Академический Документы

Профессиональный Документы

Культура Документы

Sew Ability PDF

Загружено:

Sami KocahanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sew Ability PDF

Загружено:

Sami KocahanАвторское право:

Доступные форматы

THE L+M SEWABILITY TESTER

The L&M Sewability Tester has been developed to give a damage occurs, or alternatively the high frictional forces

standard reproducible test for sewability, i.e. a test which will encountered by the needle will cause generation of heat which in

indicate to the clothier whether any supplied fabric is capable of high speed sewing will cause fusing of the fabric.

being sewn without difficulty. The information supplied by the

machine is not subject to variations of sewing conditions or The frictional characteristics of the fabric are determined by a

operator skill. number of factors. Of prime importance is the method of dyeing

and finishing, for example, solvent-scoured fabrics from which

The machine is useful to the fabric supplier: lubricants have been removed, possess high frictional

To ensure that fabric finish comes up to standard. characteristics and poor sewability, and fabrics to which lubricants

and softeners have been added have low forces for penetration and

The machine is useful to the clothing manufacturer: good sewability.

To ensure that the fabric will give a satisfactory sewing The L&M Sewability Tester enables consecutive readings of

performance. force for penetration of the fabric by a selected needle to be

measured on a small sample of fabric at a rate of 100

Advantages of the instrument: penetrations/min. Using a threshold figure high counts are

1. Only a small sample of the fabric is needed. recorded when the threshold is exceeded. Good sewability is

indicated by the absence of ‘high’ counts.

2. The test is rapid and the operating procedure simple.

The machine stops automatically and the results are displayed. THE L&M AVERAGING DEVICE

3. The versatility of the machine enables other investigations to be

carried out, such as effect of fabric finishes and constructions on The L&M Averager (built into the main machine) will assist in

sewability, studies of needle characteristics and of the optimum looking at the distribution of penetration forces (particularly

needle size for satisfactory sewing of a particular fabric. important for woven fabrics) and operates in two ways.

Average This shows the average force on the needle over a

PRINCIPLES OF OPERATION OF L&M period of 100 penetrations and will automatically

SEWABILITY TESTER adjust the average at each successive 100

penetrations.

The L&M Sewability Tester has been developed as a result of

research carried out in the Clothing Section of the Textile

Force gm This will show the peak penetration force at each

Department at the University of Leeds.

penetration. This can be useful for short-term tests

As a result of this research, it was established that the force and looking at short-term variation in fabrics.

required to penetrate a fabric with a sewing needle is related to

the sewability of a fabric, that is, its susceptibility to needle damage The average is automatically reset by resetting the total and high

by bursting or fusing, hence provides a suitable means of count buttons.

assessment of this property.

While the Averager is operating, the high count method of

The ease which a sewing needle can penetrate a fabric is sewability testing is also in operation.

determined by the frictional characteristics of that fabric. In fabrics

with low frictional characteristics, the fibres and yarns in the fabric OPTION – Software for PC connection and recording

can move easily to allow passage of the needle and hence the individual penetration forces and results.

penetration force is low and no damage occurs. In fabrics which

have high frictional characteristics the fabric components cannot The manufacturer reserves the right to alter the specification at any time in the

move easily and so the force for penetration by the needle is high. interest of offering a finer product. All goods are sold subject to the Manufacturer’s

This value may exceed the breaking strength of the yarn and so Conditions of Sale.

JOHN GODRICH

Pellow House, Old Street, Ludlow,

Shropshire SY8 1NU, England.

