Академический Документы

Профессиональный Документы

Культура Документы

Abstract Book ICRAM 2019

Загружено:

shivsagar sharmaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Abstract Book ICRAM 2019

Загружено:

shivsagar sharmaАвторское право:

Доступные форматы

International Conference on

Recent Advances in Mechanical Infrastructure

(ICRAM-2019)

April 20-21, 2019

Conveners:

Dr. Ajit Kumar Parwani

Dr. PL. RamKumar

Dr. Kumar Abhishek

Dr. Saurabh Kumar Yadav

Organized by:

Department of Mechanical Engineering

Institute of Infrastructure Technology Research

And Management (IITRAM)

www.iitram.ac.in

1 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Organizers

Patron:

Dr. Shiva Prasad, Director General, IITRAM

Dr. A. U. Digraskar, Director, IITRAM

Dr. N. N. Bhuptani, Registrar, IITRAM

Mentors:

Dr. Shanti Prasanna, Dean, IITRAM

Dr. S. Rama Mohan, Professor, IITRAM

Organizing Committee:

Conveners: Co-Conveners:

Dr. Ajit Kumar Parwani Dr. Kumar Abhishek

Dr. PL. Ramkumar Dr. Saurabh Kumar Yadav

Department of Mechanical Engineering

IITRAM, Ahmedabad

Managing Committee:

Mr. Pulkit Kumar

Mr. Sanil Shah

Mrs. Nikita Gupta

Mr. Srinivasu Chadaram

Mr. Dinbandhu Singh

2 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

PREFACE

Institute of Infrastructure, Technology, Research and Management (IITRAM) is an Autonomous

University as declared in the Gujarat Government Act no. 5 of 2013- broadly known as IITRAM Act,

provides Engineering education with undergrad and post grad courses in Civil, Mechanical, Electrical

branches. It also offers PhD programs in engineering branches of Civil, Mechanical and Electrical. It

is initiated to facilitate outstanding technical education in the field of Infrastructure, Science,

Technology and Management at Ahmedabad. To cultivate skill based Engineers, IITRAM has

advanced curriculum, labs, and industry tie ups to produce advanced, skilled and trained professionals

for technologically advanced nation. This Institute recognizes, that in addition to academic excellence

the need of the hour is having exposure to live projects and gaining on-field experience right from the

word go.

This Proceedings is brought out to mark the occasion of International Conference on Recent Advances

in Mechanical Infrastructure (ICRAM-2019) during April 20-21, 2019 organized by Department of

Mechanical Engineering, IITRAM, Ahmedabad. This conference provides a forum for discussion on

issues, concepts, skill development and possible innovations in the mechanical infrastructure sector.

ICRAM-2019 aims at bringing the best technical minds working in the field of mechanical

engineering on a common platform to share their knowledge of technical expertise, experience and

forthcoming challenges in the development of infrastructure in the country. Moreover, it will be a

great opportunity for the enthusiastic students and research scholars to learn from the experiences and

vision of eminent scientists and innovators.

The conference conveners would like to thank the delegates who have contributed for the conference

proceedings. We would also like to thank our outstanding Keynote speakers: Dr. S.S.Mahapatra,

Professor, NIT Rourkela, Dr. Vivek Vitankar, Director, FluiDimensions and Dr. Udayraj, Assistant

Professor, IIT Bhilai for sharing their deep insights on future challenges and trends. During the

conference 3 invited talks and 36 oral talks were presented, which are included in the contents of

these proceedings.

We also would like to thank all the reviewers for their great effort on reviewing the papers submitted

to ICRAM 2019. Special thanks to all the researchers and students who with their work and participate

in the conference.

3 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

We extend our sincere appreciation to our sponsors: SERB-DST Govt. of India, GUJCOST Govt. of

Gujarat and KC Engineers Limited, without whom our work would not be possible.

We are grateful to the Management of IITRAM for their help and support in organizing this mega

event.

Conveners

Dr. Ajit Kumar Parwani Dr. PL RamKumar

Assistant Professor, Assistant Professor,

Mechanical Engineering Department, Mechanical Engineering Department,

IITRAM IITRAM

Dr. Kumar Abhishek Dr. Saurabh Kumar Yadav

Assistant Professor, Assistant Professor,

Mechanical Engineering Department, Mechanical Engineering Department,

IITRAM IITRAM

4 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

From the Director General’s Desk

I am very happy that the Department of Mechanical Engineering,

IITRAM is organizing an International Conference on Recent Advances

in Mechanical Infrastructure (ICRAM-2019) during April 20-21, 2019.

The conference will provide platform for academicians, researchers and

industrial professionals to exchange views, ideas, experiences and

collaborate for expediting progress in the field of thermal, manufacturing,

planning and design infrastructure.

I extend my greeting and felicitations to the conveners and delegates and

wish the conference all success. I hope you shall have a great time and

will benefit greatly from the proceedings of the meeting.

Dr Shiva Prasad

5 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Advisory Committee

Prof. Pedro Coelho, Mech. Engineering, University of Lisbon

Prof. Dr. Ing Johannes Kiefer, Prod. Eng., Uni. of Bremen, Germany

Prof. Q Jane Wang, Mech. Eng., Northwestern Uni. Evanston, Chicago

Dr. Michel FILLON, CNRS Director of Research, France

Prof. Ramesh Agarwal, Washington University

Prof. S. P. Mehrotra, IIT, Gandhinagar

Prof. Prabal Talukdar, Mech. Engineering, IIT Delhi

Prof. PMV Subbarao, Mech. Engineering, IIT Delhi

Prof. Sanjeev Jain, Mech. Engineering, IIT Delhi

Dr. (Mrs.) Malti Goel, Chief Executive, Climate Change Research Institute, Former Senior Scientist,

Govt. of India

Prof. Satish Chandra Sharma, Mech. Engineering, IIT Roorkee

Prof. R. Venkata Rao, Former Dean, Dept. of Mech. Engineering, SVNIT, Surat Prof. S.S.

Mahapatra, Mech. Engineering, National Institute of Technology, Rourkela

Prof. D. M. Kulkarni, Dean, Dept. of Mech. Engineering, BITS Goa

Prof. N. Ramakrishnan, Mechanical Department, IIT Gandhinagar

Dr. Rajeev Kukreja, Asso. Prof. & Head, Dept. of Mech. Engineering

Dr. B. R. Ambedkar, NIT, Jalandhar (Punjab)

Dr. Chandramohan V. P., Asso. Prof., Dept. of Mech. Eng., NIT, Warangal

Dr. R. K. Mandloi, Asso. Prof., Dept. of Mechanical Engineering, Maulana Azad National Institute

of Technology, Bhopal

Dr. Hemantha Kumar, Asso. Prof., Department of Mechanical Engineering, National Institute of

Technology, Surathkal

Dr. Saurav Datta, Asso. Prof., Department of Mechanical Engineering, National Institute of

Technology Rourkela

Dr. Atul Bhargava, Asso. Prof., Mech. Dept., IIT Gandhinagar

Dr. Dipankar Deb, Asso. Prof., Electrical Engineering, IITRAM

Dr. Vinod Narayanan, Asst. Prof., Mech. Engg. IIT, Gandhinagar

Dr. P. Ramkumar, Asst. Prof., Dept. of Mech. Eng. IIT Madras

Dr. Navneet Khanna, Asst. Prof., Mech. Engineering, IITRAM

Dr. Dileep Kumar Gupta, Asst. Prof., Mech. Engineering, IITRAM

Dr. Pramod Bhingole, Asst. Prof., Mech. Engineering, IITRAM

Dr Ramesh k Guduru, Asst. Prof., Mechanical Dept., Lamar Uni.

