Академический Документы

Профессиональный Документы

Культура Документы

Forklift Inspection Checklist

Загружено:

Zeinullah 026Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Forklift Inspection Checklist

Загружено:

Zeinullah 026Авторское право:

Доступные форматы

Date: ___________ Forklift Inspection Checklist Lift Capacity: __________

Vehicle #: __________

Pre-Start (Key OUT) Pre-Start (Key OUT)

Type (circle one): LPG Gas Diesel Electric Labels

Load rating plate present and readable

Initial Hours Reading: Warning Decals & Operator’s Manual present and readable

LPG Compliance Plate present and readable (if applicable)

Tires Forklift Body

Inflated Free of excessive lint, trash, grease, or oil

Appropriate pressure ` Engine (if applicable)

Free of excessive wear or damage to side walls, cut, etc Oil is full & free of leaks

Nuts & wheel lugs are tight and present Battery

Forks Connections are tight

Not bent, worn, or cracked Covers over battery terminals

Upper limit stops OK Filters

Fork pins are not bent, worn, broken, or missing Clean & not worn

Mast Exhaust System

Hoses, chains, moving parts are not bent, worn, or cracked. Spark arrestors are OK

Lubricant on any moving parts (present but not excessive or Fuel level (if applicable)

solidified) Full & free of leaks

Visible chains are lubricated Propane (if equipped)

No rust No odor or hissing detected

Hydraulic System Fittings do not have any condensation/frost

Cylinders do not show leakage or damage Seat belt (or restraint)

Hoses & fittings do not show leakage or damage (i.e. cracks or Accessible & not damaged or dirty

painted) Horn

Carriage Works properly

Load back rest extension in place & not bent, cracked, or loose Fire extinguisher

Carriage in place and not bent, cracked, or loose Present & inspected

Date last inspected: ______________

Attachments (if equipped)

Installed correctly & are not damaged

COMMENTS:

Inspected By: ______________________________ Dept: ________________ Ext: ________

(Print Name)

Date: ___________ Forklift Inspection Checklist Lift Capacity: __________

Vehicle #: __________

Key IN (Ignition OFF) Key IN (Ignition ON)

Lights Engine (if applicable)

Head, tail, & warning lights work and aimed correctly Runs smooth & quiet

Turn signal (if equipped) operates smoothly No overheating

Exhaust System (if applicable)

Gauges and instruments

No flames or sparks

Work properly

Lift & Lower

Battery Charge Level (if applicable) Operate smoothly w/o excess drift

Full Tilt

Control Levers Operates smoothly w/o excessive drift or “chatter”

Labeled Attachments (if equipped)

Not loose or binding, & freely return to neutral Operate properly

Backup alarm (if equipped) Chains (extended when lifted)

Works properly Operational & lubricated

Not over greased

COMMENTS*: No rust on rollers

Hydraulic System

Hydraulic cylinders are working properly

No leaks

Steering

Smooth and responsive, free of excessive play

Brakes

Work & function smoothly without grabbing

No fluid leaks

Parking brake will hold the forklift on incline

Final Hours Reading:

Corrections/Repairs done by: _____________________

Date Completed: _____________________ TOTAL Hours (Final Hours Reading minus Initial Hours Reading):

Post Shutdown:

Park away from any hazards

Forklift forks are lowered & tilted to be flush with ground

Forklift in right gear for parking and parking brake is on

*Use comments section to describe any issues, as well as any Office Use Only

corrections/repairs.

(Include who corrected the issue and date it was done)

Вам также может понравиться

- Telehandler ChecklistДокумент1 страницаTelehandler Checklistjapv_pasОценок пока нет

- Forklift Pre-Operational Inspection Checklist: Operator #1 Operator #2 Operator #3 Operator #4 Operator #5Документ4 страницыForklift Pre-Operational Inspection Checklist: Operator #1 Operator #2 Operator #3 Operator #4 Operator #5Dayang Sari AndrianiОценок пока нет

- SOP of ForkДокумент15 страницSOP of ForkGyanendra Narayan NayakОценок пока нет

- Pallet Jack Safety TrainingДокумент21 страницаPallet Jack Safety TrainingIndranil Mitra100% (2)