Tel: +44 (0)1584 873153 Fax: +44 (0)1584 872424

Email: johngodrich@johngodrich.co.uk

Web site: www.johngodrich.co.uk

BS EN ISO 9002 Certificate No. 2739

Вам также может понравиться

- Iso 4920 Water RepellencyДокумент2 страницыIso 4920 Water RepellencySami Kocahan100% (1)

- FennelДокумент2 страницыFennelAlesam44bОценок пока нет

- Havehas Affirm Neg Interrogwith Aliens - 19229Документ3 страницыHavehas Affirm Neg Interrogwith Aliens - 19229Ana Victoria Cuevas BeltránОценок пока нет

- Geology Harn v1 2Документ17 страницGeology Harn v1 2vze100% (1)

- Sew AbilityДокумент1 страницаSew AbilityAnonymous zd5HPB5Оценок пока нет

- Aqe Final Assignment: Ms. Nanika Kaushal Assistant Professor, NiftДокумент12 страницAqe Final Assignment: Ms. Nanika Kaushal Assistant Professor, NiftVidya Sagar ChowdaryОценок пока нет

- Study On Denim and Gabardine Twill Fabric Cover FactorДокумент47 страницStudy On Denim and Gabardine Twill Fabric Cover FactorAtik U Bhuiyan71% (7)

- SWSManual 2018 02 RefStateДокумент7 страницSWSManual 2018 02 RefStatekanzarkarss.tx.23Оценок пока нет

- Process Control in WeavingДокумент14 страницProcess Control in WeavingmetinОценок пока нет

- Knitting Faults Causesand Remediesof Knit FabricsДокумент14 страницKnitting Faults Causesand Remediesof Knit FabricsDivya SuryavanshiОценок пока нет

- Jayashree TextileДокумент29 страницJayashree TextilePayal ParidaОценок пока нет

- Latest Textile Testing InstrumentsДокумент19 страницLatest Textile Testing InstrumentsVignesh WaranОценок пока нет

- Bahir Dar University: Ethiopian Institute of Textile and Fashion TechnologyДокумент33 страницыBahir Dar University: Ethiopian Institute of Textile and Fashion TechnologybekinewОценок пока нет

- Shanto-Mariam University of Creative Technology: Chemistry of Coated TextilesДокумент18 страницShanto-Mariam University of Creative Technology: Chemistry of Coated TextilesMd Raim razzakОценок пока нет

- Home ScienceДокумент13 страницHome ScienceJhilik DeyОценок пока нет

- Ultrasonic Welding Sewing MachineДокумент24 страницыUltrasonic Welding Sewing Machineaqsa imranОценок пока нет

- Fabric ScienceДокумент7 страницFabric ScienceArshiya GuptaОценок пока нет

- List of Fiber Testing Machine Used in TextileДокумент30 страницList of Fiber Testing Machine Used in TextileHappyness Diary OfficialОценок пока нет

- Title: Textile Testing and Quality AssuranceДокумент5 страницTitle: Textile Testing and Quality AssuranceTauqeer RazaОценок пока нет

- Final Assignment: Textile Testing & Quality Control-IIДокумент11 страницFinal Assignment: Textile Testing & Quality Control-IINoman ahmedОценок пока нет

- ProjectДокумент12 страницProjectJoshi ParthОценок пока нет

- University of Engineering and Technology, Lahore Faisalabad CampusДокумент5 страницUniversity of Engineering and Technology, Lahore Faisalabad CampusAmmar BabarОценок пока нет

- Man Made Fibre Filament and YarnДокумент26 страницMan Made Fibre Filament and YarnNarayanan Balasubramanian100% (1)

- Textile Testing & Quality: Title: Martyndale Pilling Testing MethodДокумент6 страницTextile Testing & Quality: Title: Martyndale Pilling Testing MethodTauqeer RazaОценок пока нет

- Untitled DocumentДокумент26 страницUntitled DocumentSibina AОценок пока нет

- 13 (2) 15Документ6 страниц13 (2) 15Biswa Ranjan DasОценок пока нет

- By Mahesh Pratap Under The Guidence of Dr. K.V.P.Singh Roll No. 09210104Документ18 страницBy Mahesh Pratap Under The Guidence of Dr. K.V.P.Singh Roll No. 09210104Ravi Jain100% (1)