6 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

ICRAM-2019

International Conference on Recent Advances in Mechanical Infrastructure

CONTENTS

Preface

Message

1. Emission analysis of a small capacity producer gas engine at higher hydrogen 11

concentration and compression ratios

Tehsinraza Mulla

2. Numerical Investigation for Thermo-Fluid Analysis on Tube Finned Heat Exchanger 12

using Vortex Generator

Ashishkumar Modi

3. Computational study of mist jet impingement heat transfer on a flat plate with slotted 13

nozzle

Bikram Kumar Pani

4. Generation and Characterization of Bio-Oil Through Slow Pyrolysis Process from 14

Jatropha Curcas Shell

Vikram Rajai

5. Feasibility Analysis of Photovoltaic (PV) Grid Tied System for Indian Military 15

Station Considering Grid Cyber-Security Aspects

Ashish Sharma

6. Inlet and Outlet Geometrical Condition for Optimal Installation of Gravitational 16

Water Vortex Power Plant with Conical Basin Structure

Rabin Dhakal

7. Comparative Dynamic Performance of Symmetric and Asymmetric Hole-entry 17

Journal Bearings under Turbulent Regime

Nathi Ram

8. Kinematic analysis of modified THEO JANSEN mechanism based robot made of abs 18

Keval Bhavsar

9. Finite Element Analysis of Conformal Cooling for Reduction of Cycle Time to 19

Enhance Performance in Plastic Injection Molding Process

Deepika Singh Singraur

7 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

10. Identification of Cracks length by XFEM and Machine Learning algorithm 20

Srinivasu Chadaram

11. Static Stress Analysis of Composite Rectangular Plate with Central Hole and 21

Different End Conditions

M L Pavan Kishore

12. A Study of Occupant Injuries Classification in Automobile Accidents in Relationto 22

Upper Extremities Bones

Kedar Hendre

13. Effect of heat treatment on the properties on austenitic stainless steel weld overlay 23

over SA 516 Gr. 70 steel

Jaykumar Vora

14. Experimental Performance Evaluation of Mist Cooling using Bio-Degradable 24

Coconut Oil in Turning of EN24 Steel in minimization of Tool Wear, Surface

Roughness and Chip Thickness

Veerabhadrarao Miriyala

15. Multi-response optimization of Ni55.8Ti shape memory alloy using Taguchi-grey 25

relational analysis approach

Rakesh Chaudhari

16. Evaluation of Surface Roughness by Machine Vision using Neural Networks 26

Approach

Ketaki Joshi

17. Challenges of Sustainable Manufacturing for Indian Organization: A Study 27

Lakhan Sharma

18. Investigation on the effect of input parameters on surface quality during Rotary Tool 28

Near-dry EDM

Ramver Singh

19. Application of Utility Function Approach aggregated with Imperialist competitive 29

algorithm for Optimization of Turning Parameters of AISI D2 Steel

Soni Kumari

20. Effect of condenser and evaporator temperature and an exergy analysis of ice 30

manufacturing plant

Shobit Varshney

21. Developments in Solar still: A Critical Review 31

Vivek Daraniya

8 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

22. Impact of water- diesel emulsion as fuel on Diesel engine performance and emission

characteristics- An overview 32

Kintu Patel

23. Analysis of the rooftops photovoltaic solar energy capacity in Gorkha Nepal: A Case 33

Study

Rabin Dhakal

24. Direct steam generation by an enclosed solar parabolic trough for enhanced oil 34

recovery

Ramesh V.K

25. Experimental Investigation of Two Phase Mist Jet Impingement Cooling on heated 35

Cylinder

Chunkyraj Khangembam

26. Optimization of Quality Characteristics in Laser Drilling of Ti6Al4V using VIKOR 36

Suman Chatterjee

27. Experimental investigation on surface morphology of micro-EDMed Ti-6Al-4V alloy 37

Ramver Singh

28. Multi-Objective Optimization and Experimental investigation CNC oxy-Fuel gas 38

Cutting Parameters Using Taguchi Coupled Data Envelopment Analysis

Dileep Kumar Bagal

29. Utility function approach integrated with Fuzzy for optimization in milling glass fiber 39

reinforced epoxy composites

Chirag Bagada

30. Design, Analytical Analysis and Manufacturing of 5-cylinder Hydraulic Fixture with 40

Rotary Table for Machining case on VMC EZ 5

Hardik Khunt

31. Multi Material Printing Techniques for Fused Deposition Modelling. 41

Tarun Rijwani

32. A review on Solution of Inverse Heat Transfer Problem by Conjugate Gradient 42

Method (CGM)

Gagnesh Upadhayay

33. Fluid flow study of circular jet impingement on flat plate 43

Saurabh Kango

34. Techno-Economic Assessment of Indian Power Plant Retrofitted with Calcium 44

Carbonate Looping Capture Method

Pulkit Kumar

9 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

35. Estimation of time varying heat flux for one dimensional heat conduction problem by 45

hybrid inverse method

Sanil Shah

36. Numerical Simulation of Moving Surface Boundary Layer Control Over Symmetric 46

Aerofoil

Vipul Patel

37. Thermal Transient Analysis of an Injection Moulding with Conformal Cooling 47

Channels

Shivsagar Sharma

10 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Emission analysis of a small capacity producer gas engine at higher hydrogen

concentration and compression ratios

M. Sreedhar Babu*1, Shibu Clement2, N.K.S. Rajan3, Tehsinraza Mulla1

1 Department of Mechanical Engineering, Jain College of Engineering, Belagavi – 590014, Karnataka, India

2

Department of Mechanical Engineering, BITS Pilani, K.K. Birla Goa Campus, Goa – 403726, India

3

Department of Aerospace Engineering, Indian Institute of Science, Bengaluru – 560012, Karnataka, India

Email: sreedhar@jainbgm.in1, shibu@goa.bits-pilani.ac.in2, nksr@cgpl.iisc.ernet.in3)

Abstract: In this paper, the effect of hydrogen concentration (16 to 22% by volume) in producer

gas-air mixtures at various engine compression ratios (11, 15 & 18:1) on emissions was

analyzed and reported. The experiments were carried out using bottled producer gas, with fixed

gas composition resembling close to the gas quality of an open top re-burn downdraft gasifier

of IISc make. Engine was operated close to stoichiometry at a constant speed of 1500 rpm,

under naturally aspirated mode. Hydrogen being a highly combustible component in a producer

gas-air mixture, the dynamics of in-cylinder combustion process was expected to influence the

emissions. The engine was found to operate knock free under all compression ratios and loads.

The measured emission data was compared against CPCB-2016 norms in India. The

comparative emission analysis reveals an increase in NO emission with increase in hydrogen

concentration due to higher peak in-cylinder pressures at higher compression ratios.

Keywords: Emissions, Producer gas, Hydrogen, Compression ratio

11 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Numerical Investigation for Thermo-Fluid Analysis on Tube Finned Heat

Exchanger using Vortex Generator

Ashish J. Modi1, Lalit B. Patil1, Manish K. Rathod

Department of Mechanical Engineering,

Sardar Vallabhbhai National Institute of Technology, Ichchhanath, Surat, 395007, India

Emails:ashishjmodi@gmail.com, lalitpatil031@gmail.com, mkr@med.svnit.ac.in

Abstract: In the current paper, numerical analysis has been carried out to explore the influence of

angle of attack and length of rectangular winglet vortex generators (RWVGs) on the performance of

the tube finned heat exchanger (TFHE). RWVGs are located at the downstream of the circular tubes

with three selected angles of attacks i.e. 20°, 30° and 40°. The impact of angle of attack and length of

VGs are examined on the heat transfer performance and pressure drop penalty with air-side Reynolds

number varies from 400 to 800. Nusselt number and pressure drop penalty are considered for the

performance evaluation.

Keywords: Tube finned heat exchanger, vortex generator, heat transfer, pressure drop

12 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Computational Study of Mist Jet Impingement Heat Transfer on A Flat Plate

with Slotted Nozzle

Bikram Kumar Pani, Dr. Dushyant Singh

National Institute of Technology Manipur,

Langol, Manipur-795004, India

Abstract: The work presents the numerical investigation of a slot mist jet impingement cooling on

an isothermal flat plate surface at three different temperatures 323K, 350K and 363K. A two-

dimensional model was analyzed with mist (air and water) as working fluid. The distance from nozzle

exit to the surface of the heated plate is varied from h/S=4 and 8. The numerical analysis was carried

out for jet Reynolds number Res =2750 varying the volume fraction, vof 1% -10% and size of droplet

from 1-300 micron. Addition of mist causes significant increase of Heat transfer coefficient as

compared to the single-phase Heat transfer coefficient. The numerical result of local Heat transfer

coefficient is compared with the experimental results of Gardon et al. [1]. Also, the effect of heat

transfer coefficient varying the distance from nozzle to plate spacing is shown. The turbulence models

k-ε and k-ω SST were considered for the study and their differences are also presented.

Keywords: Jet impingement, Mist, Droplet, Volume fraction.

13 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Generation and Characterization of Bio-Oil Through Slow Pyrolysis Process

from Jatropha Curcas Shell

Vikram Rajai1*, Hiren Shah1, Dhaval Patel1, Himanshu Patel2, Subarna Maiti2

1

Chhotubhai Gopalbhai Patel Institute of Technology, Uka Tarsadia University, Gopal-Vidyanagar, Maliba Campus,

Surat (Gujarat) - 394350, India

2

Process Design & Engineering Cell, CSIR-Central Salt & Marine Chemicals Research Institute, G.B Marg, Bhavnagar

364002, Gujarat, India.