- Forklift HSДокумент48 страницForklift HSJOAQUIN DOMINGUEZ100% (1)

- Operator'S Pre-Operation Checklist Electric Pallet Jack: Have A Qualified Mechanic Correct All ProblemsДокумент1 страницаOperator'S Pre-Operation Checklist Electric Pallet Jack: Have A Qualified Mechanic Correct All ProblemsPradeep ShindeОценок пока нет

- Checklist ForkliftДокумент4 страницыChecklist ForkliftAris100% (2)

- Loading Dock Safety ChecklistДокумент4 страницыLoading Dock Safety ChecklistMochammad Nur Hidayat50% (2)

- Safety & Maintenance Checklist Underground Trucks PDFДокумент1 страницаSafety & Maintenance Checklist Underground Trucks PDFGustavoОценок пока нет

- Forklift Safety BookletДокумент30 страницForklift Safety BookletAli JalilОценок пока нет

- Front-End Loader TrainingДокумент27 страницFront-End Loader TrainingOmosigho Osaro0% (1)

- Forklift OperationДокумент43 страницыForklift OperationMarcus Krueger100% (1)

- Forklift ChecklistДокумент1 страницаForklift ChecklistBuwanah SelvaarajОценок пока нет

- Safe Forklift Operation ManualДокумент32 страницыSafe Forklift Operation ManualMauricio Bulla ValenciaОценок пока нет

- ROLLERДокумент40 страницROLLEROmosigho OsaroОценок пока нет

- Tower Crane Test ReportДокумент10 страницTower Crane Test Reportguthale100% (2)

- Daily Forklift Inspection ChecklistДокумент1 страницаDaily Forklift Inspection ChecklistEDWINОценок пока нет

- Basic Rigging & Slinging CourseДокумент82 страницыBasic Rigging & Slinging CourseAdel Chelba100% (1)

- Truck Load-Out ChecklistДокумент3 страницыTruck Load-Out ChecklistIsaac Anthony100% (2)

- Forklift Daily Checklist ElectricДокумент2 страницыForklift Daily Checklist Electricmikel derrickОценок пока нет

- Lifting Beams and SpreadersДокумент2 страницыLifting Beams and SpreadersNadeem MalikОценок пока нет

- Forklift ChecklistДокумент1 страницаForklift ChecklistMohamed WatoutiОценок пока нет

- Forklift Safety TrainingДокумент22 страницыForklift Safety TrainingSteve DonardОценок пока нет

- Forklift Operator SafetyДокумент31 страницаForklift Operator Safetyalimarhoon150Оценок пока нет

- Truck and Trailer Daily ChecklistДокумент1 страницаTruck and Trailer Daily ChecklistOwais SarguruОценок пока нет

- SWP Welder Oxy-Fuel Gas AS563Документ2 страницыSWP Welder Oxy-Fuel Gas AS563Abdulrahman JradiОценок пока нет

- Genie Safe Use Plan GuidanceДокумент24 страницыGenie Safe Use Plan GuidanceJuan CarlosОценок пока нет

- Forklift Truck/Powered Indutrial Truck: I. ObjectiveДокумент4 страницыForklift Truck/Powered Indutrial Truck: I. ObjectiveprinceОценок пока нет

- Inspection Checklist ForkliftДокумент1 страницаInspection Checklist ForkliftpigooyОценок пока нет

- Forklift PDFДокумент17 страницForklift PDFANKUSHОценок пока нет

- Forklift Inspection ChecklistДокумент2 страницыForklift Inspection ChecklistKelompok 1 sawunggalingОценок пока нет

- Forklift Safety QuizДокумент10 страницForklift Safety QuizAndrew Miles100% (2)

- (Your Business Name Here) - Safe Work Procedure Oxy-Fuel Gas WeldingДокумент2 страницы(Your Business Name Here) - Safe Work Procedure Oxy-Fuel Gas WeldingSafety DeptОценок пока нет

- Overhead Crane Safety Training Employer SupplementДокумент71 страницаOverhead Crane Safety Training Employer Supplementshahrilmr6934Оценок пока нет