- Measurement of Seam Puckering and Influence of Its Causes: Sandun Fernando Tss JayawardenaДокумент7 страницMeasurement of Seam Puckering and Influence of Its Causes: Sandun Fernando Tss JayawardenaIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Sizing-Impact of Process Parameter On Beam Quality and Similarly On Loom PerformanceДокумент15 страницSizing-Impact of Process Parameter On Beam Quality and Similarly On Loom PerformanceSaad KhanОценок пока нет

- Fsa Testing (Jyoti)Документ16 страницFsa Testing (Jyoti)Jyoti RawalОценок пока нет

- (2Q) - List Down The Fabric Testing Machines Which Should Be Considered by Purest Manufacturers. (A)Документ3 страницы(2Q) - List Down The Fabric Testing Machines Which Should Be Considered by Purest Manufacturers. (A)Vidya Sagar ChowdaryОценок пока нет

- 2 QC in Preparatory Wet ProcessingДокумент114 страниц2 QC in Preparatory Wet ProcessingVERMADEENОценок пока нет

- Name: Mahmudul Hasan ID: 181-014-041 Section: A Course Title: Textile Testing & Quality Control-2 (Lab) Course Code: TXE-312Документ12 страницName: Mahmudul Hasan ID: 181-014-041 Section: A Course Title: Textile Testing & Quality Control-2 (Lab) Course Code: TXE-312Mahmudul HasanОценок пока нет

- 1541394762H08TM32 QiДокумент14 страниц1541394762H08TM32 QiJhilik DeyОценок пока нет

- Determining Fabric Quality: Prepared By: Riza Leigh I. FiguesДокумент55 страницDetermining Fabric Quality: Prepared By: Riza Leigh I. FiguesRizaLeighFiguesОценок пока нет

- Textile Spinning: Process Quality ControlДокумент30 страницTextile Spinning: Process Quality Controlaqsa imranОценок пока нет

- TEX FINAL ASSIGNMENT - Shafikul IslamДокумент18 страницTEX FINAL ASSIGNMENT - Shafikul IslamShafikul IslamОценок пока нет

- IPC-TM-650 Test Methods ManualДокумент3 страницыIPC-TM-650 Test Methods ManualjonamramukОценок пока нет

- Textile Testing MachinesДокумент14 страницTextile Testing MachinesNenadCirkovicОценок пока нет

- Fabric Science Assignment1 PDFДокумент15 страницFabric Science Assignment1 PDFDhruv MishraОценок пока нет

- Textile Nonwoven TestingДокумент10 страницTextile Nonwoven TestingSandeep Yadav100% (1)

- Quality Wise Sort Analysis To Optimize Fabric Defect Detection in Terry WeavingДокумент3 страницыQuality Wise Sort Analysis To Optimize Fabric Defect Detection in Terry WeavingMễro ĢAОценок пока нет

- New Development of A Swatch Given by BuyerДокумент11 страницNew Development of A Swatch Given by BuyerNaimul Hasan0% (1)

- Six SigmaДокумент6 страницSix Sigmasayeef khanОценок пока нет

- Spinning VviДокумент14 страницSpinning VviBithy PaulОценок пока нет

- Principles of Textile TestingДокумент20 страницPrinciples of Textile TestingBhaswati PandaОценок пока нет

- Fabric Science I: National Institute of Fashion TechnologyДокумент10 страницFabric Science I: National Institute of Fashion TechnologySHASHANK ROHITОценок пока нет

- Responsibility of QAДокумент20 страницResponsibility of QAMonjur Hossain100% (1)

- Seam Performance Evaluation of Plain Fabric UsingДокумент9 страницSeam Performance Evaluation of Plain Fabric UsingMd NurunnabiОценок пока нет

- P15ATP202 Fab & App Assess Lab WorkbookДокумент73 страницыP15ATP202 Fab & App Assess Lab WorkbookSentthil KumarОценок пока нет