*vikram.rajai@utu.ac.in

Abstract: In this era of 21st century, demand of energy is growing every day. Out of all the energy

resources, petroleum products are the major influencing parameters. But, these petroleum products

are now at their basal levels. To get an alternative solution, renewable energy sector is highly focused

to get rid of this trouble. There are various methodologies which are used for the generation of

alternative fuels and one of them is pyrolysis. Pyrolysis is a decomposition process which occurs in

thermo-chemical approach in the absence of oxygen. This paper shows the pyrolysis of jatropha

curcas shell which is a complete wastage after the production of bio-diesel from jatropha seeds.

Jatropha curcas shell was heated in a fixed bed reactor around 500 ̊C in the absence of oxygen and

after the dehydration, bio-oil was obtained. The density of the bio-oil was observed as 957.8 kg/m3,

viscosity 3.152 cP at 25.2 ̊C, calorific value 29.07 MJ/kg and refractive index 1.4557 at 26.55 ̊C. The

pour point and fire point were observed as -38 ̊C and 28.5 ̊C respectively. Apart from these, the

ultimate analysis of the bio-oil presents that it contains Carbon 61.09 % (wt %), Hydrogen 7.22 %

(wt %), Nitrogen 3.51 % (wt %), Oxygen 28.17 % (wt %) and Sulphur 819 ppm. The higher oxygen

content in this bio-oil helps the base fuel inside the internal combustion engine to burn more

efficiently.

Keywords: Bio-oil, Dehydration, Jatropha curcas, Pyrolysis, Refractive index, Thermo-chemical.

14 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Feasibility Analysis of Photovoltaic (PV) Grid Tied System for Indian Military

Station Considering Grid Cyber-Security Aspects

*

Ashish Sharmaa, V Chintalab, and Suresh Kumarb

a

T-15/2 Vayusenabad, MB Road, New Delhi, India.

b

Centre for Energy Research Centre (CAER) and Mechanical Engineering Department, School of Engineering,

University of Petroleum and Energy Studies (UPES), Dehradun, India.

Email: ashishsharma2508@gmail.com

Abstract: The Indian Government in its pursuant towards building energy infrastructure is providing

special stimulus towards utilization of renewable energy sources. India is not only bestowed with

abundant sustainable resources but also possesses the second largest army in the world having defence

establishments spread all over the country. Employment of sustainable energy in defence sector has

its own constraints. The current study looks into the feasibility case study of implementing a PV grid

tied system for an Indian military station. The Solar potential for the chosen military station is studied

and technical potential of roof top solar panels is determined by carrying out the site survey of

available infrastructure of the Indian military station. The study explains the cyber threats of a grid

connected PV system. A unified threat management security system is implemented to mitigate the

cyber threats. An economic viability of implementing the grid connected PV system with cyber

security in a military station is carried out.

Keywords: Feasibility Study, Military Station, Photovoltaic, Grid Cyber-Security, Levelized Cost

15 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Inlet and Outlet Geometrical Condition for Optimal Installation of

Gravitational Water Vortex Power Plant with Conical Basin Structure

Rabin Dhakal1,2, Sirapa Shrestha1, Hari Neupane1, Sunil Adhikari2

Triratna Bajracharya3

1 Kathmandu University, School of Engineering, Kavre, Nepal

2

Tribhuvan University, Institute of Engineering, Thapathali Campus, Kathmandu, Nepal

3

Tribhuvan University, Institute of Engineering, Pulchowk Campus, Lalitpur, Nepal

Corresponding Author: Rabin Dhakal

Email: rbndhakal@gmail.com

Abstract: This paper focuses on micro hydro power called Gravitational Water Vortex Power Plant

(GWVPP) which operates in ultra-low head requirement (0.7-3 m) and is used in off-grid energy

generation in rural areas. GWVPP is new type of hydropower system in which a channel and a basin

structure is used to form a water vortex, where the rotational energy from the water is extracted from

runner at the center of the vortex. In this study, inlet and outlet geometrical conditions, specifically

basin diameter and outlet diameter, of a recently acclaimed efficient conical basin design are found

out. Different geometrical CAD models are developed by using Solidworks software and simulation

is done with the help of commercial CFD code ANSYS CFX. Then, the geometrical relationship

among these parameters is also analyzed and established. This result is finally validated though

experimental testing of four different types of basin with distinct geometry

Keywords: Geometrical Condition, Rural Electrification, CFD, Micro-Hydro Power

16 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Comparative Dynamic Performance of Configurations

of Hole-entry Journal Bearings under Turbulent Regime

Nathi Ram*

Department of Mechanical and Automation Engineering, Indira Gandhi Delhi Technical

University For Women, Delhi, India.

*Corresponding Author: n.r.jaan10@gmail.com

Abstract: The present paper investigates the comparative dynamic performance of hole-entry

symmetric and asymmetric hybrid journal bearing configurations under turbulent lubrication.

Constantinescu turbulent model is used to account the influence of turbulent flow on bearings

performance. Reynolds equation is altered considering turbulent theory of lubrication by

Constantinescu. FEM using Galerkin’s Technique is utilized to determine the solution of altered

Reynolds equation. Dynamic performance for various values of Reynolds numbers has been

presented for the configurations of hole-entry bearings. It is observed that the effects of turbulent

lubrication on dynamic characteristics of bearings are significant.

Keywords: Hydrostatic bearing, turbulent models, finite element method, bearing configurations

17 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Kinematic Analysis of Modified Theo

Jansen Mechanism Based Robot Made of

Abs

Keval Bhavsar1, Pranav Darji2, Dharmik Gohel3, Jitendra Modi4, Umang Parmar5

Aditya Silver Oak Institute of Technology, Ahmedabad, Gujarat, India

Emails :1 kevalbhavsar42@gmail.com, 2pdarji576@gmail.com,3 dharmikgohel67@gmail.com,

4jmodi655@gmail.com5 umangparmar.me@socet.edu.in

Abstract: This paper shows the kinematic study of a prototype of an observer Robot. The aim is to

do an observation on any terrain especially in muddy areas or dessert. This robot is having 8 legs

which are powered by 2 Motors. The MODIFIED THEO JANSEN MECHANISM is used as legs.

For surveillance, a camera is used, working on its own system. Arduino is used for controlling the

robot. and that Arduino takes power from Battery. Acrylonitrile butadiene styrene (ABS) material is

used to make this robot.

Keywords: Modified Theo Janson mechanism, Walking pattern, surveillance robot, ABS material,

kinematic analysis.

18 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Finite Element Analysis of Conformal Cooling for Reduction of Cycle Time to

Enhance Performance in Plastic Injection Molding Process

Deepika Singh Singraur, Bhushan T. Patil, Yogesh T. Rampariya

Resarch Scholar, (Mechanical Engg.), Fr. Conceicao Rodrigues College of Engg., Mumbai

Professor, Production Engg., Fr. Conceicao Rodrigues College of Engg., Mmbai

Assistant Professor, Mechanical Engg., A. P. Shah Institute of Technology, Thane

Abstract: With the conventional cooling channels, the uneven cooling is occurs due to

placement of the cooling channel from the mold surface which results in defects like sink marks,

warpage and thermal residual stresses. The design variables considered for the cooling are mold

and melt temperature, injection time, cooling time and cooling temperature, packing time and

packing pressure. To improve the cooling system design, and to reduce the defects, conformal

cooling channels are used and temperature distribution along the mold cavity is studied in this

paper. In the proposed design method, the cooling channel is produced by the design tool have

been compared with the results produced by simulation through softwares. The transient

thermal analysis in ANSYS workbench is performed to analyze the thermal response of rapid

heating and cooling of mold on mold heating and cooling efficiency and cycle time of molding

operation. The maximum temperature and minimum temperature were reduced by 18.78 %.

The analysis has been done for hot and cold runners.

Keywords: Injection molding, temperature distribution, cooling efficiency, conformal cooling.

19 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Identification of Cracks length by XFEM and Machine Learning algorithm

Srinivasu Chadaram, Saurabh Kumar Yadav

Department of Mechanical Engineering, Institute of Infrastructure Technology Research and Management (IITRAM),

Ahmadabad

Corresponding author Email: chsrinivasu108@gmail.com

Abstract: In the paper a crack identification study is performed by using extended finite element

method (XFEM) and Machine learning method. XFEM is widely used for the analysis of two

dimensional and three dimensional crack simulations. XFEM is faster than the finite element method

because, it removes the burden of remeshing as crack grows. To reduce the computational effort and

cost, Machine learning based regression analysis has been performed and validated with the sample

data. The proposed algorithm is used to find the accuracy in evaluating some benchmark problems in

detection of crack length. The accuracy of the method is more than 90%.