- D Shackle Inspection ChecklistДокумент16 страницD Shackle Inspection ChecklistAbhilash PattanaikОценок пока нет

- Daily Cradle Inspection Sheet: No Type of Check Operational Status RemarksДокумент1 страницаDaily Cradle Inspection Sheet: No Type of Check Operational Status RemarksZubair Khan100% (1)

- Forklift Safety Program 11-6-12Документ11 страницForklift Safety Program 11-6-12ankur panwarОценок пока нет

- 9.5 Forklift Daily InspectionДокумент1 страница9.5 Forklift Daily InspectionArshad MahmoodОценок пока нет

- Fork Lift TrainingДокумент49 страницFork Lift TrainingJay Ann100% (2)

- Hand Trolley PDFДокумент1 страницаHand Trolley PDFcityofdarwingisОценок пока нет

- Forklift Daily Shift ChecklistДокумент4 страницыForklift Daily Shift ChecklistSrimannarayana NandamОценок пока нет

- Hydro Crane Checlist PDFДокумент1 страницаHydro Crane Checlist PDFFandy AgitaОценок пока нет

- Crane/Lifting Operations Supervisor A62: LOLER 1998 and BS 7212 Parts 1 To 3 During The Theory TestДокумент7 страницCrane/Lifting Operations Supervisor A62: LOLER 1998 and BS 7212 Parts 1 To 3 During The Theory TestMohamed FathyОценок пока нет

- LOLER Inspection Checklist - 7 Free TemplatesДокумент7 страницLOLER Inspection Checklist - 7 Free TemplatesernestozagОценок пока нет

- Crane ChecklistДокумент1 страницаCrane Checklistsajin0% (1)

- Safety Harness ChecklistДокумент2 страницыSafety Harness ChecklistTilak RajОценок пока нет

- ForkliftДокумент2 страницыForkliftAmanda MackОценок пока нет

- Gunnebo Lifting ManualДокумент59 страницGunnebo Lifting ManualseawizeОценок пока нет

- Excavator SlidesДокумент15 страницExcavator SlidesDaeng KulleОценок пока нет

- Weekly Lift Truck Pre-Use Check Sheet: Operator Signature: Supervisor SignatureДокумент2 страницыWeekly Lift Truck Pre-Use Check Sheet: Operator Signature: Supervisor Signaturetemter gandaОценок пока нет

- Forklift SafetyДокумент9 страницForklift SafetyTamirОценок пока нет

- Forklift Policy HandbookДокумент48 страницForklift Policy Handbooknezla100% (1)

- Forklift TrainingДокумент39 страницForklift Trainingagus sofyan100% (1)

- CH 13 Att2Документ3 страницыCH 13 Att2ikperha jomafuvweОценок пока нет

- Car Inspection CheckList SampleДокумент1 страницаCar Inspection CheckList SampleghanavatyОценок пока нет

- Dozer Checklist: Y N Y NДокумент1 страницаDozer Checklist: Y N Y NEkaWulandariОценок пока нет

- Bill ReportДокумент1 страницаBill Reportboshir skОценок пока нет

- Weekly Standard InspectionДокумент3 страницыWeekly Standard InspectionFrancis Salonga100% (1)

- Used Car Safety Checklist: Item ItemДокумент1 страницаUsed Car Safety Checklist: Item Itemzakarya yahyaОценок пока нет

- Shareable Report Lead - 8728712Документ1 страницаShareable Report Lead - 8728712Sachin SinghОценок пока нет

- Natural Gas VehiclesEIAДокумент84 страницыNatural Gas VehiclesEIAEduardo EnaОценок пока нет

- 30 Topics FULLДокумент129 страниц30 Topics FULLzmaximova1218100% (2)

- Road Signs One k53 Learners Licence Test WebsiteДокумент13 страницRoad Signs One k53 Learners Licence Test WebsiteTufha Niwa57% (21)

- Considerations For Implementing Maintenance Line Operations Safety Assessments (M-LOSA)Документ38 страницConsiderations For Implementing Maintenance Line Operations Safety Assessments (M-LOSA)raj6062Оценок пока нет

