Академический Документы

Профессиональный Документы

Культура Документы

A

Загружено:

Jindal HydraulicsАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A

Загружено:

Jindal HydraulicsАвторское право:

Доступные форматы

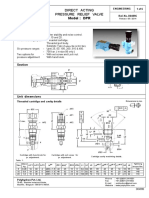

Ref. No.

D 04904

PILOT OPERATED CHECK VALVE Release: 07 / 2018

Model : CI

**** ENGINEERING - 1 of 3

A Polyhydron Group Company

Description

Pilot Operated Check valve models CI

**** allow free flow in the direction

from Port A to Port B and offer leak free closure in opposite direction.

Reverse flow can be achieved by applying Pilot pressure to its Port X.

The pilot pressure required at Port X to achieve reverse flow from its closed

position can be calculated using the formulae given in the Technical

specifications.

Generally, to achieve smooth decompression of oil in a hydraulic actuator

prior to reverse flow, it is essential to keep the Pilot pressure as close to the

calculated value as possible and the flow controlled.

Section Hydraulic symbol

Body with A - Type piston Body with B - Type piston

A B

X A B X A B

Technical specifications

Construction : Seat type valve, with decompression facility.

Mounting style : Threaded port or subplate mounting.

Mounting interface : Sub-plate mounting - As per ISO 5781.

Threaded port body - Factory standard.

Mounting position : Optional.

Flow direction : Free flow from A to B.

: Piloted flow from B to A.

Cracking pressure : 1 bar.

Working pressure : 315 bar for Ports A, B and X.

Area ratios : Type A Type B

Pilot piston : Decomp. poppet 16 : 1 4:1

Pilot piston : Main poppet 2:1 1:2

Hydraulic medium : Mineral oil.

Temperature range : -20°C to + 80°C.

Viscosity range : 10 cSt to 380 cSt.

Fluid cleanliness required : ISO 4406 20/18/15 or better.

Max. flow handling capacity : Size : 10 20 30

l/min : 80 160 350

Mass approx. : Model : CI10S CI10T CI20S CI20T CI30S CI30T

in Kg : 1.9 2.2 3 3.3 5.8 6

Formulae for Pilot pressure required at Port X open the valve for flow from Port B to Port A

Type A Type B

To open decompression poppet >PA + PB/16 + 0.5 >PA/1.5 + PB/4 + 2

To open the main poppet >PA/2 + PB/2 + 0.5 >2P B - PA + 2

Where, PA = Pressure at Port A and PB = Pressure at Port B , when the flow occurs.

Phone : +91-(0)831- 2411001

Fax : +91-(0)831- 2411002

78-80, Machhe Industrial Estate,

E-mail : polyhydron@gmail.com

Machhe, Belgaum - 590 014. INDIA.

Website : www.polyhydron.com

D 04904-CI

A Polyhydron Group Company ENGINEERING - 2 of 3

****

Unit dimensions B4

Dimensions in mm.

B2

Threaded port bod y

B3 B1

Ø10.5 thru

L5

L4

L6

L8

Ø D1

Ø D2

L3

A B

L7

B

L1

Ø D1

Ø D2

L2

X

Ø 22

G1/4

X

H2 H2

H1

Size L1 L2 L3 L4 L5 L6 L7 L8 B1 B2 B3 B4 H1 H2 ØD1 ØD2

10 115 90.5 52 18.5 17 29 67.5 46 8.3 83 66.5 87 55 27.5 30 G1/2

20 135 108.5 64 20 19 30.5 83 58 9.5 93 74 97 65 32.5 44 G1

30 167.5 133 88.5 15 22.5 35.5 105 69.5 9.5 116 97 120 80 40 60 G1 1/2

Sub-plate mounting body

Subplate mounting interface as per ISO 5781.

ØD1

@ A & B.

Ø7.5, 8 deep.

6

Ø4.8

B B B

L10

M10x1.5

L9

L1

L8

Ø 6.3

X 17 deep.

L7

L6

A A

L5

L4

X A

B3 B4

L2

L3

B5

B6

B2 B7

H1

B1 Note: Valve fixing S.H.C Screws are not in scope of supply.