Keyword: XFEM, Identification of crack, Machine learning, Regression.

20 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Influence of Material, End conditions and Cutout on Static Stress Analysis of

Rectangular Plate

M.L.Pavan Kishore1,Sreenivasulu Bezawada2

1 Assistant Professor, Dept. of Mech Engg, Faculty of Science and Technology

ICFAI Foundation for Higher Education, Hyderabad, India

kishoreml@ifheindia.org

2 Associate Professor, Dept. of Mech Engg, Siddharth Institute of Engg and Technology

Narayana vanam road, Puttur – 517583, India.

sreenivasulu.bezawada@gmail.com

Abstract: The circular cutout is considered as a typical source of stress concentrations in

rectangular plate type structures. The proper position of a cutout in a rectangular plate can be

significantly affected by the choice of material, cutout size, and various end conditions which are

relative to the externally applied force. The research work entitled in this paper deals with the

finite element formulation applied to a plate made with isotropic and laminated plates subjected

to uniform pressure with various end conditions. The vicinity of stress distribution for the

rectangular plate made of these two materials with and without the effect of circular cutouts is

discussed. The accuracy of the solution verified with the available literature, and from the

comparison, a fairly good agreement seen between the Finite element formulations in this paper

with previously available results.

Keywords: Circular cutout, End conditions, Finite element formulation, Uniform Pressure, Ply

sequence, symmetrically laminated plates.

21 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

A Study of Occupant Injuries Classification in Automobile Accidents in

Relation to Upper Extremities Bones

Kedar M. Hendre1, Kiran D. Mali1 and Dhananjay M. Kulkarni1

1Department of Mechanical Engineering, BITS-Pilani, K. K. Birla Goa Campus,

NH 17 B, Zuarinagar, Goa, India. 403 726

*Email: p20160025@goa.bits-pilani.ac.in

Phone: +91 832-2580416

Abstract. Occupant injuries in case of automotive accidents are a major concern from the point

of view of human life and the costs associated with the medical treatments. The high-speed

accidents occur above vehicle speed of 50kmph and occur for about 100ms. Restraint systems

in the cars have the effect of saving human lives in high speed impacts. This study deals with

the classification of injuries to human in case of automotive accidents and describes a

mathematical way of assigning scores to human injuries. The injury measurement scales are

studied. Research is available for injuries to vital organs like brain, chest and lower extremities,

however, very little is literature is available for upper extremities such as fore-arms and

shoulder. This paper describes bone structure for upper extremities and emphases the risk to

upper extremities in accidents. It describes the bone fractures and the permissible loads for the

fracture of bones.

Keywords: Biomechanics, Upper Extremity, Accidents, Injuries

22 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Effect of heat treatment on the properties on austenitic stainless steel weld

overlay over SA 516 Gr. 70 steel

Jay J. Vora1 *, Allwyn Lewis2, Ritesh Patel2, Bharati Rehani3

1Department of Mechanical Engineering, Pandit Deendayal Petroleum

University, Gandhinagar, India

2Larsen & Toubro Ltd. Heavy Engineering Division, Hazira, Surat, Gujarat, India

3Metallurgical and Materials Engineering Department, The Maharaja Sayajirao University of Baroda, Vadodara,

Gujarat, India

*Corresponding and Presenting author: vorajaykumar@gmail.com

Abstract: In the present investigation, austenitic stainless steel (ASS) weld overlay comprising of SS

309 as the barrier layer and SS 347 as the subsequent layers were deposited on SA 516 Gr. 70 carbon

steel base material by flux cored arc welding process (FCAW). The welded samples were then

subjected to quenching followed by tempering and subsequently for two different stress relieving

(SRMI and SRMA) cycles. The samples were taken out in as-welded condition as well as after each

and every stage of the thermal cycle. Vickers hardness was carried out on the samples and the ferrite

number was obtained with the help of portable ferritscope. Microstructural characterization was

carried out to investigate the changes due to thermal cycles. Inter-granular corrosion testing was also

carried out. The experimental results indicated that the hardness was increased as the quenching was

done, but was subsequently reduced as the tempering and stress relieving cycles were applied. Also,

the ferrite number obtained after welding was around 6.9 FN which was within the acceptable range.

Subsequently, as the consequent thermal heat treatments were carried out the ferrite content was

reduced to 3.1 FN and 3.2 FN. This reduction was attributed to the conversion of delta ferrite to sigma

phase and other intermetallic phases. Also owing to results, it was proved that ASS exhibited excellent

resistance to corrosion after rigorous thermal treatments.

Keywords: Heat treatment, Ferrite number, Austenitic stainless steel, Weld overlay

23 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Experimental Performance Evaluation of Mist Cooling using Bio-Degradable

Coconut Oil in Turning of EN24 Steel in minimization of Tool Wear, Surface

Roughness and Chip Thickness

Miriyala VeeraBhadraRao1, Bhushan T.Patil2, Vasim A.Shaikh3, D.S.S.Sudhakar4

1 Research Scholar, Fr. Conceicao Rodrigues College of Engineering,

2 Dean- R&D, Professor- Production Engg, 3 Assistant Professor- Production Engg,

4 Head of Deptt. - Production Engg, Fr. Conceicao Rodrigues College of Engineering,

Fr. Agnel Ashram, Bandstand, Bandra (W) – Mumbai, India

Miriyala VeeraBhadraRao, mdnvbr@gmail.com

Abstract: Cooling and lubrication is essential factor for any machining process for reducing cutting

tool tip temperatures, cutting tool forces and increasing cutting tool life as well as work surface

quality. Also, to reduce the machining coolants with better cooling and lubricity, Minimum Quantity

Lubrication is employed. Coconut oil being bio-degradable is recommended in most machining

processes as coolant. Comparative evaluations were drawn from data collected during turning

experiments in dry, water flooding and coconut oil mist using MQL method in view of tool wear and

surface roughness of machined work-pieces under study. It was found that performance of edible bio-

degradable vegetable cutting fluids using coconut oil is better than dry and flood cooling. Mist method

of cooling uses less quantity fluids and are comparatively safer and cleaner in applications. Through

Design of Experiments (DOE) and Analysis of Variance (ANOVA), tool wear, surface roughness and

chip thickness had a comparable reduction in values and are beneficial in machining.

Keywords: Turning, EN24 Steel, Coconut Oil, Mist Cooling, MQL

24 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Multi-response optimization of Ni55.8Ti shape memory alloy using Taguchi-grey

relational analysis approach

Piyush Rathi1, Rutvik Ghiya1, Hem Shah1, Pratyush Srivastava1, Shalin Patel1, Rakesh Chaudhari1*, Jay Vora1

1Department of Mechanical Engineering, Pandit Deendayal Petroleum

University, Gandhinagar, India

Email: chaudharirakesh5@gmail.com

Abstract: Wire electrical discharge machining process is largely applicable to any conductive

material regardless of its hardness. The present study aims to investigate the influence of input

process parameters such as pulse on time, pulse off time and current on output responses of

MRR and SR for Ni55.8Ti shape memory alloy. Taguchi’s L9 orthogonal array design has been

utilized to conduct the experiments. ANOVA is used to study significance and non-significance

of the response variables. All the process parameters are found to be significant for both the

output responses. Grey relational analysis have been used to obtain an optimal combination of

WEDM parameters to maximize the cutting rate while minimizing surface roughness for shape

memory alloys, which is the most preferred material for aerospace and biomedical application

because of its high resistance to corrosion and a non-toxic nature. Predicted values obtained at

an optimal condition using GRA has been validated by experimental trail and shows a very

close relation.

Keywords: Wedm, Anova, Shape Memory Alloys, Nitinol, Grey Relational Analysis

25 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Evaluation of Surface Roughness by Machine Vision using Neural Networks

Approach

Ketaki Joshi1, Bhushan Patil2

1 Research Scholar (Mechanical Engineering), Fr. Conceicao Rodrigues College of Engineering, Bandra, Affiliated

to University of Mumbai

2 Professor and Dean (Research and Development), Fr. Conceicao Rodrigues College of Engineering, Bandra,

Affiliated to University of Mumbai

Emails: ketaki.joshi@fragnel.edu.in, bhushan.patil@fragnel.edu.in

Abstract: Surface quality of industrial components is critical from operational, ergonomics and

aesthetics point-of-view. Surface roughness measurement using traditional contact type

instruments may not be feasible in the industries insisting on 100% inspection and monitoring.