- Fabric Assurance by Simple TestingДокумент5 страницFabric Assurance by Simple Testingsenthilkumar7374Оценок пока нет

- 10.1515 - Aut 2023 0002Документ8 страниц10.1515 - Aut 2023 0002dr ghadaОценок пока нет

- Texile TestingДокумент27 страницTexile TestingSamarth TuliОценок пока нет

- Weaving: Weaving Department Standard Operating Manual Process DefinitionДокумент20 страницWeaving: Weaving Department Standard Operating Manual Process DefinitionSabeeh Ul HassanОценок пока нет

- Yarn Specs - USTERДокумент24 страницыYarn Specs - USTERZubairShafqat50% (2)

- Fabric Science LL End Term Assignment Submitted By: Lakshita SainiДокумент25 страницFabric Science LL End Term Assignment Submitted By: Lakshita SainiLakshita SainiОценок пока нет

- Effects of Combed and Carded Yarn On Weft Knitted Finished Fabric QualityДокумент7 страницEffects of Combed and Carded Yarn On Weft Knitted Finished Fabric QualityvirtulianОценок пока нет

- Title:: Textile Testing and Quality AssuranceДокумент5 страницTitle:: Textile Testing and Quality AssuranceTauqeer RazaОценок пока нет

- Mahin - 193003051 (TTQC Lab3)Документ5 страницMahin - 193003051 (TTQC Lab3)MahinОценок пока нет

- L 15 T T F: Esson Esting of Extile AbricsДокумент12 страницL 15 T T F: Esson Esting of Extile AbricsKathirrvelu SubramanianОценок пока нет

- Introduction To Weaving Preparatory ProcessesДокумент21 страницаIntroduction To Weaving Preparatory ProcessesZakeesh FatimaОценок пока нет

- Strength Testing PDFДокумент14 страницStrength Testing PDFRafiul IslamОценок пока нет

- Elmendorf Tearing TesterДокумент3 страницыElmendorf Tearing TesterTaofiqur Rahman ShochchoОценок пока нет

- En - MM Cat b5 NT Tds - 4Документ1 страницаEn - MM Cat b5 NT Tds - 4Sami KocahanОценок пока нет

- Carpet Printing Technologies ENGДокумент16 страницCarpet Printing Technologies ENGSami KocahanОценок пока нет

- Determination of Diameter of Loose Wool Air Flow Method: Received May Accepted October 1984Документ2 страницыDetermination of Diameter of Loose Wool Air Flow Method: Received May Accepted October 1984Sami KocahanОценок пока нет

- Anyonik Surfactant Tayini PDFДокумент5 страницAnyonik Surfactant Tayini PDFSami KocahanОценок пока нет

- DyStar ProductДокумент2 страницыDyStar ProductSami KocahanОценок пока нет

- Determination of Garment PHДокумент19 страницDetermination of Garment PHSami KocahanОценок пока нет

- Silica For Adhesives BrochureДокумент1 страницаSilica For Adhesives BrochureSami KocahanОценок пока нет

- DyStar Product Selection - CA RSL - Version Apr 2013 - 3sep13 - Final PDFДокумент39 страницDyStar Product Selection - CA RSL - Version Apr 2013 - 3sep13 - Final PDFSami KocahanОценок пока нет

- AkzoNobel - Colloidal Silica For Adhesives BrochureДокумент6 страницAkzoNobel - Colloidal Silica For Adhesives BrochureCarlos GuerreroОценок пока нет

- Powerful Communication Tools For Successful Acupuncture PracticeДокумент4 страницыPowerful Communication Tools For Successful Acupuncture Practicebinglei chenОценок пока нет

- Notice of Privacy Practices (Generic)Документ3 страницыNotice of Privacy Practices (Generic)cecilled_08Оценок пока нет

- BR Interlock Pallet Racking System 2009 enДокумент8 страницBR Interlock Pallet Racking System 2009 enMalik Rehan SyedОценок пока нет