Valve fixing Tightening

Size L1 L2 L3 L4 L5 L6 L7 L8 L9 L10 B1 B2 B3 B4 B5 B6 B7 H1 ØD1 S.H.C Screws Torque

max Class 12.9 Nm

M10 x 45L

10 115 38.5 18.5 7.1 21.4 --- 31.8 35.7 42.9 80 90 45 9.2 33.3 58.7 66.7 85 51 13

4 nos

M10 x 50L

20 135 39.5 17.5 11.1 20.8 --- 44.5 49.2 60.3 95 100 50 10.3 39.7 73 79.4 100 63 22 4 nos

77

M10 x 65L

30 167.5 44.5 15.5 16.7 24.6 42.1 62.7 67.5 84.1 115 120 60 11.6 48.4 92.9 96.8 120 80 31 6 nos

All rights reserved.

Subject to revision

D 04904-CI

A Polyhydron Group Company ENGINEERING - 3 of 3

****

Ordering code CI 10 T A 13

Pilot operated check valve Design code subjected to Change .

internal drain installation dimensions remain

same for design code 09 thru 19.

Port size

Threaded Subplate

Size Pilot piston : Decomp poppet = 16:1

body mounting A Pilot piston : Main poppet = 2:1

G1/2 Ø 13 max 10

G1 Ø 22 max 20 Pilot piston : Decomp poppet = 4:1

B Pilot piston : Main poppet = 1:2

G1 1/2 Ø 31 max 30

S Subplate mounting body

T Threaded port body

Performance graph

All rights reserved.

Subject to change without prior notice.

Due to continuous improvement in the design of the product, the actual product supplied may look different than shown above.

For critical applications, please ask for certified installation drawing.

All rights reserved.

Subject to revision

Вам также может понравиться

- API 610 12th Edition Major ChangesДокумент4 страницыAPI 610 12th Edition Major ChangesTyas Utami83% (6)

- TVT Series Operator ManualДокумент268 страницTVT Series Operator ManualGeorge Bogdan100% (4)

- 2002 Cavalier Transmission DropДокумент14 страниц2002 Cavalier Transmission DropAlex HirzelОценок пока нет

- p06060Документ3 страницыp06060Daniel Sandoval FernándezОценок пока нет

- CIM - 10 PolyhydronДокумент2 страницыCIM - 10 PolyhydronJindal HydraulicsОценок пока нет

- A Polyhydron Group Company: Pilot Operated Check Valve Modular Construction Model: CIM10Документ2 страницыA Polyhydron Group Company: Pilot Operated Check Valve Modular Construction Model: CIM10mdkhandaveОценок пока нет

- Vmy UkДокумент8 страницVmy UkEdwinОценок пока нет

- Polyhydron Check ValveДокумент2 страницыPolyhydron Check ValveEzhil KumarОценок пока нет

- A Polyhydron Group Company: Pressure Compensated Flow Control Valve Model: 2PF 10Документ3 страницыA Polyhydron Group Company: Pressure Compensated Flow Control Valve Model: 2PF 10Rakesh SharmaОценок пока нет

- FILTROS Maxiflow - Series PARKERДокумент5 страницFILTROS Maxiflow - Series PARKERDaniel MarОценок пока нет

- Page 493 of 635Документ30 страницPage 493 of 635Sugadev SinghОценок пока нет

- Kawasaki Check Valve C1001Документ5 страницKawasaki Check Valve C1001Mohamed ElmakkyОценок пока нет

- Valve For Fcu PolymerДокумент2 страницыValve For Fcu PolymerBN YADAVОценок пока нет

- D4 ImoДокумент14 страницD4 ImoFelipe SalvatierraОценок пока нет

- TM - 5CC - 2016Документ72 страницыTM - 5CC - 2016Jf OngОценок пока нет

- FR-1 Series CatalogueДокумент8 страницFR-1 Series CatalogueNoelОценок пока нет

- VÁLVULA 2VS3 06 Double Throttle Check Valves Sandwich Plates EngДокумент4 страницыVÁLVULA 2VS3 06 Double Throttle Check Valves Sandwich Plates Engadriana853Оценок пока нет

- MPC 03 Pilot Operated Check ValveДокумент3 страницыMPC 03 Pilot Operated Check ValveJose Luis Quispe LuqueОценок пока нет

- Technical Manual for ACSON Ceiling Mounted C Series Air ConditionersДокумент48 страницTechnical Manual for ACSON Ceiling Mounted C Series Air ConditionersJf OngОценок пока нет

- Planta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEДокумент1 страницаPlanta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEAnthony InostrozaОценок пока нет

- Uploads Products Literature LITER BryCool BrochureДокумент4 страницыUploads Products Literature LITER BryCool BrochureParchuri PraveenОценок пока нет

- Resistividad Del TerrenoДокумент14 страницResistividad Del TerrenoedwardОценок пока нет