Machine vision based machine learning has a potential of facilitating automated inspection of

manufactured components for their surface quality. The paper presents a machine vision based

machine learning approach that works on the principle of surface texture characterization by

vision-based texture analysis techniques followed by supervised machine learning using

multilayer feedforward artificial neural network with backpropagation for fitting the response

(Surface Roughness) with the inputs (vision based texture parameters). Performance of various

texture analysis techniques based on histogram, Gray level co-occurrence matrix, Fourier and

wavelet transform used for generating the training data and training algorithms used for training

the networks are compared. The approach can be potentially used to estimate surface roughness

of industrial components.

Keywords: Surface Roughness, Machine Vision, Texture Analysis, Artificial Neural Networks

26 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Challenges of Sustainable Manufacturing for Indian Organization: A Study

Lakhan1, Ravinder Kumar1, Pratyaksh Tyagi1, Lincon Nagar1

Devdutt Gaur1

1 Department of Mechanical Engineering,

Amity University, Noida, Uttar Pradesh, India - 201303

Lsharma.edu@gmail.com

Abstract. Sustainable Manufacturing had gained prominent importance in modern time all over

the globe. Modern manufacturing is shifting from use of tradition practices and natural

resources to sustainable practices and alternate green energy sources. Use of traditional

practices and natural resources generate lot of wastes and pollution in environment. However,

the implementation & adaption of sustainable manufacturing practices is a challenging task for

Indian organizations. Most of Indian manufacturing organizations are not able to overcome

challenges of sustainable manufacturing and adopt its practices. In this paper authors have

reviewed different research papers and identified challenges of sustainable manufacturing. By

strategic planning challenges can be overcome and implementation of sustainable

manufacturing in Indian manufacturing organizations can feasible. To analyses the practical

challenges and feasibility of sustainable manufacturing adoption at ground level authors have

done a case study in Indian organization manufacturing goods.

Keywords: Sustainable manufacturing, Challenges, Practices, Manufacturing, Indian.

27 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Investigation on the effect of input parameters on surface quality during Rotary

Tool Near-dry EDM

Vineet Kumar Yadav, Ramver, Pradeep Kumar, Akshay Dvivedi

Mechanical and Industrial Engineering Department,

Indian Institute of Technology (IIT), Roorkee - 247667, India

Emails: vineet437@gmail.com , ramver.pme@gmail.com

Abstract: This paper presents an experimental study on rotary tool near-dry EDM (RT-ND-EDM) of

high speed steel using a two-phase mixture of water and air as a dielectric medium. The RT-ND-

EDM is an environmentally friendly process variant of EDM. Parametric investigation was performed

to understand the effect of various input parameters on the quality of machined surface. The

experimental results revealed that surface roughness (SR) increased with an increase in peak current

and pulse on time. An increase in gas pressure first decreased and then increased the SR, and finally

SR decreased with increased in liquid flow rate. In addition, analysis of RT-ND-EDMed surface using

FE-SEM technique revealed that the machined surface had irregularities such as micro-cracks, debris

deposition, micro-holes, micro-pores.

Keywords: EDM, RT-ND-EDM, Surface roughness, Surface integrity

28 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Application of Utility Function Approach aggregated with Imperialist

competitive algorithm for Optimization of Turning Parameters of AISI D2 Steel

Soni Kumaria*, Dinbandhub, Anshuman Kumarc, Rajiv Kumar Yadavd, K. Vivekanandae

a

Department of Mechanical Engineering, GLA University, Mathura, India

b

Department of Mechanical Engineering, IITRAM, Ahmedabad, India

c

Department of Mechanical Engineering, NIT Karnataka, Surathkal, India

d

Department of Mechanical Engineering, AITM, Varanasi, India

e

Department of Mechanical Engineering, FST, IFHE University, Hyderabad, India

Email: krabhishek1987@gmail.com

Abstract. In the fast-growing infrastructure, machining plays a vital role in industrial evolution.

However, obtaining optimal machining parameters is still a challenging assignment for

manufacturers because an inappropriate selection of machining parameters specifically spindle

speed (N), feed rate (f), and depth of cut (d) adversely affect the overall machining performance.

Therefore, this work attempts to provide optimal parameters setting for machining AISI D2 steel

in dry condition with PVD coated carbide tool. The evaluation of the optimal parameters setting

has also been done by means of utility function approach aggregated with the imperialist

competitive algorithm.

Keywords: AISI D2; Imperialist Competitive Algorithm (ICA); Turning; Optimization.

29 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

An exergy analysis and effect of condenser, evaporator temperature on ice

production plant

Shobhit Varshney 1, Hiren Shah 2*, Vikram Rajai 2

1

(M. Tech Scholar, Mechanical Engineering Department, CGPIT, UKA Tarsadia University, Bardoli, India)

2

(Assistant Professor, Mechanical Engineering Department, CGPIT, UKA Tarsadia University, Bardoli, India)

Abstract: In this study, an exergy analysis of an ice production plant was carried out. The exergy

formulas were written and solved based on actual plant data to point out the thermodynamics inutility.

For the analysis, the necessary data are obtained from an ice production plant situated at G.I.D.C

Navsari, Gujarat, India. The plant included ammonia refrigerant vapor compression refrigeration

system having 24 tonne ice manufacturing capacity per day including 4-cylinders kirloskar

reciprocating compressor, shell&tube condenser, induced draft counter flow cooling tower with fill,

and flooded type evaporator. Here the effect of condenser and evaporator temperature on exergy

efficiency of components, compressor work and on COP was also discussed. It is found that the

significant amount of exergy drop is happened in compressor out of numerous parts of the ice plant

and it depends on evaporating temperature, condensing temperature and geographical conditions. For

measure the exergy loss (irreversibility) of the ice production procedure an effort was also form. So,

to get the knowledge about the potential location for the plant execution refinement an important

detail can be obtained with the help of the exergetic study and its subsidiary derivatives.

Keywords: Co-efficient of performance, Compressor work, Condenser temperature, Evaporator

temperature, Exergy analysis, Ice- production process, Refrigeration System,

30 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

A review of Solar still performance with condenser

*Vivek Daraniya, **Shaival R. Parikh, ***Dr. Umang Patdiwala

*M.E. (Thermal Engineering), Gandhinagar Institute of Technology, Gujarat, India

**Research Scholar, Indus Institute of Technology, Gujarat, India

***Asst. Prof, Indus Institute of Technology, Gujarat, India

Abstract: Food and Water are day by day needs of life. In any case, individuals can make due for

day, weeks or month without sustenance, however can't with water. Body utilizes water for

"Processing, Absorption, Circulation, Transportation supplements, building tissues, diverting waste

and keeping up body temperature." The grown-up devours almost 2.5 to 3 liters of water/day to drink.

Sun based still is a lone gadget, which can give water more than 2.5 to 3 liters of water by

enhancement in plan or by utilizing distinctive sort of condensers. Thus, these papers indicate/shows

research done by different researchers or analysts on sun based still to improve the profitability.

Keywords: Solar still and different design, Condenser, Reflectors, Nanofluids, Fins, Thermal energy

storage

31 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Impact of Water- Diesel Emulsion as Fuel on Diesel Engine Performance and

Emission Characteristics – An Overview

K R Patel*, V. D. Dhiman, A. B. Dhruv

Vishwakarma Government Engineering College, Mechanical Engineering Department, Ahmedabad,

Gujarat-382424

Email: kintupatel@rediffmail.com

Abstract: The need for more efficient energy usage and a less polluted environment are the

prominent research areas. Water-in-diesel emulsion fuel (W/D) is one of the promising

alternative fuel that can fulfill such requirements so as to improve the combustion efficiency of

a diesel engine and reduce harmful exhaust gases emission. This review paper discusses the

recent advances in emulsion fuel studies with reference to the impact of W/D emulsion fuel on

the performance and emission of diesel engines, proposed potential research area in W/D

emulsion fuel study. It is agreed by most of the researchers that NOx and PM exhaust gas

emissions are reduced, while hydrocarbon (HC) and carbon monoxide (CO) exhaust emissions

are found to be increased by using the W/D emulsion fuel. Parameters such as engine operating

conditions, size of the dispersed water particle, water-content, type and percentage of surfactant

affect emission characteristics of diesel engine .

Keywords: Water- diesel emulsion, diesel engine, emission.