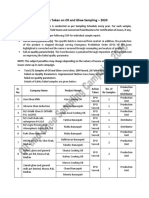

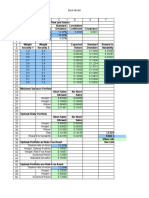

- Action Taken On Oil and Ghee Sampling - 2020Документ2 страницыAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiОценок пока нет

- Me3391-Engineering Thermodynamics-805217166-Important Question For Engineering ThermodynamicsДокумент10 страницMe3391-Engineering Thermodynamics-805217166-Important Question For Engineering ThermodynamicsRamakrishnan NОценок пока нет

- NCR RepairДокумент4 страницыNCR RepairPanruti S SathiyavendhanОценок пока нет

- Social Style InventoryДокумент12 страницSocial Style InventoryMaheshwari JaniОценок пока нет

- Tuyet W3 Unit 2 Tenses Adverbial Clause of Time Zalo HSДокумент16 страницTuyet W3 Unit 2 Tenses Adverbial Clause of Time Zalo HSVũ Thanh GiangОценок пока нет

- 3 Ways To Take Isabgol - WikiHowДокумент6 страниц3 Ways To Take Isabgol - WikiHownasirОценок пока нет

- Index Medicus PDFДокумент284 страницыIndex Medicus PDFVania Sitorus100% (1)

- Uttarakhand District Factbook: Almora DistrictДокумент33 страницыUttarakhand District Factbook: Almora DistrictDatanet IndiaОценок пока нет

- Unit-7 (EVS)Документ32 страницыUnit-7 (EVS)g6614134Оценок пока нет

- 8 Categories of Lipids: FunctionsДокумент3 страницы8 Categories of Lipids: FunctionsCaryl Alvarado SilangОценок пока нет

- Emission Estimation Technique Manual: For Mining and Processing of Non-Metallic MineralsДокумент84 страницыEmission Estimation Technique Manual: For Mining and Processing of Non-Metallic MineralsAbdelaziem mahmoud abdelaalОценок пока нет

- Cyber Safety PP Presentation For Class 11Документ16 страницCyber Safety PP Presentation For Class 11WAZ CHANNEL100% (1)

- Kingdom of AnimaliaДокумент6 страницKingdom of AnimaliaBen ZerepОценок пока нет

- Distress Manual PDFДокумент51 страницаDistress Manual PDFEIRINI ZIGKIRIADOUОценок пока нет

- Muslim Marriage (Nikah) : Mutual Rights and ObligationsДокумент10 страницMuslim Marriage (Nikah) : Mutual Rights and ObligationsSachin Kumar Singh100% (1)

- A Cook's Journey To Japan - Fish Tales and Rice Paddies 100 Homestyle Recipes From Japanese KitchensДокумент306 страницA Cook's Journey To Japan - Fish Tales and Rice Paddies 100 Homestyle Recipes From Japanese KitchensEthan F.100% (1)

- Course Guide Pe1 PDFДокумент4 страницыCourse Guide Pe1 PDFrahskkОценок пока нет

- Free Higher Education Application Form 1st Semester, SY 2021-2022Документ1 страницаFree Higher Education Application Form 1st Semester, SY 2021-2022Wheng NaragОценок пока нет

- Manual of GardeningДокумент812 страницManual of GardeningPrakash PatelОценок пока нет

- Cemco T80Документ140 страницCemco T80Eduardo Ariel Bernal100% (3)

- BKM 10e Ch07 Two Security ModelДокумент2 страницыBKM 10e Ch07 Two Security ModelJoe IammarinoОценок пока нет

- EscheatmentДокумент58 страницEscheatmentlaarigao100% (2)

- WeaknessesДокумент4 страницыWeaknessesshyamiliОценок пока нет

- Ventura 4 DLX ManualДокумент36 страницVentura 4 DLX ManualRoland ErdőhegyiОценок пока нет