- ROT Rotary Control Valves OverviewДокумент8 страницROT Rotary Control Valves OverviewPatricio AcuñaОценок пока нет

- Easy IBC Decanting with 1500L IBC Mother TankДокумент6 страницEasy IBC Decanting with 1500L IBC Mother TankWong Peng ChiongОценок пока нет

- Bombas 1Документ40 страницBombas 1AngelMLОценок пока нет

- Accumulator Design CatalogueДокумент8 страницAccumulator Design CatalogueSenthilKumarShanmughamОценок пока нет

- 19-216-5 Washer Extractor 20 KG 440 3 60Документ2 страницы19-216-5 Washer Extractor 20 KG 440 3 60Navaneeth PurushothamanОценок пока нет

- Brand: Floating and Trunnion Mounted Ball Valves Soft and Metal Seated ASME CLASS 15O 2500Документ52 страницыBrand: Floating and Trunnion Mounted Ball Valves Soft and Metal Seated ASME CLASS 15O 2500krishОценок пока нет

- BARTON Floco: Liquid Positive Displacement FlowmeterДокумент8 страницBARTON Floco: Liquid Positive Displacement FlowmeterElkin TorresОценок пока нет

- Summary of API 610 12th EditionДокумент4 страницыSummary of API 610 12th EditionYang Kyo OhОценок пока нет

- 19.2.9 Control Valves: Floresta Garden Infrastucture Project - The Pearl DohaДокумент1 страница19.2.9 Control Valves: Floresta Garden Infrastucture Project - The Pearl DohakaamОценок пока нет

- EHYD6 Hydraulic Valves HY14-2502f012Документ5 страницEHYD6 Hydraulic Valves HY14-2502f012Riki AkbarОценок пока нет

- API 608 Floating Ball ValvesДокумент2 страницыAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgОценок пока нет

- Fire DRY HydrantsДокумент4 страницыFire DRY HydrantsAbdullah RamadanОценок пока нет

- Fixed Displacement Bent Axis Motor: Advantages Design FeaturesДокумент2 страницыFixed Displacement Bent Axis Motor: Advantages Design FeaturesAdiyatma DjatnikaОценок пока нет

- H2 Product CatalogДокумент14 страницH2 Product CatalogVipul PanchalОценок пока нет

- PBV 02 Piece Flanged Trunnion ValveДокумент8 страницPBV 02 Piece Flanged Trunnion ValveAna FigueroaОценок пока нет

- Re27551 - 2020 11 04Документ12 страницRe27551 - 2020 11 04MSc Kostic MilosОценок пока нет

- sihi_aolДокумент5 страницsihi_aolmohsen fatemiОценок пока нет

- R410A Split Systems Air Conditioner Technical ManualДокумент100 страницR410A Split Systems Air Conditioner Technical ManualHenry Phan75% (4)

- LPG Compressor SpecsДокумент11 страницLPG Compressor SpecsabhishekОценок пока нет

- OM Manual AHL Pump PDFДокумент20 страницOM Manual AHL Pump PDFinok stingerОценок пока нет

- ASTR-Industrial-Range-The-Hybrid-RangeДокумент2 страницыASTR-Industrial-Range-The-Hybrid-RangeDennis CoonОценок пока нет

- National Concrete Products Co. LTD 200-20-0049 CIFA K48Документ4 страницыNational Concrete Products Co. LTD 200-20-0049 CIFA K48Yazeed Saad AlrasheedОценок пока нет

- 2-Latest EIC-C-1002-0 (Pilot Operated Relief Valve)Документ14 страниц2-Latest EIC-C-1002-0 (Pilot Operated Relief Valve)Lin LeninОценок пока нет

- Valvula wh6Документ16 страницValvula wh6Willam Hugo Luna PonteОценок пока нет

- EDNC106 & 157 AMC Check ListДокумент7 страницEDNC106 & 157 AMC Check ListtranhoachbnОценок пока нет

- Re26391 2019-10Документ12 страницRe26391 2019-10Israel RuizОценок пока нет

- Wastemaster Mit en 0715 EditДокумент4 страницыWastemaster Mit en 0715 EditPablo DonariОценок пока нет

- FEA model through port gauge port manifoldДокумент6 страницFEA model through port gauge port manifoldssmodiОценок пока нет

- Aquachill: Air Cooled Scroll Water ChillersДокумент48 страницAquachill: Air Cooled Scroll Water ChillersLee BroОценок пока нет

- Brevini-Gearmotors D SeriesДокумент1 страницаBrevini-Gearmotors D SeriespetpavkzОценок пока нет