32 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Application of Maximum Power Point Tracking Algorithm for Determination of

the Solar Electric Potential in Gorkha Bazzar, Nepal

Aamod Khatiwada1, Rabin Dhakal2, Sirapa Shrestha2

1 Department of Electronics and Communication Engineering, Thapathali Campus, Institute of Engineering, Tribhuvan

University, Kathmandu, Nepal

2 Department of Mechanical Engineering School of Engineering, Kathmandu University, Kavre, Nepal

Emails: 1aamod@tcioe.edu.np, 2rabin.dhakal@ku.edu.np

Abstract. It is inevitable fact that the use of excessive fossil fuel has established itself as a major

concern for the existence of living kinds in the world. So the development of renewable energy source

has been the must task to minimize the energy crisis as well as the problems created by the use of

fossil fuels. Nepal is a country with geographical and climatic diversity in South East Asia with mean

solar radiation of 4.7 kWh/m2 per day and a surface area of 1, 47,181 km2. It is the region in South

East Asia with a tremendous amount of solar energy potential. Among three major geographical

regions namely Himalayan, Hilly and Terai region, this study has been performed at Gorkha

Municipality, located at central Nepal in Hilly region to determine the solar energy potential for grid-

connected photovoltaic systems installed on rooftops. A methodology was developed, in which the

characteristics of the buildings were categorized, followed by the calculation of the roof surface area

where photovoltaic panels could be installed. After that, the mean solar irradiation characteristics

were defined as well as the technical parameters of the photovoltaic systems. With all these factors,

the amount of electricity that could be potentially generated per year by solar panels is estimated.

Finally, the calculations were made to estimate the amount of electricity that could be generated with

the implementation of incremental conductance method for tracking the maximum Power Point and

also, the system was developed using Arduino, PHP programming language, current and voltage

sensors which aids for the maintenance of the installed photovoltaic cells.

Keywords: Renewable Energy, Photovoltaic Cell, Solar Irradiation, Maximum Power Point

33 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Direct Steam Generation by an Enclosed Solar Parabolic Through For

Enhanced Oil Recovery

1,2,

Ramesh V.K., 2V Chintala, 2Suresh Kumar

1

Petroleum Development Oman LLC, PO Box 81, PC 100, Mina Al Fahal, Sultanate of Oman.

2

Department of Mechanical Engineering, School of Engineering, University of Petroleum and Energy Studies

(UPES), Dehradun, India-248007

Email: VK.Ramesh.Nair@gmail.com

Abstract: Steam generation for industrial applications by harnessing solar energy has picked

up momentum in recent years. One of the major applications for steam in Crude oil extraction

industries is thermal Enhanced Oil Recovery (EOR). In the current study, direct steam was

generated by enclosed parabolic troughs for improved crude oil recovery. For such a plant,

effect of Direct Normal Irradiance (DNI) on the steam generation parameters was assessed.

Further, the outlet steam temperature, pressure was also addressed in the study. Maximum DNI

in a day was in the range of 1120 - 1185 w/m2 and the maximum steam generation was 1.1 -

1.3 kg/s. Finally, it is concluded that enclosed solar troughs are promising option for solar direct

steam generation.

Keywords: Enclosed trough, DNI, EOR, Direct steam generation

34 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Experimental Investigation of Two Phase Mist Jet Impingement Cooling on

Heated Cylinder

Chunkyraj Khangembam, Dr. Dushyant Singh

National Institute of Technology Manipur,

Langol, Manipur 795004, India

Abstract: Experimental investigation of mist jet impingement cooling on heated cylinder is

presented. The cylinder being heated electrically is maintained in non-boiling temperature of

water. Multiple experimental analyses are conducted to investigate the effect of mist loading

fraction and Reynolds number on heat transfer rate. The mist loading fraction, f varies from

0.0025 to 0.01; the hydraulic diameter of the nozzle is used to define the Reynolds number, Rehyd.

and ranges from 8,820 to 17,106 and nozzle-to-surface spacing is maintained at h/d = 40. Axial

and circumferential temperature variations of the cylinder are recorded for which localized

Nusselt number distribution is presented. The experimental study shows that mist loading and

Reynolds number greatly influences the heat transfer rate and that it increases with increase in

mist loading and Reynolds number. Also, Nusselt number at the stagnation point increases by

300% for 0.01 mist loading as compared to air-jet impingement cooling for all the considered

case of Reynolds number.

Keywords: heated cylinder, heat transfer, mist loading, mist jet impingement.

35 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Optimization of Quality Characteristics in Laser Drilling of Ti6Al4V using

VIKOR

Suman Chatterjeea, Kumar Abhishekb, and Siba Sankar Mahapatraa

a

National Institute of Technology, Department of Mechanical Engineering, Rourkela, Odisha, India

b

Institute of Infrastructure, Technology, Research and Management, Department of Mechanical Engineering,

Ahmedabad 380026, India

*

Corresponding author: krabhishek1987@gmail.com

Abstract: High precision and accuracy in machining of complicated parts requisite the application

of lasers in the machining of advanced and hard to cut materials. Titanium and its alloys have

widespread applications in several sectors namely aerospace, micro-electromechanical systems

(MEMS), and medical discipline because of their plentiful advantages such as biocompatibility,

corrosion resistance, and conductivity. Titanium and its alloys are hard to machine materials due

to their thermal conductivity, toughness, and strength. To achieve good machinability and quality

of machined surfaces lasers are best alternatives due to its aforementioned advantages. In the

present study, experimental investigation of the quality of holes has been studied using CO2 laser.

The present study was extended to explore the implementation of the VIKOR method, a novel

multi-criteria decision making (MCDM) based methodology, amalgamated with Taguchi

technique for concurrent optimization of several allied drilling variables viz. laser power,

frequency, and gas assistant in laser drilling of titanium alloy (Ti6Al4V) by means of CO2 laser.

The ideal setting of machining variables has been displayed by main effects plot for S/N ratio on

the overall quality index (Qi). The adequacy of schemed methodology has been certified by the

acquired result.

Keywords: Ti6Al4V; Laser Drilling; Taguchi; VIKOR; Optimization.

36 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Experimental investigation on surface morphology of micro-EDMed Ti-6Al-4V

alloy

Ramver, Vineet Kumar Yadav, Pradeep Kumar, Akshay Dvivedi

Mechanical and Industrial Engineering Department,

Indian Institute of Technology (IIT), Roorkee - 247667, India

Emails: ramver.pme@gmail.com, vineet437@gmail.com

Abstract: Micro-machining of titanium alloys by conventional machining processes have limitations,

for instances, high tool wear, chatter, vibrations, etc. To overcome these limitations of conventional

machining processes, micro-EDM is suitable to machine titanium alloys owing to its ability to

machine hard materials. In the present work, micro-EDM was used to drill micro-holes in Ti-6Al-4V

alloy using EDM oil as a dielectric medium. The effect of applied voltage on the morphology of

machined surface was investigated. Microscopic characterization of machined surface showed that

the surface obtained at higher applied voltage embraces relatively higher non-conformities such as

micro-pore, debris deposition, porosity, un-even surface, etc. as compared to those at lower applied

voltage.

Keywords: μ-EDM., Surface integrity, Ti-6Al-4V alloy, Thermal damages

37 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Multi-Objective Optimization and Experimental Investigation of CNC Oxy-

Fuel Gas Cutting Parameters Using Taguchi coupled Data Envelopment

Analysis

Dilip Kumar Bagal1*, Ajit kumar Pattanaik1, Dulu Patnaik1, Abhishek Barua2

Siddharth Jeet2 Surya Narayan Panda3

1

Government College of Engineering, Kalahandi, Bhawanipatna, Odisha, India

2Centre for Advanced Post Graduate Studies, BPUT, Rourkela, Odisha, India.

3Birsa Institute of Technology Sindri, Dhanbad, Jharkhand, India.

dilipbagal90@gmail.com

Abstract: An optimized design of the various machining parameters for the CNC Oxy-fuel gas

cutting process on SAE/AISI–4140 steel has been carried out by using DEA based Taguchi

methodology. SAE/AISI–4140 steel or Chromoly steel has high fatigue strength, abrasion,

impact resistance, toughness and noble ductile properties. The main output responses are bevel

angle, dross breadth and dross height, and the input parameters are nozzle speed, Oxy-fuel speed

and torch height. Nine experiments were conducted on AISI 4140 Chromoly steel based on a

L9 orthogonal array of Taguchi design. The Relative efficiency was determined from Data

Envelopment Analysis (DEA) method with Lingo version 14 software package. These scores

were significantly affected by the machining parameters of Oxy-Fuel Gas Cutting process

directly..

