Академический Документы

Профессиональный Документы

Культура Документы

Color Hardener MSDS

Загружено:

WIlson Lombog0 оценок0% нашли этот документ полезным (0 голосов)

47 просмотров2 страницыColor Hardener is a dry shake material that produces a colored and patterned concrete surface when used with concrete stamping tools. It increases the density and durability of concrete while improving wear resistance and reducing maintenance. It is available in 24 colors and suitable for entrance areas, sidewalks, pools, and other commercial applications. Color Hardener should be applied after concrete is placed and screened according to manufacturer instructions to produce the colored and stamped surface.

Исходное описание:

Technical Info Sheet for Color Hardener

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документColor Hardener is a dry shake material that produces a colored and patterned concrete surface when used with concrete stamping tools. It increases the density and durability of concrete while improving wear resistance and reducing maintenance. It is available in 24 colors and suitable for entrance areas, sidewalks, pools, and other commercial applications. Color Hardener should be applied after concrete is placed and screened according to manufacturer instructions to produce the colored and stamped surface.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

47 просмотров2 страницыColor Hardener MSDS

Загружено:

WIlson LombogColor Hardener is a dry shake material that produces a colored and patterned concrete surface when used with concrete stamping tools. It increases the density and durability of concrete while improving wear resistance and reducing maintenance. It is available in 24 colors and suitable for entrance areas, sidewalks, pools, and other commercial applications. Color Hardener should be applied after concrete is placed and screened according to manufacturer instructions to produce the colored and stamped surface.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

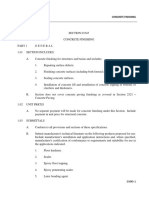

STAMPCRETE COLOR HARDENER

Color Hardener

TECHNICAL DATA

DESCRIPTION 4060 Tabor Abrasion Test placing COLOR HARDENER and

COLOR HARDENER is a dry specification: finishing.

shake material that contains 55% humidity 73 deg F Follow the recommendations of

carefully balanced pigments that Coverage .75lbs per sq ft ACI 302-Concrete Floors for

produce a colored concrete 1.8 gs loss .4% weight loss specific floor types.

surface. This surface can be Condition – Excellent

patterned with concrete stamping COLOR HARDENER has USDA METHODS: COLOR HARDENER

tools simulating brick, block, slate, approval when used without should not be mixed with other

tile or other textures. sealers. chemicals or altered in any way.

COLOR HARDENER increases Basic application is as follows:

the density and durability of LIMITATIONS: COLOR 1. Estimated material and

concrete floor surfaces. This HARDENER is not recommended equipment needs before work

improves wear resistance, reduces for extremely heavy traffic or steel begins.

dusting and minimizes concrete wheel traffic. 2. After concrete has been

maintenance and repair, all while Concrete mix design should not placed and screened an

enhancing appearance. exceed 4” slump and contain no straight edge, a non-metallic

There are 24 COLOR HARDENER more than 3% air entertainment. bullfloat should be used to

choices, including: Do not use COLOR HARDENER “open” the concrete surface. A

Antique Red Granite with concrete containing calcium metal float may prematurely

Brick Red Buff chloride or chloride based seal the concrete surface.

Dark Gray Tile Red admixtures. 3. Allow initial “bleed” water time

Silver Gray Slate COLOR HARDENER is not to surface and evaporate

Mauve Coral designed for use in areas subject before applying the color

Taupe Beige to deicing slats or chemical attack. hardener.

Russet Sand 4. Float the concrete slab open,

Plum Desert Tan TECHNICAL DATA keeping float blades flat to

Green Penn Blue Coverage rates will vary prevent “blistering”. Evenly

White Brown depending on the color and distribute about 2/3 of the color

Cordovan Terra Cotta application: hardener to the prescribed

Charcoal Chocolate Dark colors: 60lb per 100 sq ft area.