- Alaska Fabtech Pvt. LTDДокумент5 страницAlaska Fabtech Pvt. LTDVIKAS DALMIAОценок пока нет

- Jsti Eptisa 202304 012Документ8 страницJsti Eptisa 202304 012hossain iftiqarОценок пока нет

- Motor TDДокумент80 страницMotor TDLinio Calixto De JesusОценок пока нет

- Market Plan Dgi 2019 FixДокумент26 страницMarket Plan Dgi 2019 FixAziz 123100% (1)

- Introduction in Port ManagementДокумент41 страницаIntroduction in Port ManagementAlifa Alma Adlina75% (4)

- Chapter 6 Hydraulics and PneumaticsДокумент29 страницChapter 6 Hydraulics and Pneumaticsadaptive4u4527Оценок пока нет

- Design Report Eco Kart Team Exergy.Документ19 страницDesign Report Eco Kart Team Exergy.Upender Rawat50% (2)

- South Eastern Railways TimetableДокумент33 страницыSouth Eastern Railways TimetableSuman Dey50% (2)

- SEM 636D Wheel Loader Operation Maintenance ManualДокумент78 страницSEM 636D Wheel Loader Operation Maintenance Manualjuan pablo100% (2)

- Part 1 - PT 641 - General Specifications - Issue 8 - March 2023Документ12 страницPart 1 - PT 641 - General Specifications - Issue 8 - March 2023Eve TashОценок пока нет

- 2012 Qms Asphalt ManualДокумент502 страницы2012 Qms Asphalt Manualistiar100% (1)

- Job Card Retail - Tax InvoiceДокумент2 страницыJob Card Retail - Tax InvoiceMittu RajanОценок пока нет

- Liebherr Hight Standards PDFДокумент23 страницыLiebherr Hight Standards PDFmordidomi0% (1)

- Simon Report SampleДокумент16 страницSimon Report SampleBùi Đào Lâm PhươngОценок пока нет

- FLNGДокумент8 страницFLNGmoiseianОценок пока нет

- Design of A Pedestrian-Steel Bridge Crossing Auchi-Benin ExpresswayДокумент9 страницDesign of A Pedestrian-Steel Bridge Crossing Auchi-Benin ExpresswaySabin MaharjanОценок пока нет

- 18MRH-X242A Axle Service ManualДокумент60 страниц18MRH-X242A Axle Service Manualheiner duran100% (1)

- SCM Agri 1Документ146 страницSCM Agri 1rockstarchandreshОценок пока нет

- Current Affairs ENGLISH, Month of JULY' 2023 With Cover PageДокумент38 страницCurrent Affairs ENGLISH, Month of JULY' 2023 With Cover Pagenidhi017llmОценок пока нет

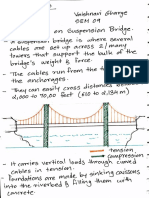

- TOS Suspension Bridge Sem 9Документ3 страницыTOS Suspension Bridge Sem 9VAISHNAVI GHARGEОценок пока нет

- Tank Capacity and Payload EDITEDДокумент7 страницTank Capacity and Payload EDITEDGita SuryaОценок пока нет

- Chapter 10 - Curves of Statical Stability (GZ Curves)Документ9 страницChapter 10 - Curves of Statical Stability (GZ Curves)Adrian B.100% (1)

- A m17 PropellerДокумент100 страницA m17 PropellerTung Phungvan100% (1)

- Mobility Aids Vehicles BizHouse - UkДокумент3 страницыMobility Aids Vehicles BizHouse - UkAlex BekeОценок пока нет

- Pantranco North Express, Inc. v. Maricar Bascos Baesa, Et AlДокумент5 страницPantranco North Express, Inc. v. Maricar Bascos Baesa, Et AlMaria Jennifer Yumul BorbonОценок пока нет

- LNGC Q-Max Lijmiliya - Imo 9388819 - Cargo Operating ManualДокумент547 страницLNGC Q-Max Lijmiliya - Imo 9388819 - Cargo Operating Manualseawolf50Оценок пока нет