- Open Center Control Block in Mono Block DesignДокумент12 страницOpen Center Control Block in Mono Block DesignnksiavashОценок пока нет

- Product Information For The Product Group: Lipumax-P-DMДокумент3 страницыProduct Information For The Product Group: Lipumax-P-DMraghuvarmaОценок пока нет

- B C N (None) : C-Spool H-SpoolДокумент2 страницыB C N (None) : C-Spool H-SpoolPasqualeОценок пока нет

- Backflow Preventer Watts Model 719 SpecificationsДокумент4 страницыBackflow Preventer Watts Model 719 SpecificationsEstevan huertasОценок пока нет

- Cartridge Valves and ManifoldsДокумент318 страницCartridge Valves and Manifoldsmunawar munawarОценок пока нет

- Boston Eaton Industrial Hose CatalogДокумент152 страницыBoston Eaton Industrial Hose Catalogoguzhan turanОценок пока нет

- TM Ceiling Cassette E McQuayДокумент120 страницTM Ceiling Cassette E McQuaySalamet TeguhОценок пока нет

- BMV 50 - Vertical Machining CenterДокумент6 страницBMV 50 - Vertical Machining CenterGreen FarmersОценок пока нет

- An Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberОт EverandAn Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberРейтинг: 5 из 5 звезд5/5 (1)

- Solar - New Domestic BrochureДокумент6 страницSolar - New Domestic BrochureJindal HydraulicsОценок пока нет

- DesignOfCFrameTypeHydraulicPunchingMachine (129 133) PDFДокумент5 страницDesignOfCFrameTypeHydraulicPunchingMachine (129 133) PDFJindal HydraulicsОценок пока нет

- JSSL Brochure PDFДокумент6 страницJSSL Brochure PDFJindal HydraulicsОценок пока нет

- DesignOfCFrameTypeHydraulicPunchingMachine (129 133) PDFДокумент5 страницDesignOfCFrameTypeHydraulicPunchingMachine (129 133) PDFJindal HydraulicsОценок пока нет

- Pneumatic Torque Wrenches PDFДокумент6 страницPneumatic Torque Wrenches PDFJindal HydraulicsОценок пока нет

- YДокумент14 страницYJindal HydraulicsОценок пока нет

- 1Документ79 страниц1Jindal HydraulicsОценок пока нет

- Pneumatic Torque Wrenches PDFДокумент6 страницPneumatic Torque Wrenches PDFJindal HydraulicsОценок пока нет

- 5 JДокумент1 страница5 JJindal HydraulicsОценок пока нет

- PCM 20 16 PolyhydronДокумент4 страницыPCM 20 16 PolyhydronJindal HydraulicsОценок пока нет

- PRESSURE SWITCH TITLEДокумент4 страницыPRESSURE SWITCH TITLEJindal HydraulicsОценок пока нет

- DSHG 06 3C4 YukenДокумент16 страницDSHG 06 3C4 YukenJindal HydraulicsОценок пока нет

- CWДокумент4 страницыCWJindal HydraulicsОценок пока нет

- 2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Документ12 страниц2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Sujeet KumarОценок пока нет

- Description: Direct Acting Pressure Relief ValveДокумент6 страницDescription: Direct Acting Pressure Relief Valvesukesh bhagatОценок пока нет

- DSHG 06 3C4 YukenДокумент16 страницDSHG 06 3C4 YukenJindal HydraulicsОценок пока нет

- SYДокумент65 страницSYJindal HydraulicsОценок пока нет

- Hydraulic Plate Shearing Machine SpecsДокумент4 страницыHydraulic Plate Shearing Machine SpecsJindal HydraulicsОценок пока нет

- PRESSURE SWITCH TITLEДокумент4 страницыPRESSURE SWITCH TITLEJindal HydraulicsОценок пока нет

- YДокумент14 страницYJindal HydraulicsОценок пока нет

- Fet Up Diploma Mechanical Engineering DaycoursesДокумент58 страницFet Up Diploma Mechanical Engineering DaycoursesVikas AgrawalОценок пока нет

- NДокумент7 страницNJindal HydraulicsОценок пока нет

- Cs Fss Eco Ma Economics 2016Документ32 страницыCs Fss Eco Ma Economics 2016Asim ShakeerОценок пока нет

- Engineering SyllabusДокумент35 страницEngineering SyllabusJindal HydraulicsОценок пока нет

- List of Industries Identified For Random InspectionДокумент14 страницList of Industries Identified For Random Inspectionsubaranjidhan100% (1)