Keywords: CNC oxy-fuel gas cutting, SAE/AISI–4140 steel, DEA, Taguchi methodology,

Relative efficiency

38 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Utility function approach integrated with Fuzzy for optimization in milling

glass fiber reinforced epoxy composites

Chirag Bagada1, Himanshu Damor1, Vishalkumar Prajapati1, Kumar Abhishek1

1

Department of Mechanical Engineering, IITRAM Ahmedabad, India

Email: krabhishek1987@gmail.com

Abstract: The Glass fiber reinforced polymer (GFRP) composites are popular nowadays due

to their widespread applications in aerospace and automobile industries. This is mainly because

of their light weight and high strength properties. But these materials need to be machined for

any assembly or application. Therefore, it becomes crucial for the manufacturers to maintain

the required product quality without affecting the rate of productivity. In order to get an

effective machining, it is necessary to find favorable machining combinations. Hence, in this

paper, the utility function based on fuzzy logic has been adapted with the purpose of assessing

the favorable machining combination amid the end milling of GFRP composites.

Keywords: GFRP; Milling; Utility function; Fuzzy rule; Optimization

39 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

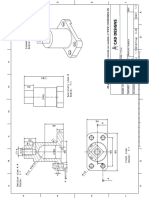

Design, Analytical Analysis and Manufacturing of 5 Cylinder Hydraulic

Fixture with Rotary Table for Machining Case on VMC EZ5

Dr. Nirav P. Maniar1, Niraj J. Sanghani1, Hardik A. Khunt1, Sudhir Thaker2

Pradeep Thanki2

1 V. V. P. Engineering College, Virda-Vajdi, Opposite Motel The Village, Kalawad Road, Rajkot – 360005, Gujarat,

India

2 M/s Supra Technology, 51 A Bhaktinagar Industrial Estate, Behind Shaktivan Manufacturers, Rajkot – 360002,

Gujarat, India

Abstract. It is apparent that almost all the literature is focused on theoretical aspects of fixture design.

This puts a question of the practical value of research. The present volume of this research work

satisfies the demand of functional approach by applying theoretical principles of fixture design for

real industrial component. The component is case of motor body widely used in automobile industry.

The major operations to be performed are drilling and grooving. The research includes design,

analytical analysis and manufacturing of a hydraulic fixture with unique concept of rotary table for

machining 5 operations on various faces of component in one setup on VMC EZ5. The innovative

use of rotary table eliminates the needs of multiple set up of fixture and thus results in huge cost

saving. Fixture is not only designed but manufactured also, it sets the classical example of design

manufacturing and excellence in manufacturing infrastructure.

Keywords: Fixture, Hydraulic, Design for manufacturing, Rotary table, Analytical Analysis,

Manufacturing Infrastructure

40 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Design Modification for Multi Material Printing with Fused Deposition

Modeling

Tarun Rijwani1 Dr. PL Ramkumar 2

Rahul Asnani 3 Nandan Patel 4

1,3,4 Students of Mechanical Engineering Department

Institute of Infrastructure, Technology, Research and Management

Ahmedabad, Gujarat, India

2 Assistant Professor of Mechanical Engineering Department

Institute of Infrastructure, Technology, Research and Management

Ahmedabad, Gujarat, India

pl.ramkumar@iitram.ac.in

Abstract: Fused Deposition Modeling 3D Printers have wide future scope as most of FDM printers

are small enough to qualify for desktop printer and easy to be operated by a layman which enables its

opportunity to become a consumer product for common people in coming future, on top of that

addition of multi material printing feature at desktop level 3D printers will be an attractive feature as

3D Printing with multiple materials unleashes the various advantages whether it be printing with

multiple colors or printing with different types of materials, like printing soluble supports with PVA

(Polyvinyl Alcohol), printing pre-assembled complex structures, getting different combination of

properties in a single part etc., in this paper currently available techniques for multi-material printing

are reviewed thoroughly with advantages and disadvantages of each as well a better alternative

approach is proposed

Keywords: Fused Deposition Modeling, Multi Material Printing, 3D Printing, multi extrusion,

Bowden extruder.

41 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

A Review on Solution of Inverse Heat Transfer Problem by Conjugate

Gradient method (CGM)

Gagnesh Upadhyay, Avanish Maurya, Surya deep Soni, Ajit Kumar Parwani

Department of Mechanical Engineering, Institute of Infrastructure Technology Research and Management, Ahmedabad,

India

Abstract: The Conjugate Gradient Method (CGM) is used for solving Inverse Heat Transfer Problem

of Conduction, Convection and Radiation in order to estimate heat flux and various other

thermophysical properties when the direct measurement of such quantities is difficult. The literature

review done here discusses about the use of CGM for estimating conductive, convective and radiative

inverse heat transfer problem. This paper also discusses the algorithm of CGM for Two dimensional

steady state convection between two parallel plates.

Keywords: Inverse heat transfer, conjugate gradient method, Heat flux estimation

42 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Fluid flow study of circular jet impingement on flat plate

Dushyant Singh1 and Saurabh Kango2

1

Department of Mechanical Engineering, NIT Manipur, India

2

Department of Mechanical Engineering, NIT Jalandhar, India

dushyant7raghu@gmail.com

Abstract: In this present study, the round jet impingement on flat plate is analyzed numerically

using four different RANS turbulence models. The four turbulence models considered are k-

SST, Realizable k-ε, RNG k-ε and 2f. The numerical results in terms of Turbulent kinetic

energy have been compared with the previously published experimental results for the purpose

of validation. It has been observed that 2f model predicted the variation in turbulent kinetic

energy accurately in the wall jet region above the near wall as compared with other models.

Keywords: Circular jet impingement, RANS turbulence models, Turbulent kinetic energy

43 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Techno-Economic Assessment of Indian Power Plant Retrofitted with Calcium

Carbonate Looping Capture Method

Pulkit Kumar1, Ajit Kumar Parwani1,

1 Institute of Infrastructure Technology Research and Management ,

Maninagar, Ahmedabad,India

Email:ajitkumar.parwani@iitram.ac.in

Abstract. The increase in concentration of carbon dioxide (CO2) into the atmosphere has now

become a serious threat to the world. Agriculture is now getting badly affected due to changes

in weather pattern which is caused by the presence of huge amount of CO2, a potential

greenhouse gases (GHG). Developing country like India where agriculture and services plays a

major role in the GDP is more concerned about the global warming. Major source of CO2

emission in India is thermal power plant which accounts for almost 65% of CO2 being emitted

into the atmosphere. So implementation of CO2 capture unit with minimum cost in thermal

power plant is very necessary in order to cut the emission of CO2. In this paper techno economic

assessment of carbon capture unit in thermal power plant of India is performed using IECM

software developed by the Carnegie Mellon University of the United States Department of

Energy. It is estimated that the implementation of calcium carbonate looping combustion

method of carbon capture will increase the total amount by almost Rs.2687/ MWh. This amount

can be reduced by utilizing and selling the stored CO2 to the different industries.

Keywords: Greenhouse gas, Calcium Looping Combustion, IECM, Techno-economic

44 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Estimation of Time Varying Heat Flux for One Dimensional Heat Conduction

Problem by Hybrid Inverse Method

Sanil Shah1, Dr. Ajit Kumar Parwani2

1Research Scholar, Mechanical Engineering Department, Institute of Infrastructure Technology Research and

Management, Ahmedabad,India.

2

Assistant Professor,Mechanical Engineering Department, Institute of Infrastructure Technology Research and

Management, Ahmedabad,India.

(Corresponding author: ajitkumar.parwani@iitram.ac.in)

Abstract: Time varying heat flux for one dimensional heat conduction problem is estimated by

inverse heat transfer method. The Conjugate Gradient Method (CGM) and hybrid of JAYA-CGM

algorithm are used for estimation. Finite volume method (FVM) is used to discretize one dimensional

problem domain for determining simulated temperature measurements. These temperature

measurements are utilized in CGM and developed hybrid algorithm in order to estimate transient heat

flux. Results show that hybrid algorithm estimates constant, linearly increasing and linearly

decreasing heat flux better than CGM.

Keywords: Conjugate gradient method, Inverse heat transfer, hybrid algorithm, JAYA

45 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Numerical Simulation of Moving Surface Boundary Layer Control over

Symmetric Aerofoil

Vipul Patel [1], Swapnil Parekh [1], Ajit Kumar Parwani [1]

1 Department of mechanical Engineering, Institute of Infrastructure Technology Research And Management,

Ahmedabad, India

Abstract- The objective of the current study is to increase the lift and decrease the drag for

NACA 0012 aerofoil by Moving Surface Boundary Layer Control (MSBC). The numerical

simulation of lift and drag for two moving surfaces of aerofoil is carried out with commercial

software “Ansys Fluent”. In the first configuration, one moving surface is considered of length

10% and other of length 15% of the chord length, both are at the upper side of the aerofoil. In

the second configuration both moving surfaces are considered of same length 10% of chord

length but one is at the upper side while other is at the lower side of the aerofoil. The results of

both configurations are compared for different angle of attack and surface to free stream

velocity ratio (Uc/U).