Medium colors: 75lb per 100 sq. ft 5. Allow enough time for the

BASIC USE: COLOR HARDENER Light colors: 100lb per 100 sq. ft hardener to absorb moisture

should be used with concrete Applying more material will from the concrete. Proper

stamping tools for an exceptional intensify the final color absorption will be evident by

concrete appearance and is appearance. Contact a an evenly dark color.

recommended for: Stampcrete representative for 6. Work the color hardener into

1. Entrance / lobby floors additional technical information. the concrete slab surface in a

2. Sidewalk / courtyard areas consistent manner with a

3. Commercial / shopping floors APPLICATION nonmetallic float. Do not add

4. Pool / sun decks water to the concrete surface.

MAINTENANCE: Opened 7. Evenly distribute the remaining

COMPOSITION and MATERIAL: containers should be used 1/3 of the color hardener to the

COLOR HARDENER is a specially immediately or discarded. Material prescribed area. Allow enough

blended mixture of cement, natural should be stored in a cool, dry time for the hardener to absorb

silica aggregate, inorganic place when not in use. Shelf like moisture from the concrete.

pigments and proprietary of properly stored material is 8. Work the remaining hardener

admixtures. approximately one year. into the concrete slab surface

with a non-metallic float. Do

SIZES: COLOR HARDENER is PREPARATORY WORK: not add water to the concrete

available in 60lb pails. The label Calculate the correct amount of surface.

includes complete application material required for the slabs to 9. If not patter is required, begin

Instructions. be finished that day and have it finish troweling as soon as

near the placement location. possible. The concrete should

APPLICABLE STANDARDS: Check equipment to make sure it have no sheen and no water at

COLOR HARDENER has been is in proper working order. the surface.

tested according to the ASTM-C- Schedule sufficient manpower for

10. If a pattern is required, evenly WARRANTY

distribute the color release Stampcrete International, Ltd.

agent to the prescribed area. warrants that this product will

11. Opened pails should be used

be free from defects and will

immediately and discarded.

Clean tools immediately perform as represented in

12. Use the stamping tools in a writing provided application of

consistent manner with even product is in accordance with

pressure to create the pattern manufacturer’s

in the concrete surface. recommendations and

13. Allow the concrete surface to application instruction.

remain undisturbed for Stampcrete International, Ltd.

approximately 1 day before will refund the purchase price of

washing off residual release any product proven defective,

agent.

but shall in no way be liable for

14. Allow the concrete surface to

dry before sealing with a indirect, consequential, special

Stampcrete UV resistant, or resultant damages, whether

acrylic sealer. due to breach of warranty or

Unusual applications or conditions negligence. Stampcrete

may require the technical International, Ltd. makes no

assistance of a Stampcrete guarantee or warranty, express

representative. or implied, including, without

limitation, warranties of fitness

PRECAUTIONS: It is mandatory or merchantability, with respect

that the users take the following

to this product.

precautionary actions to protect

workers and the public.

1. KEEP OUT OF THE REACH MANUFACTURER

OF CHILDREN. Stampcrete International Ltd

2. Avoid inhalation of dust. 325 Commerce Blvd.

Ensure adequate ventilation Liverpool, NY 13088

3. Avoid contact with skin.

Protective clothing is CONTACT

recommended. Contact areas

Shoreline Stampcrete

should be thoroughly washed

with soap and water 672 Chicago Dr

4. Avoid contact with eyes. Jenison, MI 49428

Protective goggles are Phone: 616-437-5047

recommended in case of www.shorelinestampcrete.com

splashing. Flush eyes with

water if contact occurs.

5. Avoid ingestion of material. If

ingestion occurs, contact a

poison center or physician.

Additional precautions, safety

information and first aid treatments

are contained in the Material

Safety Data Sheet.

Вам также может понравиться

- Design and Control of CONCRETE MIX PDFДокумент459 страницDesign and Control of CONCRETE MIX PDFCRISTIAN RAMIREZ75% (8)

- How to Build a Simple Three Bedroom Shipping Container HouseОт EverandHow to Build a Simple Three Bedroom Shipping Container HouseРейтинг: 4 из 5 звезд4/5 (2)

- Method Statement For External PaintingДокумент8 страницMethod Statement For External PaintingRafi' Ramli100% (1)

- Steel Preparation and PaintДокумент6 страницSteel Preparation and PaintbernardinodinoОценок пока нет

