of the inlet pipe. The filter is supplied with strainer insert made from perforated sheet

metal. Gasket material class 2 (per EN12560-2) for temperatures up to 200 ° C. The filter is

supplied either with a sludge nozzle (type N).

Filter DN800 PN40 – BIO 4

Doc. No.: TS01-OP1703304 Project: Index: 0 Page: 3/4

Doosan Škoda Power

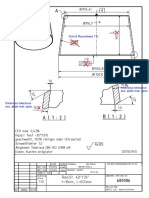

L

P

A

DN DN

IN OUT

B

C

DNd

OD1

4. STORAGE RULES

The filter shall be stored in an undercover storage.

6. ASSEMBLY RULES

• Assembly to be executed by qualified erection company according to the assembly and

erection rules prepared by this company

• Position of filter is according to plant project.

• The direction of the fluid flow shall agree with the arrow shown on the filter body

• Welds on the inlet/outlet nozzle of the filter to be executed according to piping

documentation and requirements.

7. OPERATION INSTRUCTIONS

Operation of the filter is maintenance-free and without any need of control. The filter shall be

drained periodically or once the differential pressure drop across the filter reaches 0.3 bar. The

differential pressure measurement is not part of the strainer supply.

If the drain nozzle becomes blocked, it is necessary to open the top cover and clean the filter from

inside and the filter mesh insert shall be visually checked and cleaned.

After every 2 years of operation the top cover shall be opened, and the filter shall be cleaned and

visually checked. If the filter insert is visibly damaged it needs to be replaced.

8. SPARE PARTS

2 pieces of the full-face gasket for the top cover

Filter DN800 PN40 – BIO 4

Doc. No.: TS01-OP1703304 Project: Index: 0 Page: 4/4

Doosan Škoda Power

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- HC3518 HC3520 HC3521 HC3522 HC3530 HC3535 HC3536Документ8 страницHC3518 HC3520 HC3521 HC3522 HC3530 HC3535 HC3536cbОценок пока нет

- Vessel Design Course NotesДокумент29 страницVessel Design Course NotescbОценок пока нет

- TS03 OP1703304 Hazard AnalysisДокумент3 страницыTS03 OP1703304 Hazard AnalysiscbОценок пока нет

- RealCAD Mechanical SymbolsДокумент60 страницRealCAD Mechanical SymbolscbОценок пока нет

- CatiaДокумент124 страницыCatiacbОценок пока нет

- Title Block Tutorial in CATIA V5Документ2 страницыTitle Block Tutorial in CATIA V5prateekg92Оценок пока нет

- AngliaДокумент111 страницAngliacbОценок пока нет

- Red - St. 42"/36" T 16mm, L 600mmДокумент1 страницаRed - St. 42"/36" T 16mm, L 600mmcbОценок пока нет

- Technical Drawing PDFДокумент53 страницыTechnical Drawing PDFcb100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Petroleum Dissertation TopicsДокумент7 страницPetroleum Dissertation TopicsEnglishPaperHelpCanada100% (1)

- HACCP Manual For Grape Packing Jan-2019Документ33 страницыHACCP Manual For Grape Packing Jan-2019Juan Antonio Sono Fernandez0% (1)

- Gates Usa Mectrol 2007Документ68 страницGates Usa Mectrol 2007glamuraОценок пока нет

- GUIDE-MQA-017-006 (Good Manufacturing Practice For Assemblers of Medicinal Products)Документ15 страницGUIDE-MQA-017-006 (Good Manufacturing Practice For Assemblers of Medicinal Products)William ChandraОценок пока нет

- Spe 180853 MSДокумент18 страницSpe 180853 MSkerron_rekhaОценок пока нет

- Green Building Plumbing: Mohammed Athar Mansury Farjana Priyanka Sengar Mohammed Waseem RezaДокумент20 страницGreen Building Plumbing: Mohammed Athar Mansury Farjana Priyanka Sengar Mohammed Waseem RezaAthar MansuryОценок пока нет

- DIN 10511 - EnglishДокумент27 страницDIN 10511 - EnglishJim SmithОценок пока нет

- Distortions: M. Vedani Failure and Control of Metals - AY 2020/21Документ7 страницDistortions: M. Vedani Failure and Control of Metals - AY 2020/21MarcoОценок пока нет

- ESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root GapДокумент1 страницаESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root Gapalok987Оценок пока нет

- Planar MetalsДокумент11 страницPlanar MetalsSilvano Prado0% (1)

- 50 Easy and Free FertilizersДокумент12 страниц50 Easy and Free FertilizersScott Odam100% (1)

- Fluid Mechanics Chapter 1-5Документ32 страницыFluid Mechanics Chapter 1-5Kristine Ann Reclosado38% (8)

- GATE-2018 - Mechanical Engineering Online Test Series ENGINEERING THERMODYNAMICSДокумент10 страницGATE-2018 - Mechanical Engineering Online Test Series ENGINEERING THERMODYNAMICSDebashis NayakОценок пока нет

- Stop Anticoagulation Neuraxial AnesthesiaДокумент3 страницыStop Anticoagulation Neuraxial AnesthesiaGihan NakhlehОценок пока нет

- Suelo, Agua Subterranea y Sedimento Norma CanadienseДокумент40 страницSuelo, Agua Subterranea y Sedimento Norma CanadiensehensilОценок пока нет

- Bs en 357 - 2004 Glass-Frp ClassДокумент16 страницBs en 357 - 2004 Glass-Frp ClassKwong chi hoОценок пока нет

- For NAT Review Earth and Life ScienceДокумент2 страницыFor NAT Review Earth and Life ScienceKier CorbitaОценок пока нет

- E Shield6421 Datasheet PDFДокумент1 страницаE Shield6421 Datasheet PDFYo AОценок пока нет

- En 10263-1Документ30 страницEn 10263-1Mogos PaulОценок пока нет

- Identification of CarbohydratesДокумент2 страницыIdentification of CarbohydratesChristine Pearl Po0% (2)

- Technological Advancements in The Drying of Fruits and Vegetables: A ReviewДокумент14 страницTechnological Advancements in The Drying of Fruits and Vegetables: A ReviewMaria MadanОценок пока нет

- USP Monographs - Miconazole NitrateДокумент2 страницыUSP Monographs - Miconazole NitrateMukarram MudjahidОценок пока нет

- To Achieve 100% 3D Printing Reliability: Our Easy Cheat SheetДокумент7 страницTo Achieve 100% 3D Printing Reliability: Our Easy Cheat Sheetfeere feeer0% (1)

- Deepwater DrillingДокумент54 страницыDeepwater DrillingQuag MireОценок пока нет

- ASTM D874 - 2000 - Sulfated Ash From Lubricating Oils and AdditivesДокумент5 страницASTM D874 - 2000 - Sulfated Ash From Lubricating Oils and AdditivesConstantinos ChristodoulouОценок пока нет

- Bab 4 ObjektifДокумент9 страницBab 4 ObjektifFida NordinОценок пока нет

- MetalCoat 470 480 Brochure enДокумент9 страницMetalCoat 470 480 Brochure endanceОценок пока нет

- BR Int LD Id Inspiration 55-70plusДокумент11 страницBR Int LD Id Inspiration 55-70plustarkett tОценок пока нет

- Praktikum Biofarmasetika: Data Penetrasi TransdermalДокумент6 страницPraktikum Biofarmasetika: Data Penetrasi TransdermalCindy Riana Putri FebrianiОценок пока нет

- Hydrodynamic Journal BearingДокумент4 страницыHydrodynamic Journal BearingEbe Nezer GОценок пока нет