- Client Communication TrackerДокумент2 страницыClient Communication TrackerJindal HydraulicsОценок пока нет

- Manufacturer List New 2013 PDFДокумент93 страницыManufacturer List New 2013 PDFYogesh ChhaprooОценок пока нет

- DRV MasterDrives Compact PLUS InvertersДокумент12 страницDRV MasterDrives Compact PLUS InvertersLateef AlmusaОценок пока нет

- Tyco SchrackДокумент200 страницTyco SchrackGiau Ngoc Hoang100% (1)

- 600/1000V, PVC Insulated Cables According To IEC 60502-1: Kitty@caledonian-Cables - Co.ukДокумент11 страниц600/1000V, PVC Insulated Cables According To IEC 60502-1: Kitty@caledonian-Cables - Co.ukS.M.Touhidur RahmanОценок пока нет

- Minimum Clearance in HVДокумент3 страницыMinimum Clearance in HVbdaminda6701Оценок пока нет

- Futek Hid Electronic SpecsДокумент3 страницыFutek Hid Electronic SpecsAEEE100% (2)

- UAND-specs Rudd Achiever Series PDFДокумент16 страницUAND-specs Rudd Achiever Series PDFBen KuxhouseОценок пока нет

- Writing BDR (JULIANA)Документ2 страницыWriting BDR (JULIANA)jodie comerОценок пока нет

- Belts and PulleysДокумент28 страницBelts and PulleysIwan SurachwantoОценок пока нет

- Microprocessor 8086 by Nirvaan MahajanДокумент14 страницMicroprocessor 8086 by Nirvaan MahajanHallucinatory100% (1)

- Chapter 4 Energy ConversionДокумент3 страницыChapter 4 Energy ConversionLuelsonCordovaDeclaradorОценок пока нет

- Schneider PLC Module Bmxdra1605 PDFДокумент4 страницыSchneider PLC Module Bmxdra1605 PDFjoapmeОценок пока нет

- Copy of OS Supply MTN ALLДокумент48 страницCopy of OS Supply MTN ALLIhsanОценок пока нет

- Title: Model Ut50A/B/C: Operating ManualДокумент33 страницыTitle: Model Ut50A/B/C: Operating ManualEibar016Оценок пока нет

- Air Cadet Pumps ManualДокумент12 страницAir Cadet Pumps ManualEdgar Campusano SanchezОценок пока нет

- Honda IDSI SM - 5 PDFДокумент14 страницHonda IDSI SM - 5 PDFauto projectОценок пока нет

- LHD Engine Control (4HK1 (Full Air Brake) )Документ1 страницаLHD Engine Control (4HK1 (Full Air Brake) )Wilber Castell Jr.Оценок пока нет

- UC Inspection Sheet Samsung Dash 2 SeriesДокумент5 страницUC Inspection Sheet Samsung Dash 2 SeriesLuis BertaoОценок пока нет

- DWE4120 B3 T1 Dewalt PBДокумент4 страницыDWE4120 B3 T1 Dewalt PBJose MolinaОценок пока нет

- Eaton RM10 Product BrochureДокумент2 страницыEaton RM10 Product BrochureEagan Wafi IndrastaОценок пока нет

- LT1275X3 NCAT Service GuideДокумент118 страницLT1275X3 NCAT Service GuidejustmerrillОценок пока нет

- Daikin DAR SpecsДокумент8 страницDaikin DAR SpecsGian Carlos Gonzales ChaconОценок пока нет

- AOPEN Embedded PC BrochureДокумент12 страницAOPEN Embedded PC BrochurepaulaОценок пока нет

- 2 Basic Working Principle, ConfigurationДокумент17 страниц2 Basic Working Principle, Configurationrichardcaroncstj100% (1)

- Gas Material and ServicesДокумент6 страницGas Material and ServicesSachin SinghОценок пока нет

- LM2695 High Voltage (30V, 1.25A) Step Down Switching RegulatorДокумент14 страницLM2695 High Voltage (30V, 1.25A) Step Down Switching RegulatorYoyok CahyonoОценок пока нет

- Technical Specs and Features of CIFA SL/SLA Concrete Mixer TrucksДокумент2 страницыTechnical Specs and Features of CIFA SL/SLA Concrete Mixer TrucksJack Norhy100% (1)

- Ldb-Ac-Cal-001 - Ac Calculation - Rev.d - 15.11.18 + CRSДокумент32 страницыLdb-Ac-Cal-001 - Ac Calculation - Rev.d - 15.11.18 + CRSArys FarandyОценок пока нет