- Onboard Maintenance Paint Guide Tcm40 67407Документ9 страницOnboard Maintenance Paint Guide Tcm40 67407Costas AggelidisОценок пока нет

- 1282094111153Документ9 страниц1282094111153PaperCraft VNОценок пока нет

- Bouwpaco Powder Dosing & PackingДокумент33 страницыBouwpaco Powder Dosing & PackingAlexander AeromodelistaОценок пока нет

- Experiment 4 CombustionДокумент8 страницExperiment 4 CombustionJof RomanОценок пока нет

- Bostik Powermix Tds Rev1 PDFДокумент2 страницыBostik Powermix Tds Rev1 PDFRafael Obusan IIОценок пока нет

- Mechanical Design Calculation of Pipe Rack Under Pass 1Документ7 страницMechanical Design Calculation of Pipe Rack Under Pass 1tobeeprassОценок пока нет

- 10-1 PaintДокумент5 страниц10-1 PaintdetteheartsОценок пока нет

- 2011 VND O&M ManualДокумент12 страниц2011 VND O&M Manualsequeira.cedric6742Оценок пока нет

- Asme Sec 9 PDFДокумент144 страницыAsme Sec 9 PDFसंजय घिल्डियालОценок пока нет

- 01CS1S02Документ5 страниц01CS1S02raobabar21Оценок пока нет

- Deep Patch TDS - 110812Документ2 страницыDeep Patch TDS - 110812Osmar PalaciosОценок пока нет

- 4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1Документ5 страниц4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1yoxan25808Оценок пока нет

- Polished PlasterДокумент3 страницыPolished PlasterZubair IrshadОценок пока нет

- Rubber Matting Installation Procedure Required ToolsДокумент14 страницRubber Matting Installation Procedure Required ToolsBryan BcalОценок пока нет

- 4 Rockgrip 2 1 en Prep Plasterprimer 2020 Rev5Документ4 страницы4 Rockgrip 2 1 en Prep Plasterprimer 2020 Rev5yoxan25808Оценок пока нет

- Guide Specification For Sealtight Liqui-Hard: Concrete Densifier and Chemical Hardener CompoundДокумент4 страницыGuide Specification For Sealtight Liqui-Hard: Concrete Densifier and Chemical Hardener CompoundPriyesh DubeyОценок пока нет

- Euclid Chemical Dry Shake Floor Hardeners Application Instructions Installation Instructions B26664Документ2 страницыEuclid Chemical Dry Shake Floor Hardeners Application Instructions Installation Instructions B26664John ShaneОценок пока нет

- 02-Earth Colors Data SheetДокумент2 страницы02-Earth Colors Data SheetBuzaareОценок пока нет

- Lightweight Aggregates - How Do You Make The Right Decision - NPCAДокумент2 страницыLightweight Aggregates - How Do You Make The Right Decision - NPCARafael Obusan IIОценок пока нет

- 8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5Документ5 страниц8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5yoxan25808Оценок пока нет

- 20240116TD AquaRoute HB - TTP1952 - CCode - GMMYДокумент2 страницы20240116TD AquaRoute HB - TTP1952 - CCode - GMMYJelian Grace Gonti�asОценок пока нет

- Super Diamond ClearДокумент2 страницыSuper Diamond ClearElisa Pavez A.Оценок пока нет

- Fosroc GMS Nitoplate LaminateДокумент6 страницFosroc GMS Nitoplate Laminatejohn paulОценок пока нет

- Ceresit Global Ce40 Aquastatic TdsДокумент3 страницыCeresit Global Ce40 Aquastatic TdsSurush ZikrilobekovОценок пока нет

- Archi Concrete PDFДокумент1 страницаArchi Concrete PDFKamal Kumar MallikarjunaОценок пока нет

- Joint EpoxiДокумент1 страницаJoint EpoximchanОценок пока нет

- Sikafloor - 957 SSDДокумент3 страницыSikafloor - 957 SSDRodo Samuel SitorusОценок пока нет

- Polyhard: Mineral Based Dry Shake Floor HardenerДокумент2 страницыPolyhard: Mineral Based Dry Shake Floor HardenerAlexi ALfred H. TagoОценок пока нет