Keywords- NACA, MSBC, flow separation, moving surface, angle of attack

46 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

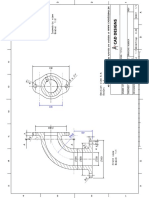

Transient Analysis of an Injection Mould with Conformal Cooling Channels

Shivsagar G. Sharma1, Deepika S. Singraur2, D. S. S. Sudhakar3

1

Research Student (M.E), Fr. CRCE, Bandra

2

Assistant Professor, Production Engg. Dept. Fr. CRCE Bandra.

3

Professor, Production Engg. Dept. Fr. CRCE, Bandra.

Abstract. Injection moulding is a manufacturing process to create plastic parts and it consists

of four major processes injection, packing, cooling and ejection. Cooling process takes almost

half of the whole cycle time in injection moulding. Injection moulds were cooled by creating

straight drilled channel in mould but that channel does not provide uniform and efficient cooling

since it does not conform the shape of the mould. Conformal cooling channel takes the exact

shape of the mould cavity and therefore it provides efficient cooling. Circular, profiled circular

and trapezoidal profile cooling channels have been designed for injection mould. To optimize

the effectiveness of the cooling channels with constant heat transfer between mould and cooling

channels, constant perimeter and different convective heat transfer co-efficient have been taken.

Thermal analysis has performed on Ansys 14.5 and Taguchi method has used to optimize the

best cooling channel.

Keywords: Conformal channels, Heat transfer, Constant perimeter, Taguchi

47 |INTERNATIONAL CONFERENCE ON RECENT ADVANCES IN MECHANICAL INFRASTRUCTURE [ICRAM-2019]

Вам также может понравиться

- Machines Mechanism and Robotics-Proceedings of INaCoMM 2017Документ841 страницаMachines Mechanism and Robotics-Proceedings of INaCoMM 2017EdsonAlvesОценок пока нет

- Sustainable Engineering Products and Manufacturing TechnologiesОт EverandSustainable Engineering Products and Manufacturing TechnologiesОценок пока нет

- Advances in Industrial and Production Engineering 2021 PDFДокумент951 страницаAdvances in Industrial and Production Engineering 2021 PDFthị sô phiaОценок пока нет

- E-Proceedings ICRACEM 2020Документ578 страницE-Proceedings ICRACEM 2020Arpita SaxenaОценок пока нет

- International Conference On: About The University About The DepartmentДокумент1 страницаInternational Conference On: About The University About The DepartmentBalaji DsОценок пока нет

- 10 01 Mechanical BrochureДокумент2 страницы10 01 Mechanical BrochureNimish SinghОценок пока нет

- Power Plant Engineering:: Advances and Practices in Power Generation Systems"Документ2 страницыPower Plant Engineering:: Advances and Practices in Power Generation Systems"csdharankar2Оценок пока нет

- June 24-25, 2021: International Conference OnДокумент2 страницыJune 24-25, 2021: International Conference OnReby RoyОценок пока нет

- Virtual International Conference On Recent Advances in Manufacturing Engineering Research (ICRAMER 2021)Документ8 страницVirtual International Conference On Recent Advances in Manufacturing Engineering Research (ICRAMER 2021)SaravananОценок пока нет

- Proceedings ICAME 09Документ1 141 страницаProceedings ICAME 09Nishant Pratap Singh100% (1)

- Biodata DR S C LaroiyaДокумент9 страницBiodata DR S C LaroiyaSurjit Kumar GandhiОценок пока нет

- Advances in Simulation, Product Design AДокумент839 страницAdvances in Simulation, Product Design Aankan_papuОценок пока нет

- Advanced Machining and Finishing 1St Edition Kapil Gupta Full ChapterДокумент43 страницыAdvanced Machining and Finishing 1St Edition Kapil Gupta Full Chapterwilliam.rainey525100% (18)

- Workshop Brochure (NIT Nagaland)Документ2 страницыWorkshop Brochure (NIT Nagaland)Swapnil DeyОценок пока нет

- Brochure Ncicec 2019Документ12 страницBrochure Ncicec 2019vinsakmОценок пока нет

- Sustainable Materials, Design and Applications (ICSMDA 2018)Документ2 страницыSustainable Materials, Design and Applications (ICSMDA 2018)maruns004Оценок пока нет

- Aspire - Achieve - Succeed: "Advances in Cad Modeling Techniques Using Catia"Документ12 страницAspire - Achieve - Succeed: "Advances in Cad Modeling Techniques Using Catia"kolkarevinayОценок пока нет

- Solarstill Report FypДокумент53 страницыSolarstill Report Fypbenzmr869Оценок пока нет

- Icmts 2017 - SouvenirДокумент29 страницIcmts 2017 - SouvenirRamesh KumarОценок пока нет

- August ICIRST 19 (Madurai, India) (1) 1Документ106 страницAugust ICIRST 19 (Madurai, India) (1) 1sundarrajan100% (1)

- Recent Trends in Mechanical EngineeringДокумент878 страницRecent Trends in Mechanical EngineeringAvijit BurmanОценок пока нет

- Advances in Additive Manufacturing and JoinningДокумент723 страницыAdvances in Additive Manufacturing and JoinningLino Rodrigues100% (1)

- AM Brochure V03Документ1 страницаAM Brochure V03manojОценок пока нет

- Brochure - International Webinar - 11sep2020.Документ3 страницыBrochure - International Webinar - 11sep2020.harshbhagchandaniОценок пока нет

- PosterДокумент1 страницаPosterTusheet Pal SinghОценок пока нет

- 10.1007@978 981 15 1201 8 PDFДокумент1 161 страница10.1007@978 981 15 1201 8 PDFankita awasthi100% (1)

- Dokumen - Pub - Fatigue Durability and Fracture Mechanics Proceedings of Fatigue Durability India 2019 1st Ed 9789811547782 9789811547799Документ645 страницDokumen - Pub - Fatigue Durability and Fracture Mechanics Proceedings of Fatigue Durability India 2019 1st Ed 9789811547782 9789811547799nestorОценок пока нет

- Ebook Machining and Tribology PDF Full Chapter PDFДокумент67 страницEbook Machining and Tribology PDF Full Chapter PDFjeffrey.lewis435100% (24)

- AIMTDR BrochureДокумент6 страницAIMTDR Brochurekachu0408Оценок пока нет

- Advances in Mechanical Engineering: B. B. Biswal Bikash Kumar Sarkar P. Mahanta EditorsДокумент1 624 страницыAdvances in Mechanical Engineering: B. B. Biswal Bikash Kumar Sarkar P. Mahanta EditorsPinaki SankarОценок пока нет

- 1 s2.0 S2212827115007830 MainДокумент2 страницы1 s2.0 S2212827115007830 MainAnilОценок пока нет

- Automated Feed Handling System For Stamping Process: Chanvim Engineering Industries Pvt. LTDДокумент28 страницAutomated Feed Handling System For Stamping Process: Chanvim Engineering Industries Pvt. LTDmayank soniОценок пока нет

- Final Report 7th-August-1 (1) (Repaired)Документ70 страницFinal Report 7th-August-1 (1) (Repaired)Rupak MandalОценок пока нет

- Mlrit Int ConfДокумент8 страницMlrit Int ConfvempadareddyОценок пока нет

- BoA ICAMIE 2020 OriginalДокумент119 страницBoA ICAMIE 2020 OriginalErwin BondanОценок пока нет

- ERAMS 2017 BrochureДокумент6 страницERAMS 2017 BrochureHuruk BrosnanОценок пока нет

- Academic Profile Dr. Raju Mahadeorao TayadeДокумент4 страницыAcademic Profile Dr. Raju Mahadeorao TayadeShalk GОценок пока нет

- Design, Build and Test Small Scale Liquid Rocket EngineДокумент67 страницDesign, Build and Test Small Scale Liquid Rocket EngineS DMОценок пока нет

- Proceedings of The 8Th International Conference On Mechanical Automotive and Materials Engineering John P T Mo Fakher Chaari Francesco Gherardini Vitalii Ivanov Mohamed Haddar Francisco Ca All ChapterДокумент68 страницProceedings of The 8Th International Conference On Mechanical Automotive and Materials Engineering John P T Mo Fakher Chaari Francesco Gherardini Vitalii Ivanov Mohamed Haddar Francisco Ca All Chapterangeline.pendergrass490100% (4)

- The Gains of Studying Mechanical EngineeringДокумент10 страницThe Gains of Studying Mechanical Engineeringyikaha7594Оценок пока нет

- Final Mechanical Engg AICTE 2023Документ162 страницыFinal Mechanical Engg AICTE 2023Srinivasan GОценок пока нет