- TDS 0033 FlexoTop 202003Документ3 страницыTDS 0033 FlexoTop 202003Mearg NgusseОценок пока нет

- The City of Galveston: Concrete FinishingДокумент12 страницThe City of Galveston: Concrete Finishingshariful islamОценок пока нет

- B680 BulkДокумент3 страницыB680 BulkJM ArcillaОценок пока нет

- Hebron Brick - Recommended Cleaning ProcedureДокумент2 страницыHebron Brick - Recommended Cleaning ProcedurehebronbrickОценок пока нет

- TDS Levelling - PlasterДокумент3 страницыTDS Levelling - PlasterNandhagopal DhandapaniОценок пока нет

- Hebron Brick - Cleaning ProceduresДокумент1 страницаHebron Brick - Cleaning Procedureshebronbrick100% (1)

- TDS 2121 JOTUN Mur Acrylic Topcoat Euk GBДокумент3 страницыTDS 2121 JOTUN Mur Acrylic Topcoat Euk GBAnis GharsellaouiОценок пока нет

- Guide Specification For Monolithic Terrazzo: Part 1 - General 1.01 Related Work Specified in Other SectionsДокумент3 страницыGuide Specification For Monolithic Terrazzo: Part 1 - General 1.01 Related Work Specified in Other SectionsDennis DunnОценок пока нет

- 3 MS - Bostik CereBest ProfiДокумент3 страницы3 MS - Bostik CereBest ProfiAngelo Carlo MalabananОценок пока нет

- MonoshakeДокумент13 страницMonoshakeAhmad ElghazolyОценок пока нет

- Asian Paints Tractor EmulsionДокумент2 страницыAsian Paints Tractor EmulsionAsian PaintsОценок пока нет

- Guidelines For Durable DrivewaysДокумент6 страницGuidelines For Durable DrivewaysAmine HakimiОценок пока нет

- Cemento PulidoДокумент2 страницыCemento Pulidogeric1446Оценок пока нет

- Nippon Paint Coating Solution For Exterior SurfacesДокумент2 страницыNippon Paint Coating Solution For Exterior SurfacesNippon Paint Total Coating and Construction SolutionsОценок пока нет

- MdhuДокумент3 страницыMdhuAjith KumarОценок пока нет

- Weberfill F&W Grout - 0320 - R03Документ2 страницыWeberfill F&W Grout - 0320 - R03KC BcoolОценок пока нет

- Cipoxy 17Документ2 страницыCipoxy 17KishoreОценок пока нет

- 3 MS - Bostik CereBest FugaДокумент3 страницы3 MS - Bostik CereBest FugaAngelo Carlo MalabananОценок пока нет

- 302 Epoxy Ester Floor Paint TDSДокумент2 страницы302 Epoxy Ester Floor Paint TDSraja qammar100% (1)

- 7.0 Field Quality ControlДокумент3 страницы7.0 Field Quality ControlRafi' RamliОценок пока нет

- Prepare Surface For PaintingДокумент26 страницPrepare Surface For PaintingHans De la CruzОценок пока нет

- Epoxy Floor Coating: Description FeaturesДокумент2 страницыEpoxy Floor Coating: Description FeaturesRayon 9Оценок пока нет

- 3 MS - Bostik Ardacolor Xtrem EasyДокумент3 страницы3 MS - Bostik Ardacolor Xtrem EasyAngelo Carlo MalabananОценок пока нет

- Vinilex 5400 Wall SealerДокумент2 страницыVinilex 5400 Wall SealerEzuan AdamОценок пока нет

- Smartcare Damp Sheath Interior PiseeДокумент2 страницыSmartcare Damp Sheath Interior PiseeAreho YoutuberОценок пока нет

- Section - 03 35 00 - Polished Concrete FinishingДокумент4 страницыSection - 03 35 00 - Polished Concrete FinishingEliseo LagmanОценок пока нет

- 511 ImpregnatorДокумент9 страниц511 Impregnatorbob3mcardleОценок пока нет

- 1104-23-24-33 Datasheet File Nitoflor HardtopДокумент2 страницы1104-23-24-33 Datasheet File Nitoflor Hardtoptatamulia formosaОценок пока нет

- AI Hempadur EM 35740 EnglishДокумент2 страницыAI Hempadur EM 35740 Englishshanti prakharОценок пока нет

- 5 Materials Typical SpecipicationДокумент11 страниц5 Materials Typical SpecipicationAnshika SinghОценок пока нет

- Uzin L 3 Gold: Product Data SheetДокумент2 страницыUzin L 3 Gold: Product Data SheetFloorkitОценок пока нет

- Supreme Wall-Base Adhesive: BasebondДокумент2 страницыSupreme Wall-Base Adhesive: BasebondYASHICA VAITTIANATHANОценок пока нет

- Duracrete FichaДокумент2 страницыDuracrete FichavankarpОценок пока нет

- Multi Purpose Floor Coating - Nippon PaintДокумент2 страницыMulti Purpose Floor Coating - Nippon PaintNippon Paint Total Coating and Construction SolutionsОценок пока нет

- Waterproof Range PainterДокумент38 страницWaterproof Range PainterPankaj KumarОценок пока нет

- Crouse Hinds Rs RSM Rss Junction Boxes Catalog PageДокумент1 страницаCrouse Hinds Rs RSM Rss Junction Boxes Catalog Pagejose luisОценок пока нет

- 1805P ReguladoresДокумент8 страниц1805P ReguladoresALBERTOОценок пока нет

- S2 G 460 - TDS PDFДокумент3 страницыS2 G 460 - TDS PDFWawanDarmawanОценок пока нет

- Specifications Virgin Fuel Oil D6: Method Units Test Result UnitДокумент1 страницаSpecifications Virgin Fuel Oil D6: Method Units Test Result UnitDavid garzaОценок пока нет

- AcryGuard TDS 2020Документ3 страницыAcryGuard TDS 2020sarah magdyОценок пока нет

- Hardtop XP Alu: Technical Data SheetДокумент5 страницHardtop XP Alu: Technical Data SheetAfrizal Albar RamadhanОценок пока нет

- Blast Stove ModelДокумент2 страницыBlast Stove Modelnag_akОценок пока нет

- Master enДокумент40 страницMaster enKosta KockovОценок пока нет

- D A42 1362 0001J 17 Isometric ExtractedДокумент3 страницыD A42 1362 0001J 17 Isometric ExtractedAnhNtCaoОценок пока нет

- 4KN Enuk V3 1Документ8 страниц4KN Enuk V3 1MustaphaMehdiHamamineОценок пока нет

- Sae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsДокумент3 страницыSae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsAnonymous 7ZTcBn100% (1)

- Sample Medium Maintenance PlanДокумент20 страницSample Medium Maintenance PlanRajipah OsmanОценок пока нет

- Boge Up To 300kw - PDFДокумент12 страницBoge Up To 300kw - PDFparsmessengerОценок пока нет

- Analysis of Ink by TLCДокумент7 страницAnalysis of Ink by TLCkeshavОценок пока нет

- CBC COVID19 Product List 3 - 20 - 2020 PDFДокумент10 страницCBC COVID19 Product List 3 - 20 - 2020 PDFCandra SuryaОценок пока нет

- Carbomastic 15 PDS 2013Документ2 страницыCarbomastic 15 PDS 20134508366279Оценок пока нет

- Structural Material, Electronic CeramicsДокумент22 страницыStructural Material, Electronic CeramicschuotkimhyОценок пока нет

- CM P1 11643 en SKF Microlog Accessories CatalogДокумент100 страницCM P1 11643 en SKF Microlog Accessories CatalogJeffersonDeOliveiraFerreiraОценок пока нет

- NBK TA Brochure 2016-EmailДокумент11 страницNBK TA Brochure 2016-EmailPietrus NimbusОценок пока нет

- Astm f899 PDFДокумент6 страницAstm f899 PDFengineОценок пока нет

- CI Injection P&ID (Printable)Документ2 страницыCI Injection P&ID (Printable)Mehtab Alam ShaikhОценок пока нет

- Turbine Start Up Curve in Cold Start Up: Automatic Speed IncreaseДокумент2 страницыTurbine Start Up Curve in Cold Start Up: Automatic Speed Increasekumarmm1234Оценок пока нет